Supercharge your IWS strategy with Augmentir’s AI-powered platform. Digitize work, upskill workers, and drive continuous improvement in manufacturing.

An Integrated Work System (IWS) strategy is essential for driving continuous improvement and achieving world-class manufacturing performance. Originally developed by Procter & Gamble (P&G), IWS is a comprehensive approach to optimizing operations by aligning people, processes, technology, and culture. It focuses on improving manufacturing reliability, reducing costs, and increasing productivity through standardization, capability building, and a relentless focus on continuous improvement.

But even the best-designed IWS strategies can fall short without the right tools to support execution and sustain momentum. That’s where Augmentir comes in.

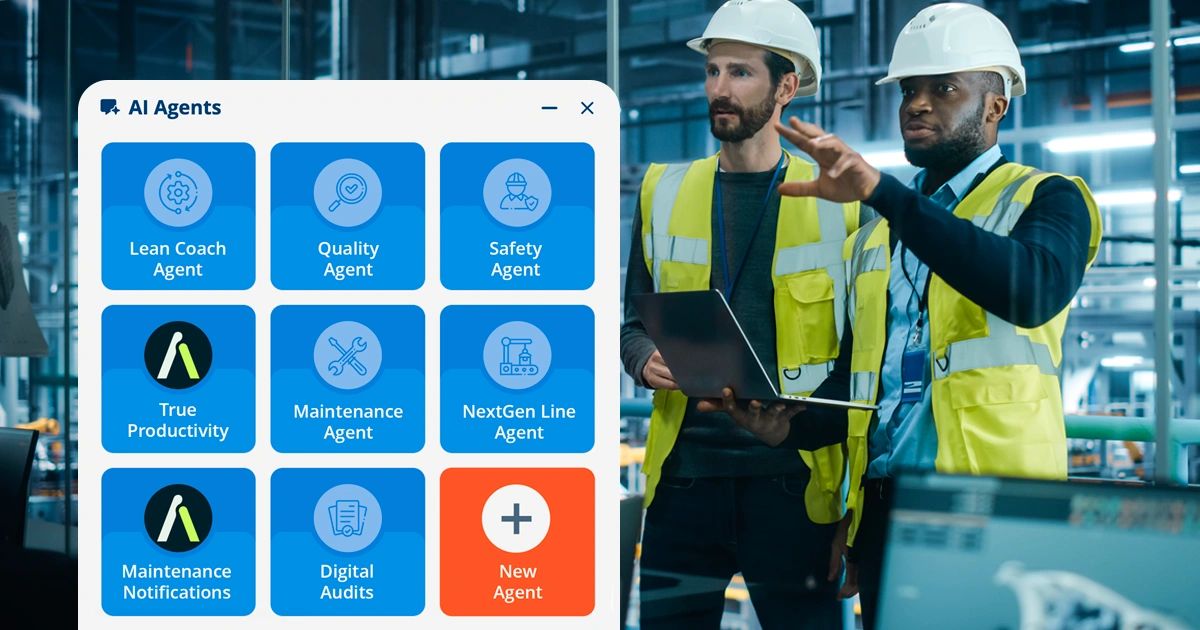

Augmentir is an AI-powered connected worker platform that supercharges your IWS strategy by digitizing, guiding, and optimizing frontline operations. From standard work execution and skills development to real-time performance insights, Augmentir enhances every IWS pillar — making your system smarter, more agile, and more effective.

