What is a Layered Process Audit (LPA)?

A Layered Process Audit, or LPA, is a quality management system in manufacturing. LPA’s are designed to create layers of protection against rework, quality defects, product recalls, dissatisfied customers, and more. Rather than focus on just the final production result, layered process audits focus on observing and verifying how the products are created and manufactured.

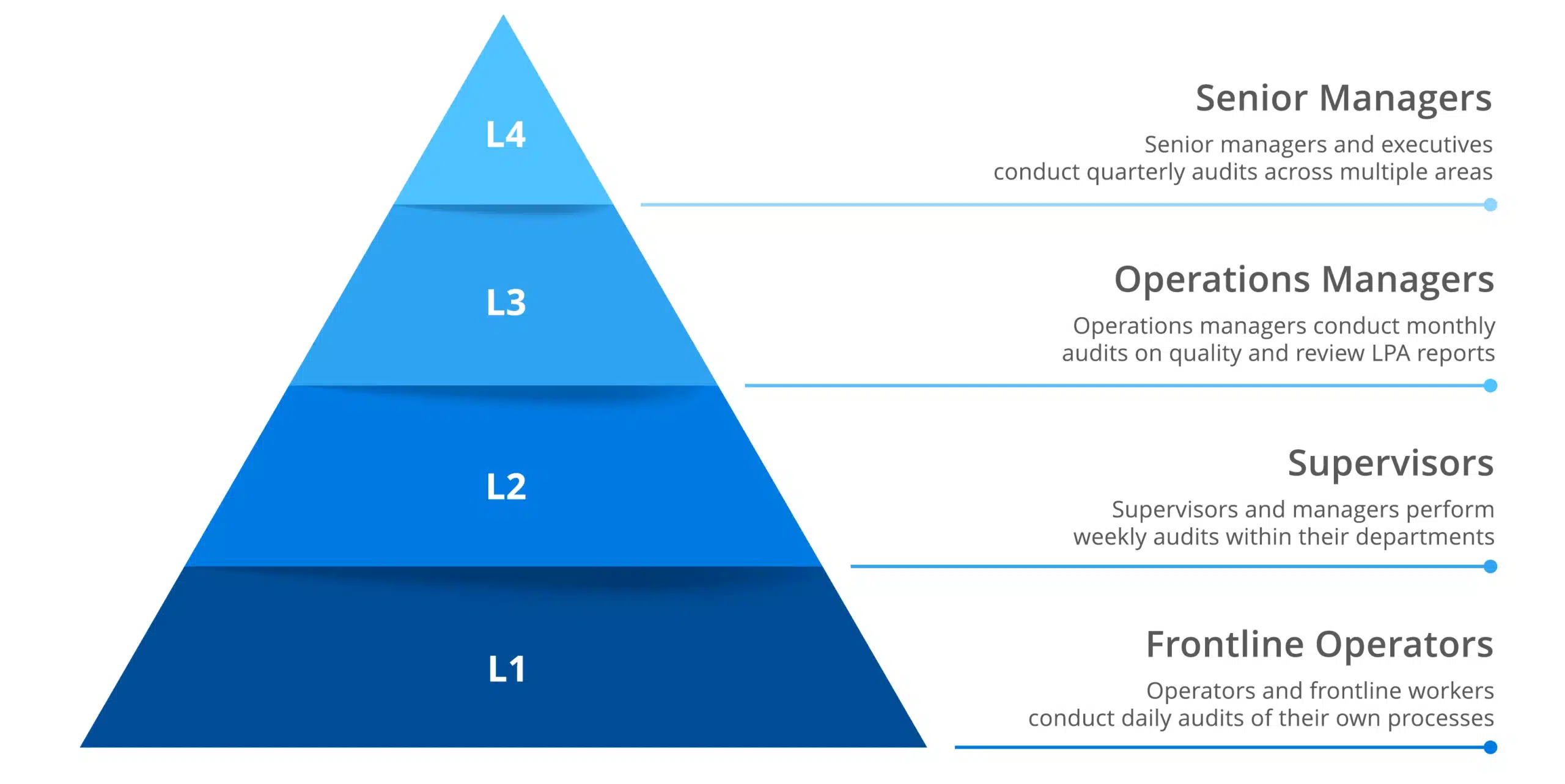

Layered process audits set up different “layers” of auditors – who can be comprised of staff, employees, or frontline personnel – that are assigned the exact same set of audits to ensure that high-risk steps in production do not deviate from set standards and specifications. This is a structured, standardized, and systematic audit that ensures optimal functioning of a process/system.

Read our guide below to learn what an LPA in manufacturing entails, how to create a layered process audit checklist, the benefits of layered process audit software, and more.