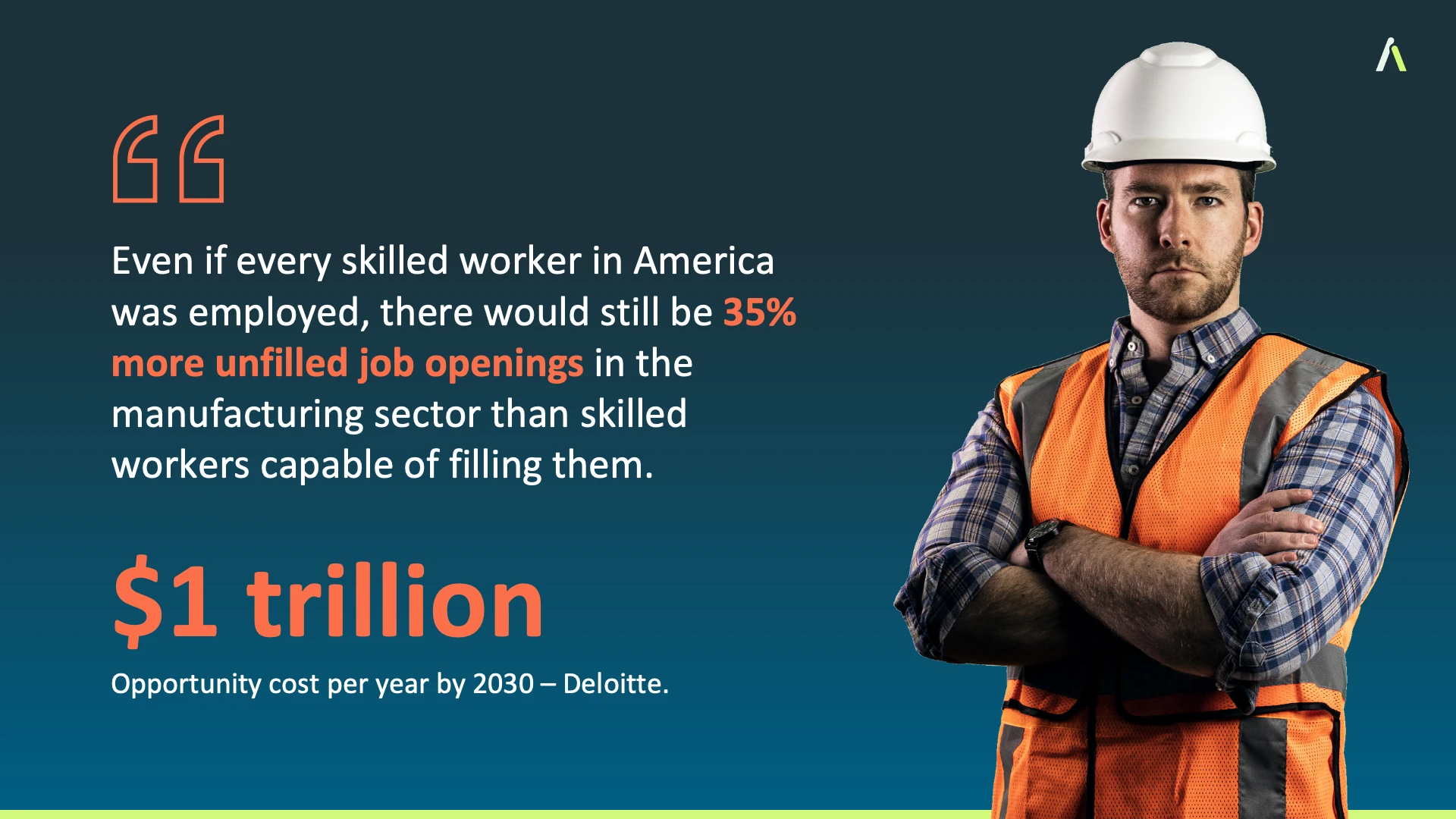

In a recent write-up, Tech-Clarity highlighted how Augmentir is addressing one of manufacturing’s most pressing challenges: enabling a smaller, less experienced frontline workforce to perform at a higher level with intelligent systems and AI agents that operate as “digital workers” alongside human workers on the factory floor.

When respected industry analysts take notice, it’s a strong signal that something meaningful is happening in the market. In a recent write-up, Tech-Clarity highlighted how Augmentir is addressing one of manufacturing’s most pressing challenges: enabling a smaller, less experienced frontline workforce to perform at a higher level with intelligent systems and AI agents that operate as “digital workers” alongside human workers on the factory floor.

The analysis points to Augmentir’s expanding use of machine learning, generative AI, and agentic AI as key differentiators—driving measurable gains in productivity, training effectiveness, and continuous improvement across global operations.