Digitize and Standardize Work Processes

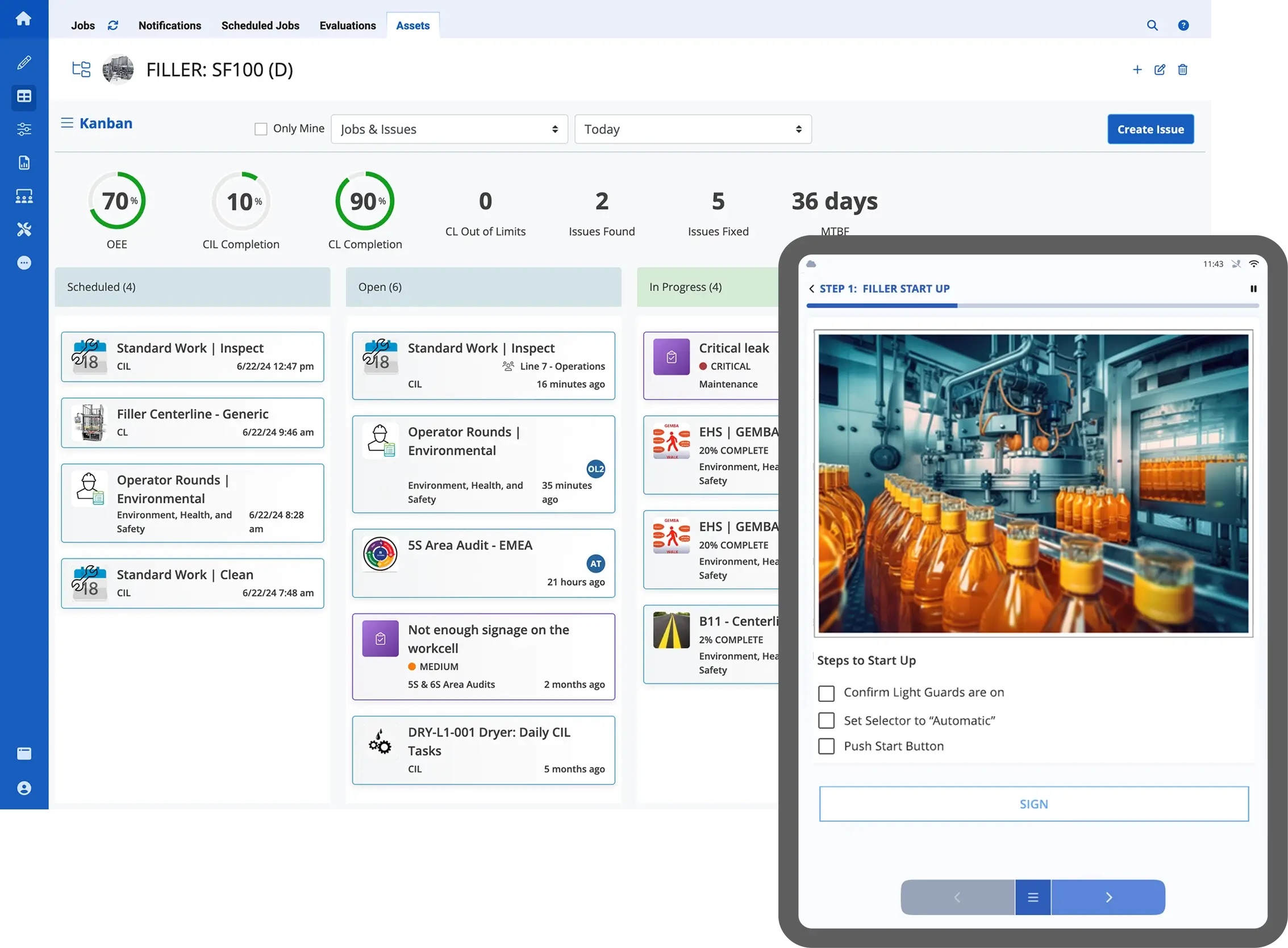

At the heart of IWS is a commitment to standardized work — clearly defined, repeatable processes that reduce variation and waste. Augmentir makes it easy to digitize and deploy standardized work instructions across your organization. With intuitive, no-code tools, you can rapidly create digital workflows that are accessible on any device, ensuring consistency and adherence to best practices.

Digitize Total Productive Maintenance and Asset Management with Augmentir

But Augmentir goes a step further. It doesn’t just digitize your SOPs — it continuously improves them. Through built-in AI, Augmentir identifies where processes break down, which steps cause the most errors, and how top performers complete tasks more efficiently. This gives you a data-driven foundation for refining your standards and driving continuous improvement.

