Automotive Manufacturing

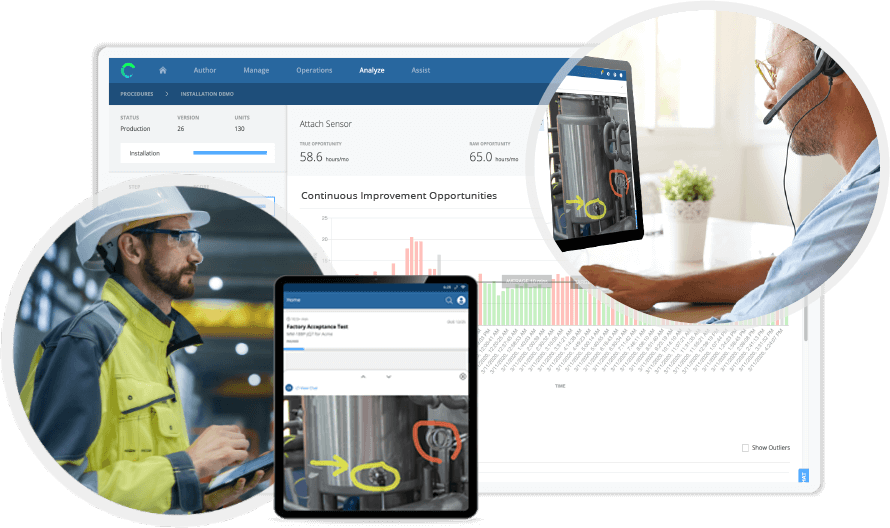

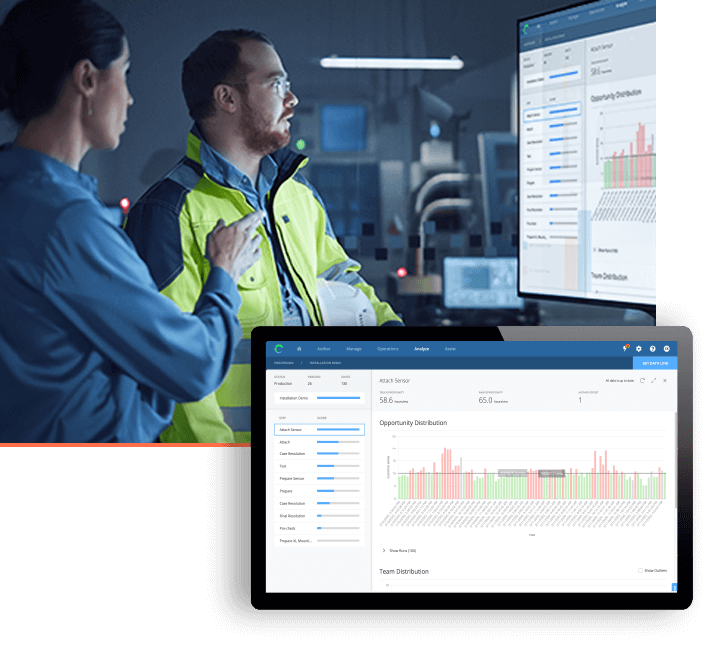

Boost productivity, reduce errors, improve uptime

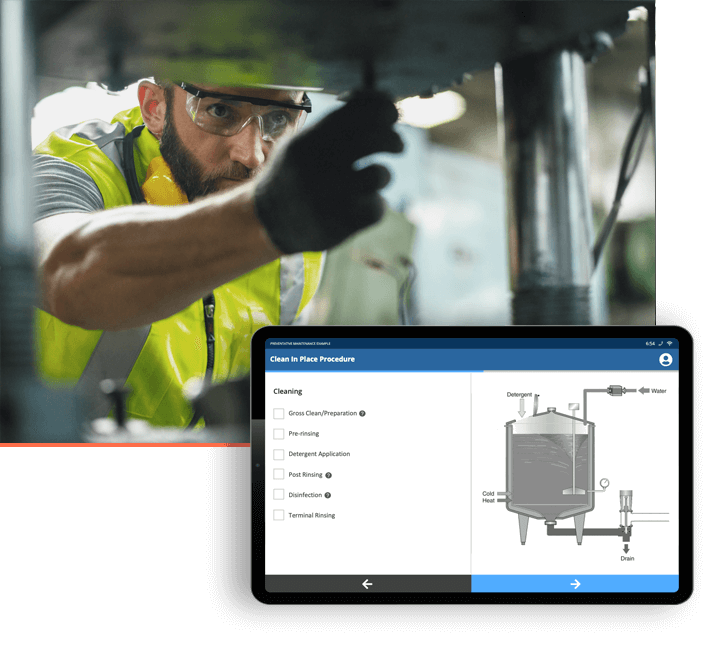

Digitize safety, quality, and maintenance processes to boost productivity, reduce downtime, and continually improve worker performance with Augmentir’s smart connected worker solution