Explore the fundamentals of continuous improvement, the challenges of traditional CI methods, and how technologies like Augmentir are transforming continuous improvement in modern manufacturing.

In today’s competitive global market, manufacturers are under constant pressure to produce more efficiently, reduce costs, and deliver higher-quality products—faster than ever before. To stay ahead, continuous improvement is no longer optional; it is essential. This methodology, rooted in principles like Lean Manufacturing, Six Sigma, and Kaizen, focuses on incremental and ongoing enhancements in processes, productivity, and quality. But what sets the leaders apart in the modern era is how they leverage technology to drive and sustain these improvements at scale.

In this article, we explore the fundamentals of continuous improvement, examine the challenges of traditional CI methods, and highlight how technologies like Augmentir are transforming continuous improvement in modern manufacturing.

The Core of Continuous Improvement

Continuous improvement (CI) in manufacturing involves systematically identifying, analyzing, and enhancing production processes. It is not just about big innovations; often, the smallest tweaks—reducing downtime, improving machine reliability, or streamlining communication—can yield significant ROI.

Key principles include:

- Employee Involvement: Workers on the shop floor often have the most direct insights into inefficiencies and can be powerful agents of change.

- Data-Driven Decisions: Improvements should be driven by measurable performance indicators.

- Standardization and Feedback Loops: Once better methods are discovered, they need to be adopted, documented, and continuously reassessed.

While the philosophy is sound, many manufacturers struggle with implementation. And that’s where the problems begin.

The Problems with Traditional CI Programs

Despite decades of focus on Lean and Six Sigma, many CI initiatives fall short. Why? Because traditional CI programs are often hampered by outdated practices, lack of engagement, and poor data visibility. Here are some of the most common issues:

1. Siloed and Manual Processes

In many plants, improvement efforts are manually tracked—on paper, spreadsheets, or disconnected systems. This siloed data leads to slow feedback loops and inconsistent execution across shifts or facilities.

2. One-Size-Fits-All Approaches

Traditional CI programs often rely on standardized procedures that assume all workers have the same skills and experience. This ignores the wide variation in frontline worker proficiency and limits personalization in training or task guidance.

3. Lack of Real-Time Data

Many organizations make decisions based on lagging indicators like end-of-month scrap reports or audits. Without real-time insight into what’s happening on the floor, it’s impossible to react swiftly or identify the root cause of issues as they emerge.

4. Low Frontline Engagement

CI often becomes a top-down initiative driven by managers and engineers, rather than frontline workers. When operators aren’t empowered or incentivized to contribute, critical on-the-ground insights are lost.

5. Sustainability Challenges

Even when initial improvements are made, organizations often struggle to sustain gains. Without built-in systems for reinforcement, training, and measurement, improvements fade, and old habits resurface.

These problems don’t mean CI is broken—they highlight the need for modernization. That’s where connected technologies and AI come in.

Technologies Fueling Modern Continuous Improvement

To accelerate continuous improvement, modern manufacturers are increasingly embracing Industry 4.0 technologies—an approach popularized by German engineer and economist Klaus Schwab in his 2016 book The Fourth Industrial Revolution. This movement is reshaping manufacturing by integrating smart technologies that optimize production processes and enhance decision-making. Among the most impactful advancements are Connected Worker Platforms and Artificial Intelligence (AI), both of which are transforming how work is executed and improved on the shop floor.

Connected Worker Platforms

Connected worker platforms provide real-time visibility and data from the shop floor. These platforms link frontline workers with digital tools that enhance communication, guide tasks, and collect performance data. Key benefits include:

- Standardized Work Instructions

- Real-Time Communication and Support

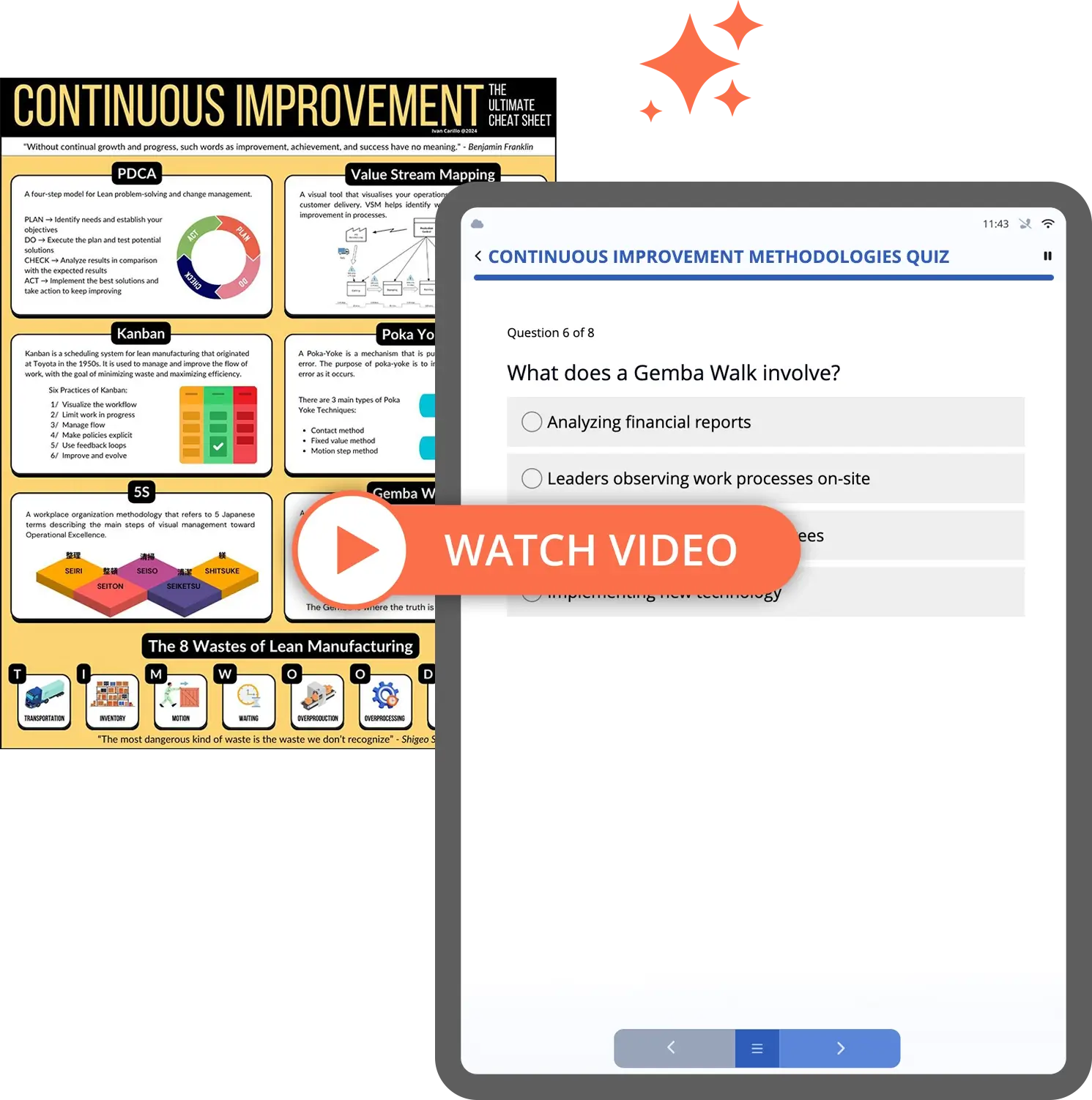

- Digital Training approaches that enhance corporate training methodologies, such as Training Within Industry (TWI)

- Performance Data for Targeted Improvements

Artificial Intelligence (AI)

AI takes CI to the next level by analyzing massive amounts of operational data—spotting trends, predicting outcomes, and recommending optimizations. Benefits include:

- Root Cause Analysis

- Predictive Maintenance and Forecasting

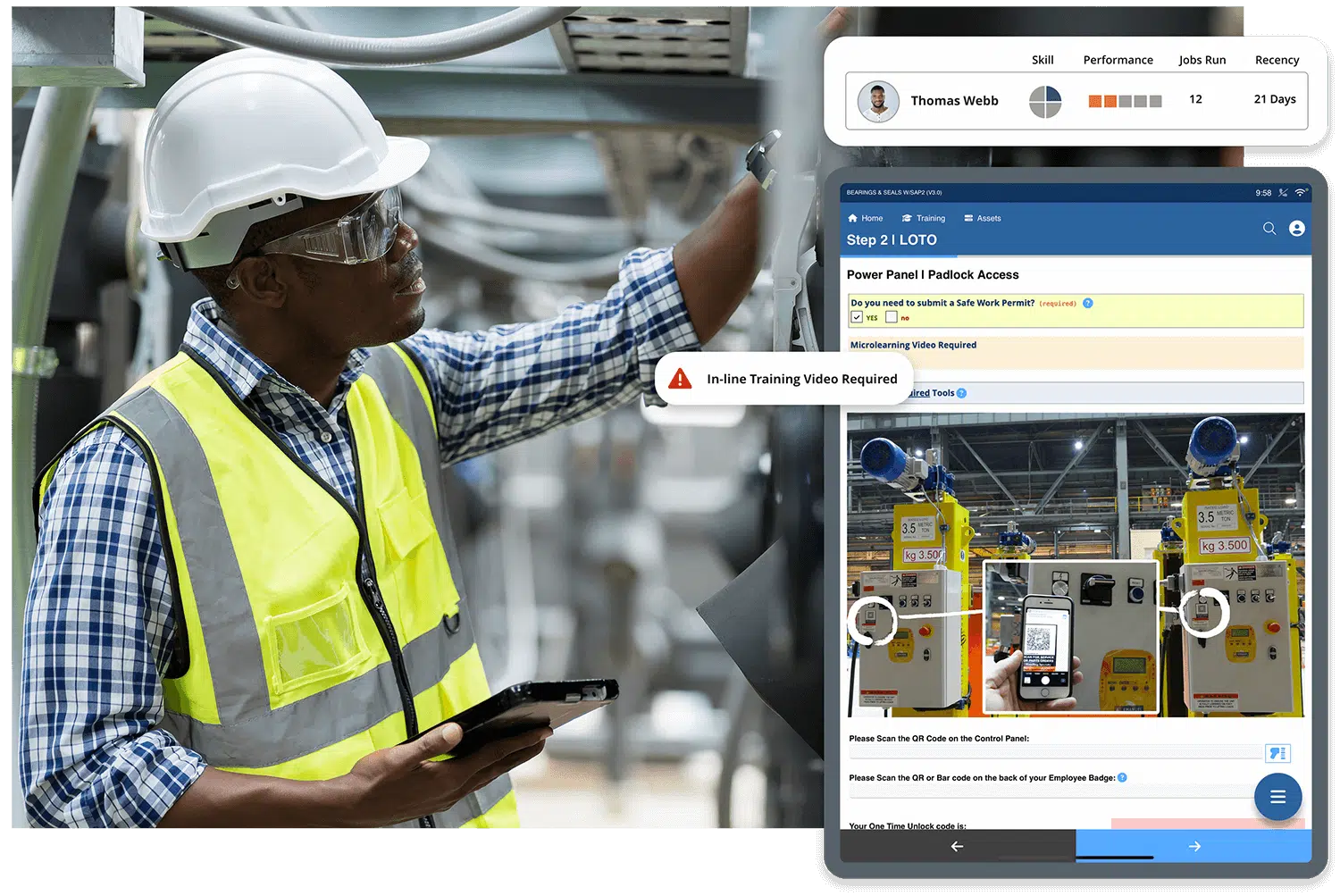

- Intelligent Guidance for Tasks and Training

Together, these technologies enable a dynamic, responsive CI process that adapts to real-world conditions and human variability.

