What is Tribal Knowledge and How Do You Capture It?

Tribal knowledge is undocumented or unwritten information that is not generally known across an organization.

In manufacturing, tribal knowledge consists of valuable (and often times essential) information on how to manufacture a product, operate a machine, or perform other factory processes. This information is typically acquired over decades of experience, yet remains undocumented.

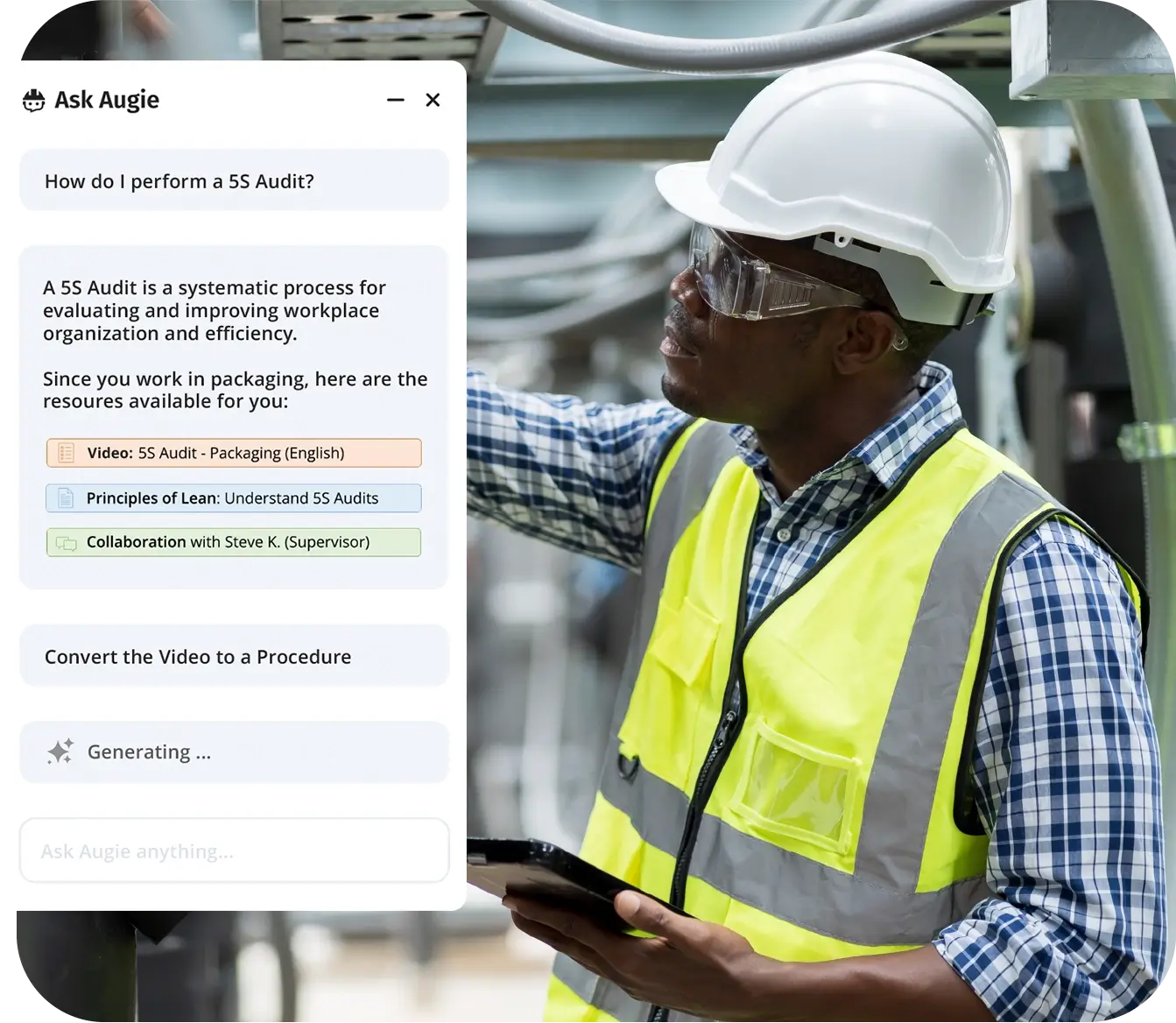

Capturing and formalizing tribal knowledge helps improve efficiency, maintain consistency, and reduce dependency on individual workers, yet many companies struggle finding effective ways to capture and digitize tribal knowledge.

Read our article below to learn more about tribal knowledge: