What is Digital Standard Work?

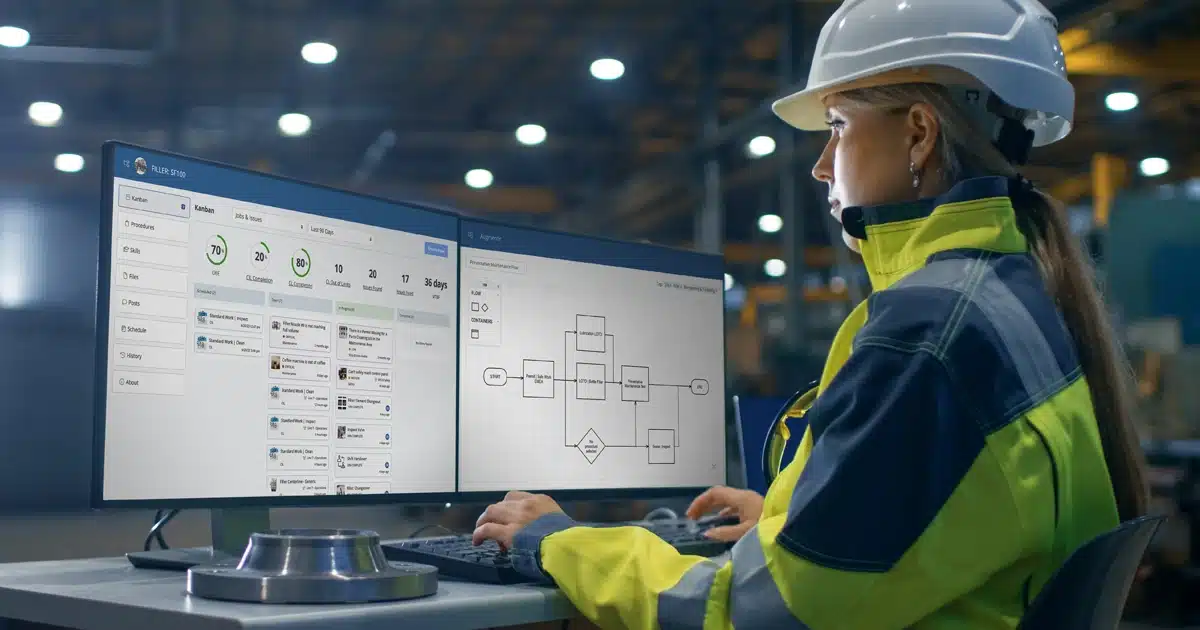

Digital standard work refers to the digitization and modernization of standard work practices and daily management procedures in manufacturing and industrial operations. It involves transitioning from traditional paper-based work instructions to interactive digital formats that leverage multimedia, real-time data, and advanced technologies like augmented connected workforce solutions, generative AI assistants, and more.

Examples of manufacturing standard work that benefit from digitization are:

- Centerlining, or run-to-target, processes

- Machine setup and changeover procedures

- Inspection checklists (for safety, quality, troubleshooting, etc.)

- Preventative maintenance tasks (machine cleaning, lubrication, etc.)

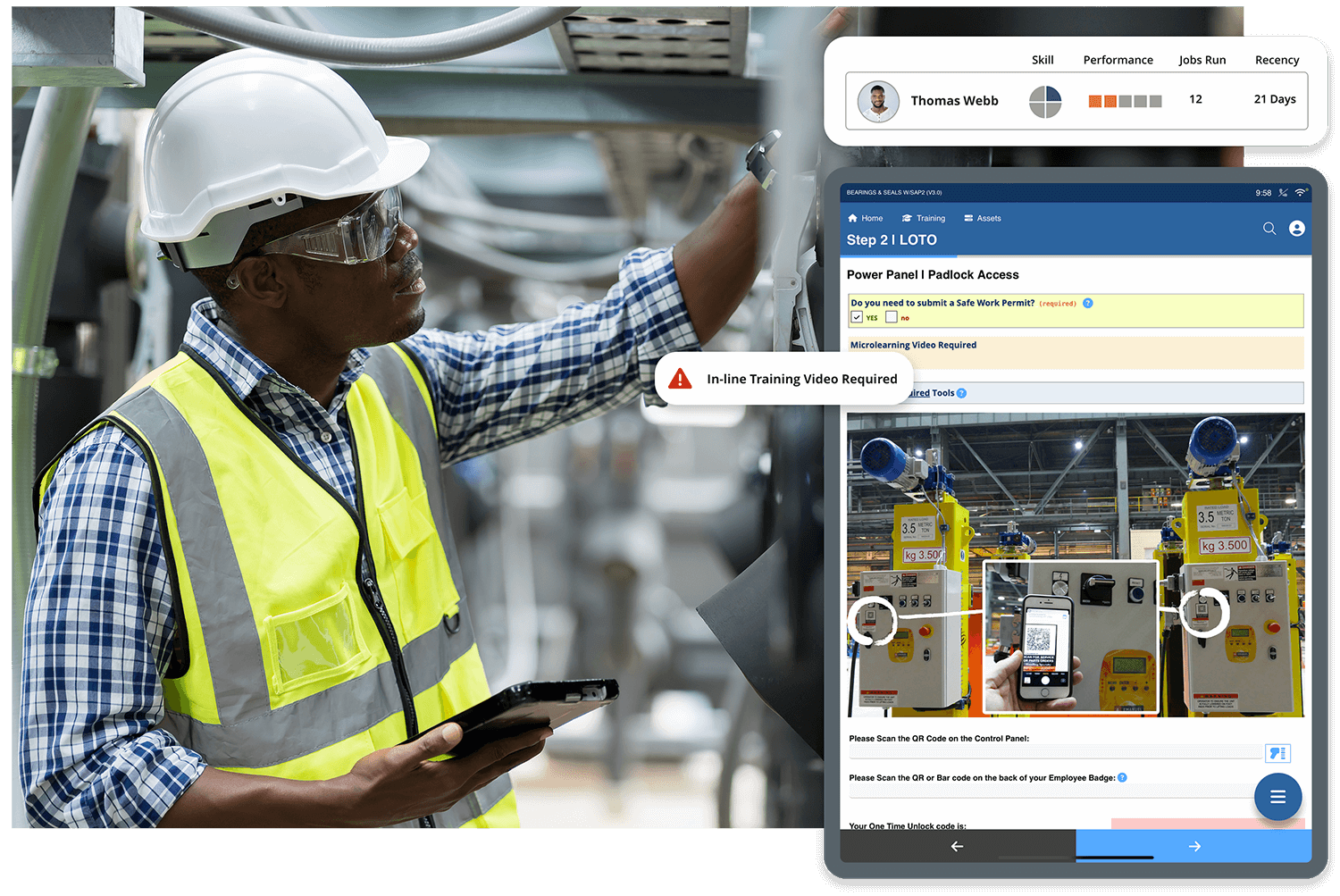

- Workforce training

Digital work instructions and AI-powered connected worker guides level-up manufacturing operations empowering frontline workers with tools such as interactive decision trees guiding operators through root cause analysis and corrective actions for common machine faults or product defects, and electronic, mobile instructions detailing proper safety protocols like lockout/tagout, PPE usage, handling hazardous materials etc. to ensure workplace safety.

Read below for more information on digital standard work, how it benefits manufacturing operations and frontline workers, how AI and connected worker technologies enable the digitization process, and how digitizing standard work allows manufacturers to identify and address bottlenecks, optimize workflows, and increase throughput, ultimately driving higher productivity and operational excellence.