Augmentir: Elevating Continuous Improvement with AI-Powered Connected Work

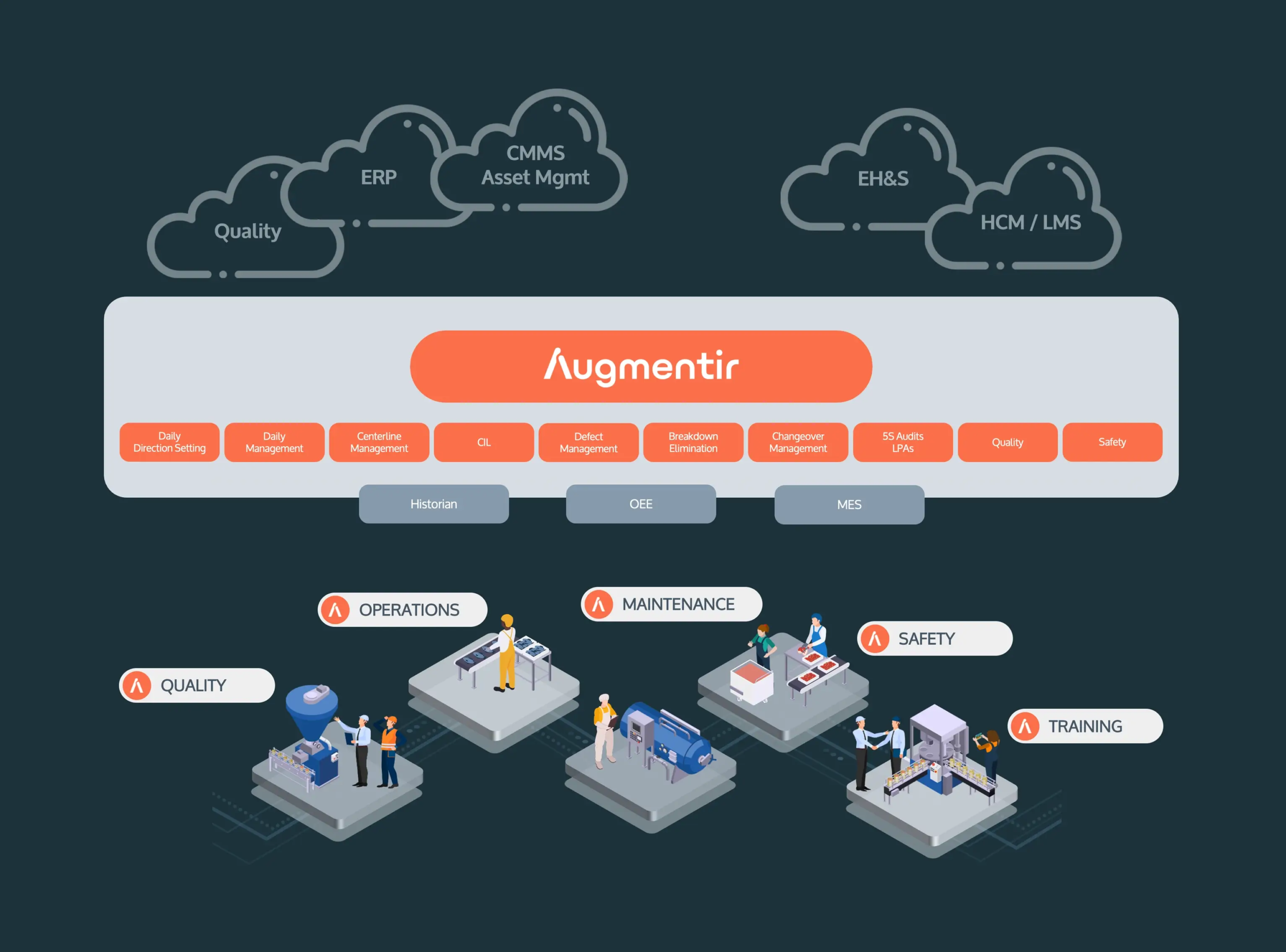

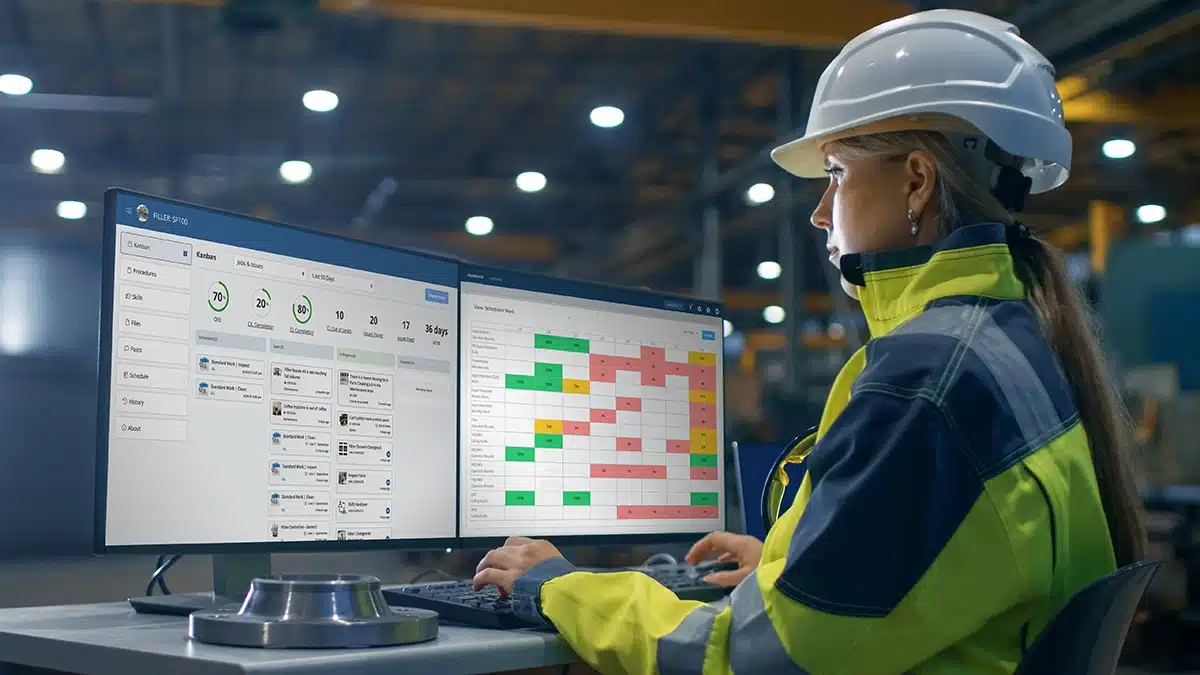

In the modern manufacturing landscape, tools that enhance worker productivity, decision-making, and operational visibility are essential. That’s where Augmentir stands out. As a next-generation Smart Connected Worker Platform, Augmentir is uniquely designed to empower frontline workers and enable continuous improvement at scale—using the power of artificial intelligence.

Unlike traditional connected worker solutions that merely digitize paper-based processes, Augmentir goes further. It not only captures data from the frontline—it makes that data intelligent, actionable, and personalized. With built-in AI capabilities, Augmentir helps manufacturers bridge the gap between people, processes, and performance improvement.

What Makes Augmentir Different?

