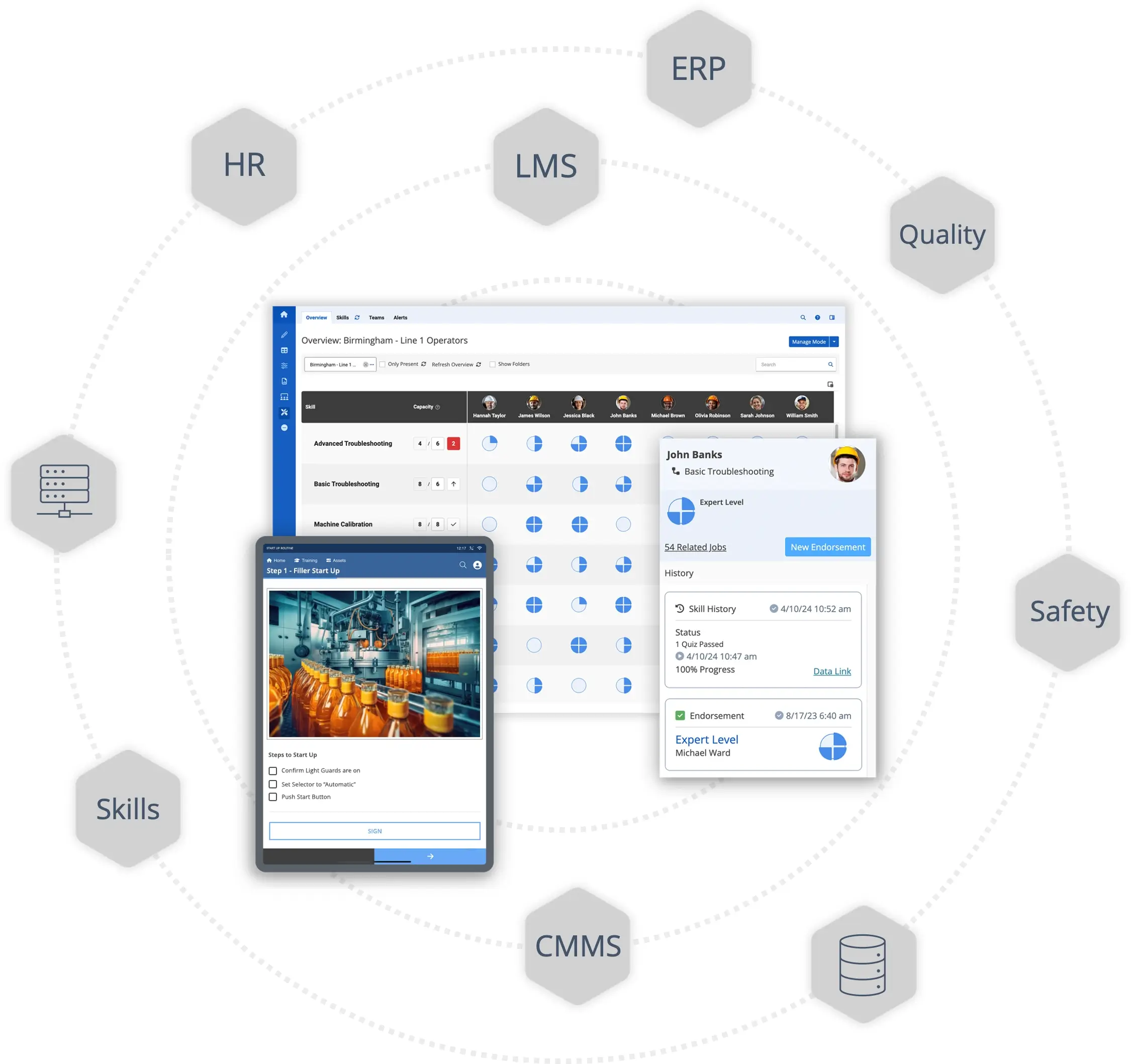

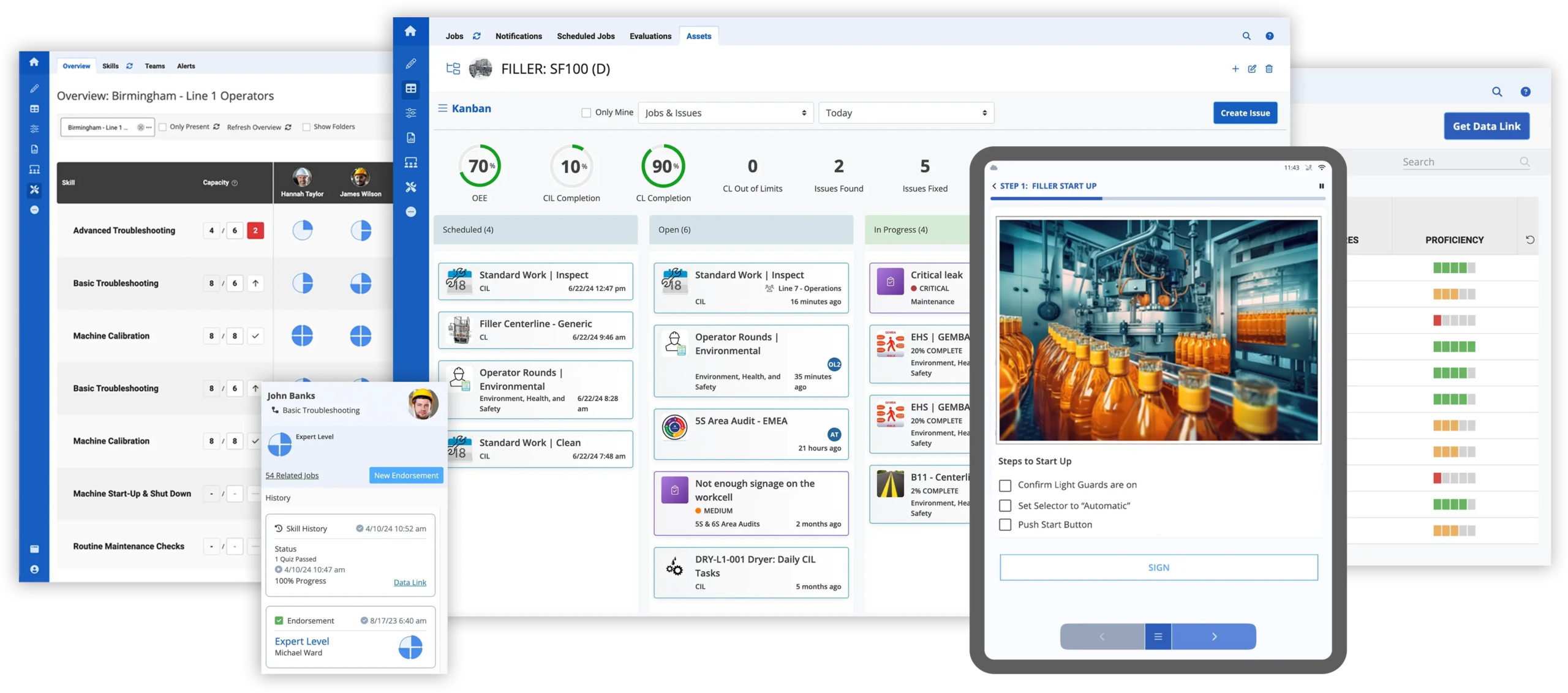

1. Real-Time Access to Information

Connected worker platforms provide frontline workers with real-time data on production status, machine performance, and quality checks through mobile devices, wearables, or augmented reality (AR). This instant access ensures that workers are always informed, enabling faster decision-making and reducing delays.

2. Enhanced Collaboration and Communication

These platforms facilitate seamless communication between workers, supervisors, and experts, even across different locations. Using tools like video calls, chat, and AR-based remote assistance, employees can collaborate in real-time to solve problems and share insights, improving teamwork and productivity.

3. Increased Productivity and Efficiency

By delivering digital work instructions, task checklists, and step-by-step guidance, connected worker platforms help employees complete tasks more efficiently and accurately. This minimizes errors, speeds up workflows, and ensures consistent performance across the workforce.

4. Data-Driven Decision-Making

Connected manufacturing generates a wealth of data. Connected worker platforms deliver personalized insights and performance analytics directly to employees, enabling them to make data-driven decisions on the shop floor. This optimizes processes and supports continuous improvement.

5. Empowered Workforce and Training

These platforms provide on-the-job training, skill assessments, and adaptive learning resources, helping workers stay up-to-date with new processes and technologies. Augmented reality (AR) and interactive training modules reduce the learning curve and empower workers to handle complex tasks.

6. Improved Safety and Compliance

Connected worker platforms help maintain workplace safety by delivering real-time alerts for hazards, safety guidelines, and compliance checklists. Digital records ensure that safety protocols are followed, reducing risks and ensuring regulatory compliance.

7. Faster Problem Resolution

When issues arise, connected worker platforms enable workers to quickly access troubleshooting guides or contact remote experts for assistance. This reduces downtime, minimizes production interruptions, and helps maintain operational flow.

8. Flexibility and Adaptability

In a dynamic connected manufacturing environment, workers need to adapt to changing tasks and processes. Connected worker platforms provide the tools and support needed to adjust quickly, ensuring that the workforce remains agile and responsive to new demands.

Connected Worker Platforms enhance Connected Manufacturing by enabling real-time communication, empowering workers with data-driven insights, and supporting continuous learning and adaptability. They ensure that human workers remain an essential, productive, and informed part of the connected manufacturing ecosystem, driving efficiency, safety, and innovation.