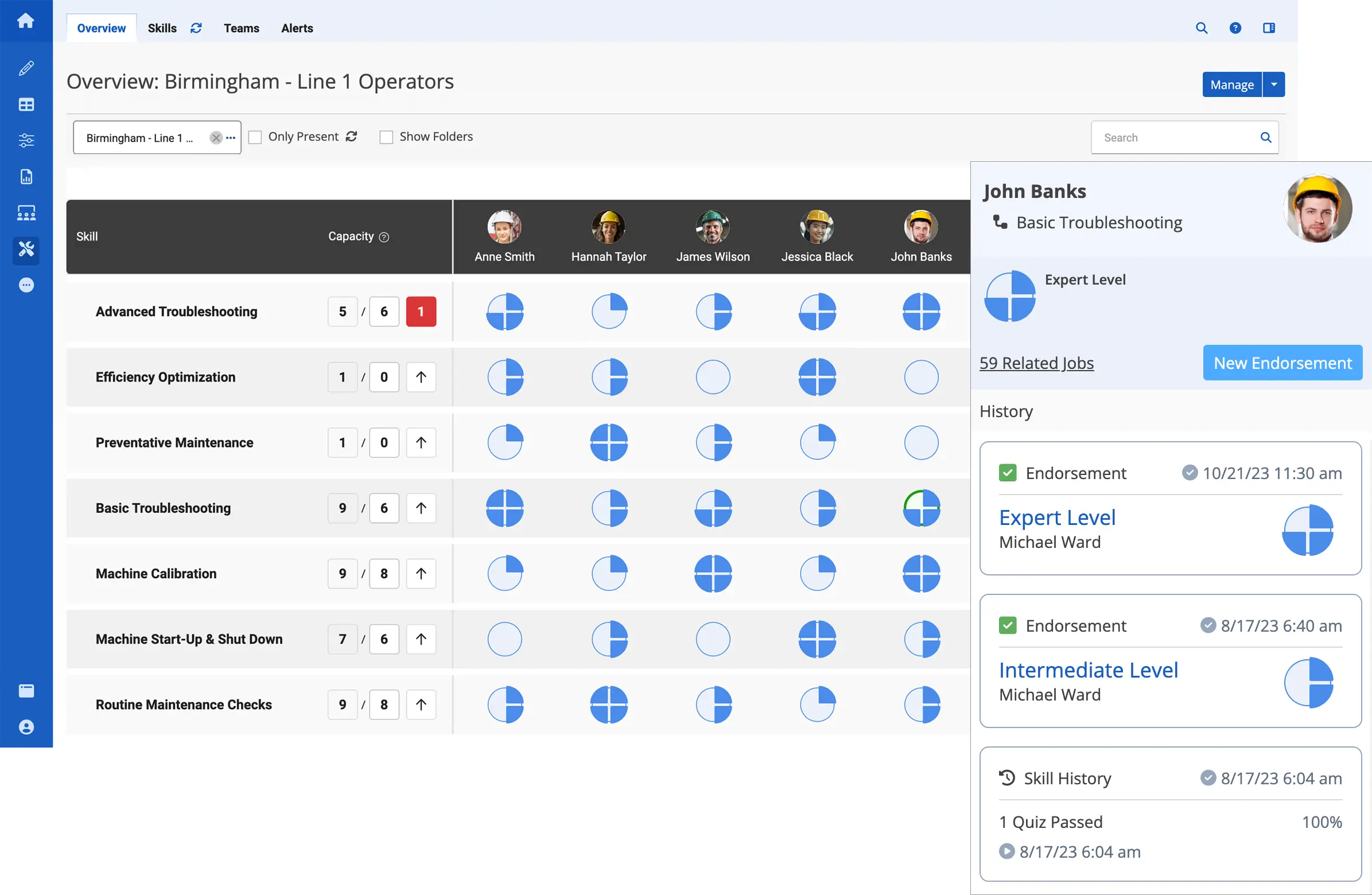

A Single Pane of Glass for the Frontline

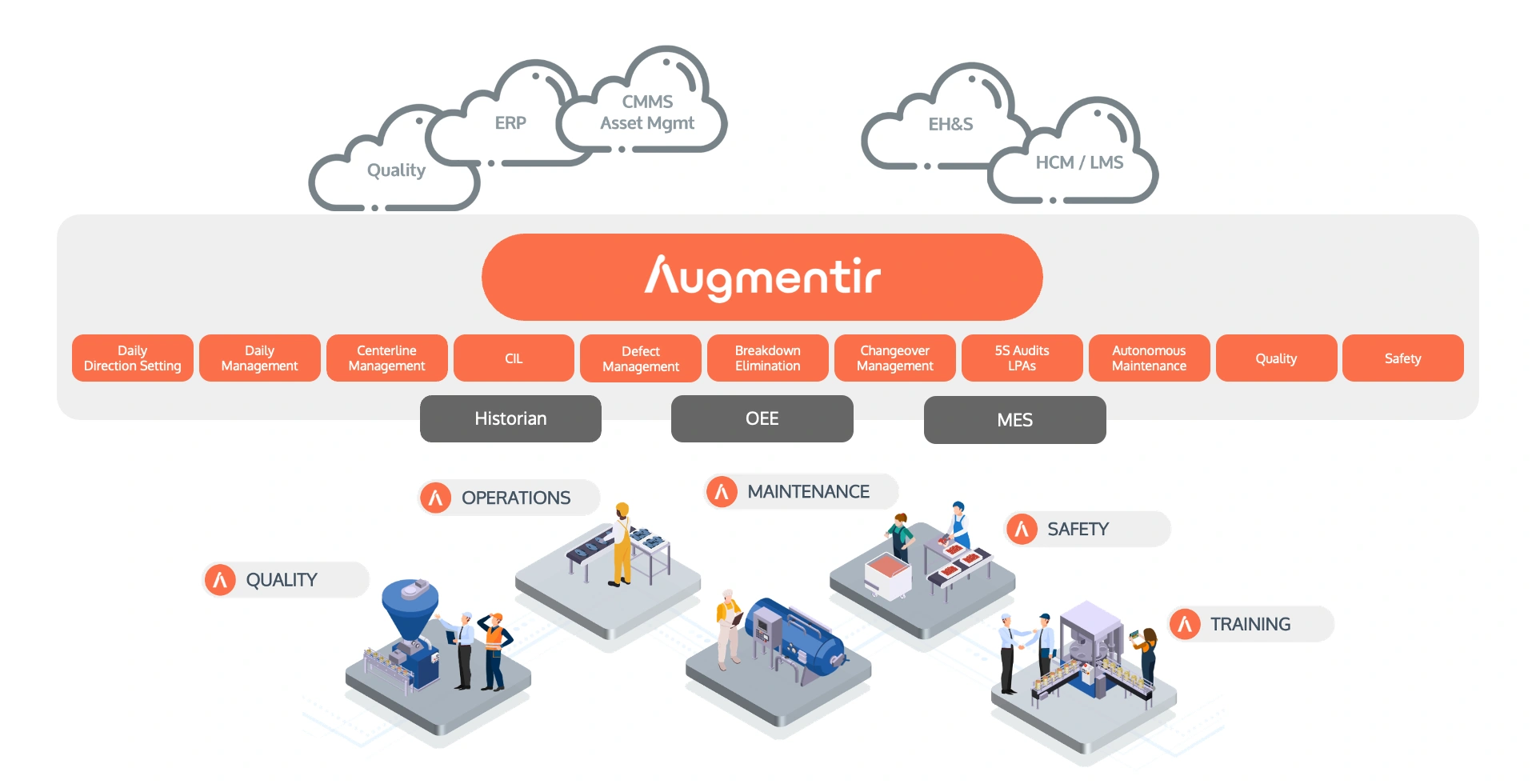

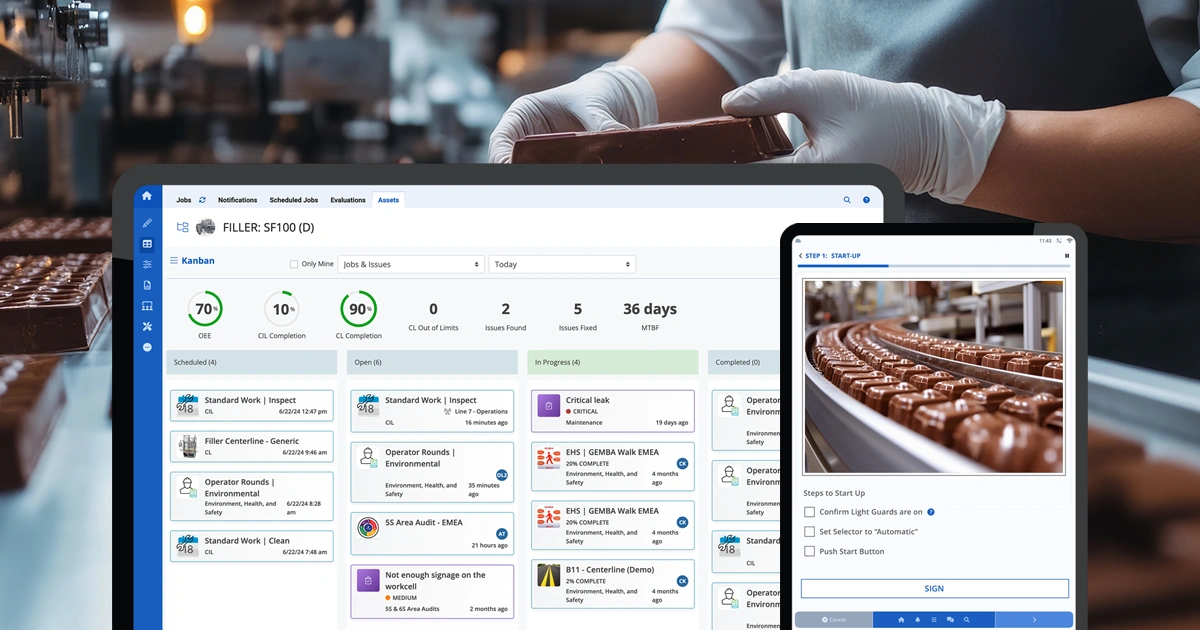

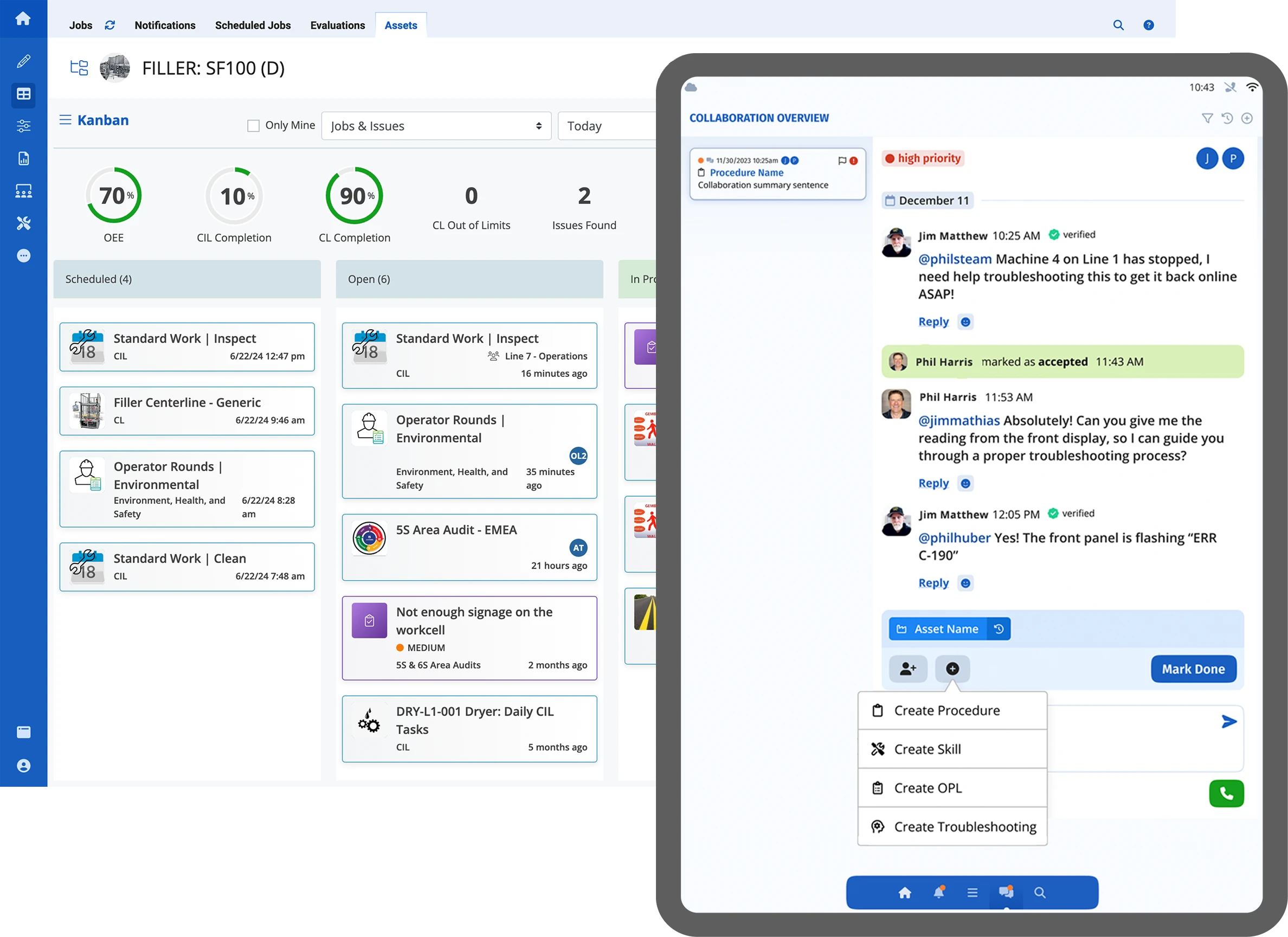