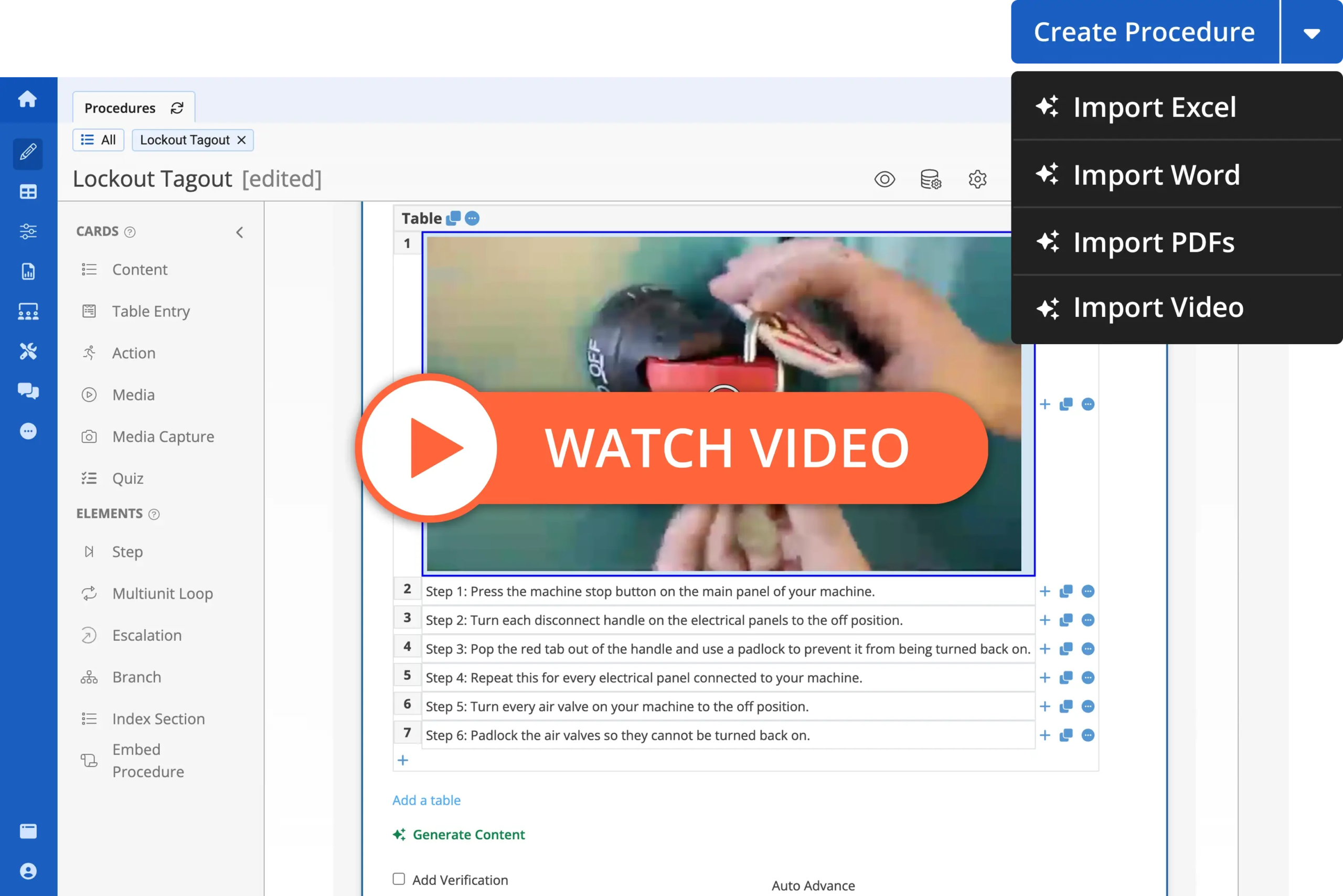

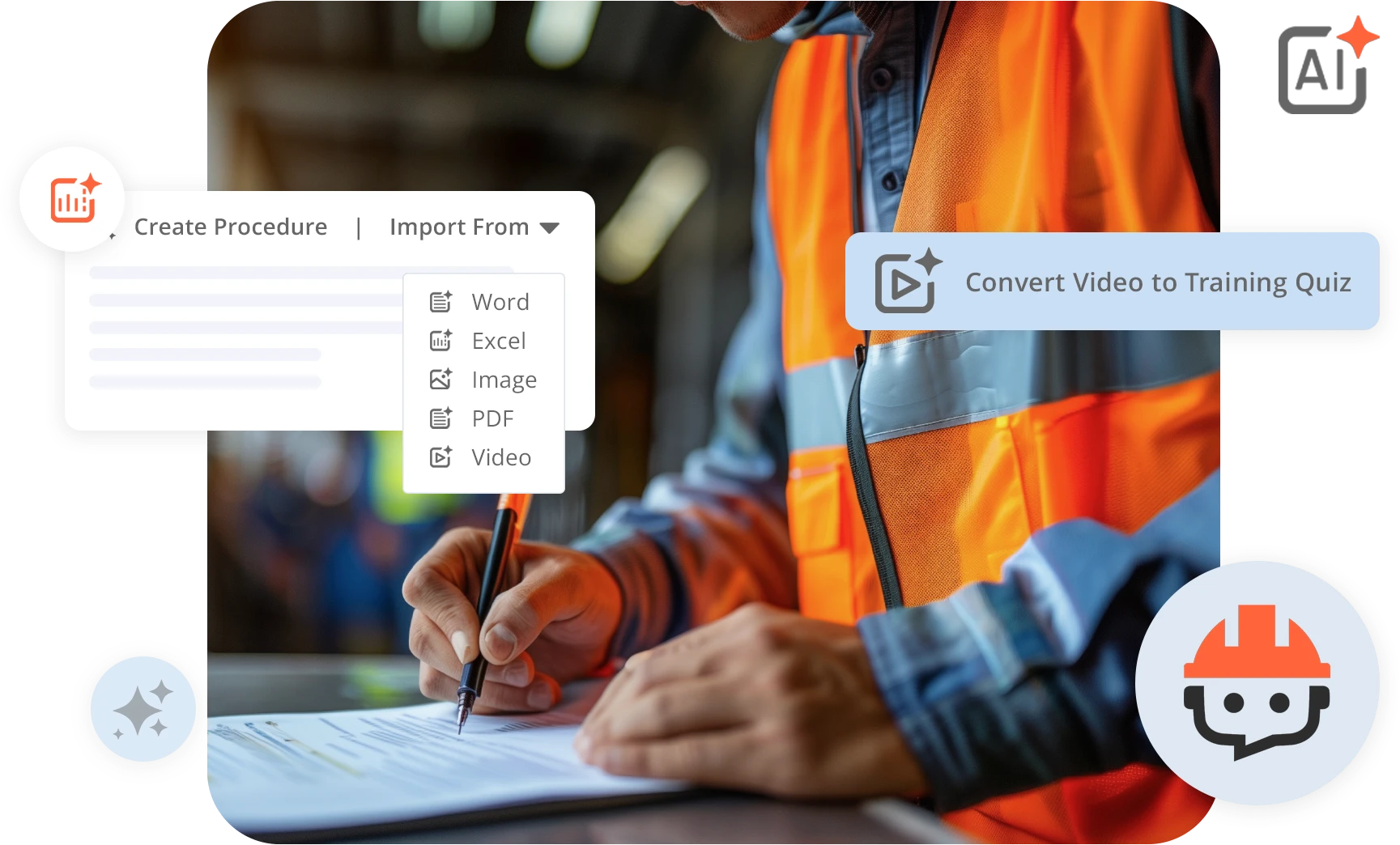

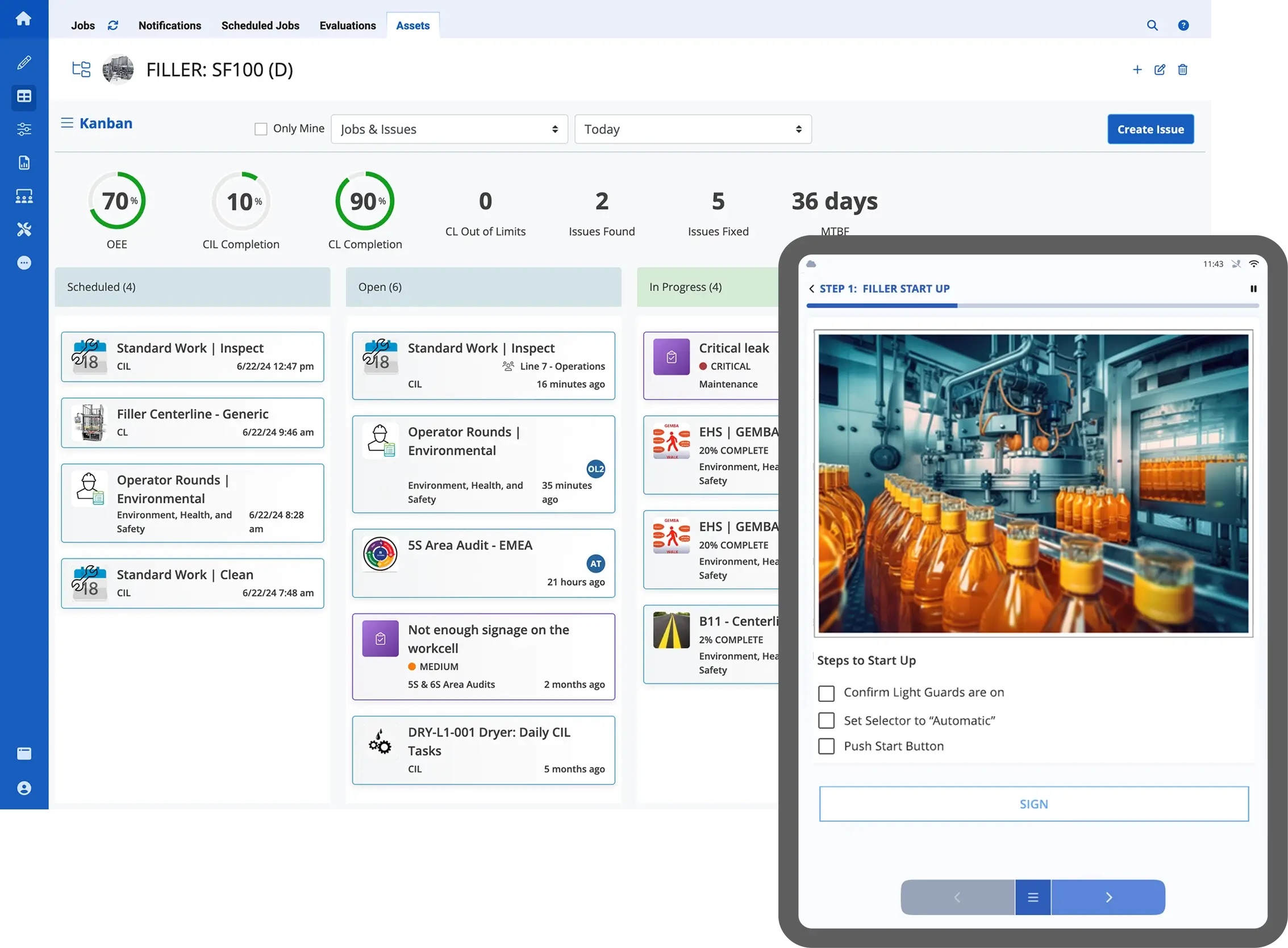

At its core, Augmentir offers a suite of tools that digitize, guide, and optimize frontline work:

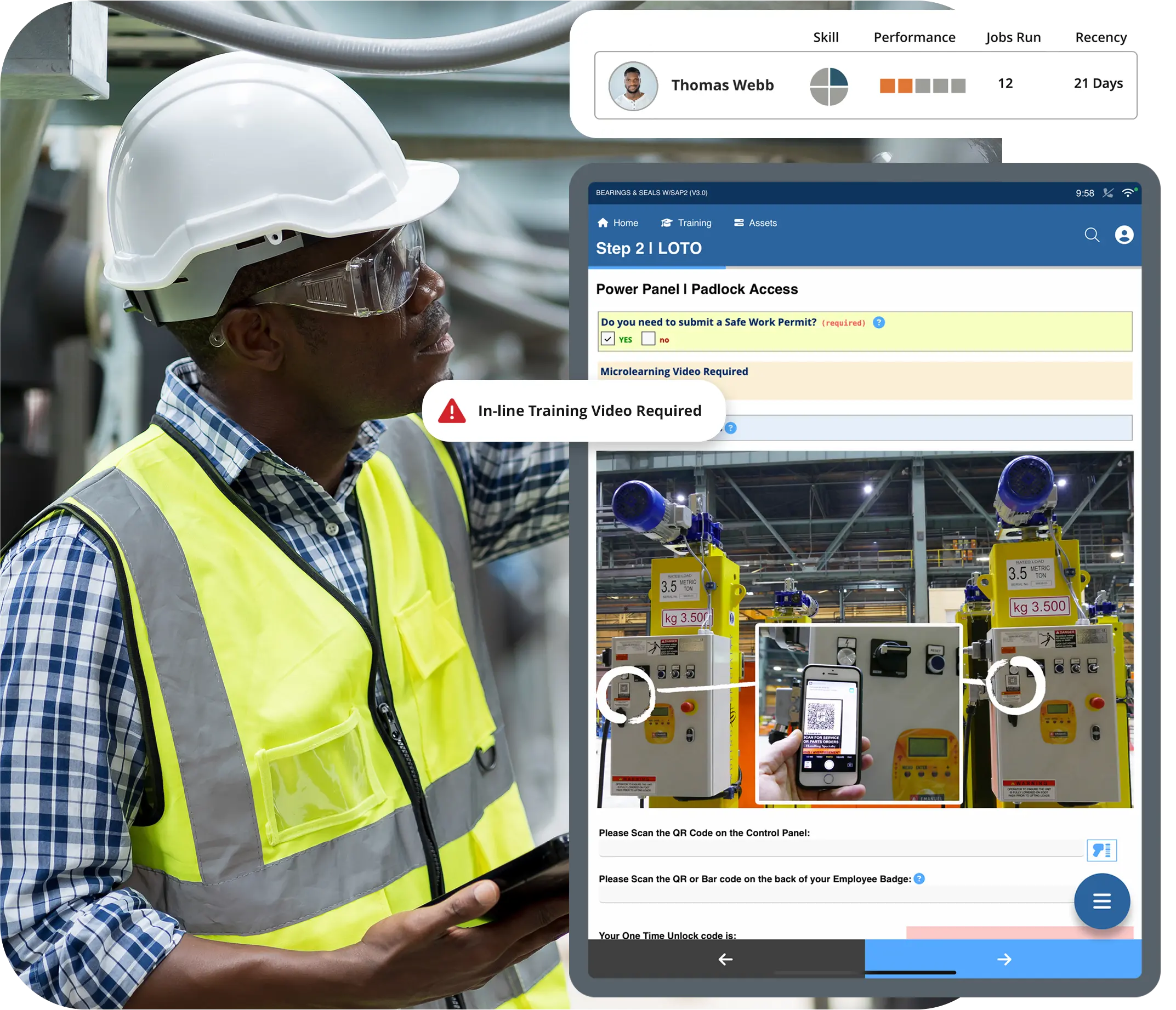

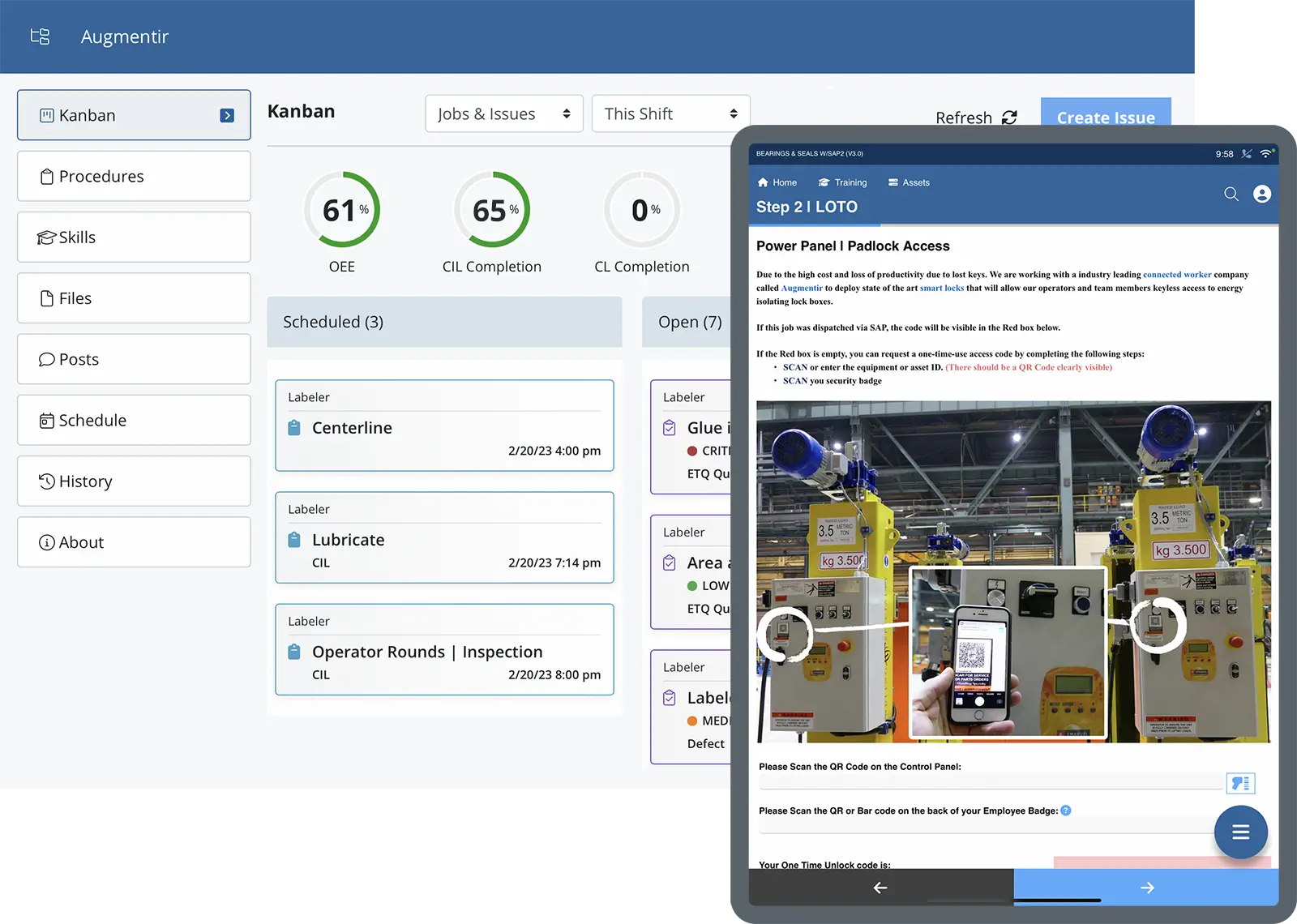

Personalized Digital Work Instructions

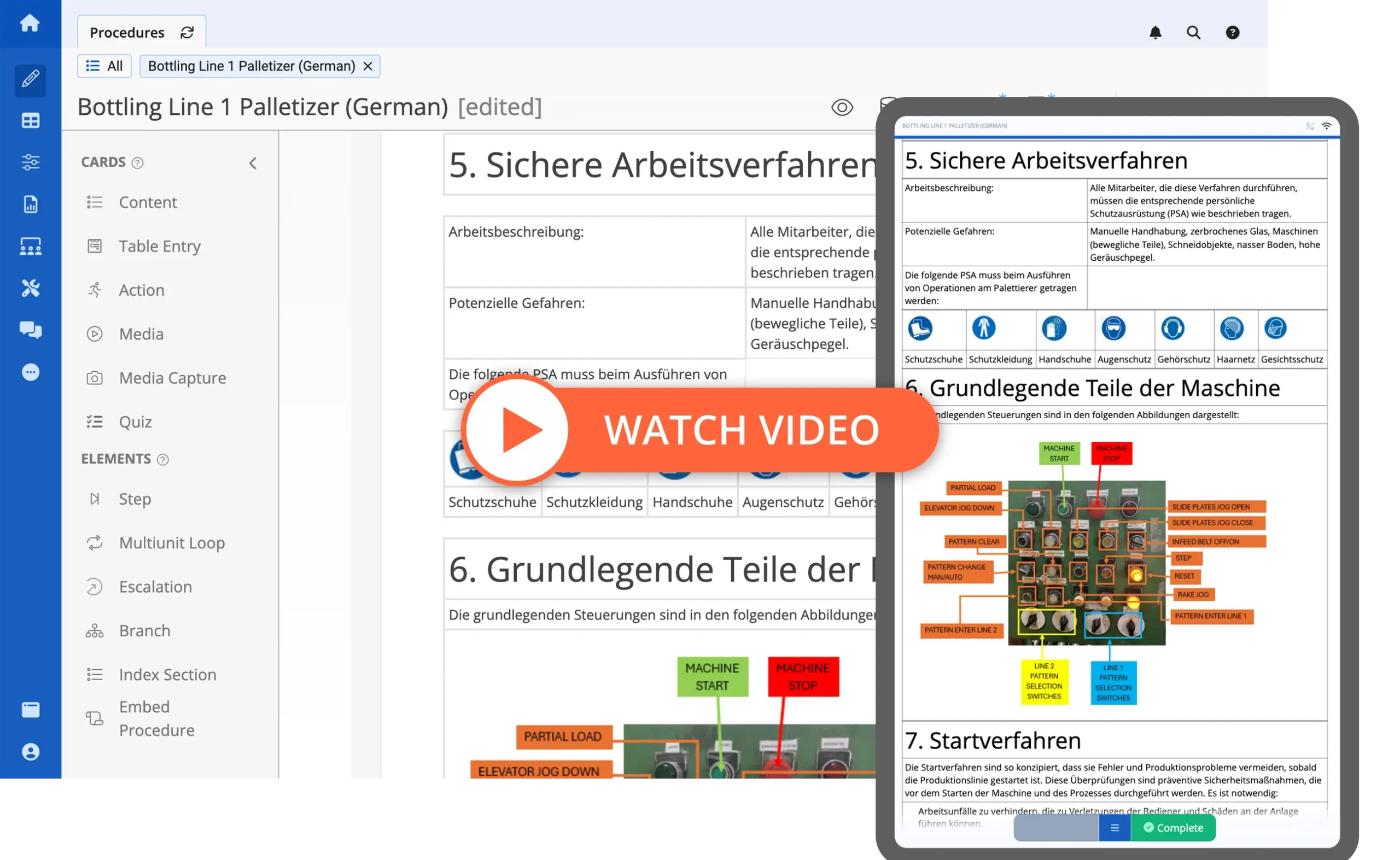

Augmentir enables the creation and deployment of dynamic, multimedia-rich work instructions. These are personalized based on worker proficiency, reducing errors and improving quality.

