Operations

Boost productivity, reduce errors, improve uptime

Ensure equipment uptime and yield and improve the safety, quality, and efficiency of operator care routines performed by plant management, operations, and maintenance.

Operations Use Cases

Improve quality, productivity, and knowledge sharing across your manufacturing operation. Use Augmentir to digitize a wide range of operational processes – autonomous maintenance, CIL, centerlining, shift handoffs, daily management, and more. Digital work instructions help guide operators and technicians in daily operations, increase productivity, identify bottlenecks, and reduce training time. Improve processes around operator rounds, line changeovers, and shift handoff. Use AI-based insights to target the largest opportunities for ongoing improvements.

- Eliminate paper with digital work instructions

- Pre-built manufacturing templates allow you to create new work instructions quickly

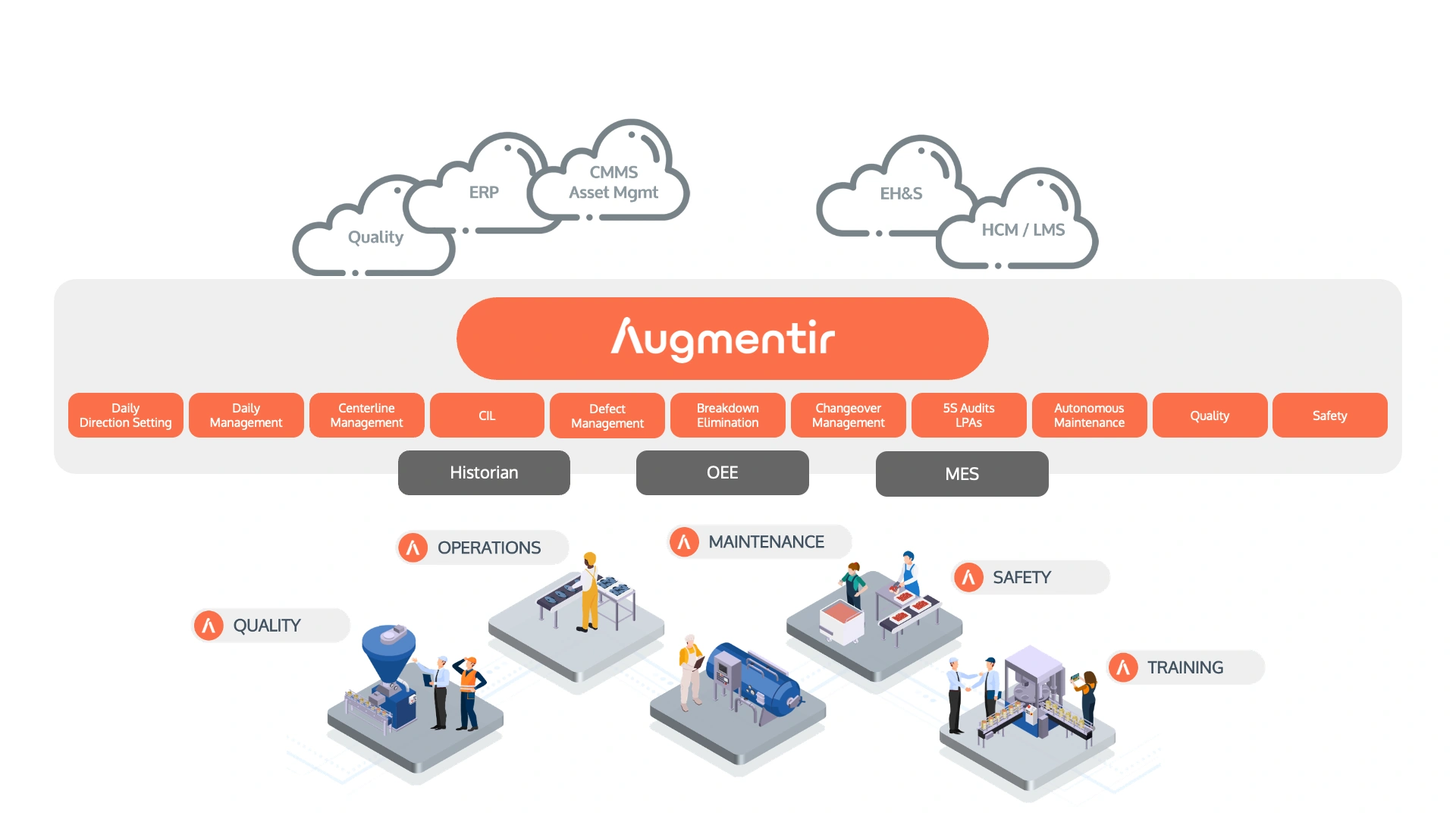

- Easily integrate digital workflows within Augmentir with existing ERP, MES, LIMS, and other operations systems

- AI-based insights help identify the largest capturable opportunities, helping drive continuous improvement initiatives in the areas of productivity, training, and quality

- Ensure equipment uptime and yield and improve the safety, quality, and efficiency of operator care routines performed by plant management, operations, and maintenance. Streamline manufacturing procedures.

Augmentir is a Single Pane of Glass Across Your Entire Frontline Operations

Autonomous Maintenance

Ensure equipment uptime and yield while improving the safety, quality, and efficiency of operator care routines.

Clean, Inspect, Lubricate (CIL)

Ensure equipment uptime and yield by standardizing Clean, Inspect, and Lubricate (CIL) routines to improve safety, quality, and operational efficiency.

Changeover

Minimize the time it takes to switch a machine or production line from one task or product to another, reducing downtime and increasing flexibility.

Centerlining

Reduce downtime and improve throughput by standardizing line changeover procedures to ensure safe, efficient, and consistent execution.

Shift Handoff

Augmentir’s AI-based workforce intelligence enables closed-loop performance management and automatically identifies your largest workforce improvement opportunities.

Daily Management

Focus on creating a routine and systematic process for monitoring, managing, and continuously improving daily work at the operational level.

Operator Rounds

Maintain equipment reliability and performance by standardizing operator rounds to ensure consistent, safe, and efficient execution.

5S Audit Checklists

Improve the accuracy and reporting of 5S processes with digital 5S audit checklists.

Clean in Place

Minimize downtime and ensure product quality by standardizing clean-in-place (CIP) procedures for safe, consistent, and efficient execution.

Breakdown Elimination

Maximize equipment availability and performance by systematically eliminating breakdowns through standardized, proactive maintenance practices.

Issue Management

Resolve operational issues quickly and prevent recurrence by standardizing issue management for timely, transparent, and effective action.

Digital Checklists

Ensure consistent, accurate, and compliant operations by using digital checklists to streamline tasks and reduce errors.