Learn how shop floor data capture improves manufacturing efficiency, quality, and agility. Discover how Augmentir’s AI-powered connected worker platform transforms real-time data collection on the shop floor.

Shop floor data capture is the process of collecting real-time information from manufacturing operations—including machine performance, labor activity, and production status—to improve visibility and decision-making. Connected worker platforms streamline and enhance this process by embedding data capture into digital workflows, enabling accurate, real-time input directly from frontline workers.

Read this article to learn more about shop floor data capture in manufacturing:

- What is Shop Floor Data Capture?

- Why Shop Floor Data Capture Matters in Manufacturing

- Who Benefits from Shop Floor Data Capture

- Common Use Cases for Shop Floor Data Capture

- Shop Floor Data Capture is the First Step Towards Industry 4.0

- How Technology is Transforming Shop Floor Data Capture

- How Augmentir Elevates Shop Floor Data Capture

What is Shop Floor Data Capture?

Shop Floor Data Capture (SFDC) is the process of collecting real-time operational data from the manufacturing floor. This includes tracking machine status, work order progress, labor inputs, quality checks, safety reports, material usage, and unplanned downtime—essentially, any data that reflects how work is being done in real-time.

Modern SFDC systems gather this information digitally using a combination of mobile devices, connected worker technology, sensors, connected machines (Industrial IoT), and software platforms, replacing traditional paper forms, spreadsheets, and delayed manual entry.

Why Shop Floor Data Capture Matters in Manufacturing Today

For manufacturers, every second on the shop floor counts. Without accurate, real-time insight into what’s happening, teams are forced to rely on outdated reports, gut feelings, or tribal knowledge to make decisions. This leads to:

- Production delays

- Low first-pass yield

- Excessive downtime

- Underutilized labor

- Missed improvement opportunities

Shop floor data capture bridges the gap between what’s planned and what’s actually happening. When data is captured as work occurs, manufacturers gain the visibility needed to:

- Identify inefficiencies immediately

- Pinpoint training gaps or human error, which according to OSHA makes up 80-90 percent of serious injuries in the workplace.

- Improve scheduling and resource allocation

- Make data-driven decisions for continuous improvement

Who Benefits from Shop Floor Data Capture?

Shop floor data capture benefits multiple roles across manufacturing operations:

Operations Managers

- Gain real-time visibility into production

- Identify areas for process improvement

Supervisors & Line Leaders

- Track shift performance and labor productivity

- Ensure compliance with standard work

Continuous Improvement Teams

- Analyze trends and root causes using accurate, structured data

- Measure impact of Kaizen events or Lean initiatives

Quality Assurance

- Detect deviations and non-conformances quickly

- Link quality issues to specific operators, machines, or conditions

Executives

- Align factory performance with strategic KPIs

- Justify investments in digital transformation with hard data

Common Use Cases for Shop Floor Data Collection

1. Production Tracking

Capture cycle times, completion rates, and progress toward production targets.

2. Labor Time Reporting

Track how operators spend time on tasks, setups, changeovers, and idle periods.

3. Quality Checks

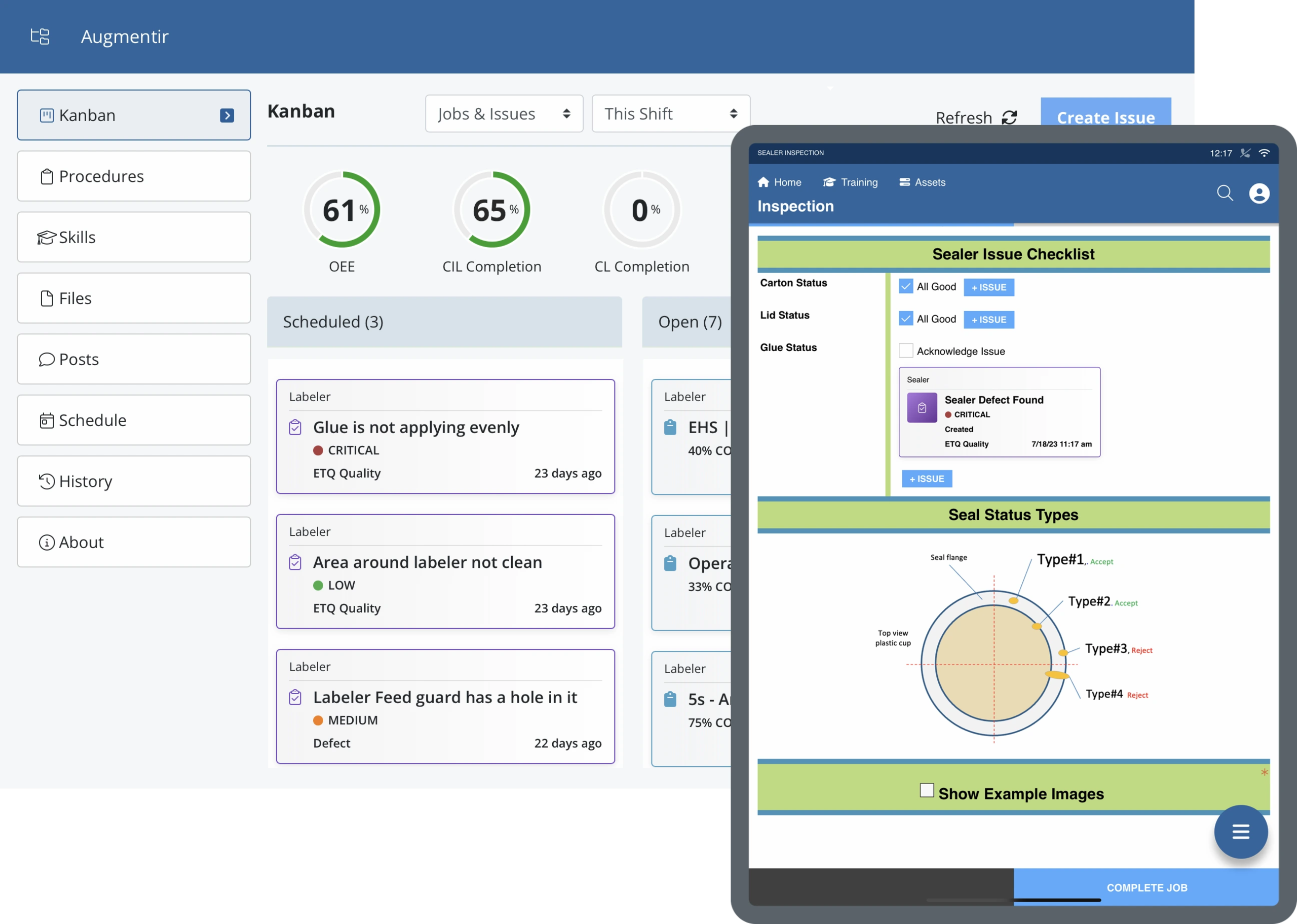

Real-time data collection with digital checklists and issue reporting—detect deviations and non-conformances quickly and link quality issues to specific operators, machines, or conditions.

Quality use case for shop floor data collection using the Augmentir Connected Worker Platform

4. Downtime and OEE Monitoring

Identify unplanned stoppages, categorize downtime, and improve OEE (Overall Equipment Effectiveness).

5. SPC Data Collection

Use modern software tools to support Statistical Process Control (SPC) data collection via mobile devices, allowing operators to input measurements directly from the shop floor. Visual dashboards and interactive SPC charts help teams quickly identify and respond to process variations.

6. Digital Work Instructions with Feedback

Capture data as operators follow digital work instructions—ensuring standard work is followed and insights are logged automatically.