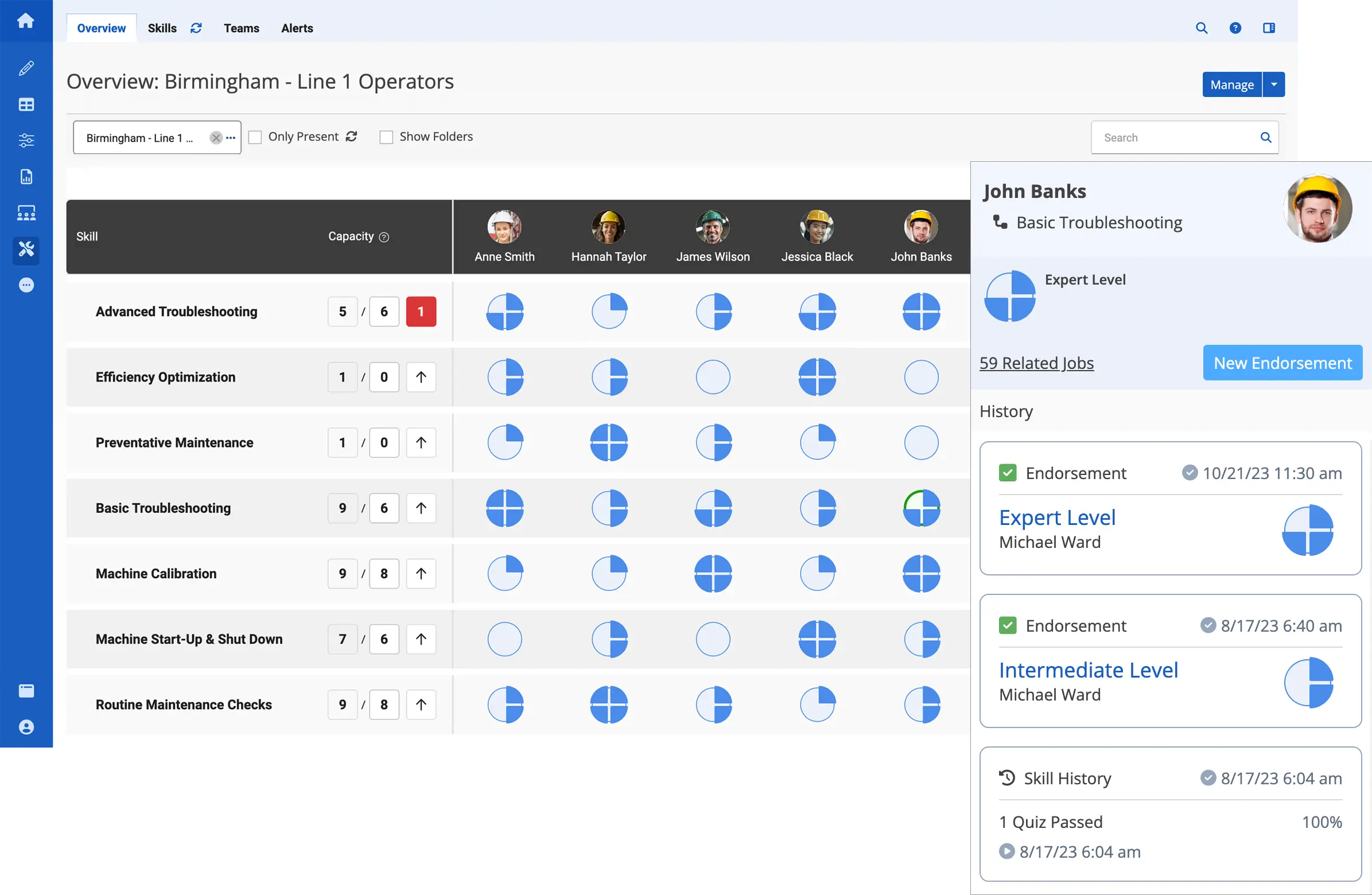

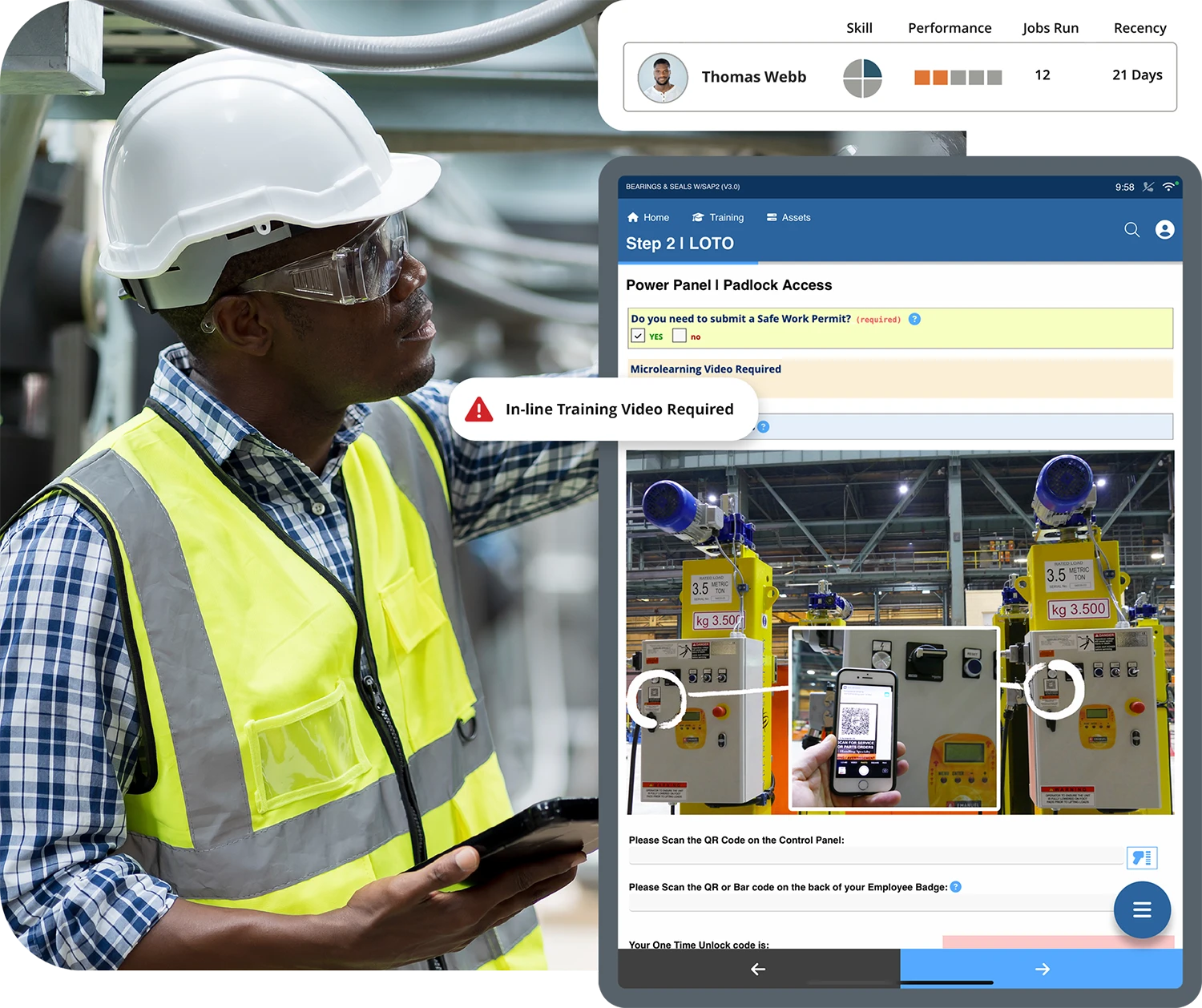

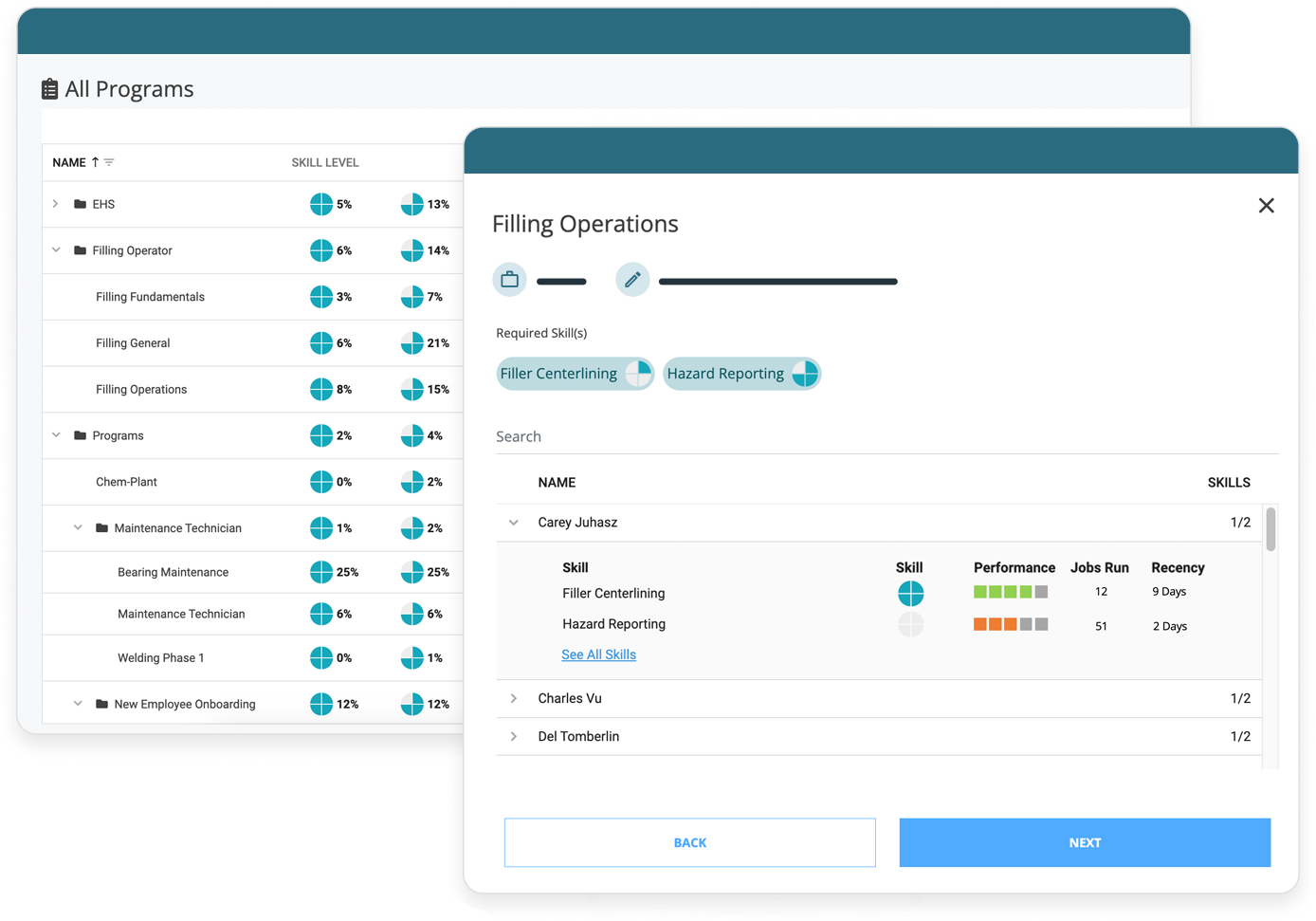

Smart Workforce Management

With real-time skill tracking and performance analytics, Augmentir ensures that the right task is assigned to the right worker—improving efficiency and safety.