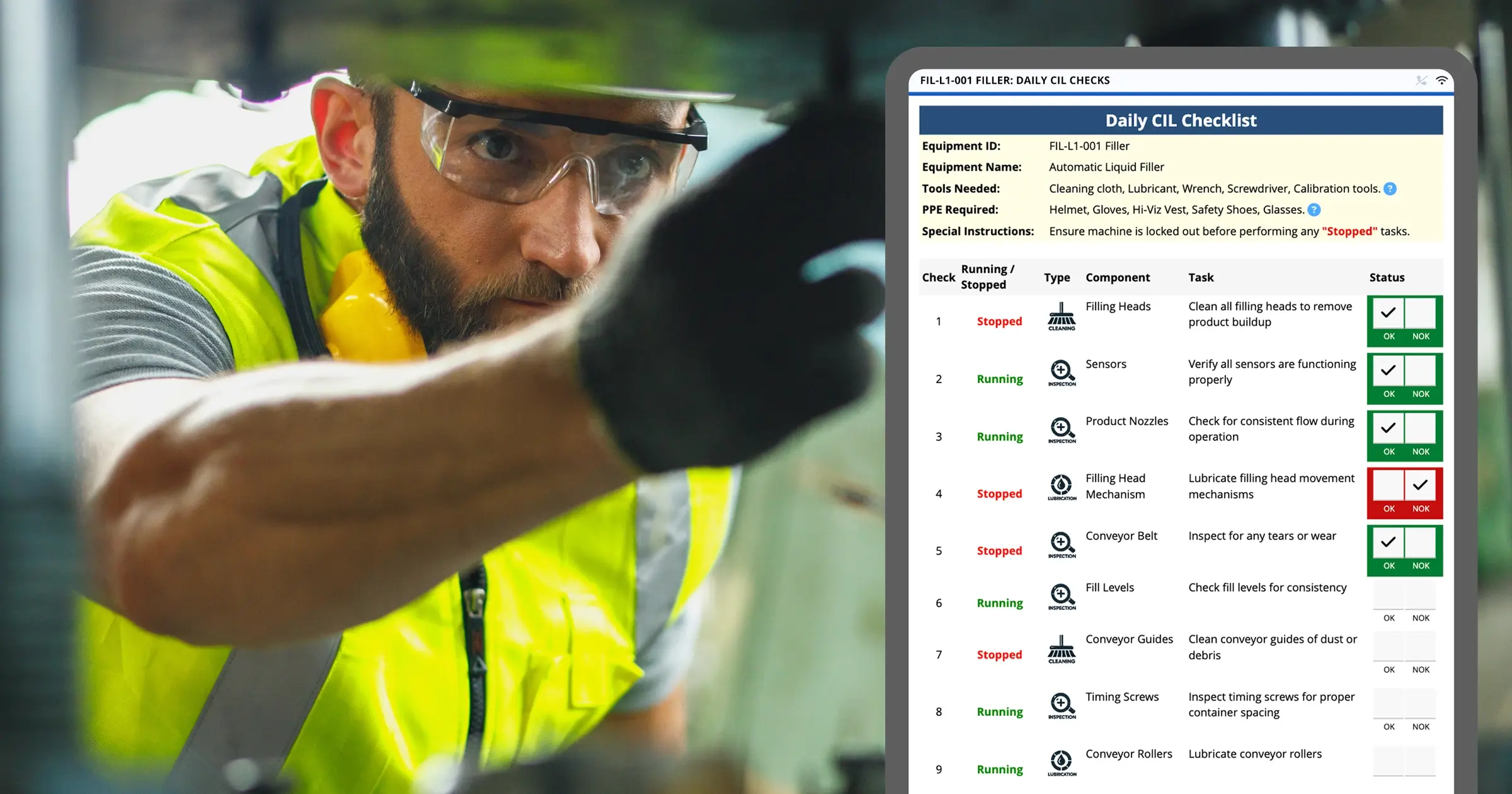

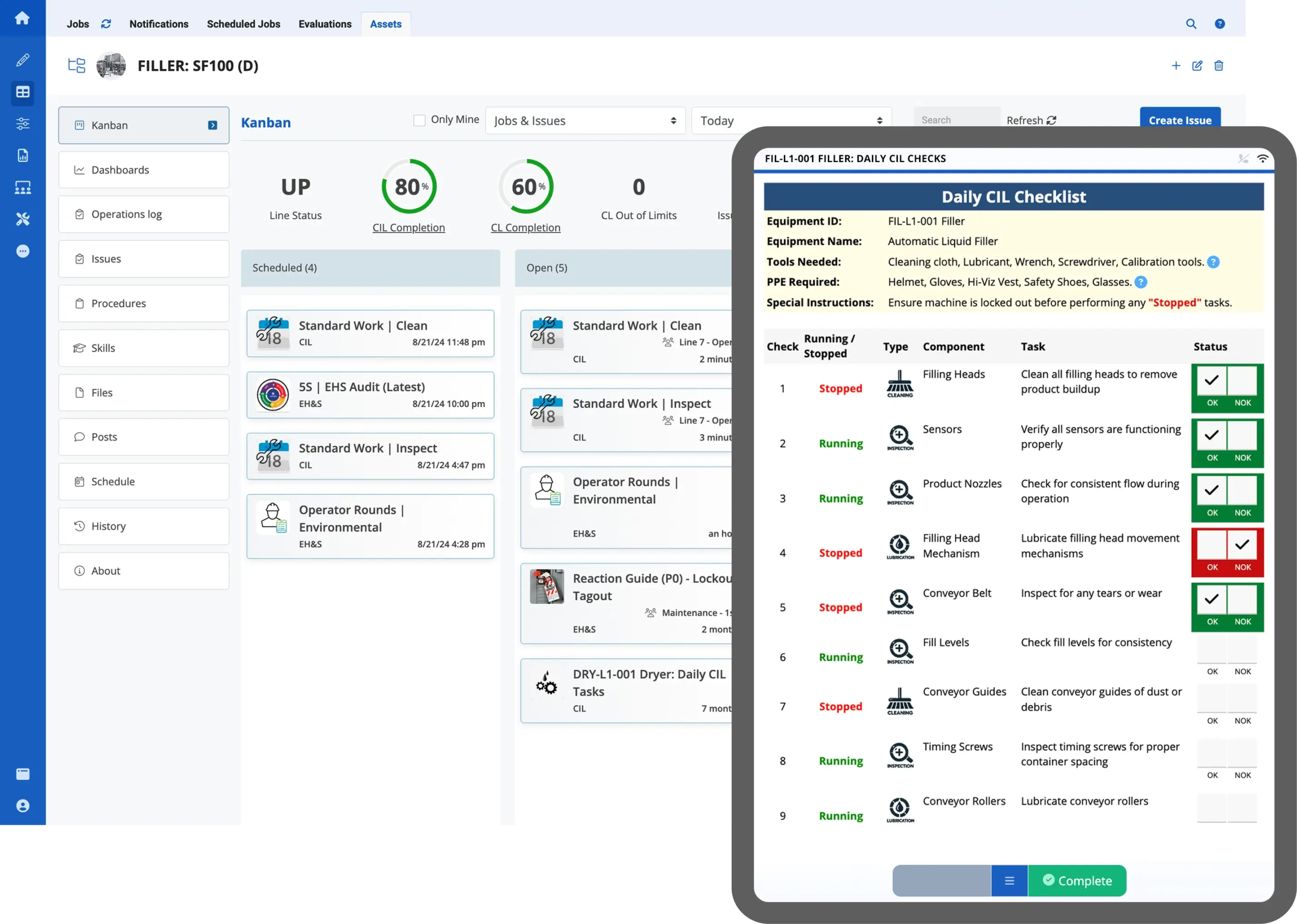

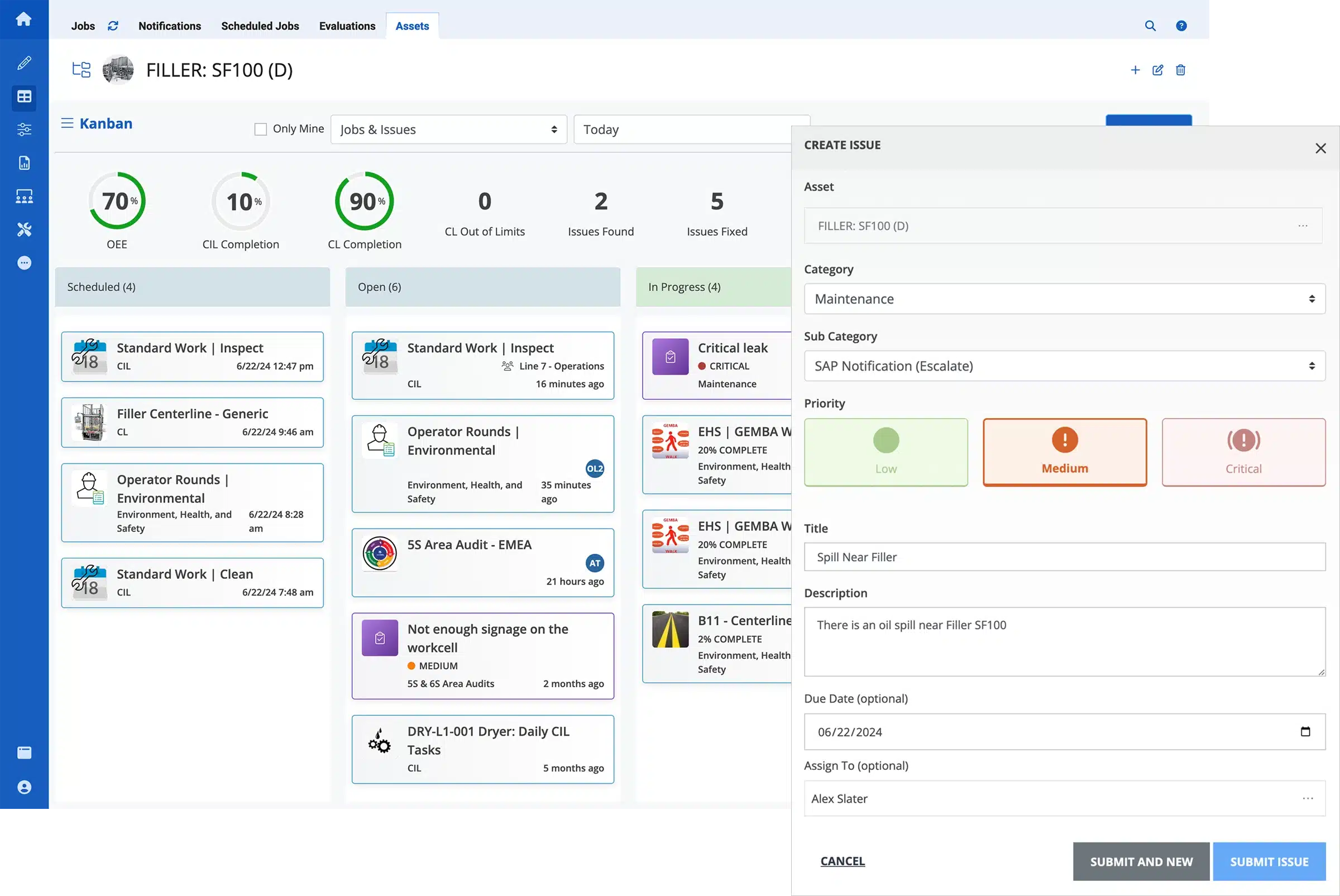

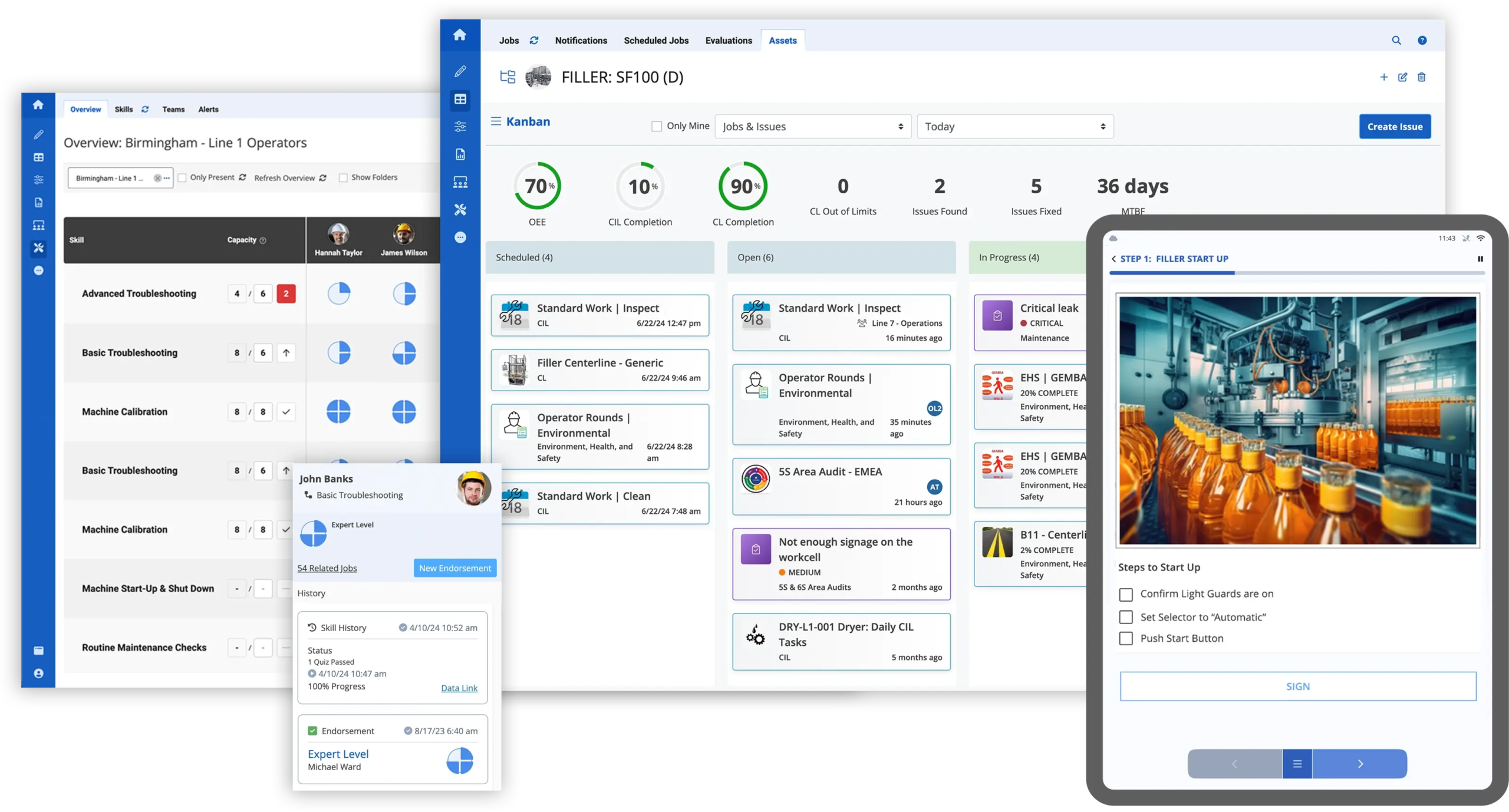

