New 5 Why Coach, Root Cause Investigator, and Data Analyst Agents add to Augmentir’s growing library of agents and assistants for frontline work – helping operations, quality, maintenance, and CI teams accelerate root cause analysis and continuous improvement.

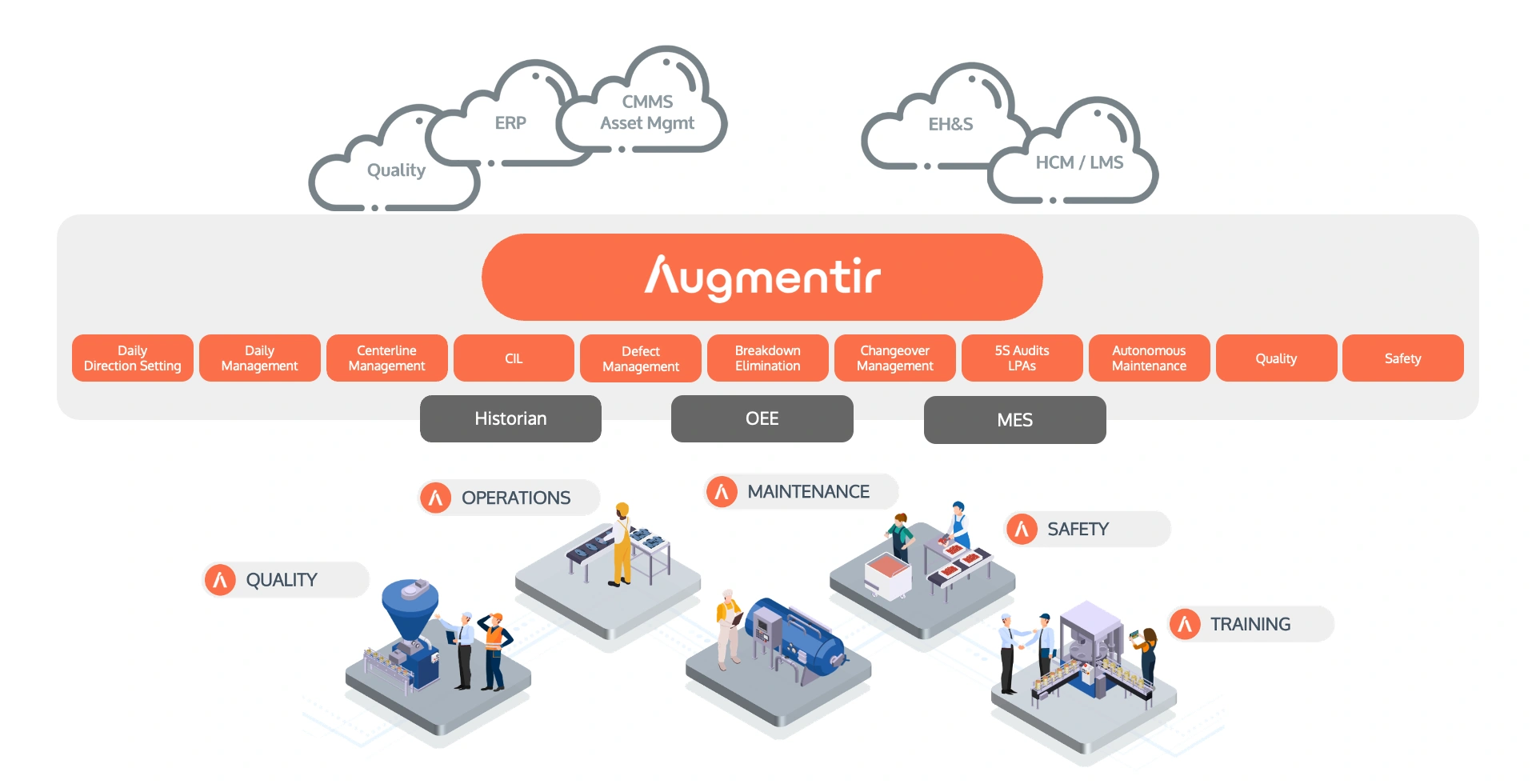

February 25, 2026 – Augmentir, the world’s only Agentic AI platform for connected work, today announced the availability of new out-of-the-box AI agents for manufacturing operations, further expanding the industry’s most comprehensive and fastest-growing suite of industrial AI agents. The new agents — a 5 Why Coach, a Root Cause Investigator, and a Data Analyst — work together as an intelligent digital problem-solving team, empowering industrial organizations to analyze operational data, uncover root causes faster, and accelerate continuous improvement across the factory floor.