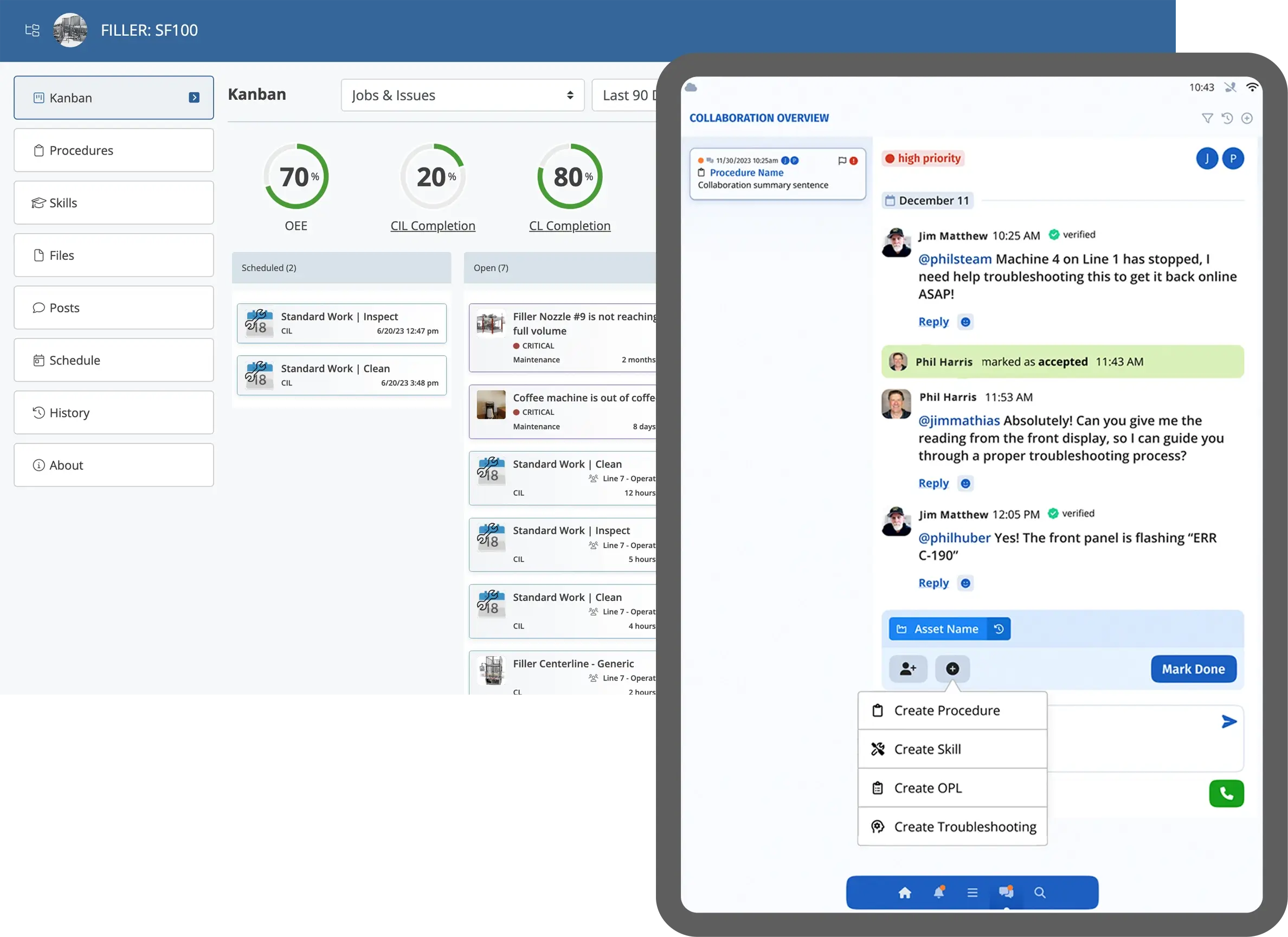

Industrial Collaboration

With manufacturing collaboration software from Augmentir, frontline teams can effectively collaborate and share information across across shifts, plants, and languages.