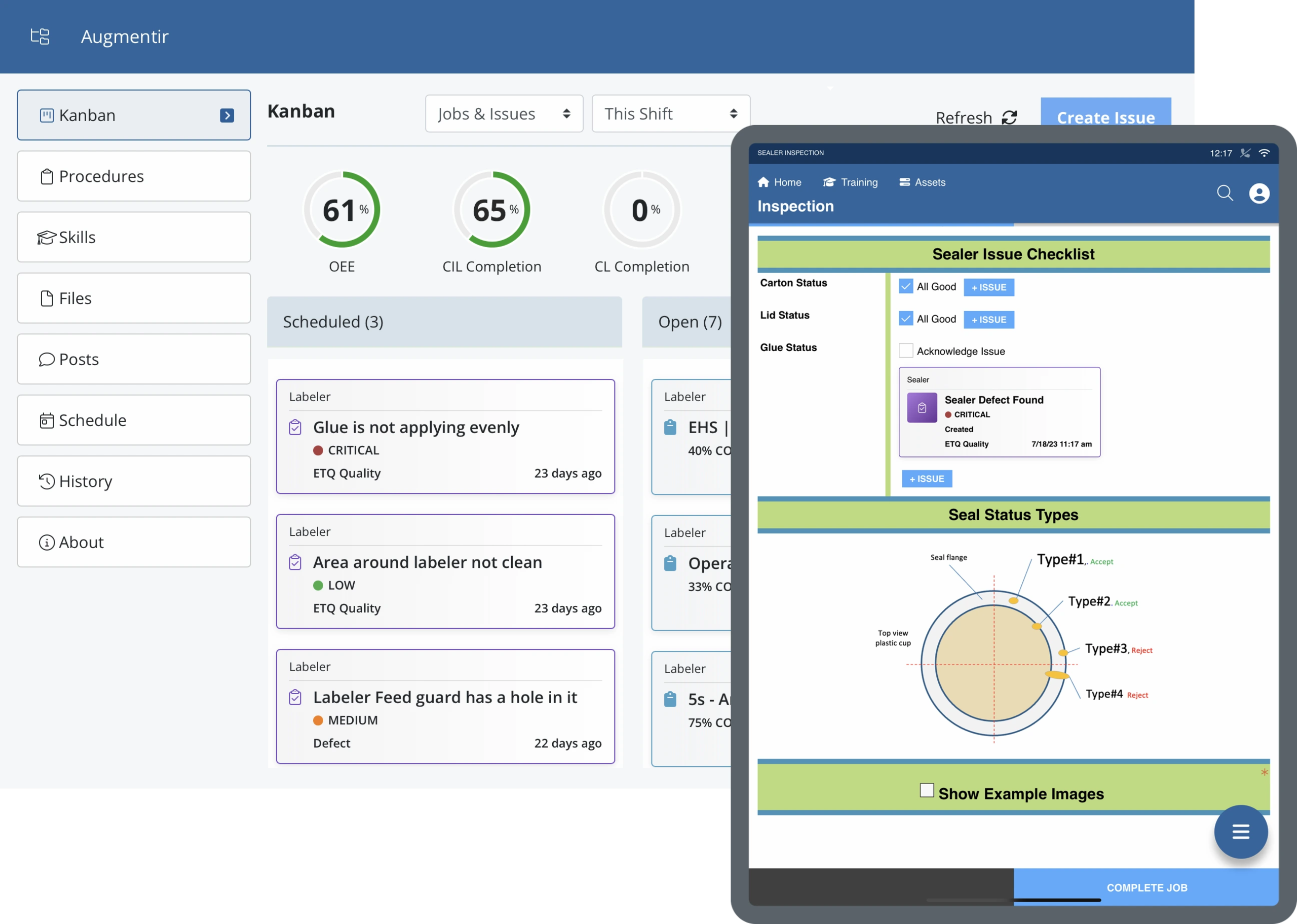

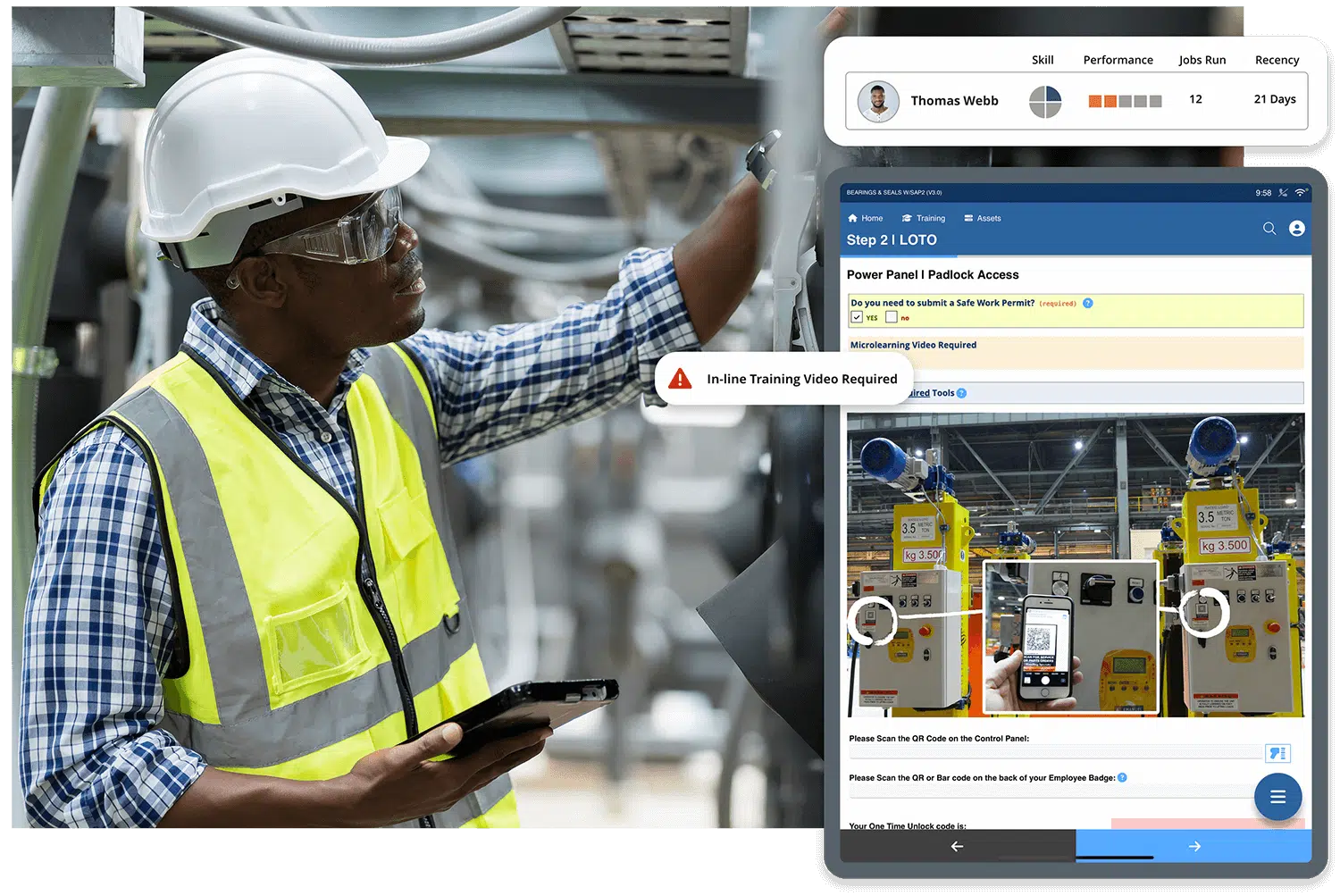

At the core of Augmentir’s approach is a simple but powerful concept: give frontline workers exactly what they need, when they need it—no more, no less. Tech-Clarity notes that Augmentir delivers this through a single, contextual interface that integrates with a broad ecosystem of plant and enterprise systems.

