Daily Management helps track today — but it’s not enough. Discover why top manufacturers are turning to Integrated Work Systems to drive continuous improvement.

Walk into any modern manufacturing facility and you’ll likely see some form of Daily Management in action — shift handovers taking place, whiteboards filled with KPIs, supervisors tracking downtime or productivity issues. For many factories, this is the heartbeat of frontline operations. And rightly so — Daily Management plays a critical role in keeping teams aligned and performance on track.

But here’s the thing: Daily Management is not enough.

More and more manufacturers are realizing that simply tracking what happened today — and reacting to it — doesn’t drive long-term improvement. It doesn’t prevent breakdowns. It doesn’t fix the root cause of recurring quality issues. And it certainly doesn’t help build a digitally enabled, agile, and resilient operation.

If you’re searching for a Daily Management System or software tool to better manage frontline tasks, that’s a great first step. But don’t stop there. Because the real value lies in thinking bigger — in building an Integrated Work System (IWS) that brings all the moving parts of your frontline operations together.

Let’s unpack why.

The Daily Management Trap

At its core, Daily Management helps answer the question: “How are we doing today?”

It gives your team structure — a cadence of check-ins, dashboards, and updates. But the more you rely on it as your primary tool, the more you risk getting stuck in a reactive loop:

- Downtime occurred? Log it and move on.

- A defect showed up again? Note it and check the box.

- A shift fell short of the target? Talk about it and try again tomorrow.

The result? Problems keep resurfacing. Equipment ages faster than it should. Tribal knowledge stays in workers’ heads. And improvement efforts feel like a game of whack-a-mole.

Daily Management shines a light on the symptoms — but an Integrated Work System tackles the root causes.

The Bigger Picture: What’s Missing?

What separates top-performing factories from the rest isn’t just how well they manage today — it’s how they build systems to improve tomorrow.

As highlighted by Ernst & Young, in collaboration with Procter & Gamble, leading manufacturers are moving beyond reactive daily routines and embracing integrated digital systems that connect operations, empower frontline teams, and enable continuous improvement across all use cases that are critical to frontline operations.

Here are just a few critical areas that often extend beyond traditional daily management:

- Issue Management: Logging problems is easy. Solving them — through root cause analysis, countermeasures, and tracking — requires structure.

- Autonomous Maintenance: Operators should be empowered to care for their equipment, not just report when it fails.

- CILs (Cleaning, Inspection, Lubrication): These are the fundamentals of machine reliability — yet many teams lack standard routines.

- Changeovers: Transitioning between products or shifts introduces variability. Standardizing this is key to minimizing downtime.

- Centerline Management: Decrease product and procedure inconsistencies by optimizing machine effectiveness.

- Breakdown Elimination: Recurring failures don’t go away by chance. They go away when someone owns them — and has the tools to eliminate them.

- Manufacturing Collaboration: Improvements aren’t made in isolation. Visibility, communication, and shared accountability are critical.

- 5S Audits and Layered Process Audits: Safety and quality audits should be woven into the flow of work — not tacked on as separate compliance exercises.

Individually, these areas may seem like “extra” layers. But together, they form the foundation of an Integrated Work System.

From Managing the Day to Managing the Work

An Integrated Work System doesn’t just organize tasks — it connects the work, the people, and the insights needed to operate at a higher level.

Instead of fragmented tools and outdated spreadsheets, IWS brings everything into one unified approach — so your team can:

- Identify issues in real-time

- Standardize best practices

- Eliminate variability and waste

- Collaborate across shifts and functions

- Improve continuously — not just reactively

It’s a shift from firefighting to problem-solving. From knowing what happened to knowing why it happened — and preventing it from happening again.

Technology That Supports the Shift

Of course, none of this is possible with whiteboards and paper checklists. Manufacturers need modern tools that support the reality of the factory floor — and help bring Integrated Work Systems to life.

That’s where connected worker technology comes in.