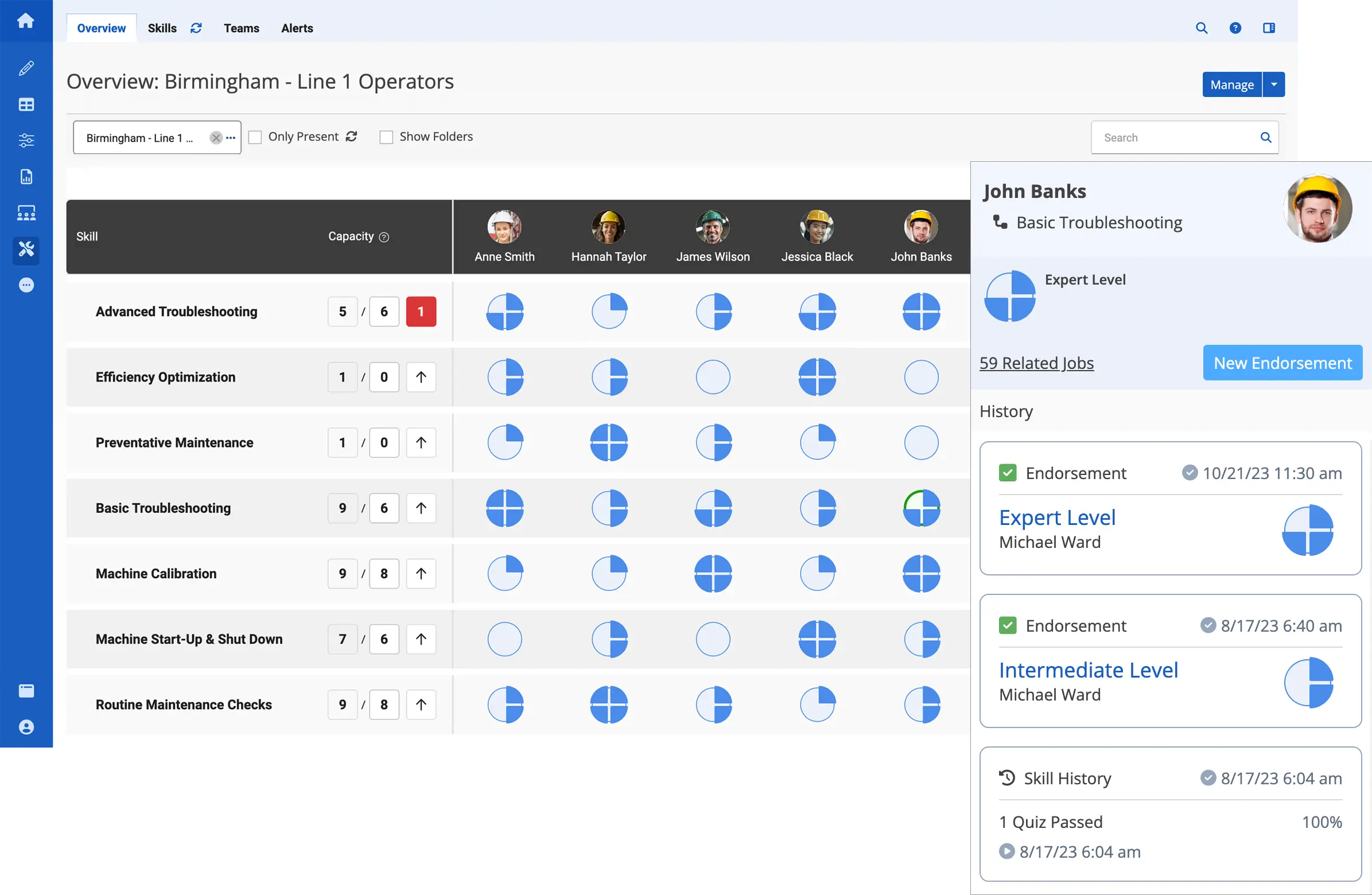

7. Training and Skill Tracking

Use skills management tools to monitor how skill levels and training impact performance, and identify upskilling opportunities.

Shop Floor Data Capture is the First Step Toward Industry 4.0

Capturing accurate shop floor data is not just an operational improvement—it’s a foundational step in the journey toward smart manufacturing. By digitizing and automating data collection, manufacturers can:

- Enable predictive maintenance

- Support AI-driven decision-making

- Improve workforce development strategies

- Achieve greater agility in response to market changes

Whether you’re adopting Lean Manufacturing, Six Sigma, or Industry 4.0, real-time, accurate shop floor data is essential for success.

How Technology is Transforming Shop Floor Data Capture

Technology is revolutionizing how manufacturers collect and use data on the shop floor. Traditional manual methods—like paper checklists, spreadsheets, and standalone terminals—are being replaced by digital, connected solutions that enable real-time visibility, reduce errors, and unlock continuous improvement.

