Discover smarter issue management strategies to boost efficiency, reduce downtime, and streamline industrial operations with intelligent, proactive solutions.

Issue management in industrial settings is the structured process of identifying, documenting, and resolving operational problems to maintain efficiency, safety, and quality. Connected worker tools play a transformative role by enabling frontline teams to report and address issues in real time, ensuring faster resolution and continuous improvement.

Read our article below to learn more about Issue Management in Manufacturing:

- What is Issue Management in Industrial Operations

- Common Challenges in Issue Management

- Digital Solutions to Address Issue Management

- Types of Digital Solutions for Issue Management

- Best Practices for Issue Management in Manufacturing

- How Augmenitr Enhances Issue Management

What is Issue Management in Industrial Operations?

Issue management in industrial settings is the structured process of identifying, documenting, and resolving operational problems to maintain efficiency, safety, and quality. Connected worker tools play a transformative role by enabling frontline teams to report and address issues in real time, ensuring faster resolution and continuous improvement.

Issue management refers to the process of identifying, tracking, and resolving problems that impact daily operations. These issues can include equipment malfunctions, quality deviations, safety incidents, process bottlenecks, and supply chain disruptions. In complex industrial environments—such as manufacturing plants, energy facilities, and logistics hubs—even small issues can ripple through the operation, causing costly downtime and rework.

Effective issue management is essential for maintaining operational efficiency, consistency, and safety. It ensures problems are not only addressed quickly but also documented and analyzed for future prevention.

Issue management is also a fundamental component of Lean manufacturing. Within a Lean framework, addressing issues swiftly and at the source is critical for minimizing waste (muda), improving process flow, and enabling continuous improvement (Kaizen). Effective issue management supports Lean principles, originally identified by Taiichi Oohno, by promoting standardization, visual control, and empowering frontline workers to contribute to quality and productivity improvements.

Common Challenges in Issue Management

Organizations often face several challenges when managing operational issues:

- Manual Processes: Paper-based or spreadsheet systems slow down response times and increase the risk of human error.

- Lack of Visibility: Disconnected systems hinder real-time tracking, making it difficult to prioritize and resolve problems effectively.

- Poor Communication: Important details are lost during shift handover or between departments, especially in 24/7 operations.

- Delayed Resolution: Without a standardized, traceable process, recurring issues continue to disrupt performance and morale.

These challenges lead to longer downtime, inconsistent quality, and reduced trust in issue reporting systems.

Using connected worker solutions can help improve issue management with improved visibility and reporting, mobile reporting and issue tracking, workflow automation, and collaboration tools.

Digital Solutions to Address Issue Management

Modern industrial operations require more than reactive problem-solving. They need connected, real-time, intelligent tools that help prevent issues before they escalate. Traditional methods simply can’t keep up with the speed and complexity of today’s operations, where problems can rapidly multiply and impact cost, quality, and customer satisfaction.

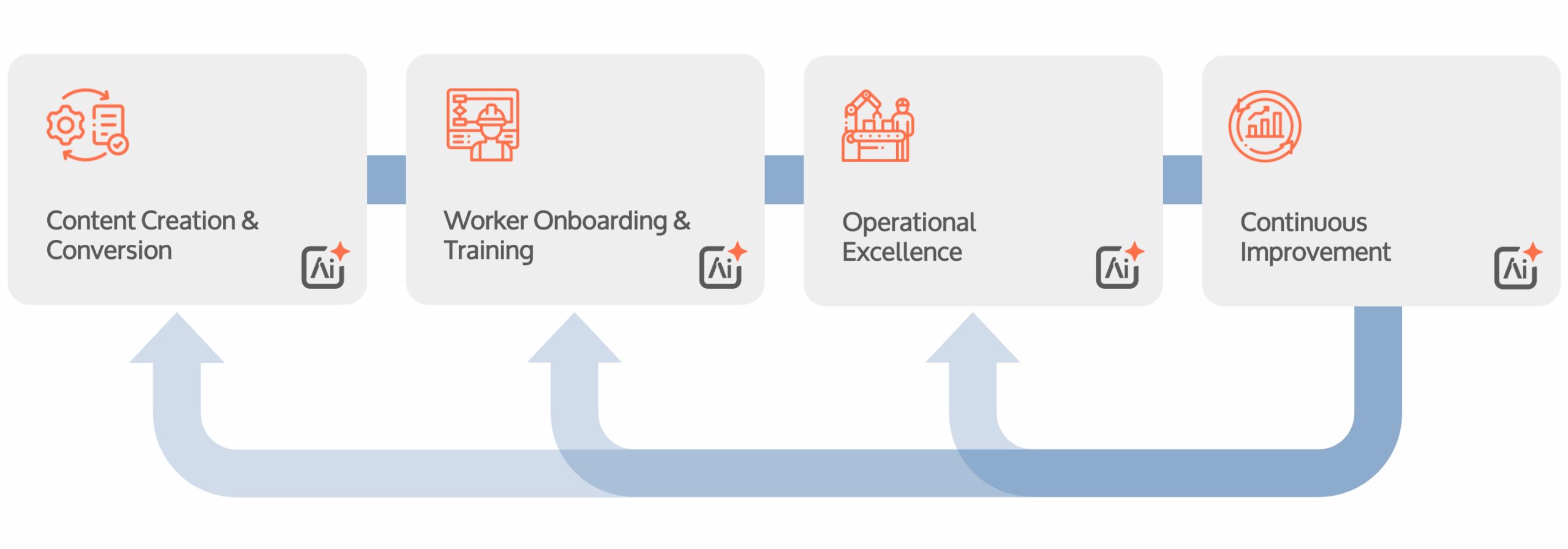

A digital solution helps organizations move from reactive issue handling to a more predictive, proactive, and data-informed strategy. These systems not only streamline how issues are reported and resolved but also enable greater transparency and continuous improvement.

Types of Digital Solutions for Issue Management:

Connected Worker Tools

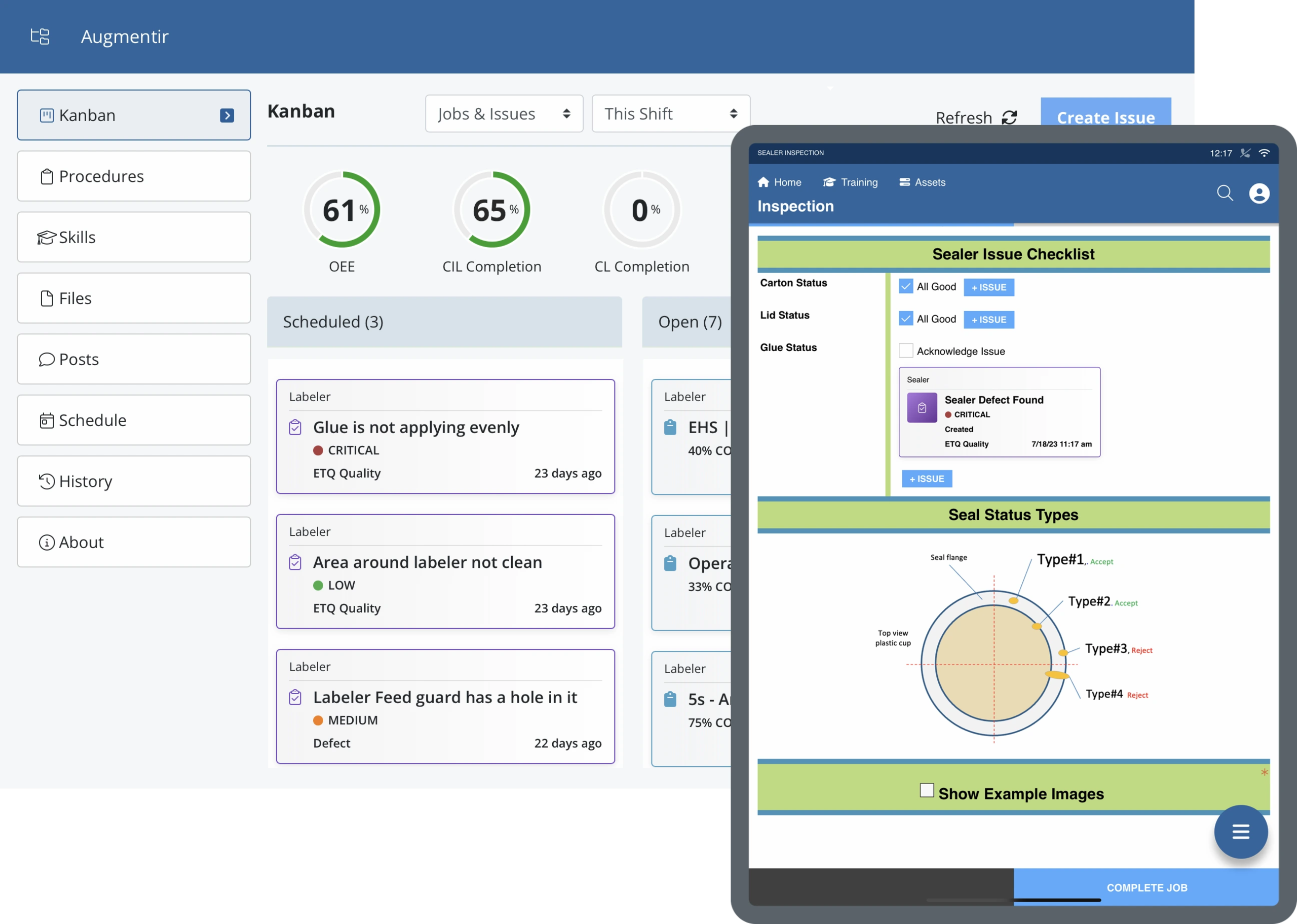

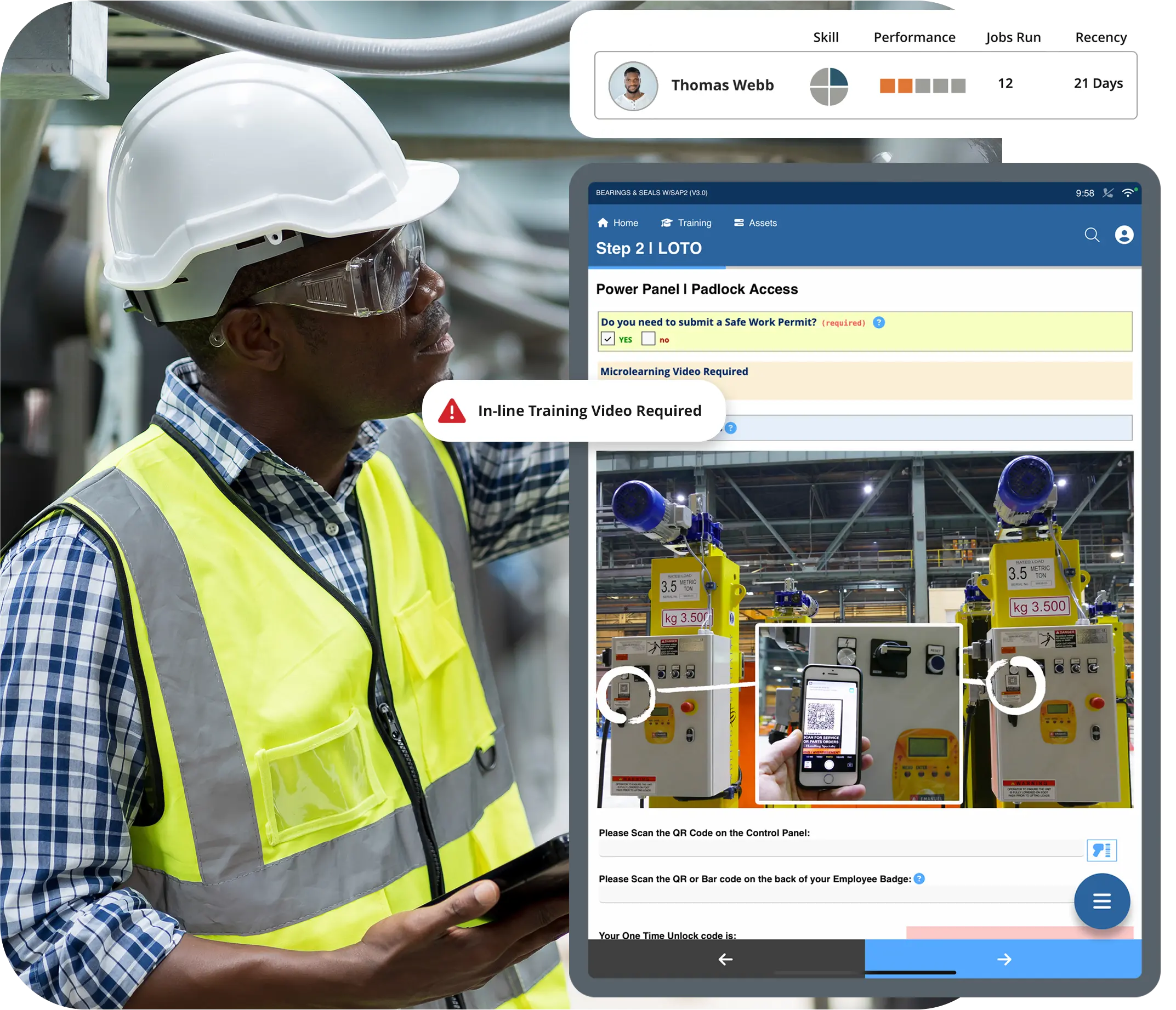

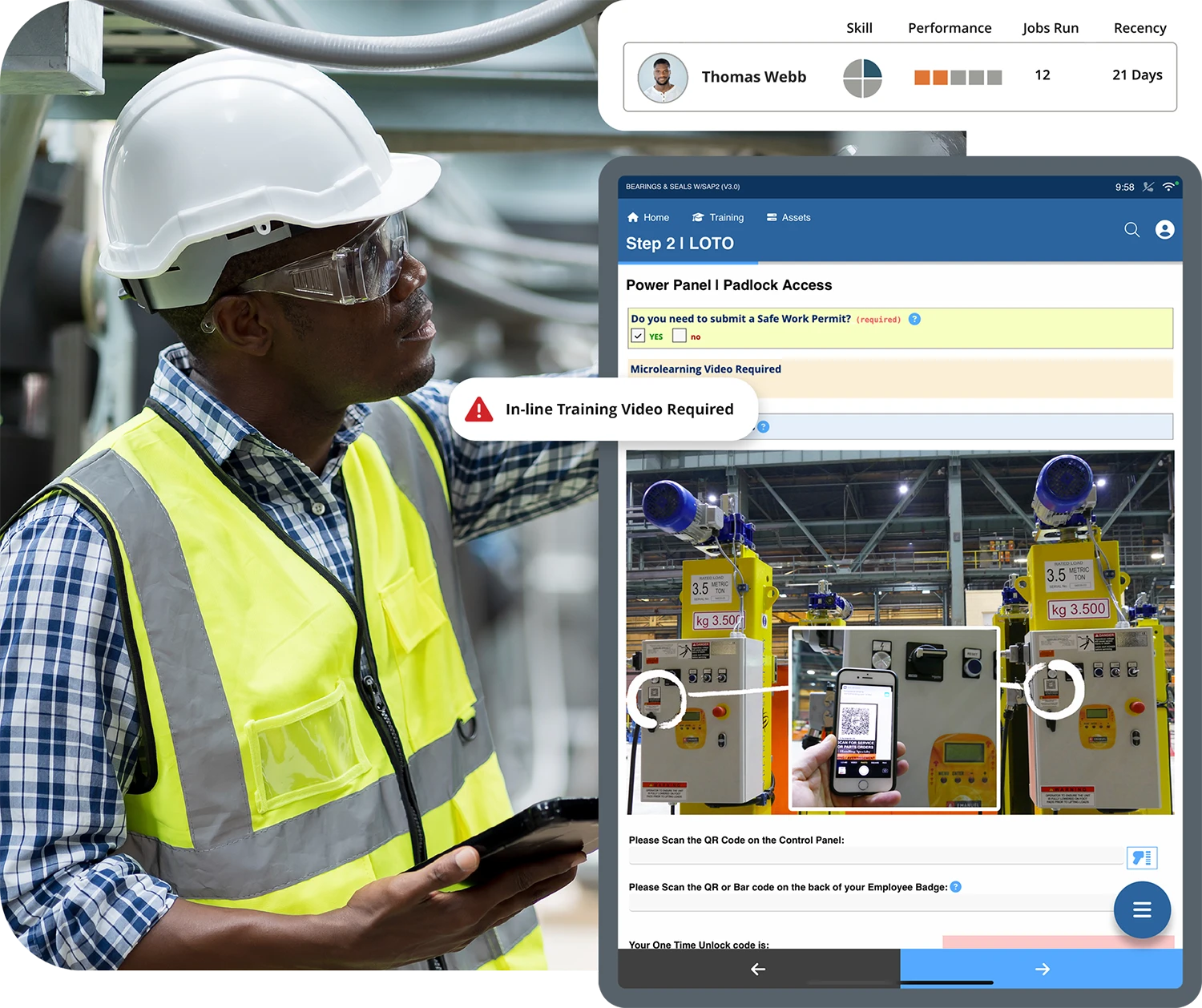

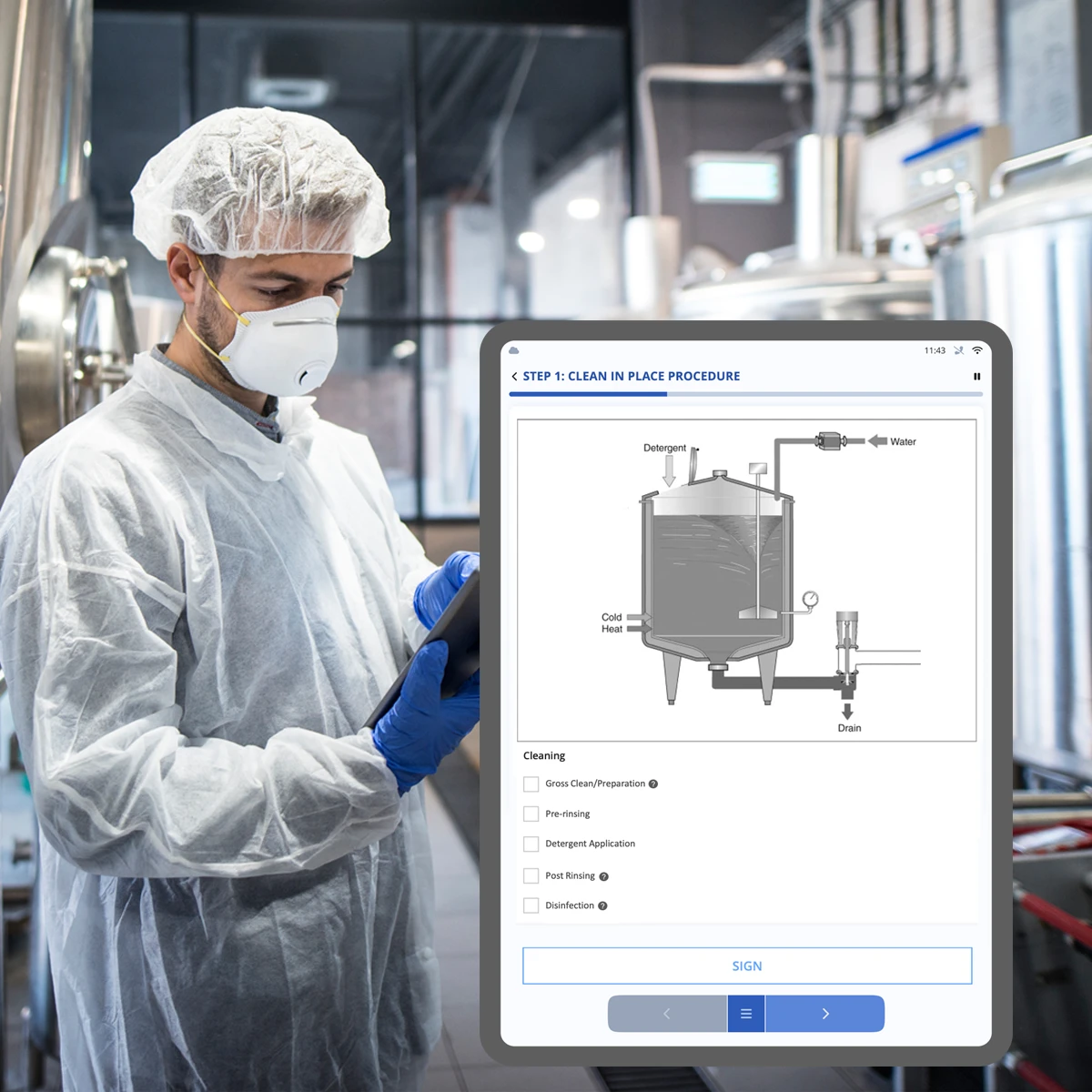

Combine digital guidance, remote collaboration, performance support, and real-time feedback into one platform. These tools empower frontline workers with the right information at the right time, enhance decision-making, and drive faster issue resolution.

Mobile Reporting Tools

Allow frontline workers to report issues directly from their mobile devices with photos, voice notes, and structured forms.

Collaborative Platforms: Facilitate real-time communication between teams to ensure quick action and alignment.

Workflow Automation

Automatically assign tasks, trigger alerts, and ensure accountability across teams and shifts.