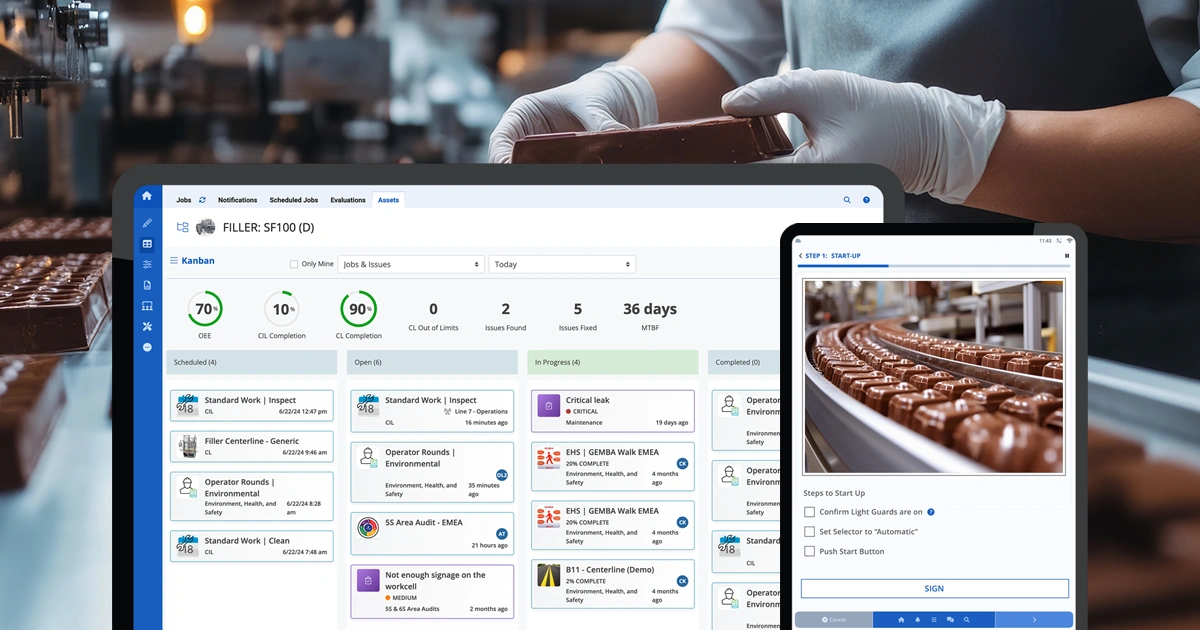

Manufacturers today face increasing pressure to improve safety, quality, productivity, and uptime — yet operational data is often siloed, underutilized, or slow to translate into action. The new Augie™ AI Agents address this challenge by delivering structured, AI-driven problem-solving capabilities directly to operations, quality, maintenance, and continuous improvement (CI) teams.

New Augie™ AI Agents Now Available

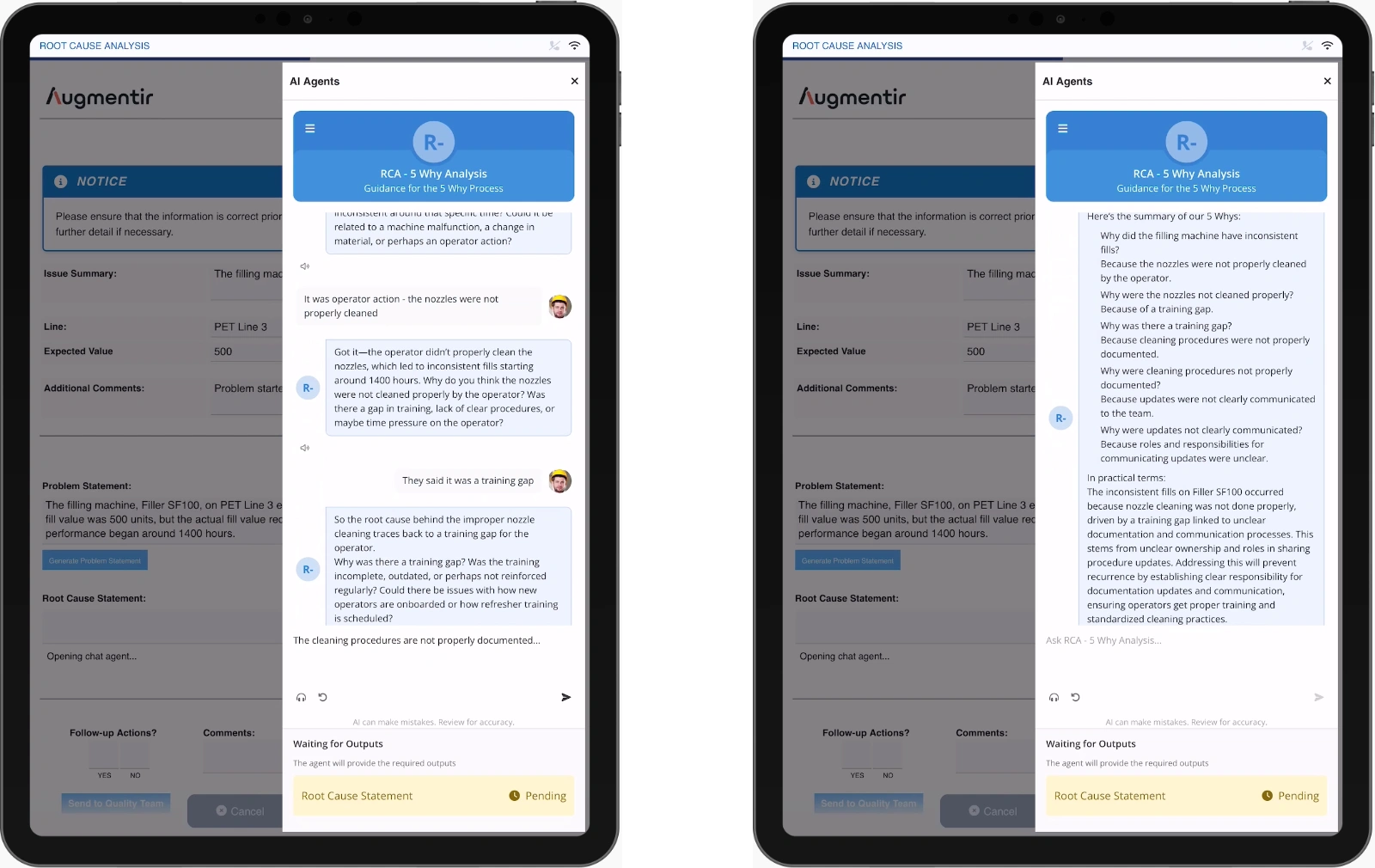

Root Cause Investigator

Accelerates formal root cause analysis by organizing symptoms, correlating operational signals, and helping teams evaluate contributing factors. The agent produces structured RCA (Root Cause Analysis) outputs aligned with quality systems and continuous improvement workflows.