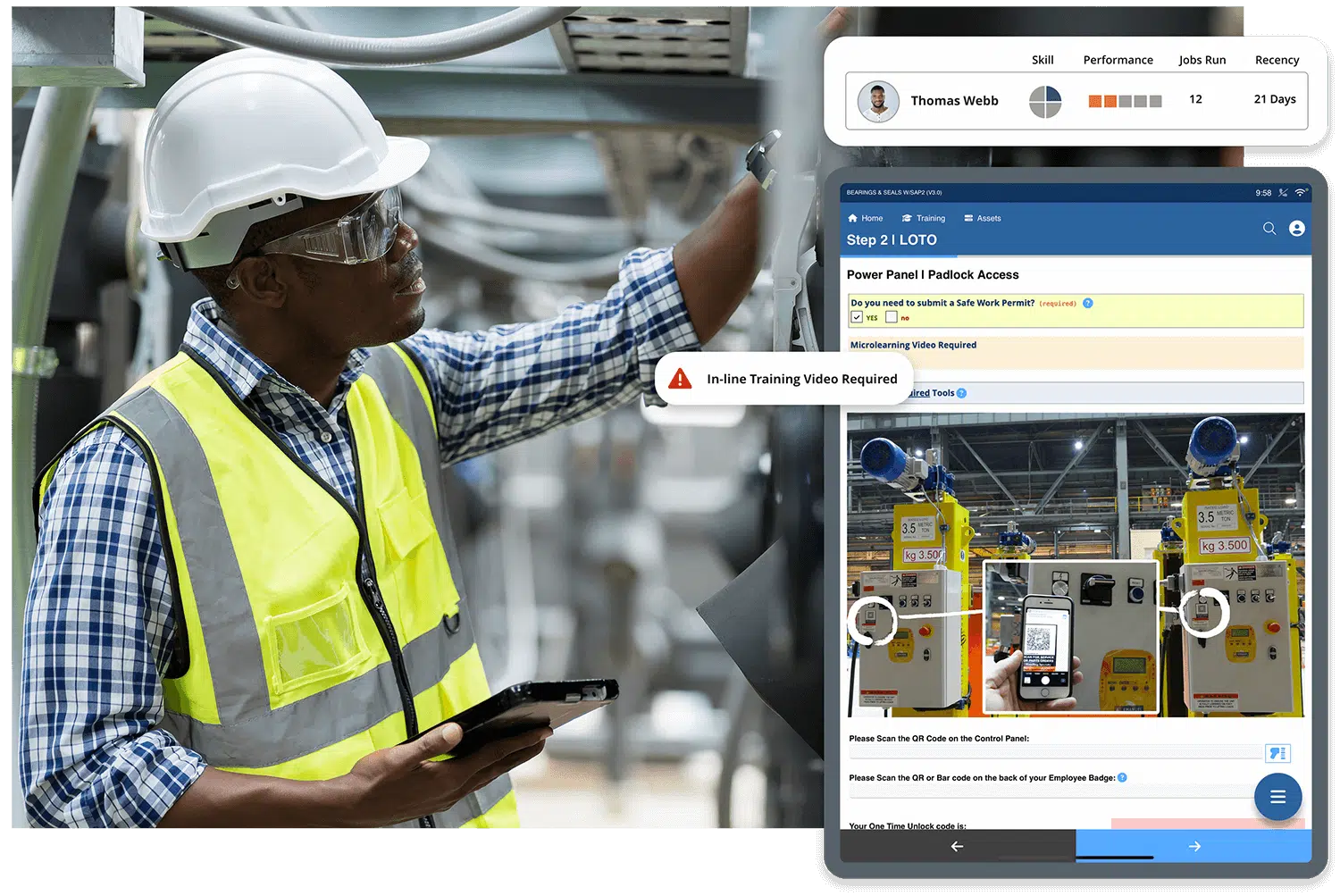

One of the most impactful advancements is the rise of Connected Worker Platforms. These platforms equip frontline workers with mobile devices, wearables, or voice-enabled tools that guide them through tasks while automatically capturing data in the flow of work. This eliminates the need for redundant data entry and ensures that information is accurate, consistent, and immediately available for analysis.