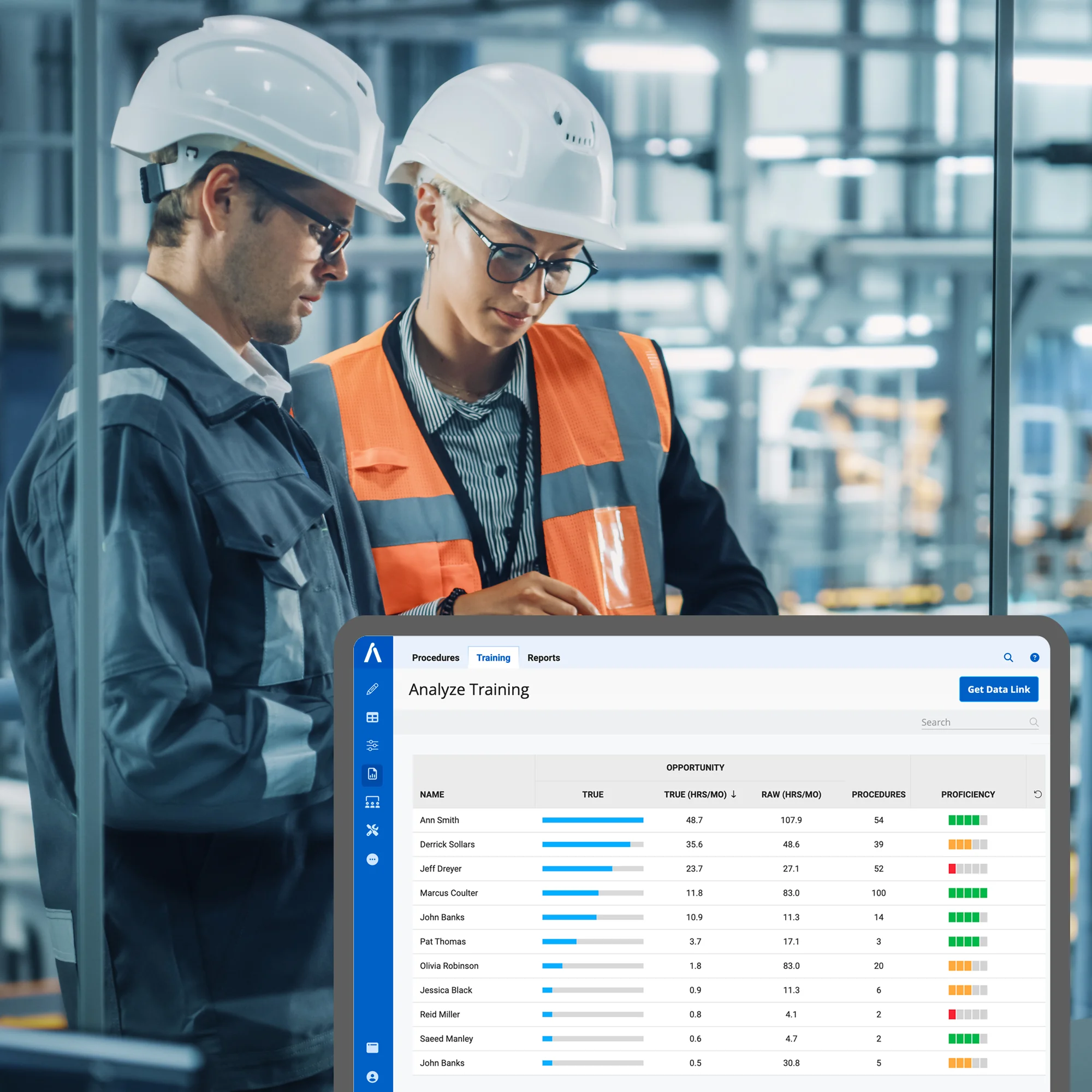

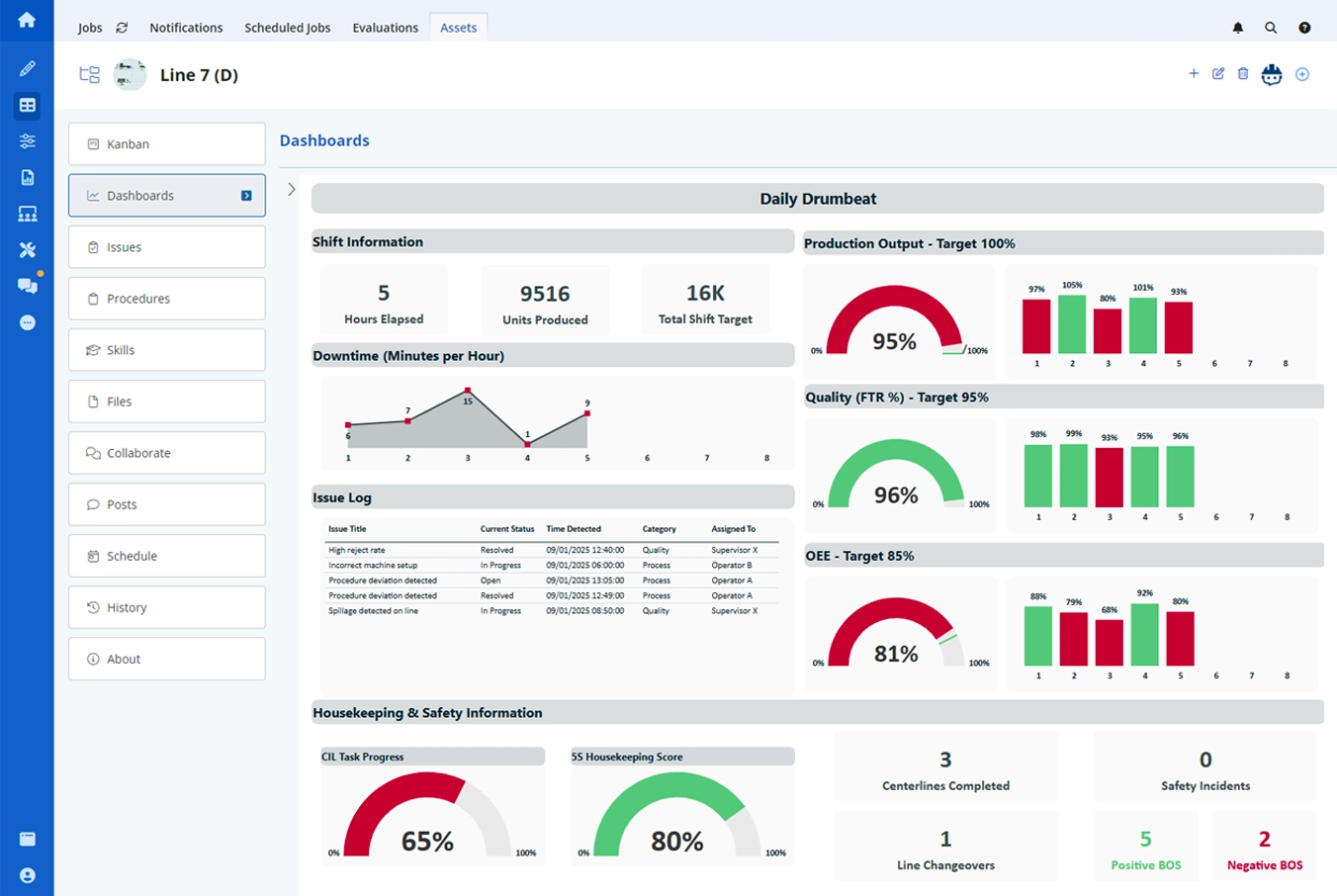

Operational Visibility

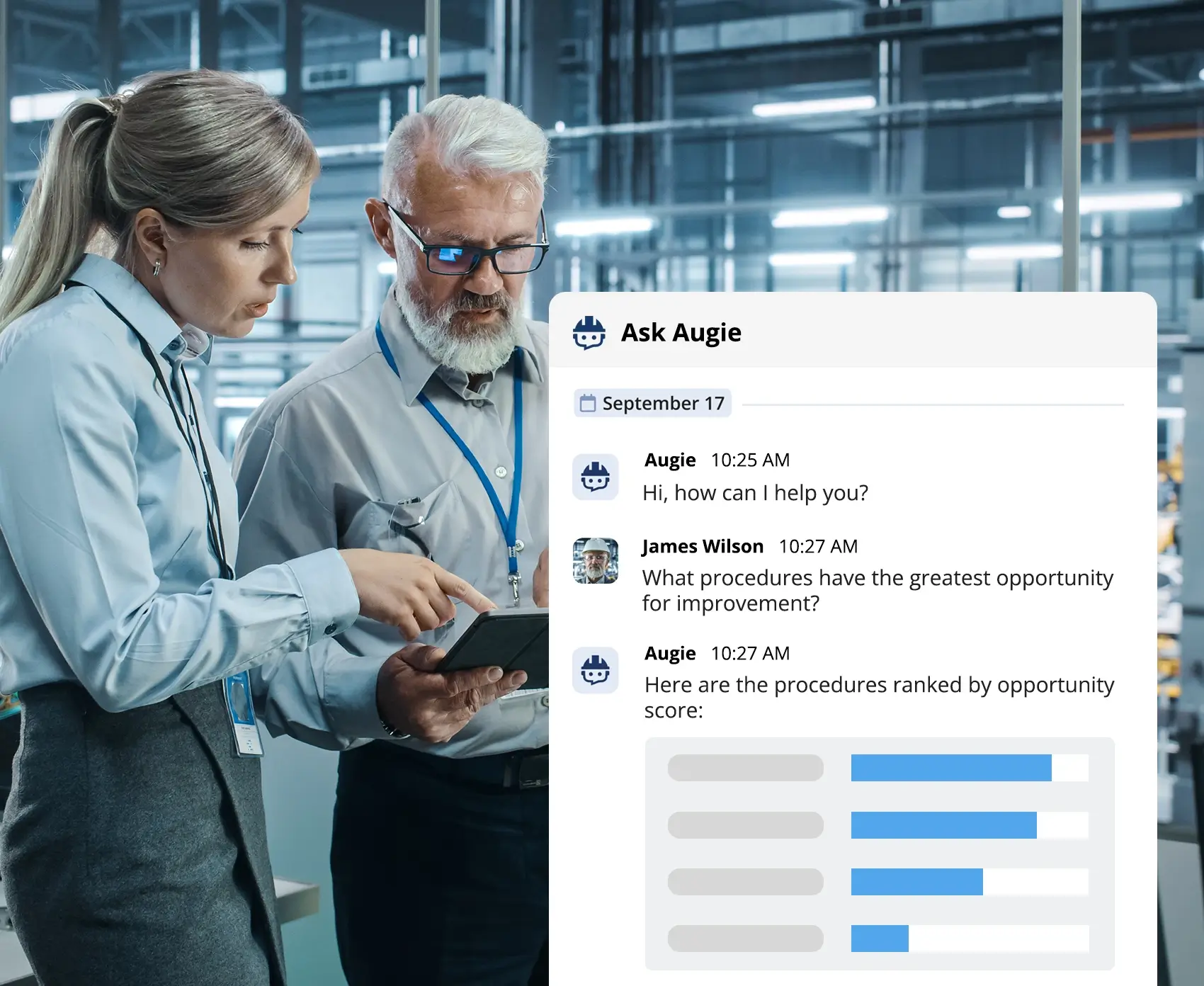

Every interaction on the shop floor is captured and analyzed to surface trends, bottlenecks, and areas for improvement. Unlike traditional audits or passive reports, Augmentir offers continuous, real-time insights.