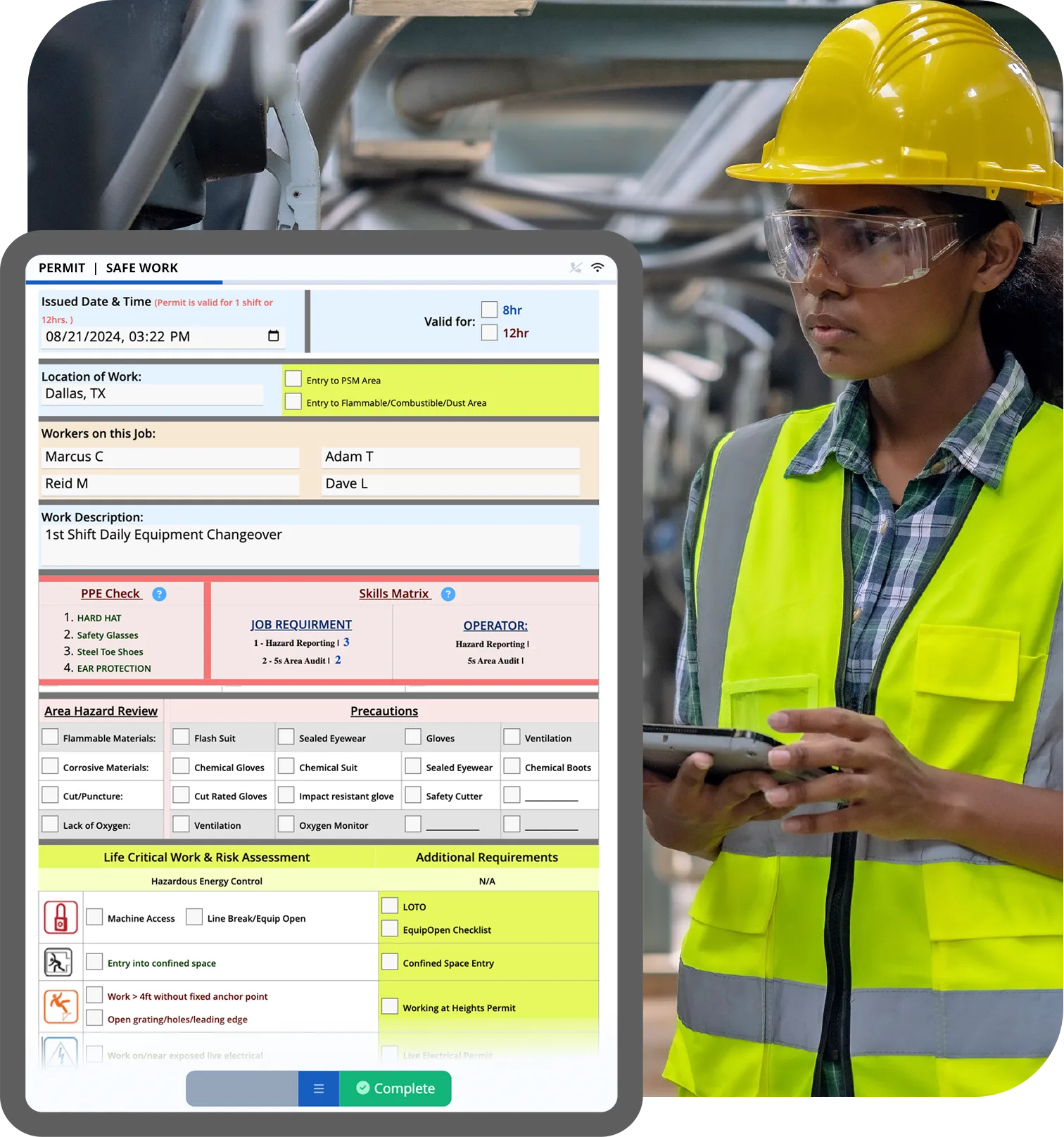

The platform supports the full spectrum of connected worker needs, including:

- Digital work instructions and content authoring

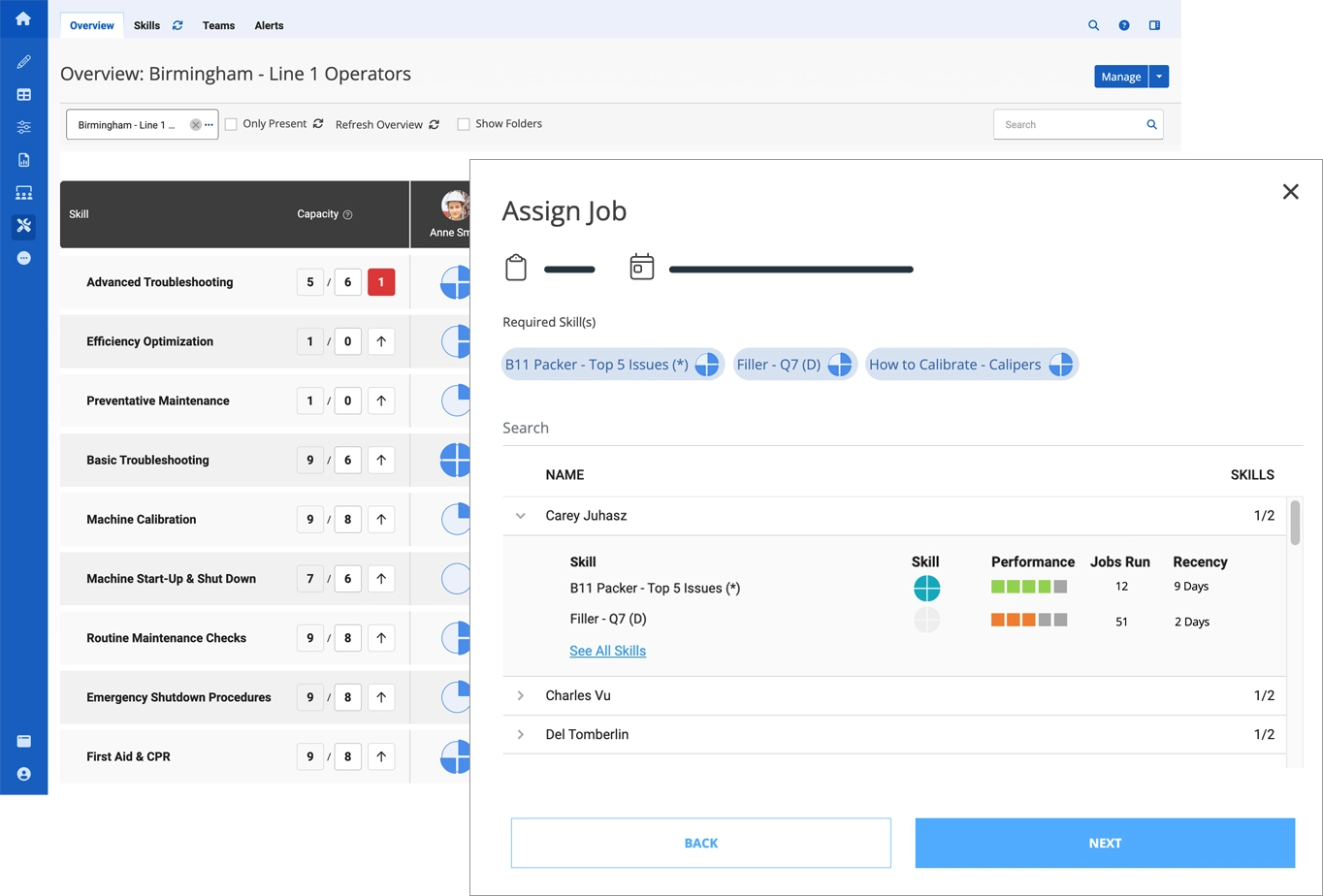

- Skills matrices and knowledge sharing

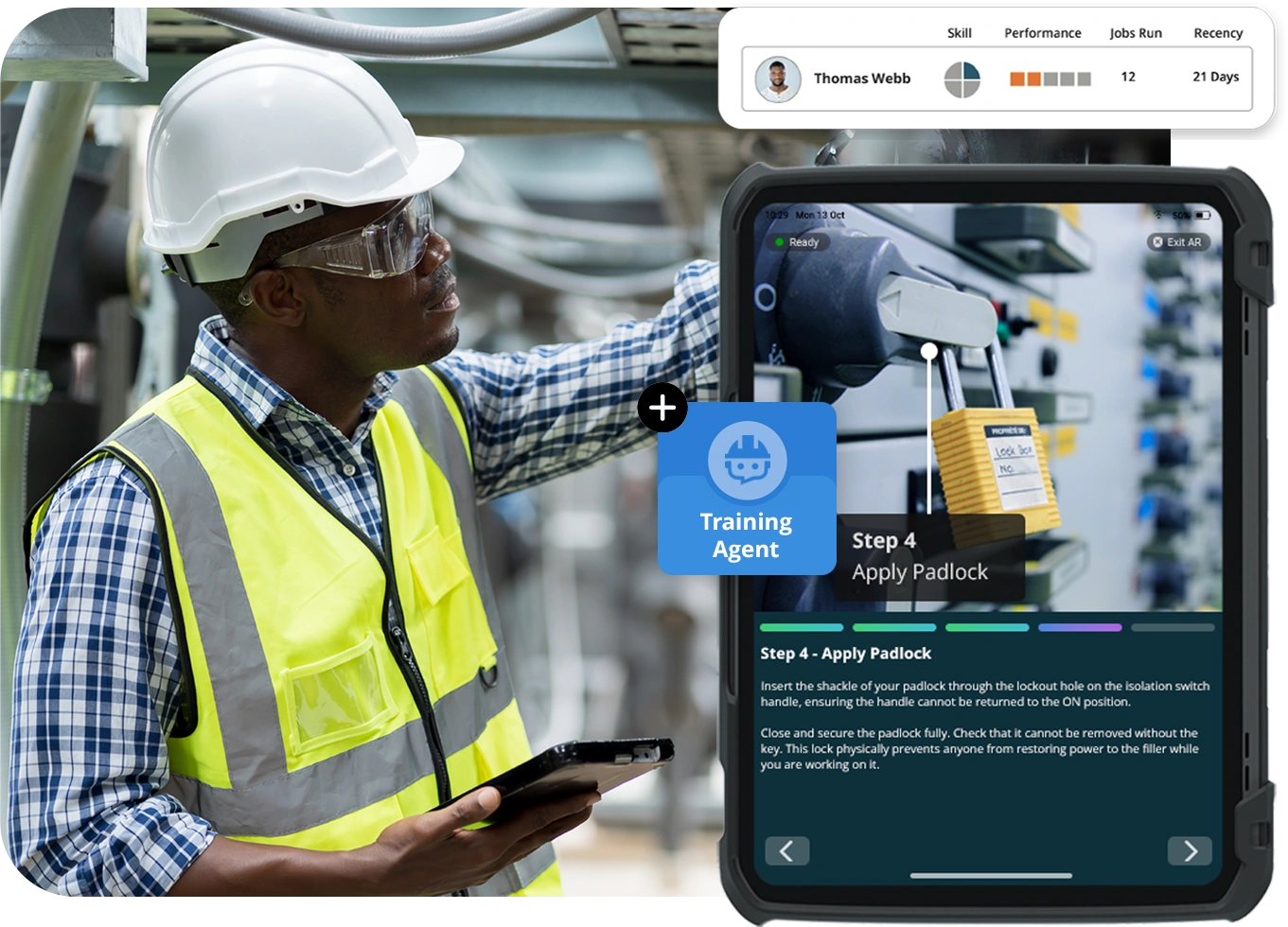

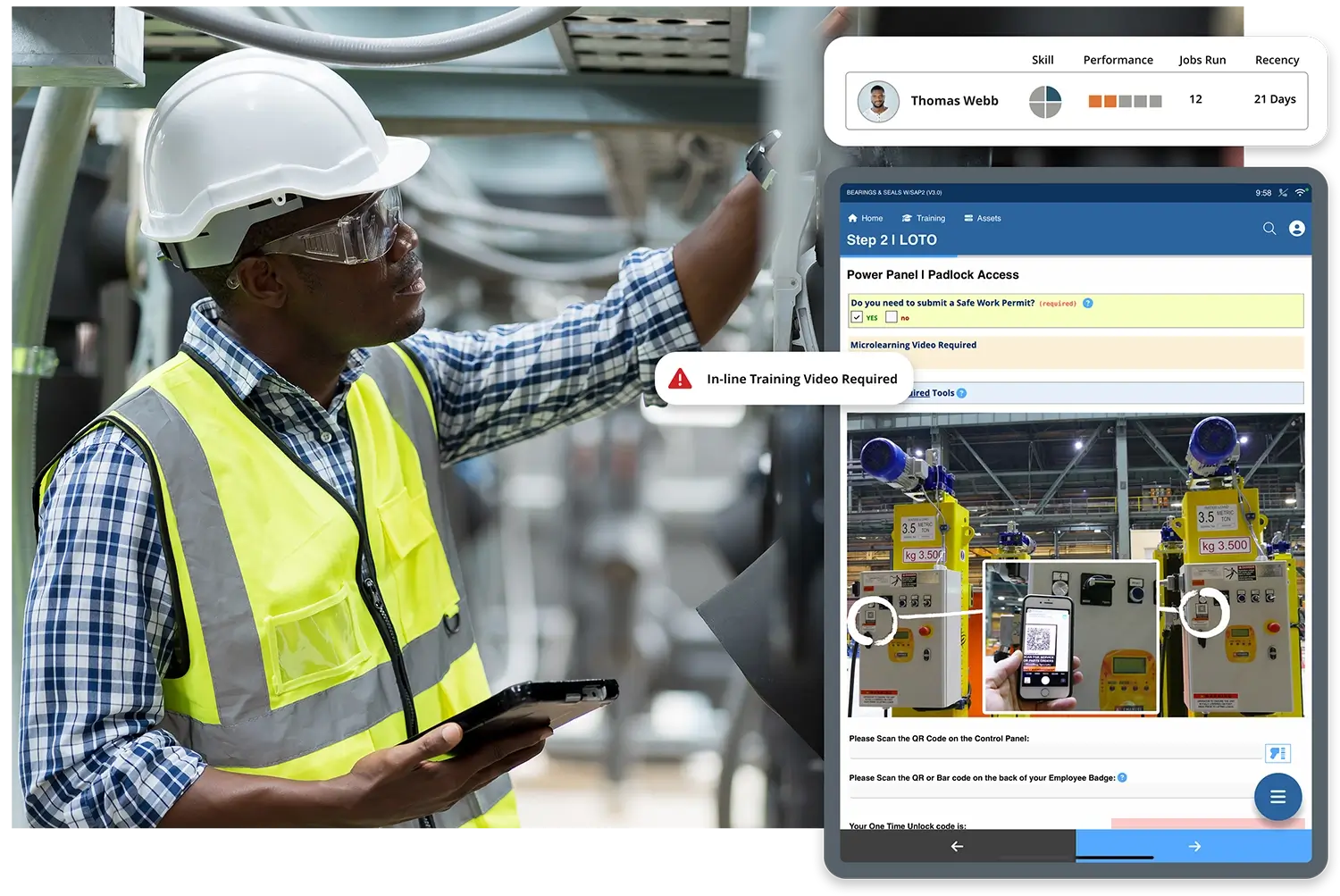

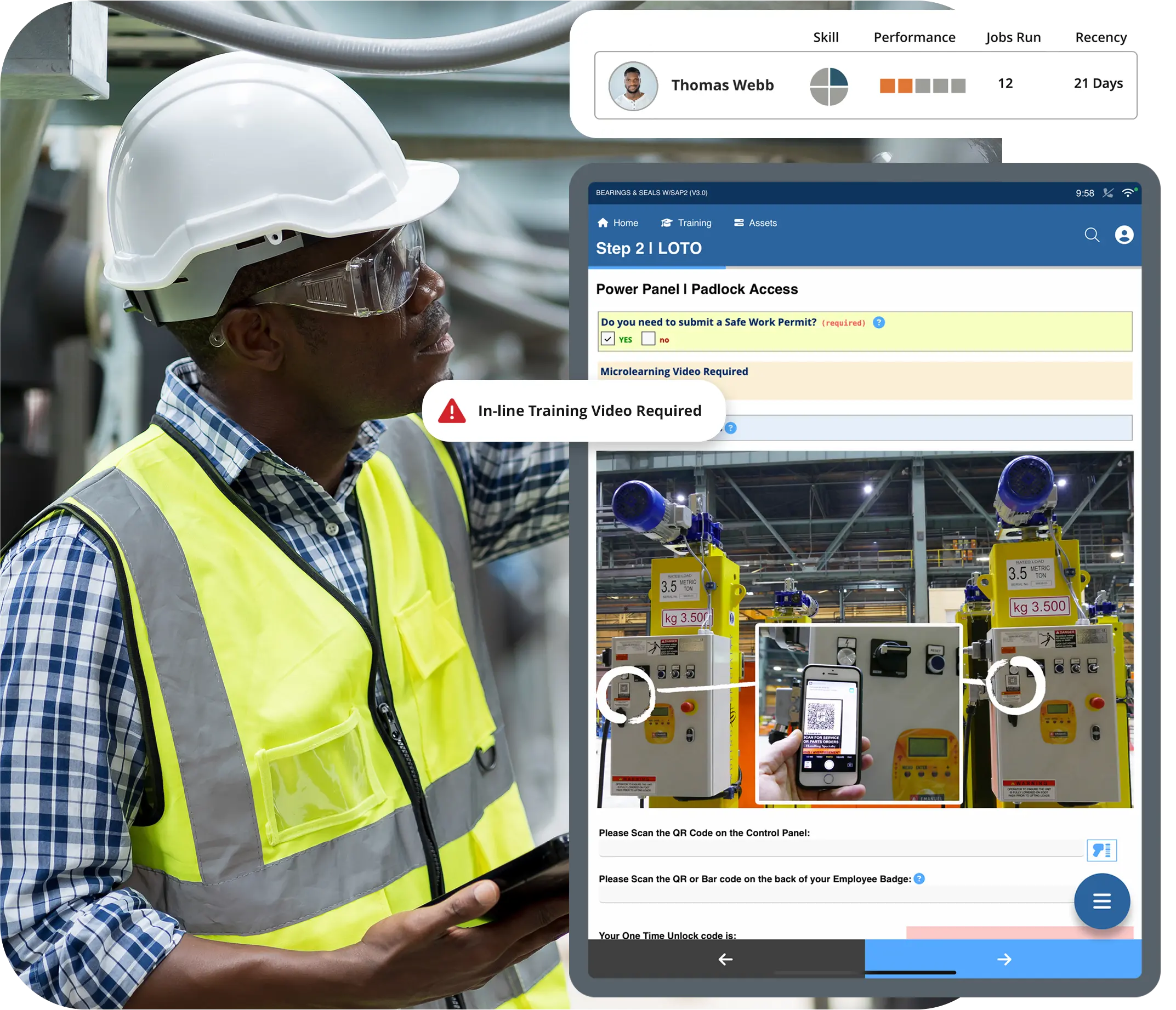

- Contextual, personalized training delivered in the flow of work

- AI Agents that act as “digital workers” within the connected worker platform – operating alongside human frontline workers

- Embedded analytics and reporting, including Microsoft Power BI

Because Augmentir’s founders come from an augmented reality background, immersive and experiential learning is a native part of the platform rather than an afterthought.

Closing the Loop with True Insights™

What truly differentiates Augmentir, according to Tech-Clarity, is how it closes the loop between frontline execution and continuous improvement. As work is performed, the platform applies machine-learning–driven AI to analyze operational data across tasks, machines, individuals, and cohorts.

These insights—what Augmentir calls True Insights™—surface where performance breaks down and where improvement efforts will have the greatest impact. This could mean refining instructions, improving process efficiency, enhancing safety, or delivering targeted training exactly where it’s needed.

Rather than static reporting, Augmentir continuously learns from real work being done on the shop floor.