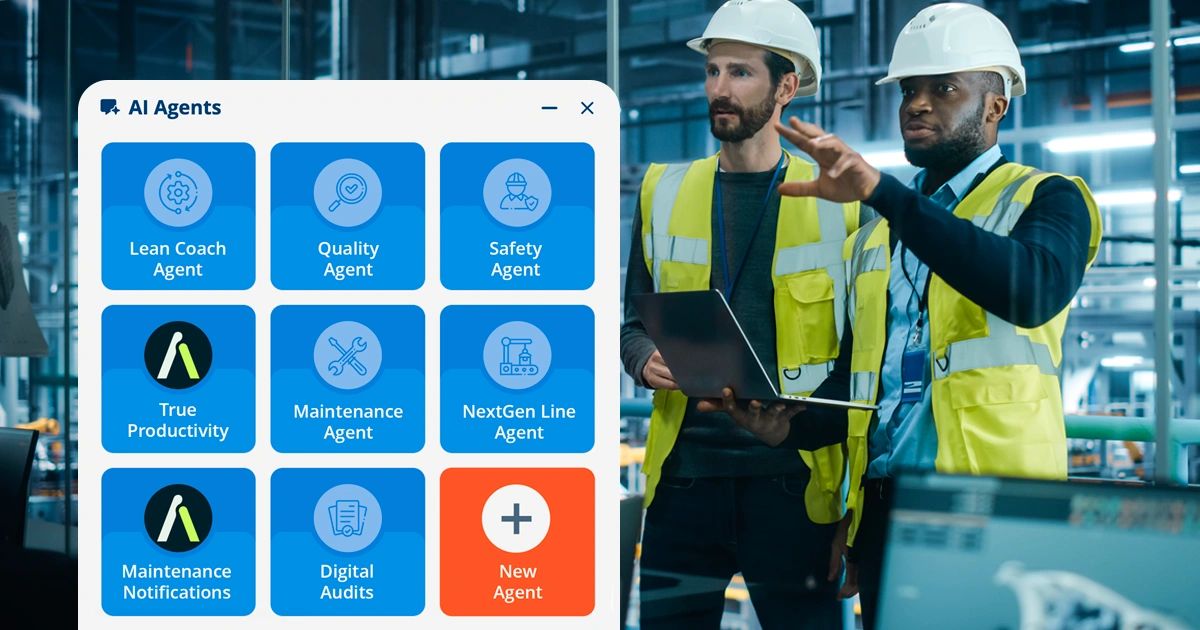

Adding to this transformation is the emergence of AI-powered digital assistants, such as Augie, Augmentir’s GenAI Assistant for Manufacturing. These AI tools analyze the data captured from the shop floor and deliver proactive insights, recommendations, and real-time support to workers and supervisors. Whether it’s identifying patterns in downtime, highlighting skill gaps, or surfacing quality issues, AI Agents enable a more intelligent, adaptive approach to managing operations.

Key Technology Advancements Driving Change:

- GenAI Assistants like Augie: Transform raw data into intelligent, actionable insights that drive continuous improvement and smarter decision-making.

- Connected Worker Platforms: Digitize frontline work and embed data capture into standard processes.

- Mobile and Wearable Devices: Allow workers to input data quickly and hands-free, improving efficiency and safety.

- IoT Sensors and Smart Machines: Enable automatic capture of machine data without human input.

- Cloud and Edge Computing: Ensure real-time access to data across facilities and roles.

By integrating these technologies, manufacturers are not only improving data collection but also building a foundation for a more agile, efficient, and intelligent factory floor.