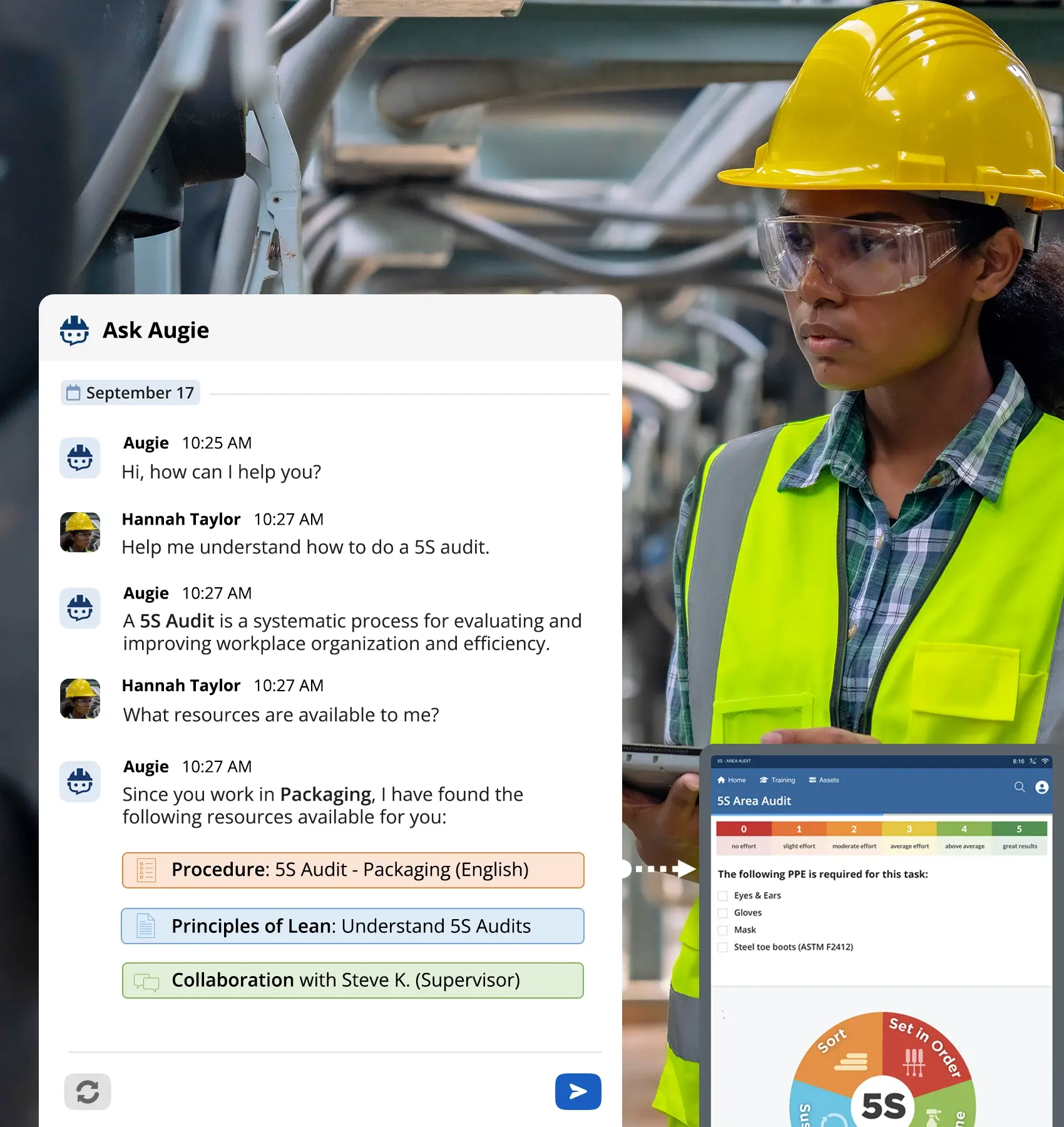

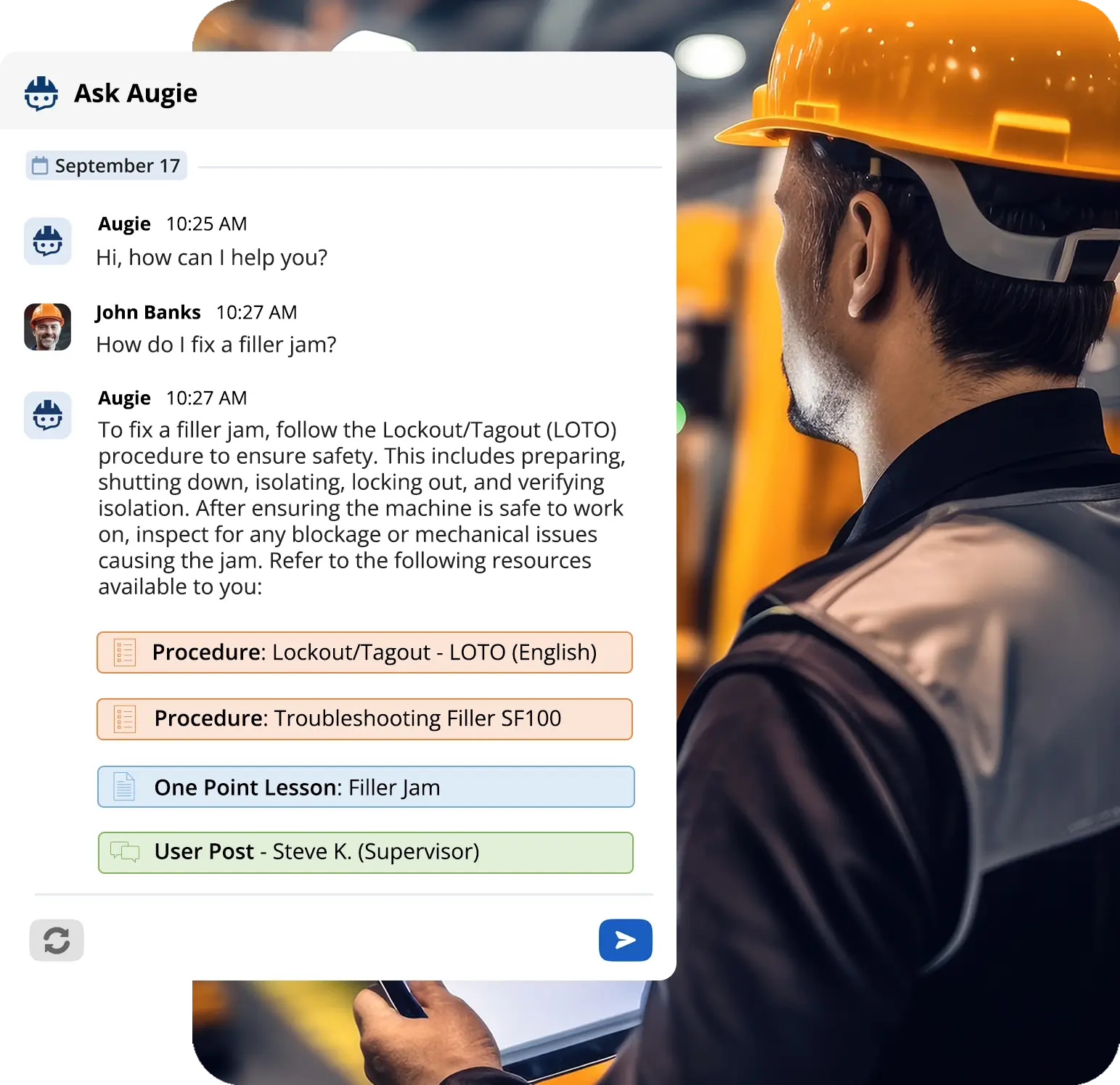

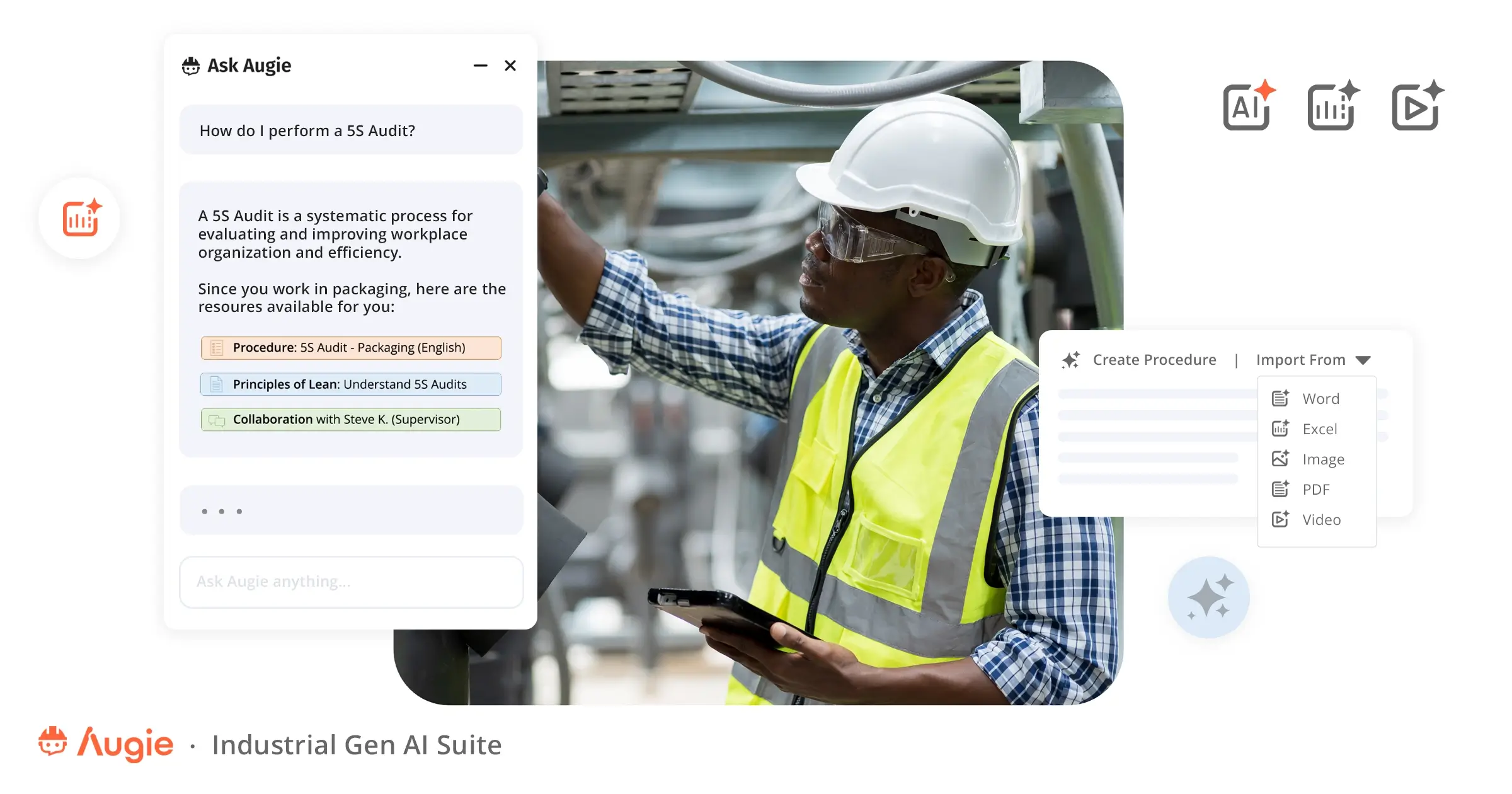

Generative AI Assistant

Augie, Augmentir’s generative AI assistant, accelerates continuous improvement by delivering real-time insights, generating digital SOPs, and offering intelligent recommendations based on frontline data. By transforming operational activity into actionable guidance, Augie empowers teams to identify inefficiencies, reduce errors, and drive faster, more effective improvements.

Continuous improvement is the heartbeat of modern manufacturing excellence. But in today’s environment, traditional methods alone are not enough. The path forward lies in combining proven CI philosophies with digital innovation.

With platforms like Augmentir, and tools like Augie, manufacturers can move from reactive problem-solving to proactive performance enhancement—empowering workers, accelerating learning, and ensuring sustainable results.

The future of manufacturing is connected, intelligent, and continuously improving.