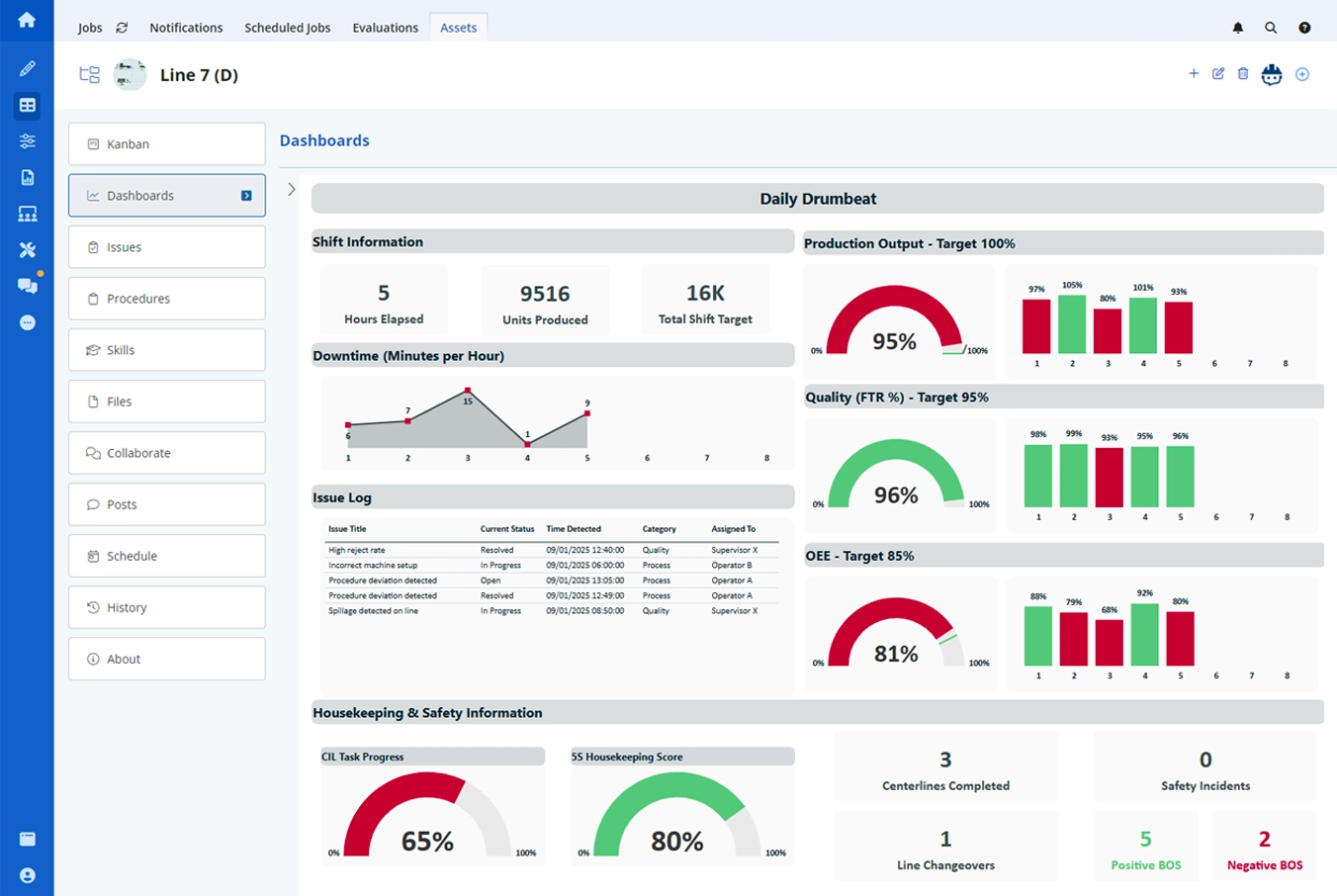

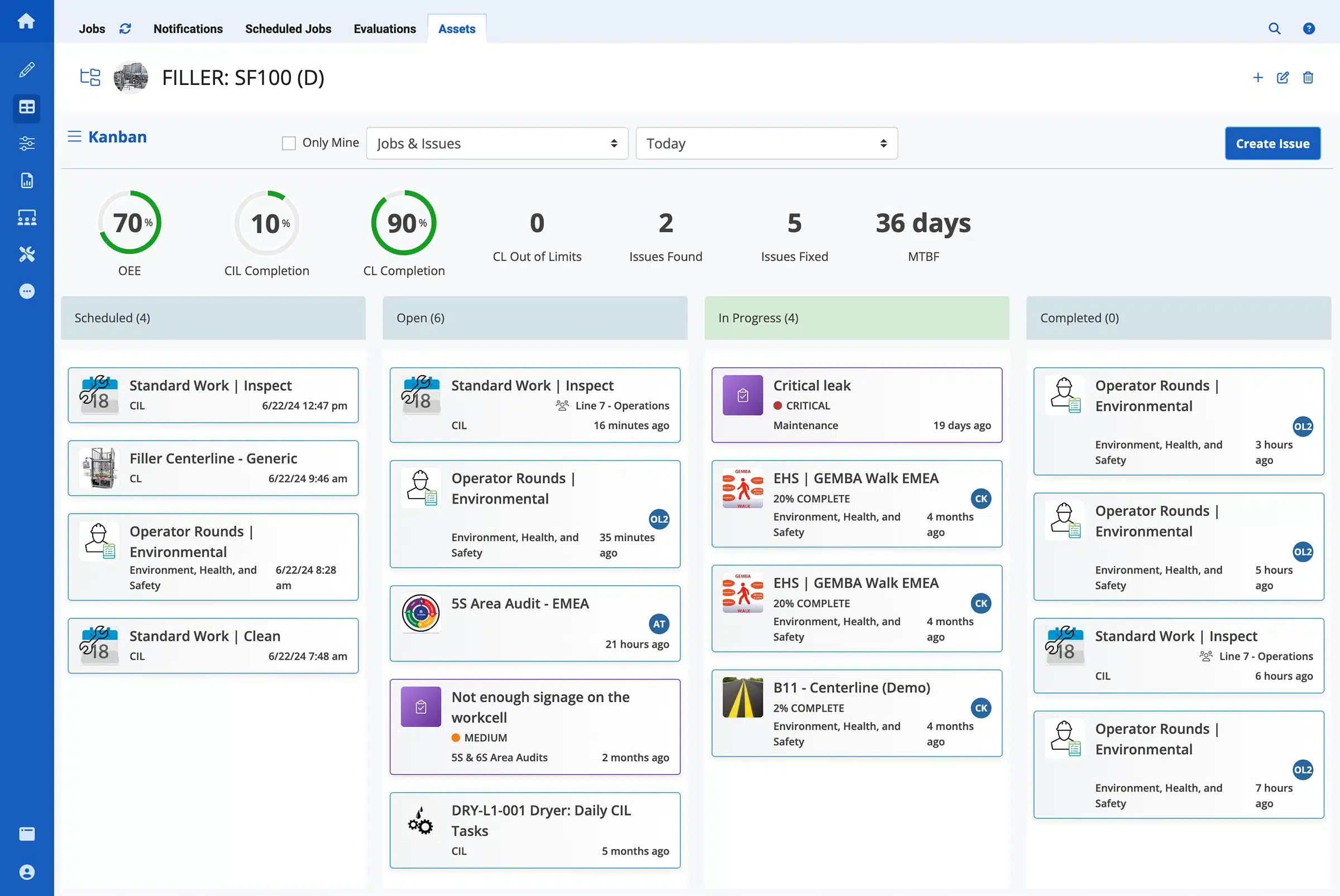

Integrated Dashboards

Provide visibility into issue trends, resolution time, and performance metrics.

AI and Analytics Tools

Analyze data to identify recurring issues, uncover root causes, and recommend preventive actions.

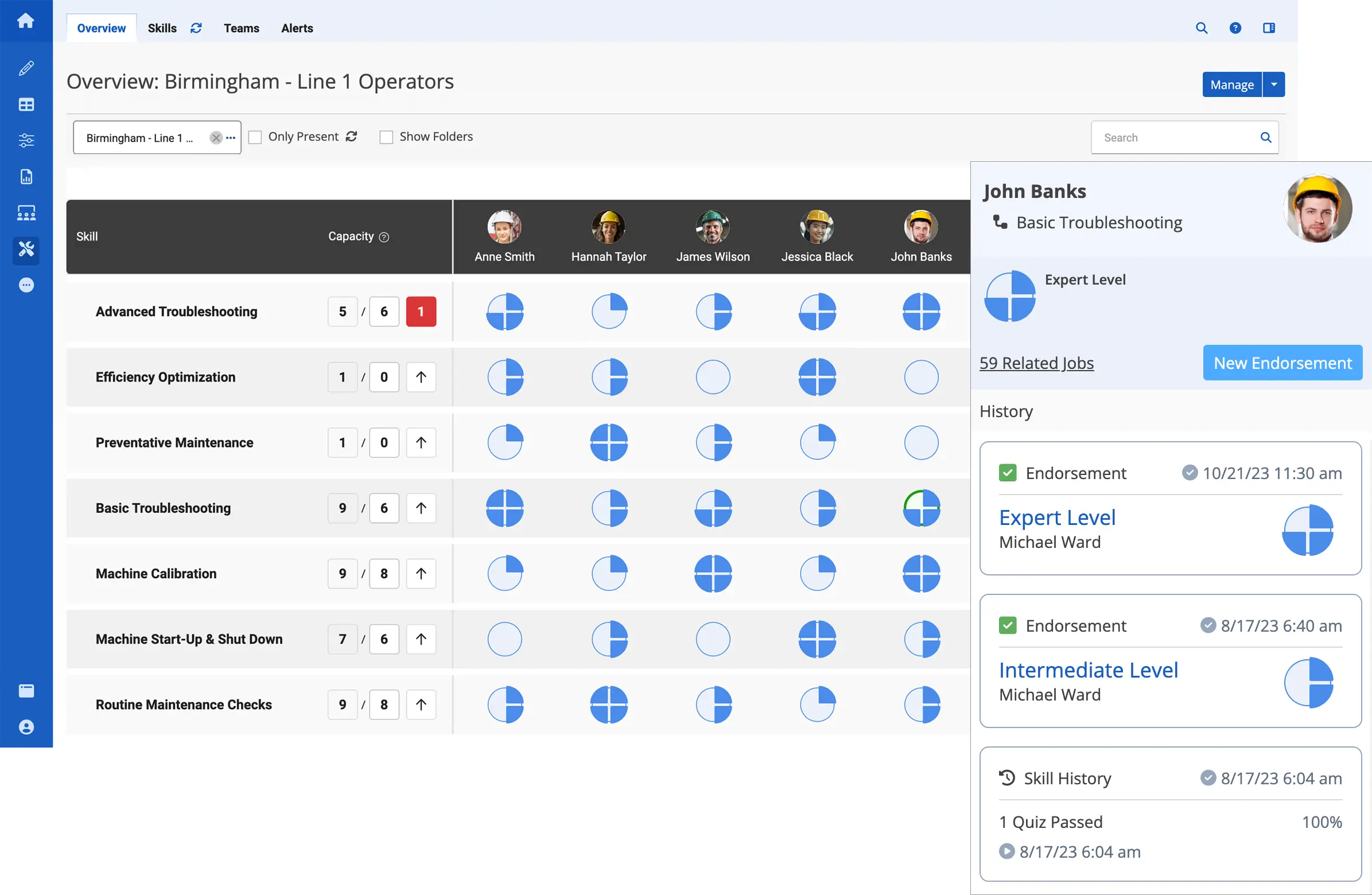

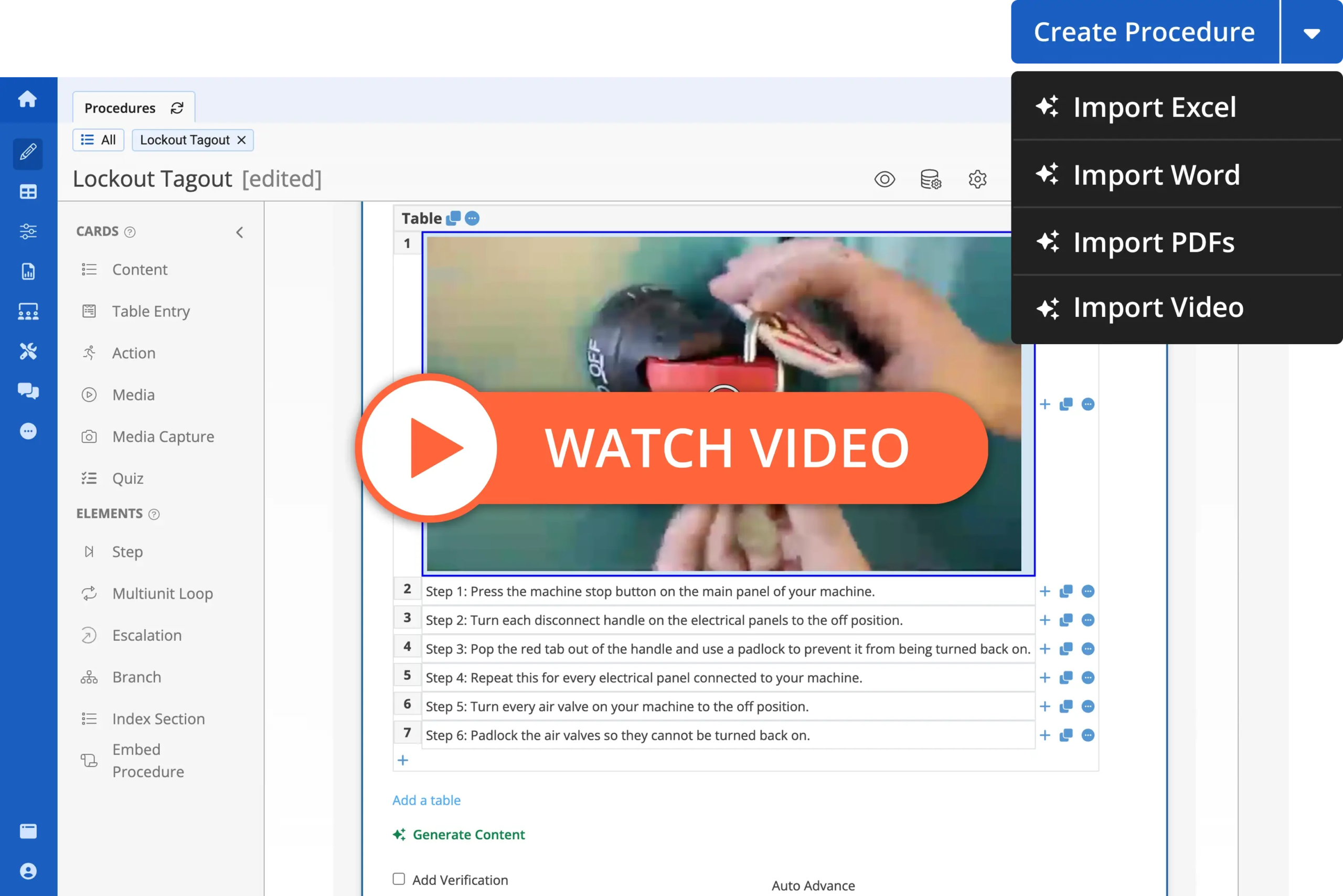

Training and Knowledge Management Systems

Tie issue management to employee training, so workers can learn from past incidents and avoid repeating mistakes.