Expanding into Agentic AI

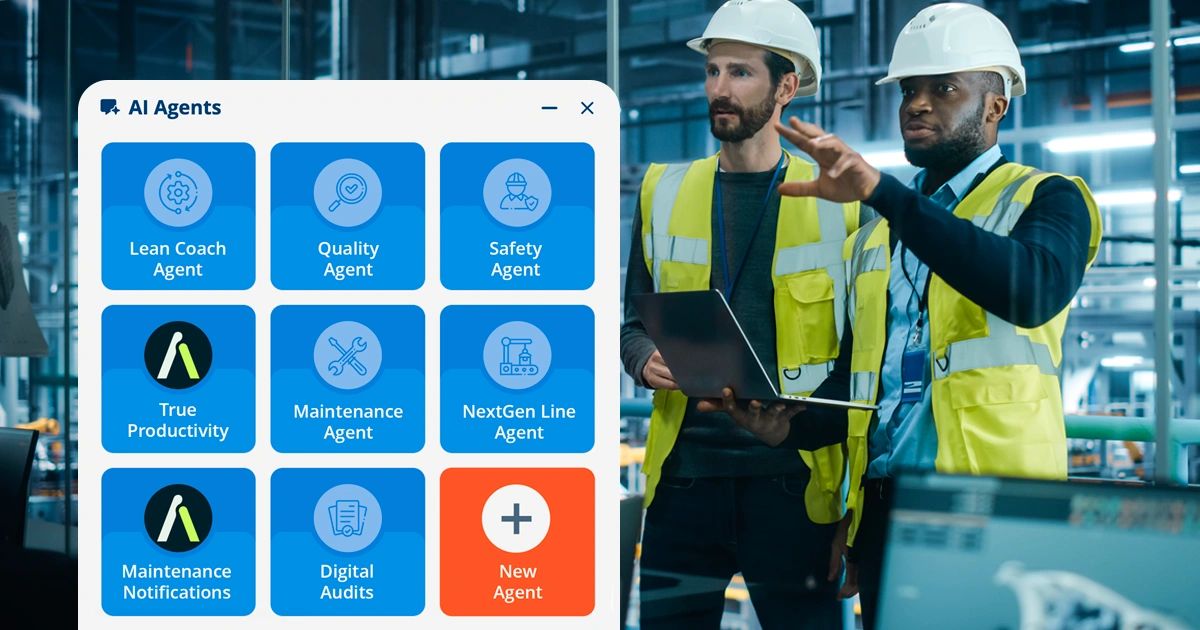

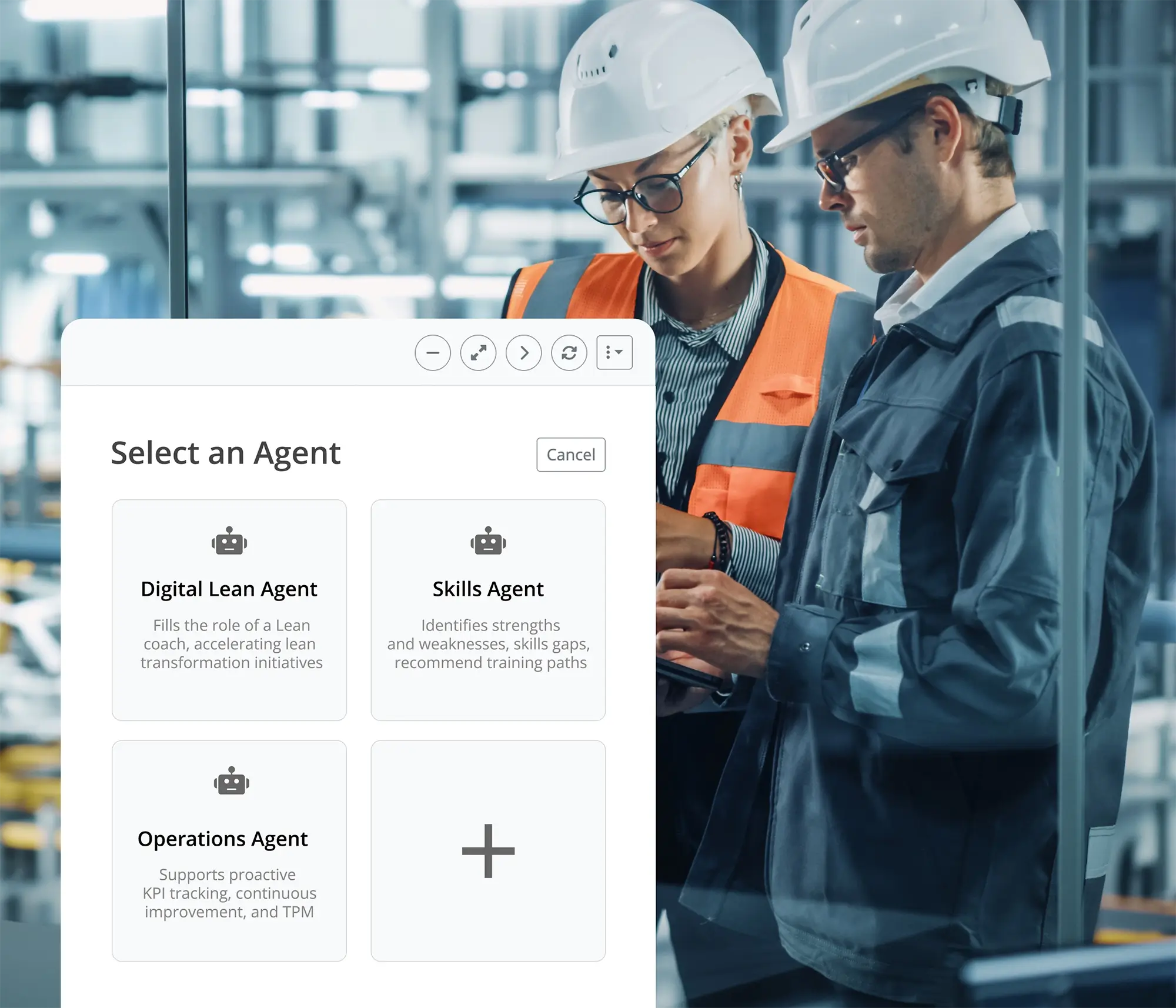

In early 2025, Augmentir introduced its Industrial AI Agent Studio, building on its existing GenAI assistant, Augie. Tech-Clarity highlights this as a major step forward, enabling customers to create custom, no-code AI agents tailored to their unique operational needs.

These agents extend Augmentir’s capabilities with autonomous digital workers that support key frontline use cases:

- Digital Lean Coach: AI agents that fill the role of a Lean coach, helping accelerate lean transformation initiatives.

- Adaptive Training and Skills Management: AI agents that can act on frontline workers’ skills and training data to support frontline managers by identifying strengths and weaknesses, skills gaps, and recommend training paths.

- Operations: Operational agents that support more proactive KPI tracking, unparalleled visibility across Operations, Continuous Improvement, and TPM.

- Safety: AI agents that automatically analyze safety data and activities to provide early warning notifications.

- Proactive Maintenance Execution: Agents that monitor equipment health and integrate with CMMS to trigger work orders, report issues, or initiate preventive maintenance tasks before failures occur.

Built-In Governance with the 6 Laws of AI Agents

Tech-Clarity also praised Augmentir’s thoughtful approach to AI governance. The platform embeds the company’s 6 Laws of AI Agents, ensuring safety, transparency, and accountability as customers deploy AI at scale:

- Transparency in execution

- Clear human ownership

- AI origin disclosure

- Persistent AI disclosure

- Human-in-the-loop for impactful actions

- No generative AI for life-critical actions

These principles are especially important for industrial environments where trust, safety, and compliance are non-negotiable.

Proven Customer Value at Scale

With customers in more than 70 countries across industries such as food & beverage, pharmaceuticals, chemicals, CPG, and industrial equipment, Augmentir’s impact is already measurable.

Tech-Clarity highlights results reported by customers, including:

- Up to 31% efficiency gains when standard work is consistently followed

- 82% reduction in onboarding time, even amid high employee turnover

- Faster issue resolution and reduced downtime

- Over 5 million optimized time-and-motion studies conducted on the platform

Notably, Tech-Clarity points out that customers see a 250%–400% performance delta when comparing Augmentir’s AI-driven approach to earlier-generation or non-AI connected worker solutions.

Tech-Clarity’s Take

In their closing assessment, Tech-Clarity emphasizes that Augmentir’s comprehensive use of AI—combined with real operational feedback loops—makes it particularly well suited for organizations looking to accelerate continuous improvement, not just digitize instructions.

They also note that Augmentir’s experienced founding team and growing roster of global enterprise customers speak volumes about market confidence in both the company and its platform.

As Tech-Clarity concludes, organizations evaluating connected frontline worker solutions would be well served to take a close look at Augmentir—and where it’s taking the future of industrial work.