5 Why Coach

Guides teams through a structured 5 Whys methodology to uncover underlying causes of production, quality, safety, and maintenance issues. The agent captures reasoning, documents evidence, and generates a clear, traceable chain of causality to support corrective and preventive actions.

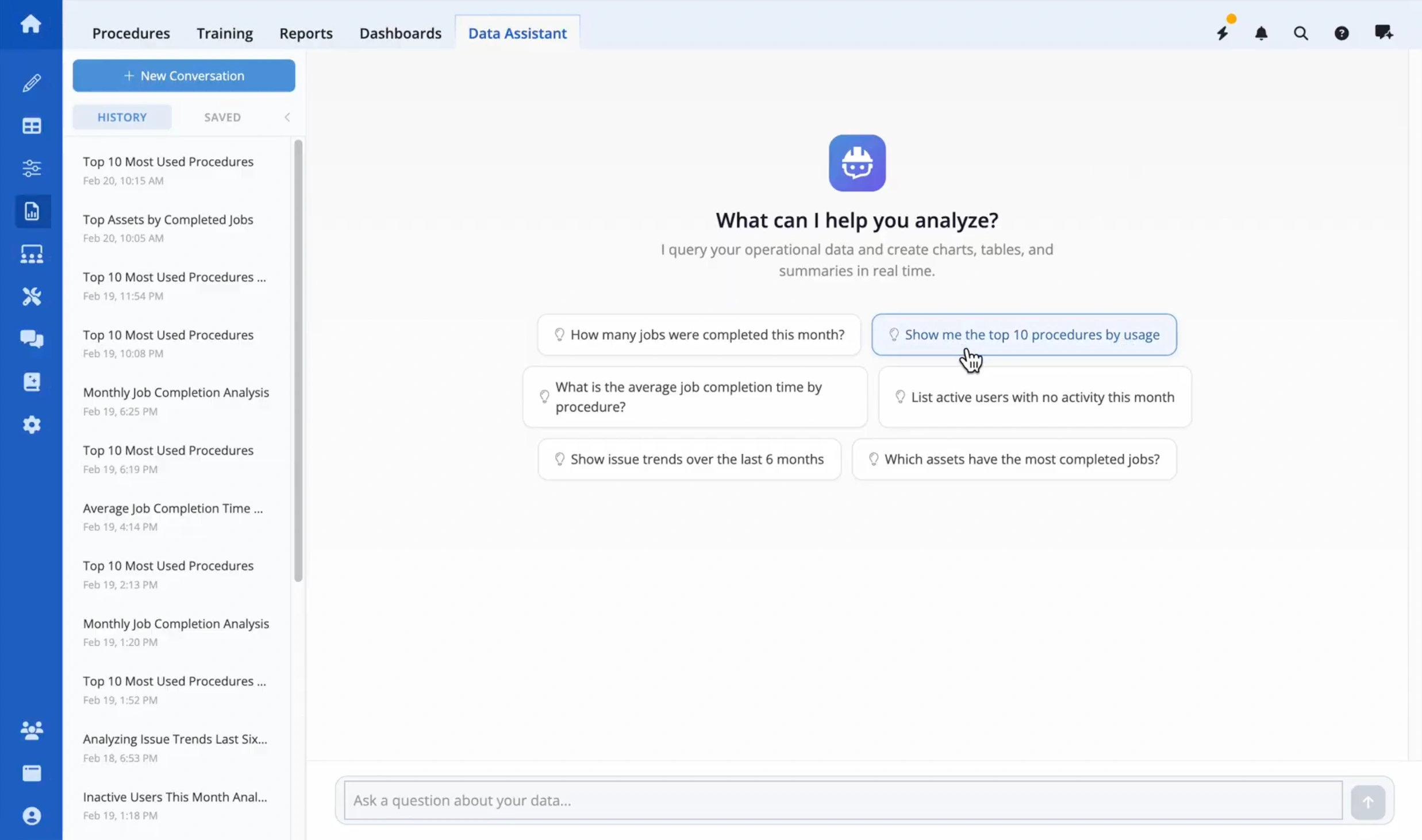

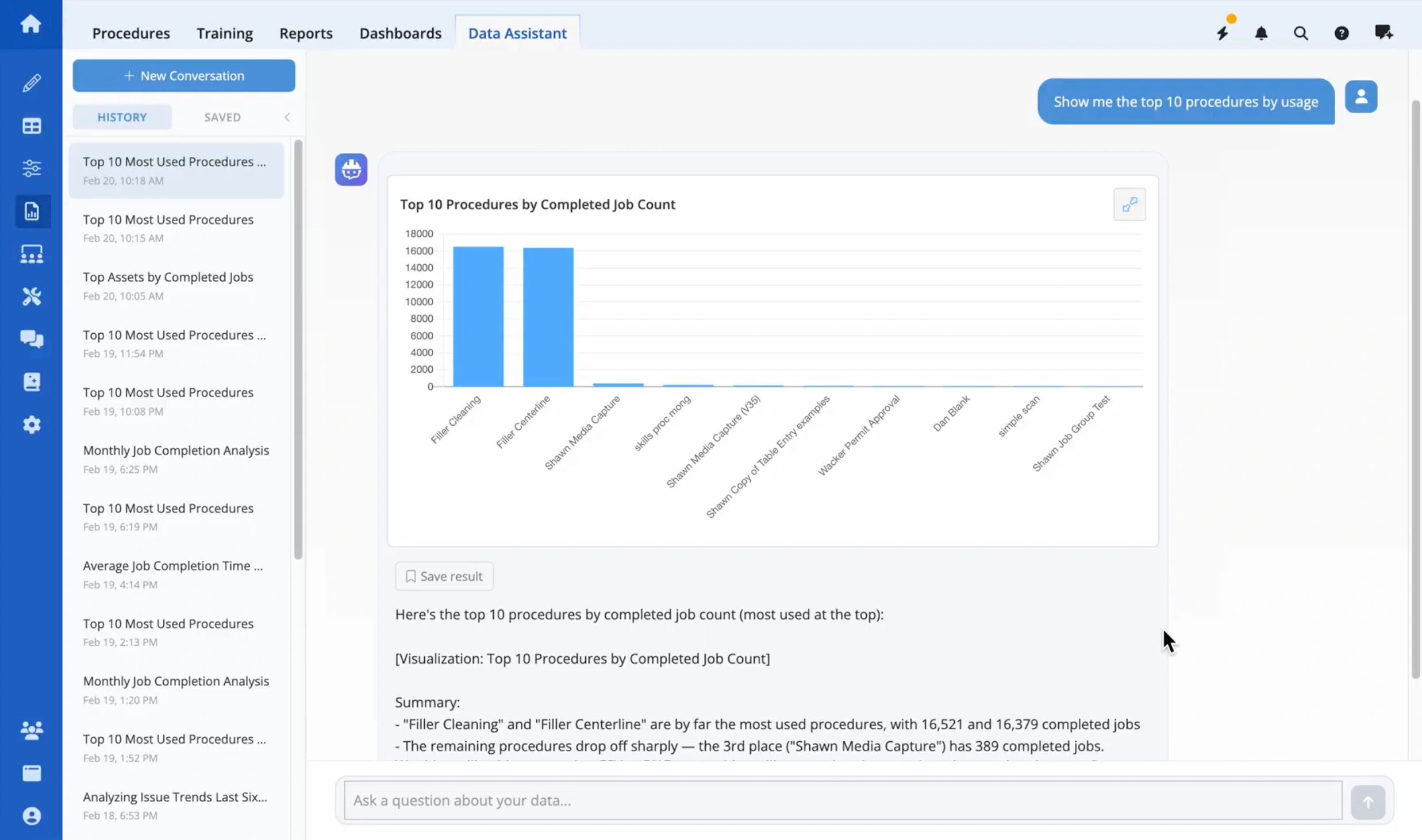

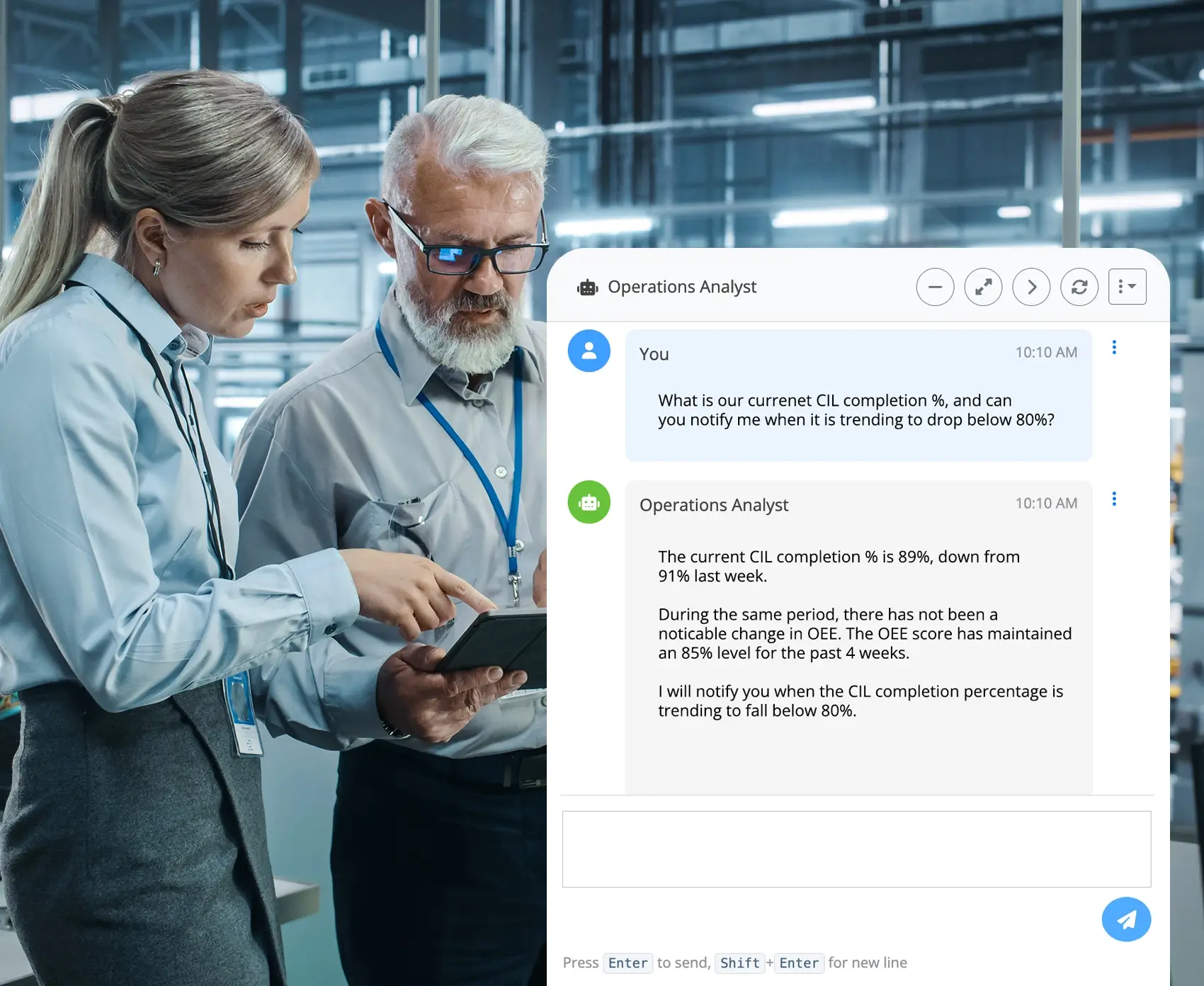

Data Analyst Agent

Enables teams to converse with operational and historical data using natural language — eliminating the need to build static reports or rely on specialized analytics expertise. Users can ask questions and instantly explore job and procedure data, issue trends, asset performance, user activity, downtime patterns, and other operational metrics.

The agent supports interactive drill-downs, generates visualizations and shareable reports on demand, and allows teams to save datasets and dashboards for ongoing monitoring. It maintains conversational context while continuously working from a fresh view of underlying operational data — ensuring insights are timely, accurate, and actionable.

Together, these agents help manufacturers reduce the time between issue detection and resolution — enabling faster decision-making, more consistent problem-solving, and measurable operational gains.