How Augmentir Elevates Shop Floor Data Capture

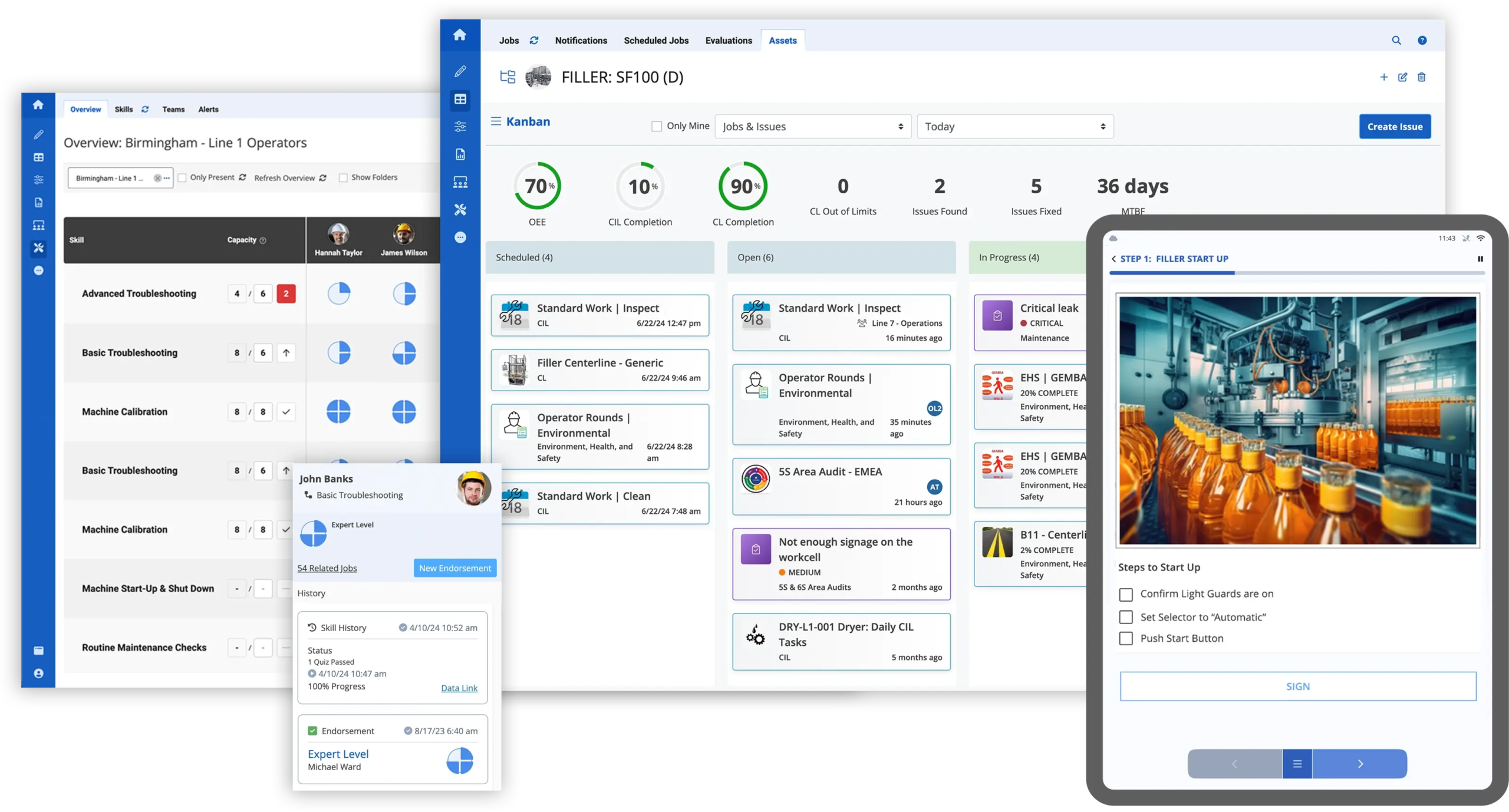

Augmentir goes beyond basic data collection by embedding data capture directly into the flow of work through AI-powered connected worker tools. Rather than asking operators to fill out separate forms or spreadsheets, data is automatically gathered as workers execute tasks using digital work instructions, smart checklists, or mobile guidance.The

Augmentir platform is a suite of connected worker software tools that helps customers digitize and optimize all frontline processes including autonomous and preventive maintenance, quality, safety, asset management, and workforce training and development. The solution combines skills management, digital workflow, collaboration, and knowledge sharing to deliver continuous value in a wide range of verticals.

At the core of this system is Augie, Augmentir’s Suite of GenAI tools. Augie continuously monitors captured data to deliver intelligent, context-aware insights to workers and supervisors—helping identify inefficiencies, recommend improvements, and provide real-time support when it’s needed most.

Key Capabilities:

- Embedded Data Capture: Workers enter data naturally during task execution—no extra steps required.

- Automated Time and Activity Tracking: AI accurately logs who did what, when, and how long it took.

- AI-Driven Insights: Augie analyzes workforce and operational data to uncover skill gaps, detect process variation, and suggest workflow optimizations.

- Closed-Loop Feedback: Capture feedback from the frontline to continuously improve instructions and processes.

- Seamless Integrations: Sync with ERP, MES, or CMMS systems to create a unified data environment.

- Real-Time Assistance with Augie: Augie acts as a digital assistant on the shop floor, guiding workers, surfacing knowledge, and enabling just-in-time learning and decision support.

With Augmentir, manufacturers move from reactive firefighting to proactive optimization—unlocking measurable gains in productivity, quality, and agility, all powered by real-time data and intelligent AI support.

Ready to Modernize Your Shop Floor?

With Augmentir, you can start capturing high-quality shop floor data in days—not months. Empower your teams with tools that make work easier while giving you the insight to continuously improve operations.

Request a demo or Contact us to see how Augmentir can help.