With a modern digital solution, organizations can:

- Capture and categorize issues in real-time from any device

- Assign tasks with clear accountability and deadlines

- Track resolution progress across shifts and teams

- Surface trends that inform strategic improvements

- Enhance collaboration and cross-functional learning

Best Practices for Issue Management in Manufacturing

Implementing effective issue management requires more than just tools—it demands consistent best practices that support a culture of accountability and improvement. Here are key practices to follow:

- Standardize Reporting: Ensure all employees use the same process and language to report issues. Digital templates and forms help create consistency.

- Empower Frontline Workers: Make it easy for anyone on the floor to log an issue quickly, without bureaucratic roadblocks.

- Respond in Real Time: Establish clear protocols for triaging and escalating issues based on severity and impact.

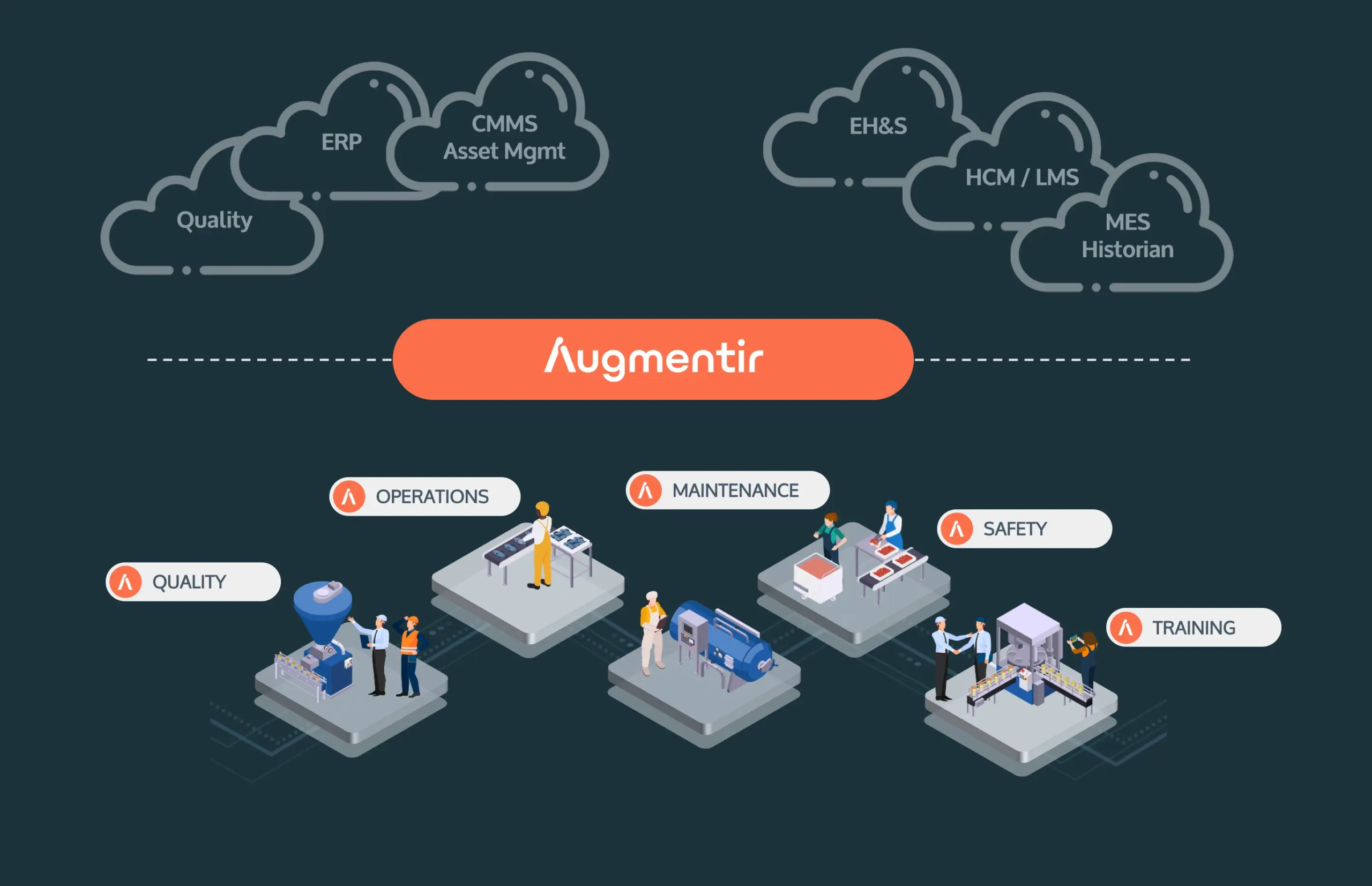

- Integrate with Existing Systems: Sync issue tracking with maintenance, quality, and training systems to provide full visibility and context.

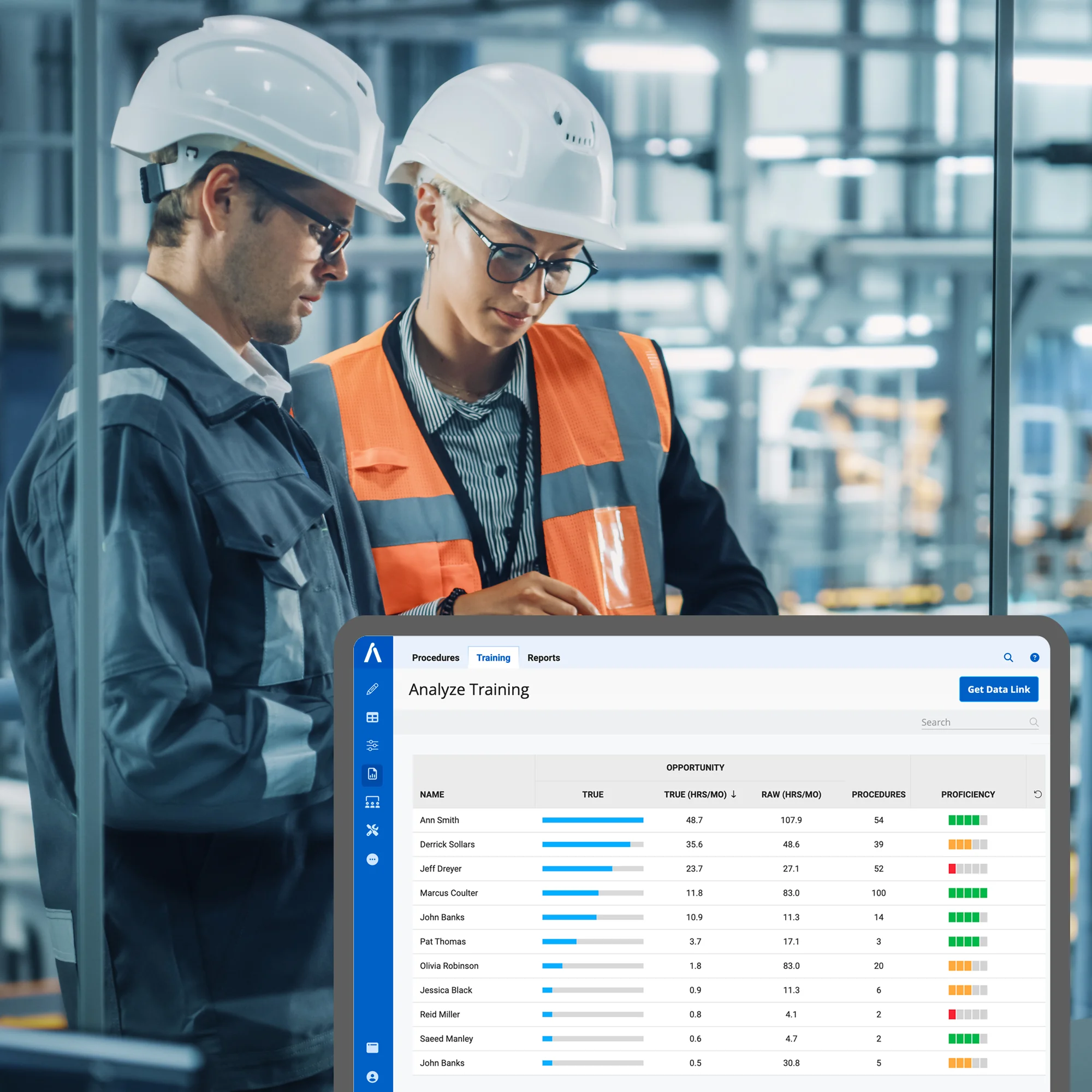

- Track and Analyze Trends: Use dashboards and analytics to identify recurring problems and opportunities for improvement.

- Close the Loop: Make sure every issue leads to a documented resolution, including root cause analysis and preventive actions.

- Promote Continuous Improvement: Use issue data to drive Kaizen events, lean manufacturing projects, or training enhancements.