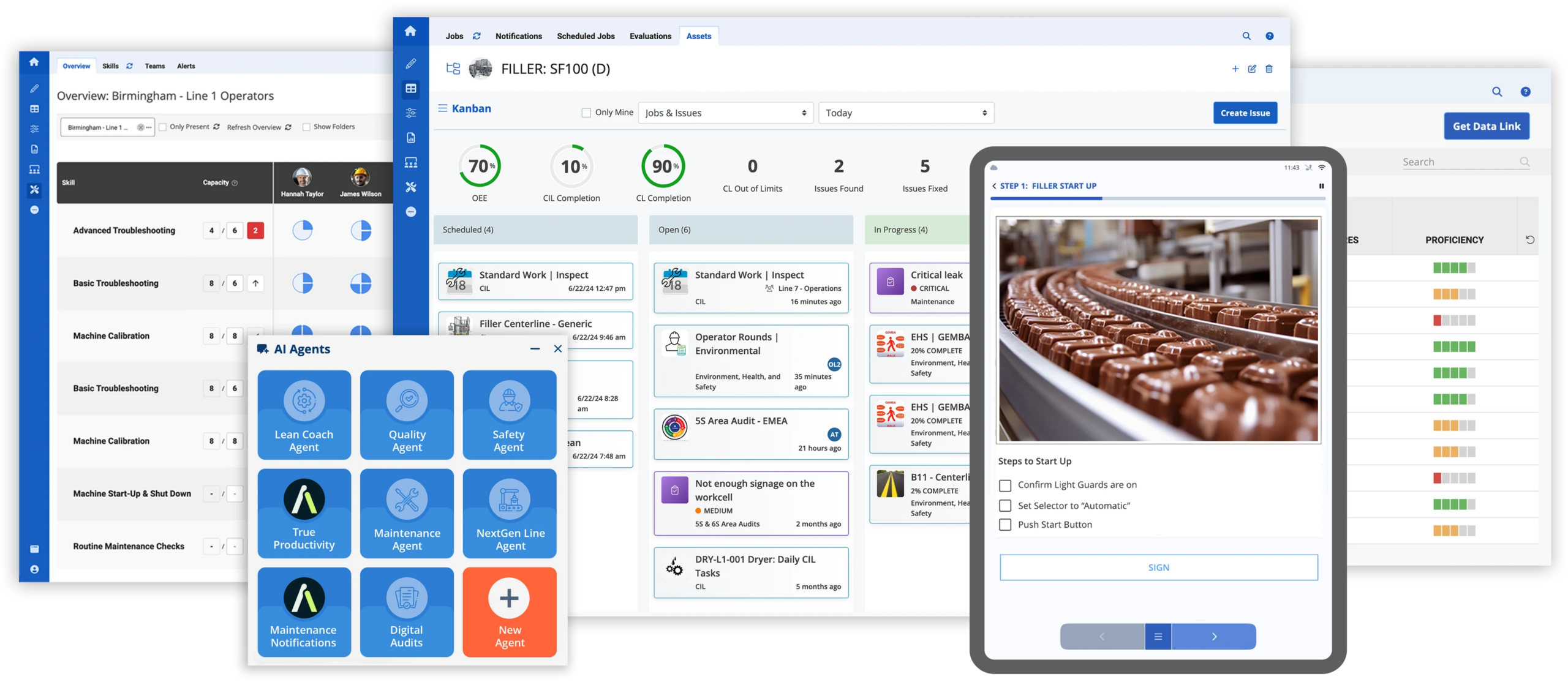

Powered by the Augie™ Industrial AI Suite

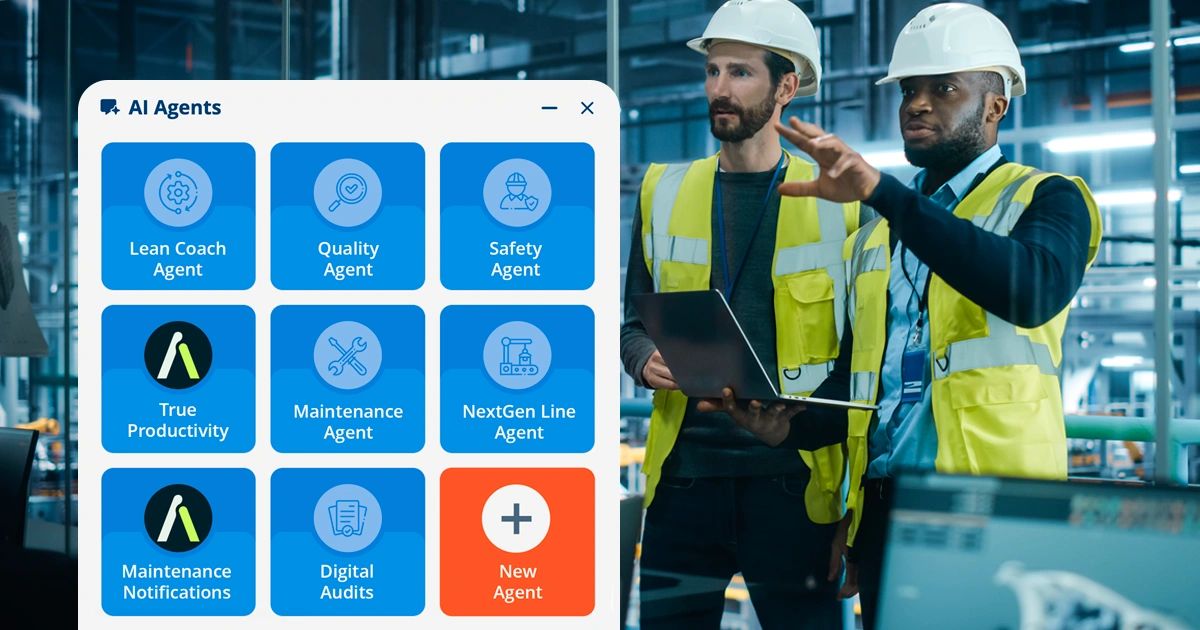

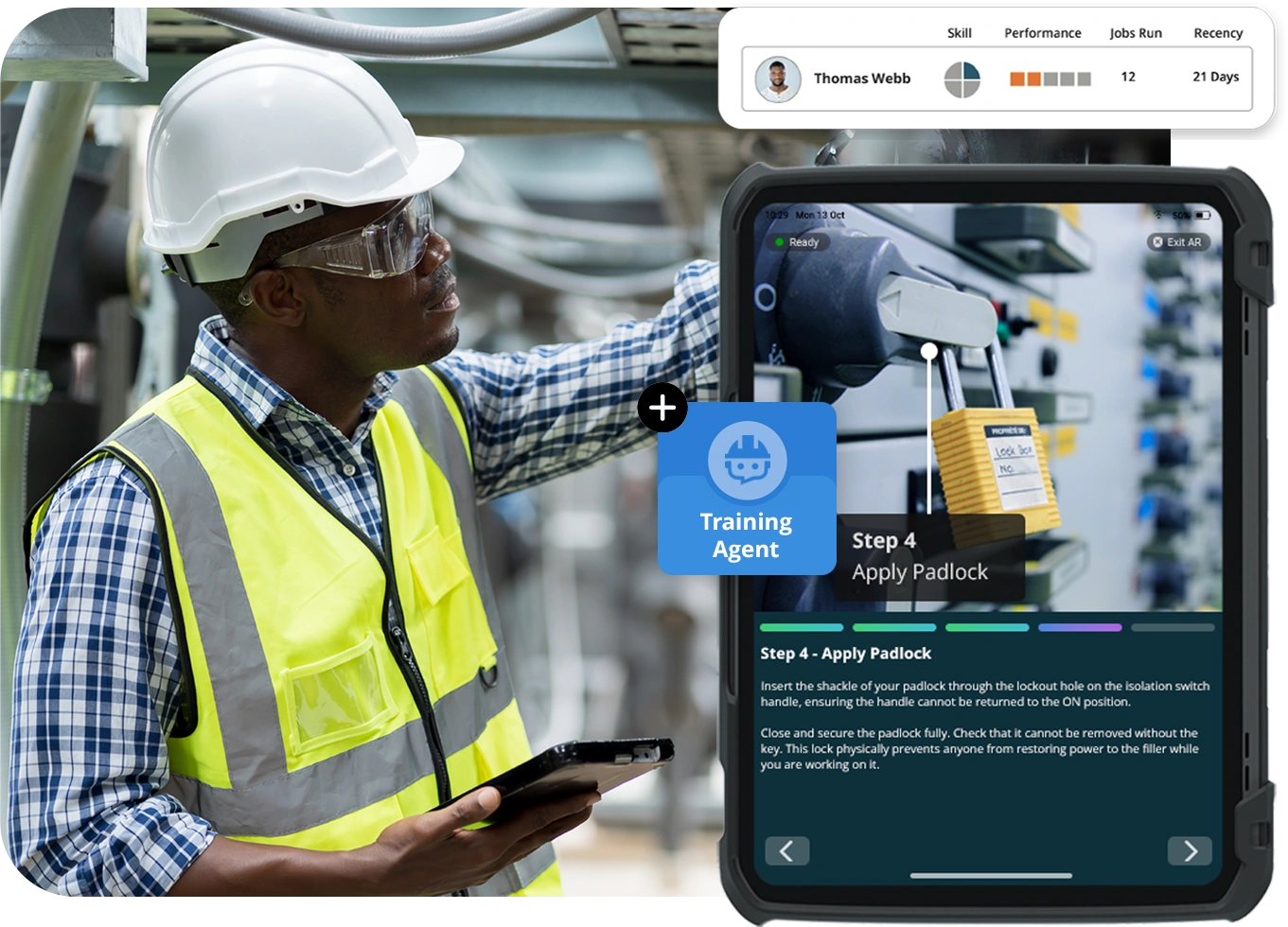

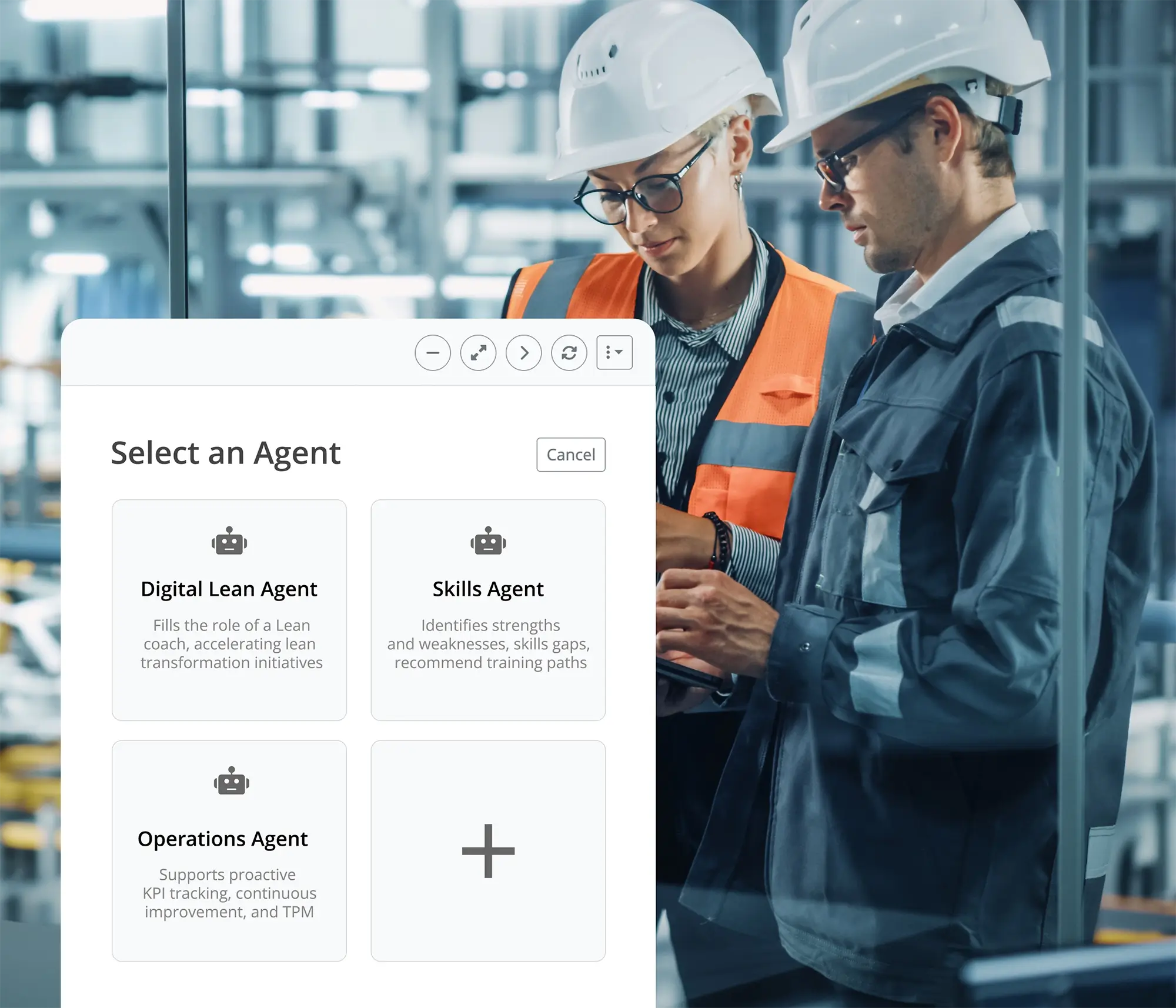

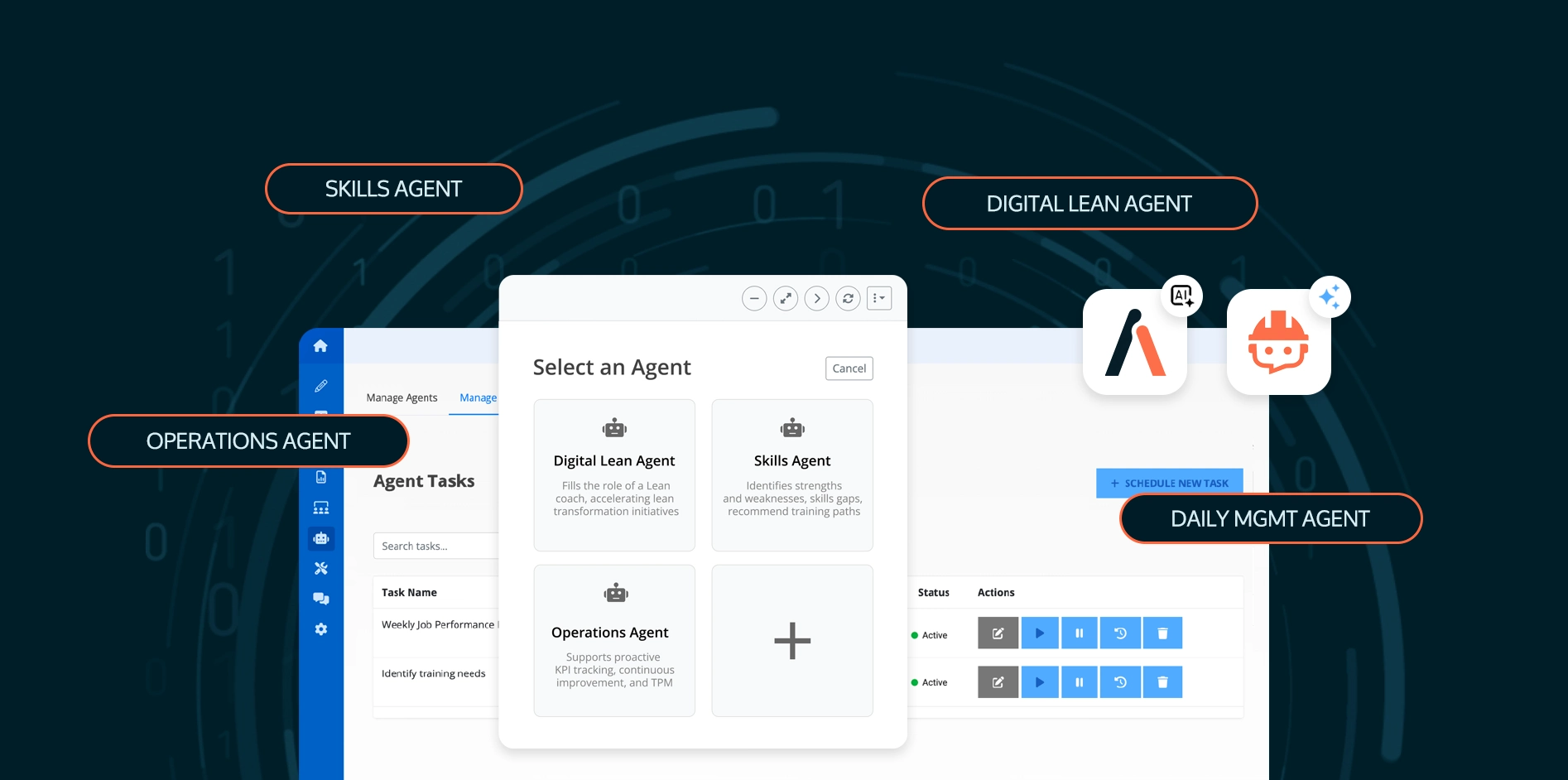

The new agents are delivered as part of the Augie™ Industrial AI Suite and built on Augie™ Agent Studio, which enables manufacturers to configure, extend, and develop custom AI agents tailored to their unique processes and KPIs.

With Augie™ Agent Studio, organizations can:

- Quickly build new Chat AI agents to support every role in their organization

- Build and Deploy Autonomous Agents to add AI into existing internal workflows

- Integrate plant-specific data sources and performance metrics

- Scale best practices consistently across lines, shifts, and facilities

By combining ready-to-deploy AI agents with a flexible development framework, Augmentir enables manufacturers to deploy practical, scalable industrial AI with immediate impact.

“The expansion of the Augie Industrial AI Suite represents a major step forward in bringing purpose-built AI to manufacturing operations,” said Russ Fadel, CEO of Augmentir. “Our Agent Studio democratizes the Agent creation process, letting subject matter experts create new agents that embody their expertise, in hours, not weeks or months. Between Aumentir and its partner network, we expect dozens of new Augmentir Ready agents to be made available in the coming months. The availability of these new AI agents will help teams move beyond reactive troubleshooting and toward proactive, data-driven continuous improvement.”

Interested in learning more?

If you’d like to learn more about Augmentir and our Augie Industrial AI Suite, schedule a demo with one of our product experts.