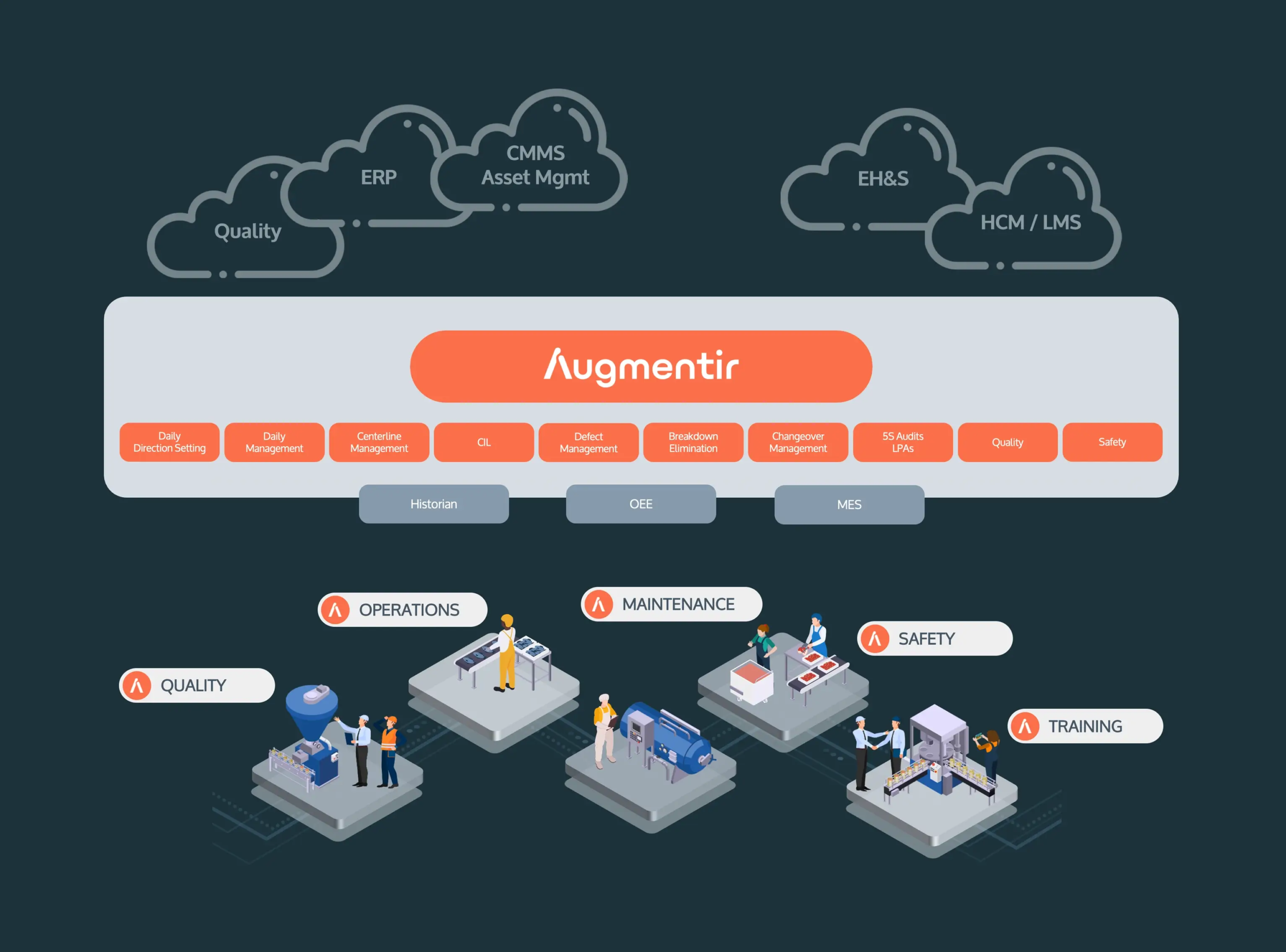

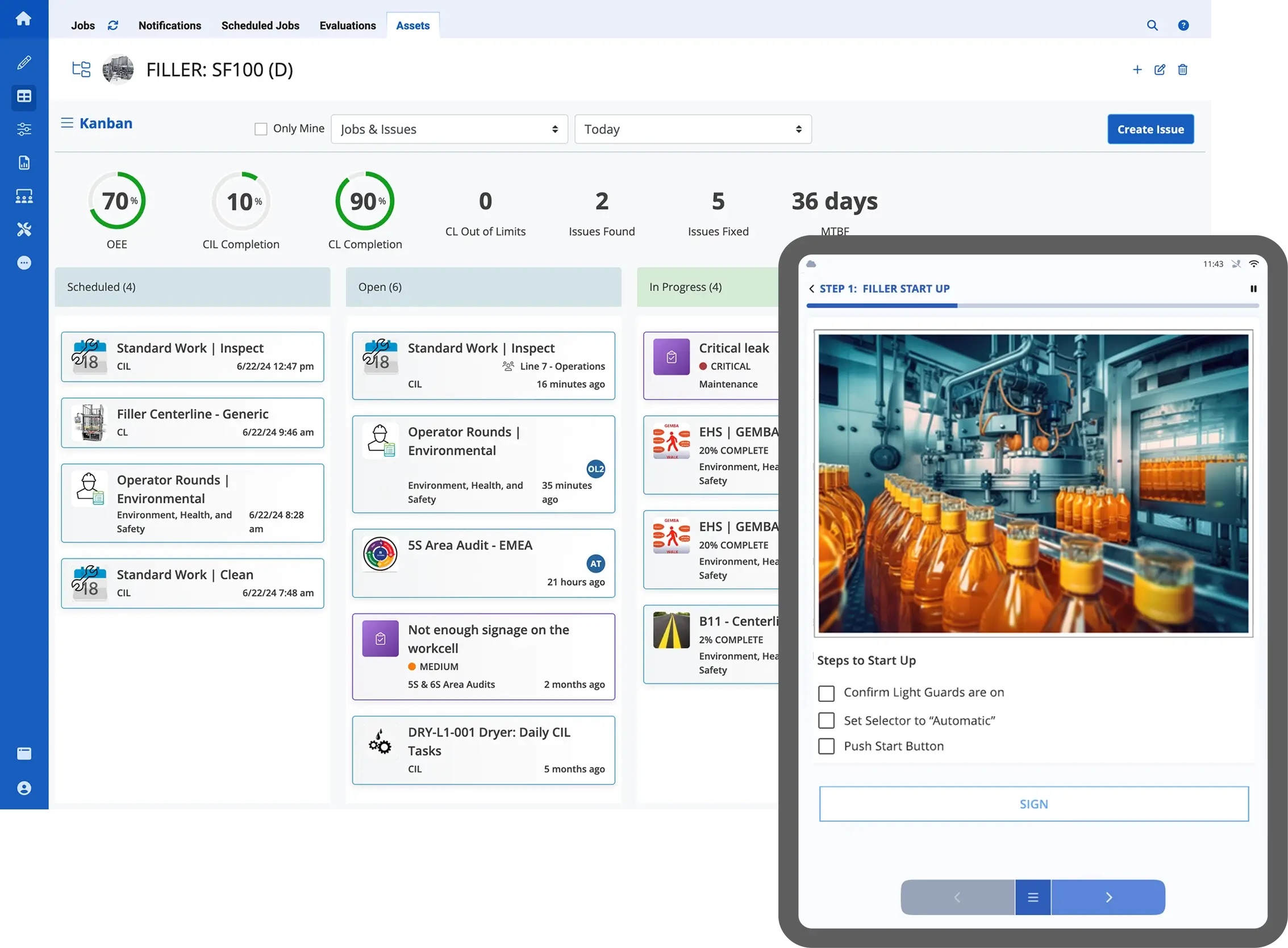

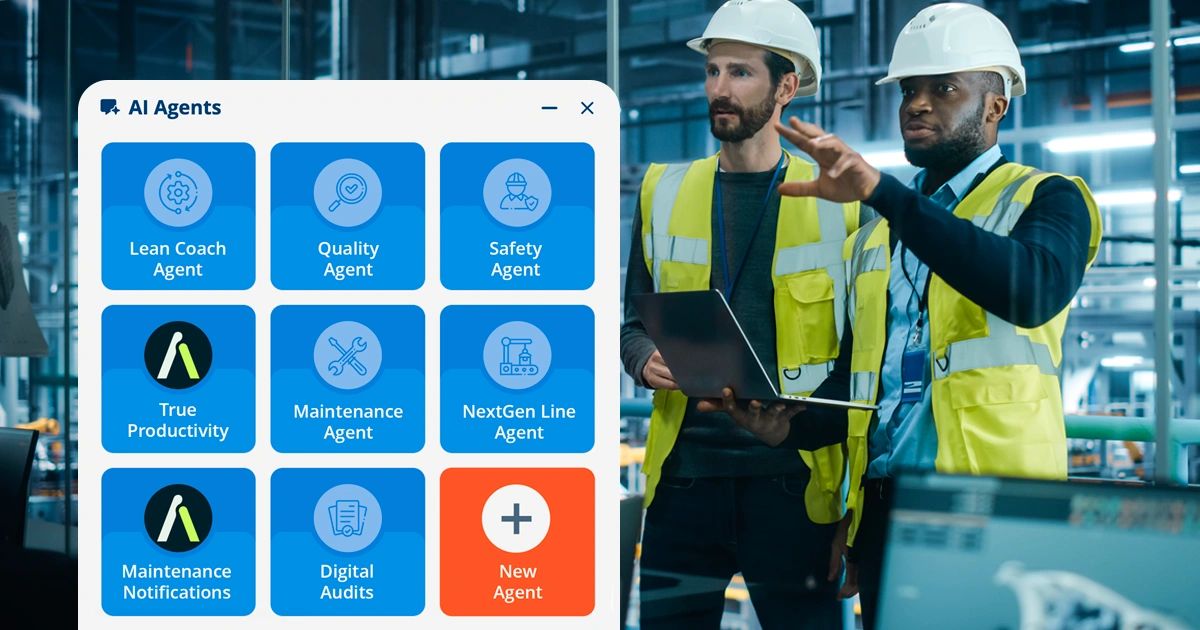

Platforms like Augmentir give manufacturers the digital foundation they need to:

- Turn SOPs, audits, and maintenance routines into smart digital workflows

- Capture real-time data from the frontline without adding admin overhead

- Personalize guidance and support for each worker based on skill level and performance

- Analyze trends and surface insights using AI — so you can focus improvement where it matters most

Augmentir helps you go beyond daily visibility. It helps you build a connected, data-driven, and continuously improving frontline operation.

Think Bigger Than Daily

Yes, you need a system to manage the day — but you also need a system to manage improvement.

A Daily Management System may be the entry point, but don’t let it be the end goal. Start thinking holistically about your operations. Ask the hard questions. Look at the gaps between your teams. Audit the processes that break down too often. And most importantly, give your workers the tools they need to contribute — not just comply.

The future of manufacturing isn’t just about managing tasks. It’s about connecting work, people, and performance.

That’s the promise of an Integrated Work System.

That’s where real transformation begins.

And with solutions like Augmentir, it’s never been more achievable.