How Augmentir Enhances Issue Management

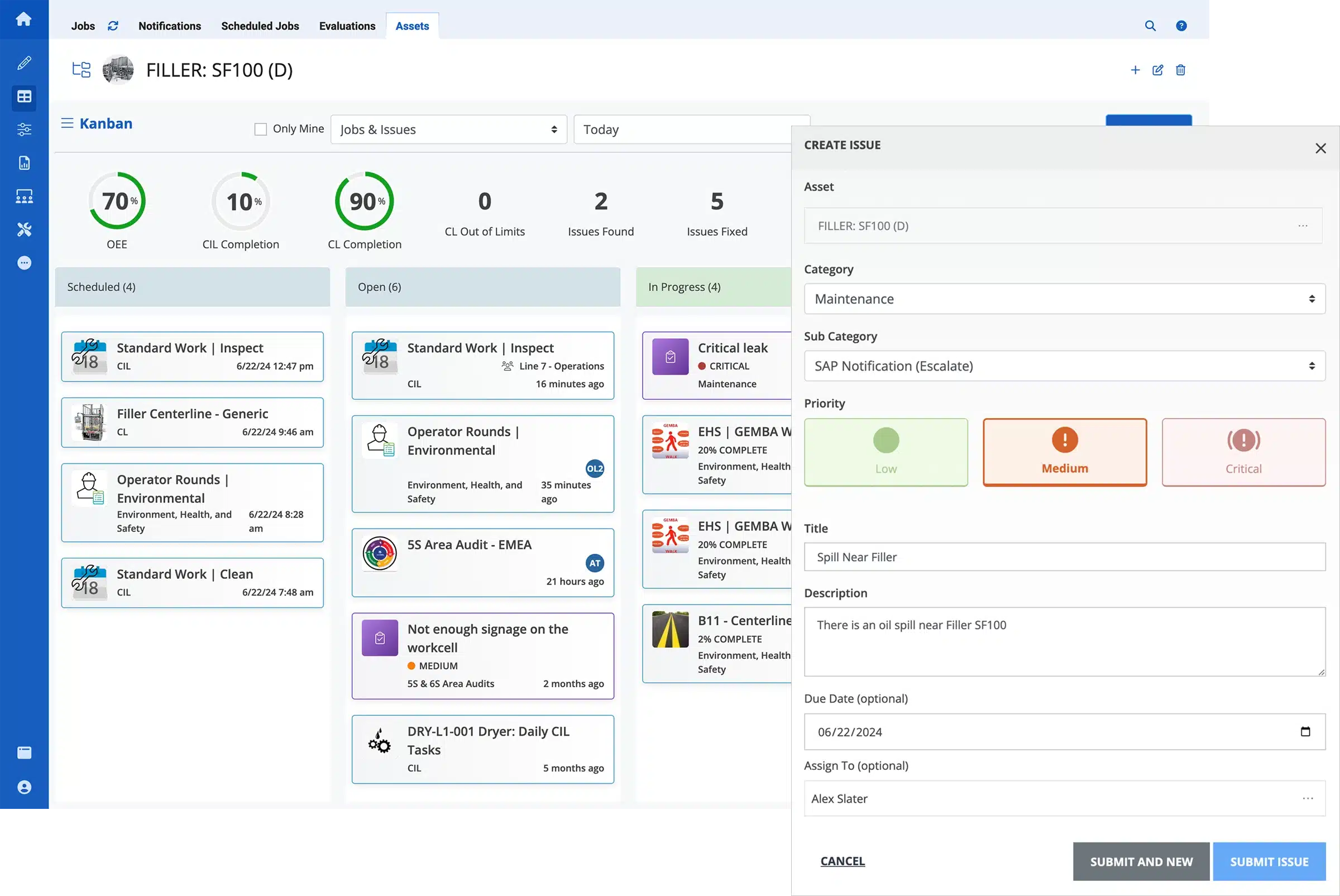

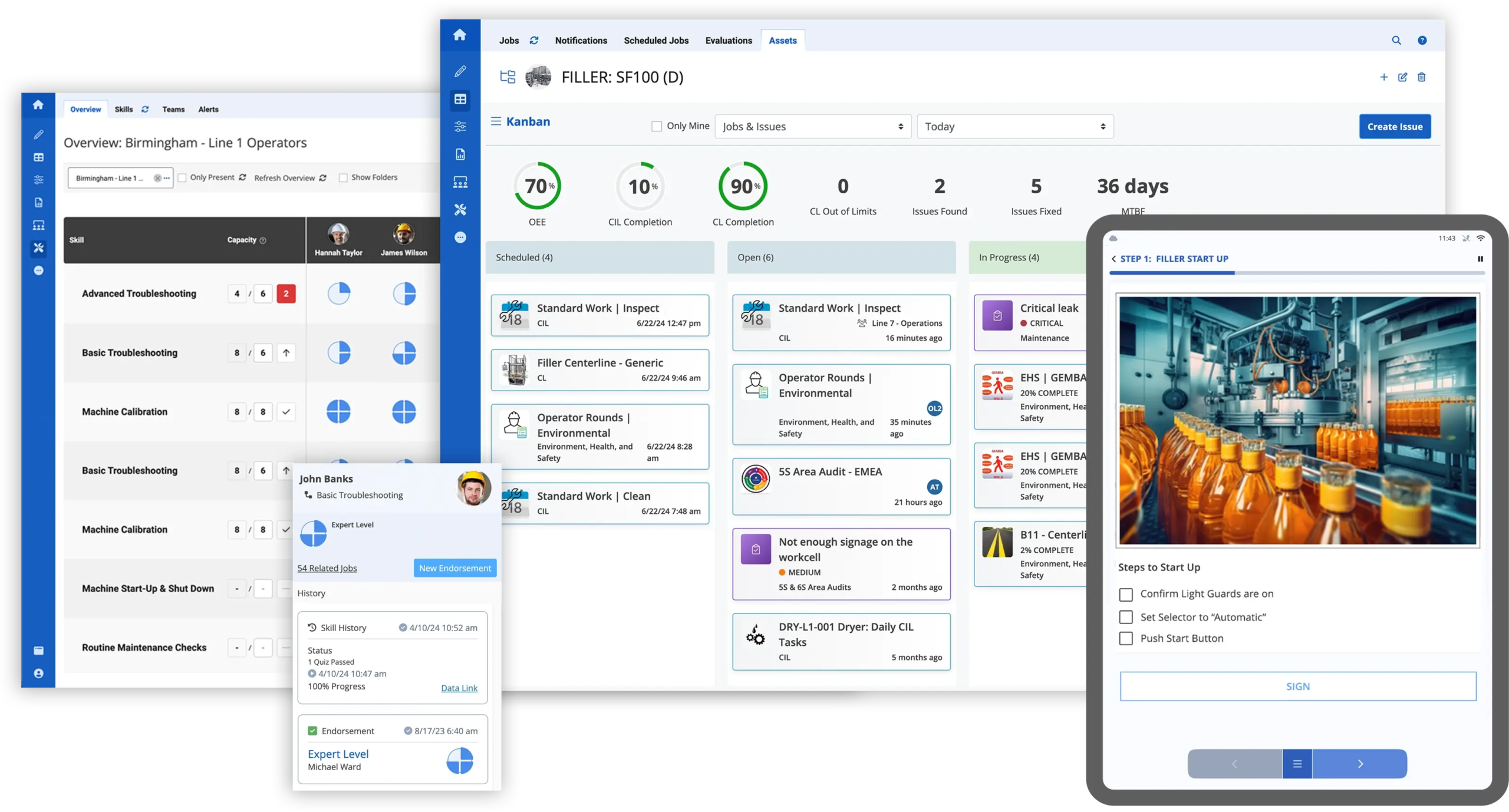

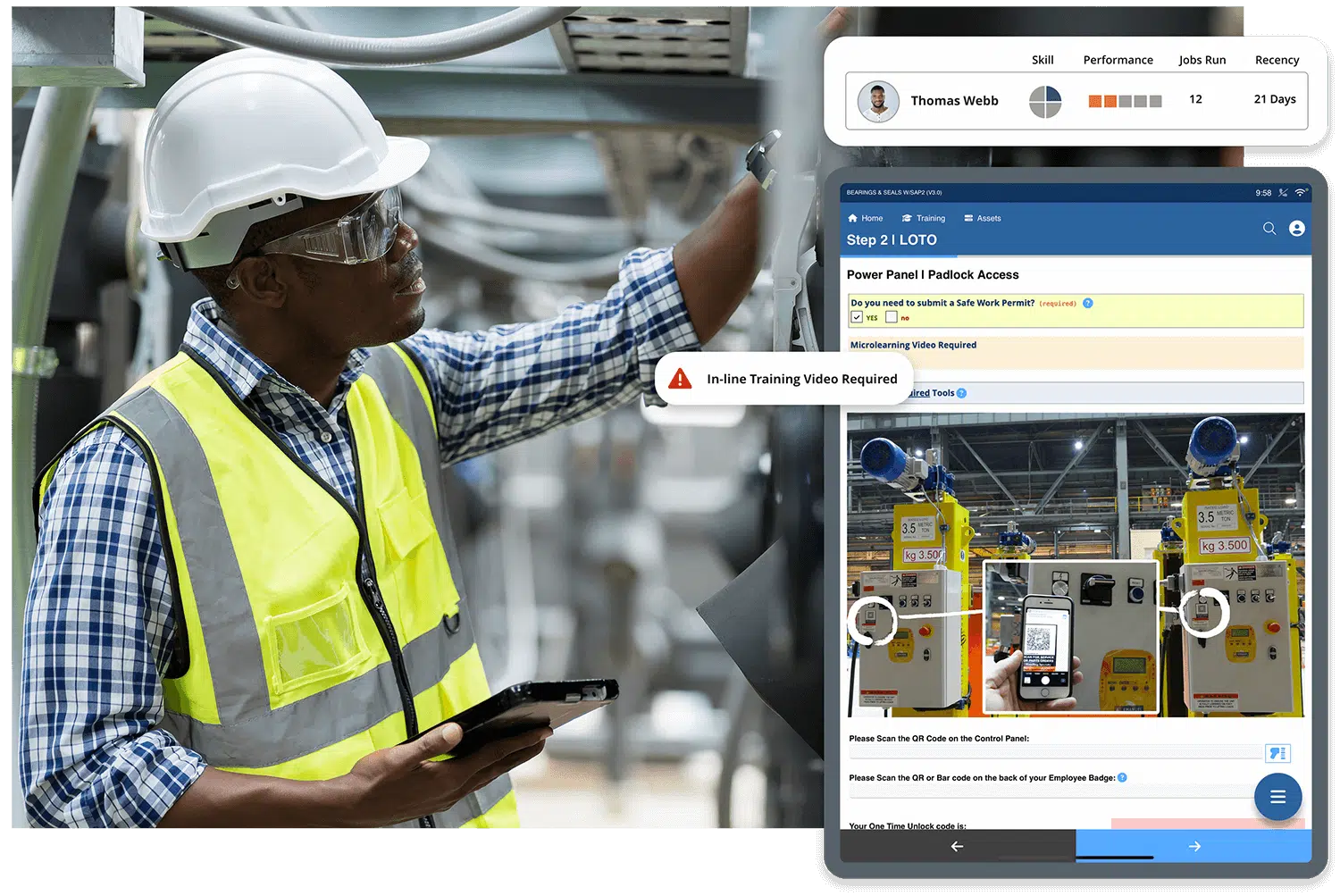

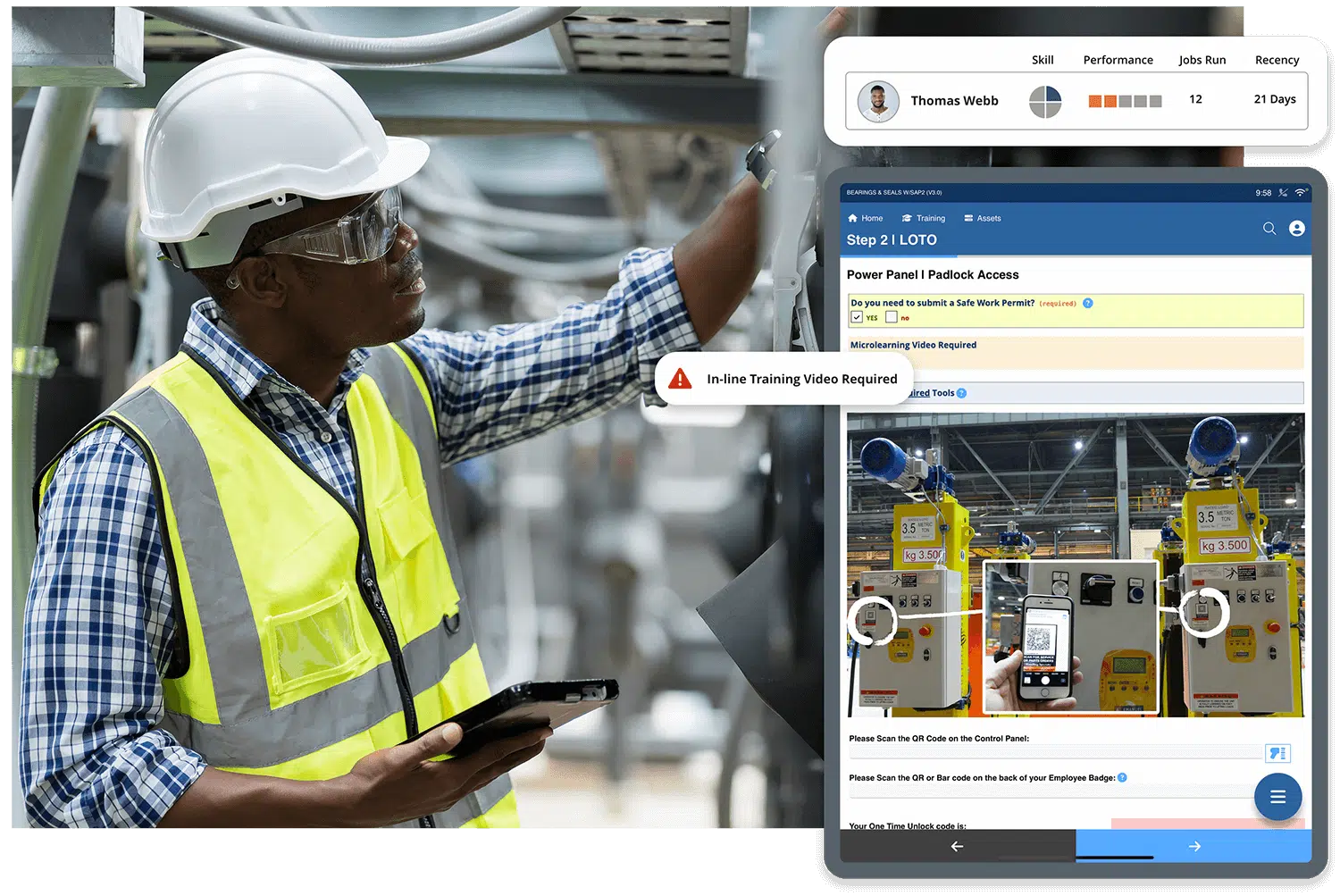

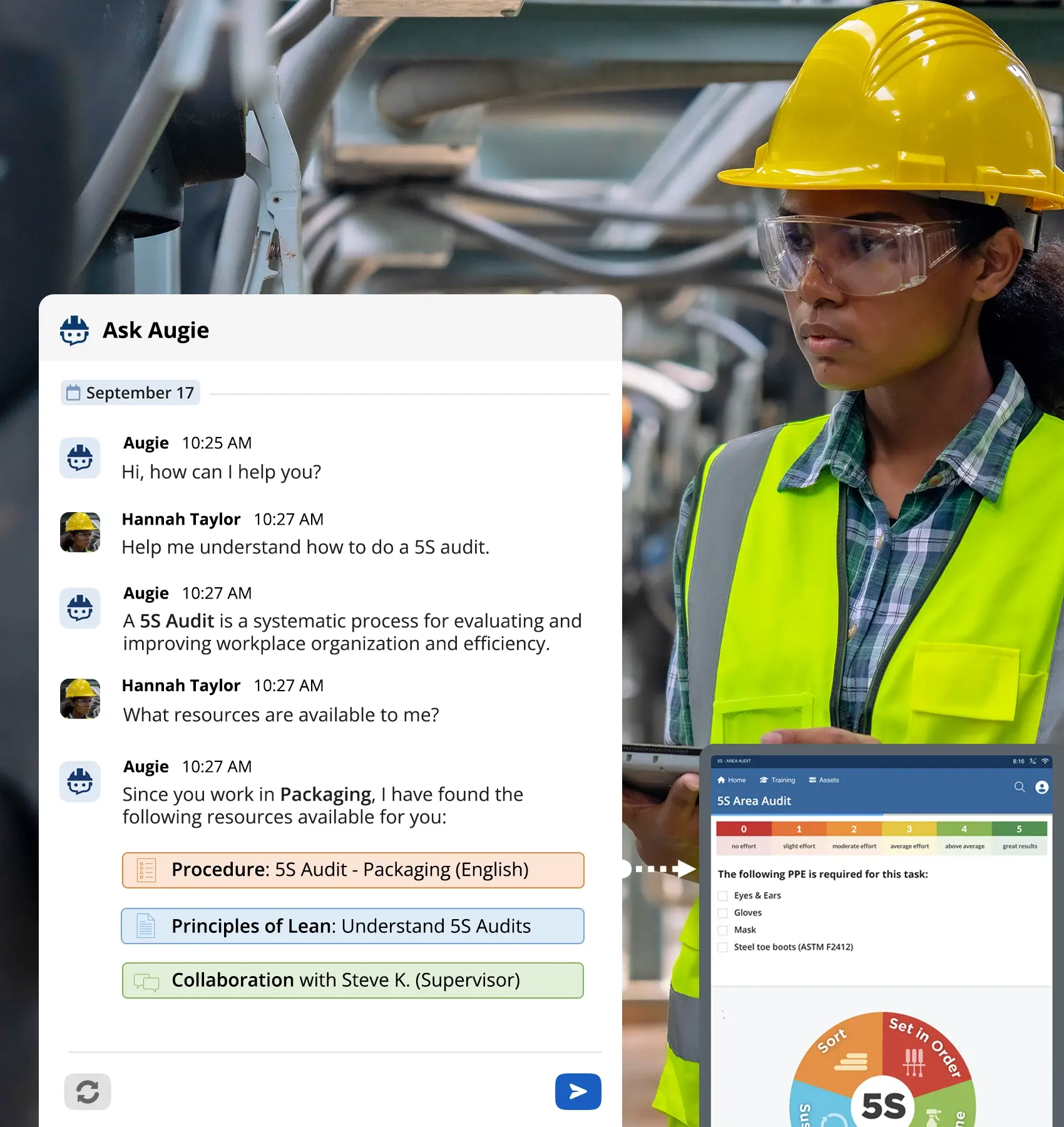

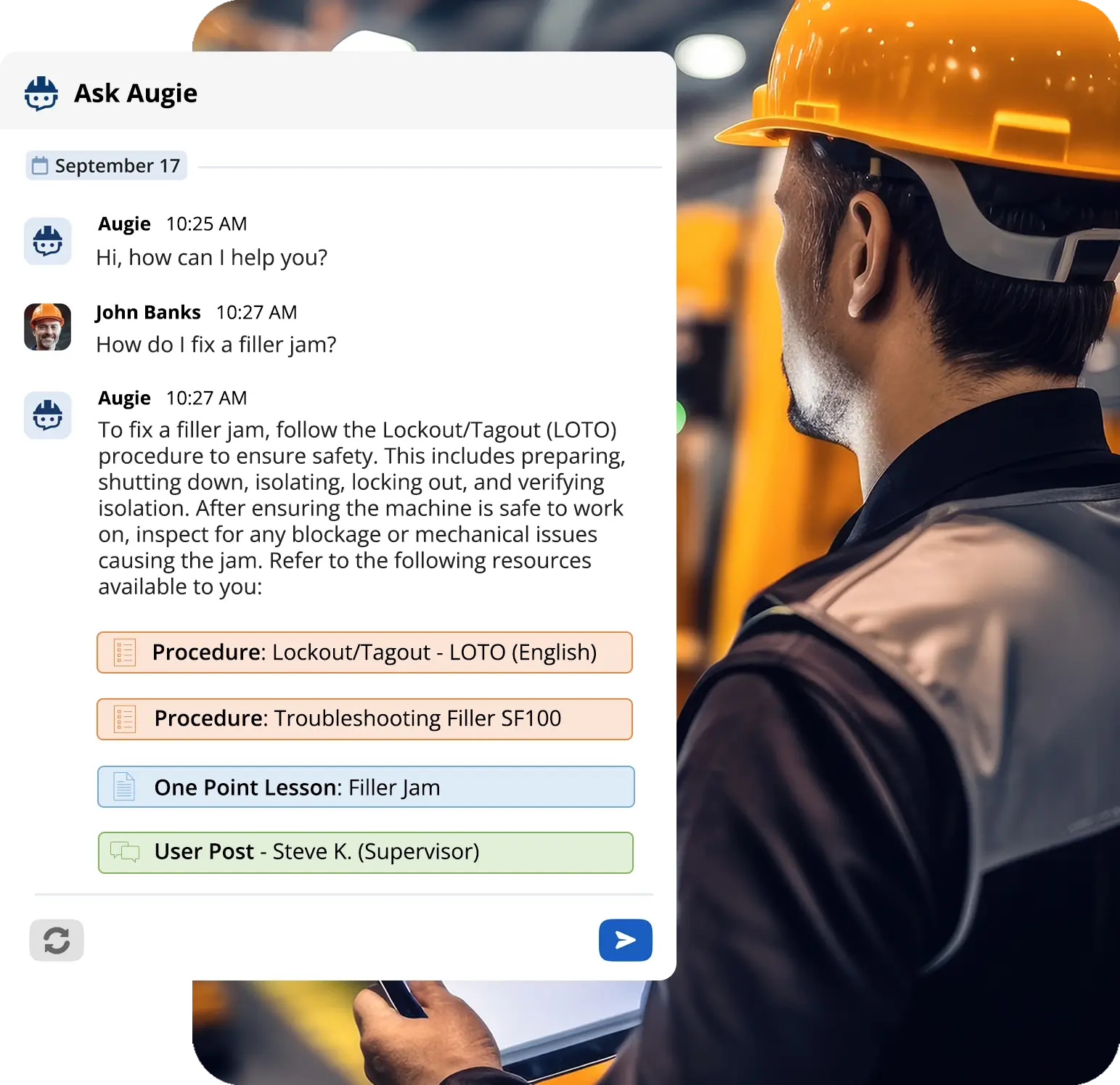

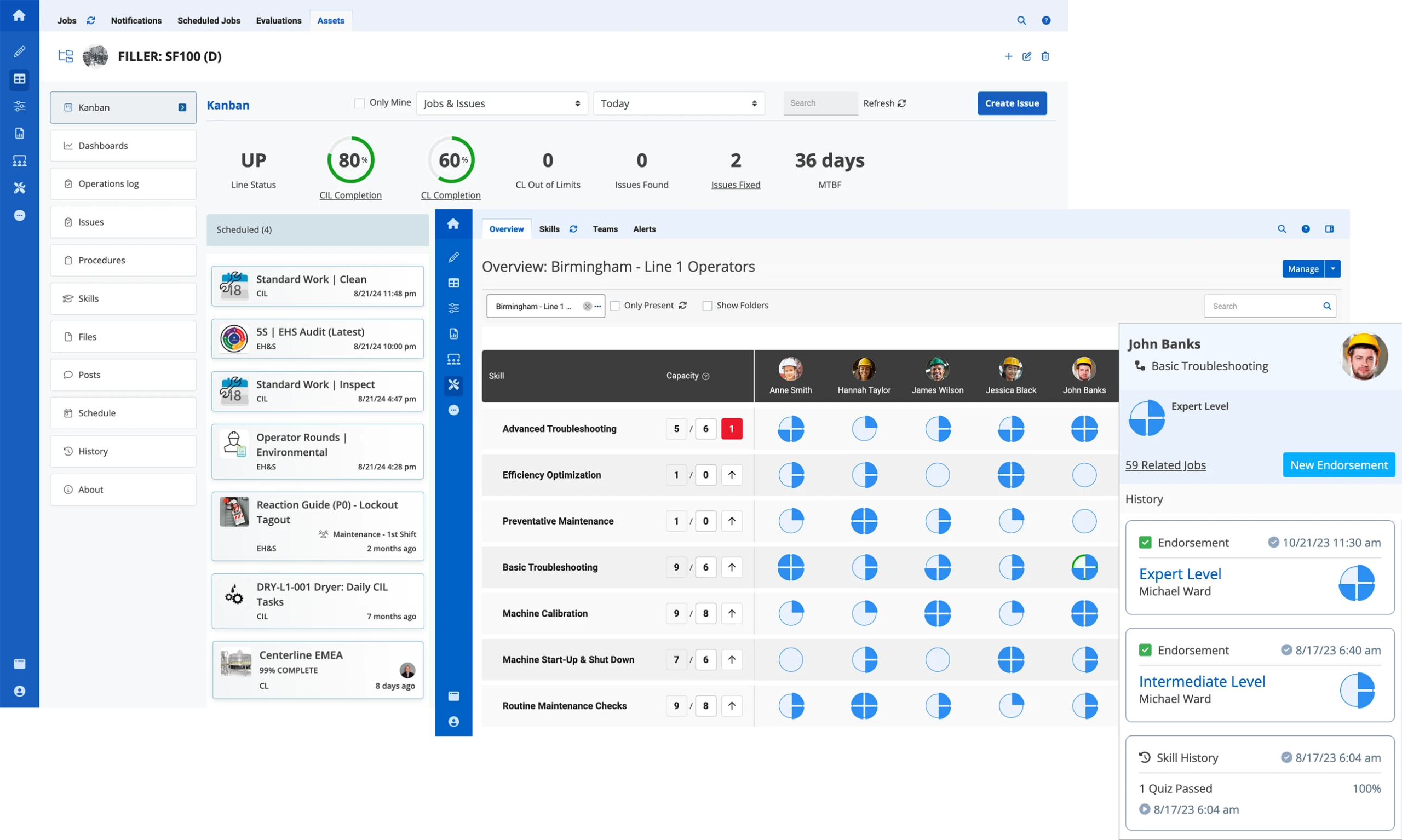

Augmentir’s connected worker platform transforms how frontline teams identify and solve problems. By embedding AI and collaboration tools into everyday workflows, Augmentir ensures that no issue goes unnoticed—or unresolved.

Key capabilities include:

- Digital Issue Capture: Workers can report issues with rich detail (text, photos, voice), improving clarity and response.

- Real-Time Notifications: Alerts and escalations ensure the right people are engaged immediately.

- AI-Powered Root Cause Analysis: Augmentir continuously learns from your operations, suggesting root causes and identifying patterns.

- Connected Workflows: Seamlessly link issues to related work instructions, safety protocols, and training content.

- Operational Insights: Dashboards visualize issue frequency, impact, and resolution efficiency across teams, sites, or business units.

Augmentir goes beyond digital forms and basic tracking—it provides an intelligent, end-to-end issue management system. With built-in AI, collaboration tools, and analytics, Augmentir equips your workforce with everything needed to detect, manage, and eliminate operational problems at their source.

Whether you’re operating a multi-site manufacturing network, running a high-stakes field service team, or managing supply chain logistics, Augmentir delivers the tools to keep your operations resilient and responsive.

Ready to upgrade your issue management process?