Empower and Upskill Frontline Workers

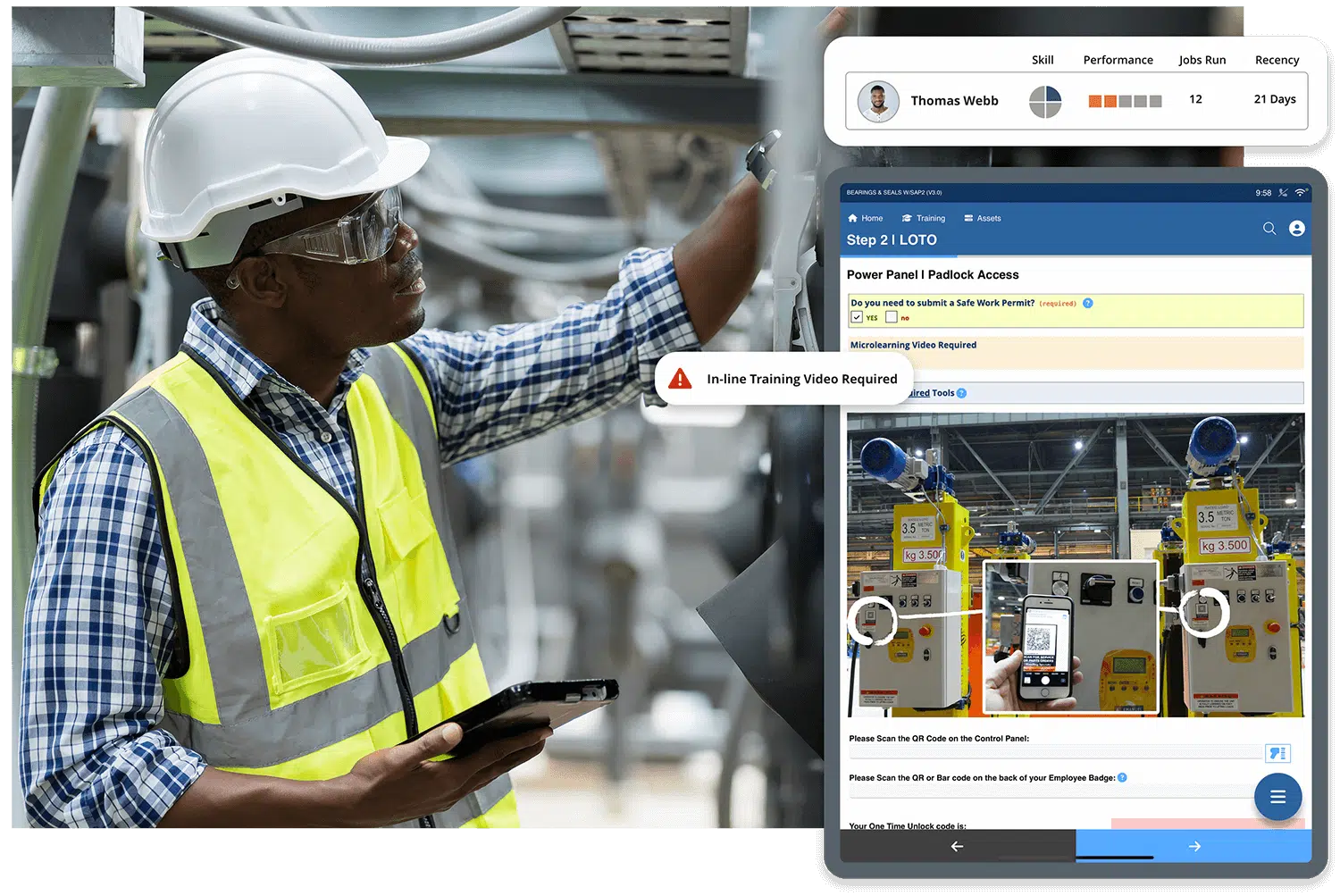

A successful IWS strategy empowers every employee to contribute to performance gains. Augmentir’s connected worker platform personalizes the work experience for each operator. Whether it’s delivering real-time guidance based on current skill level or surfacing just-in-time training content, Augmentir helps close skill gaps and build workforce capability on the job.

With Augmentir’s integrated skills management system, you get a live view of workforce readiness across your lines, shifts, and sites. You can align training investments with actual performance needs, monitor certification status, and track progress against capability-building goals — all within the same platform.

Enhance Autonomous Maintenance and Problem Solving

Autonomous maintenance is a key component of IWS, empowering operators to identify and resolve issues at the source. Augmentir supports these initiatives by guiding workers through inspection, lubrication, and minor maintenance tasks with step-by-step digital instructions. Workers can capture and report issues on the spot, while supervisors gain visibility into completion rates and problem trends.

What’s more, Augmentir facilitates structured problem solving by giving teams the tools to document root causes, track countermeasures, and share lessons learned — all within the context of day-to-day operations.

Streamlined Daily Management and Shift Handovers

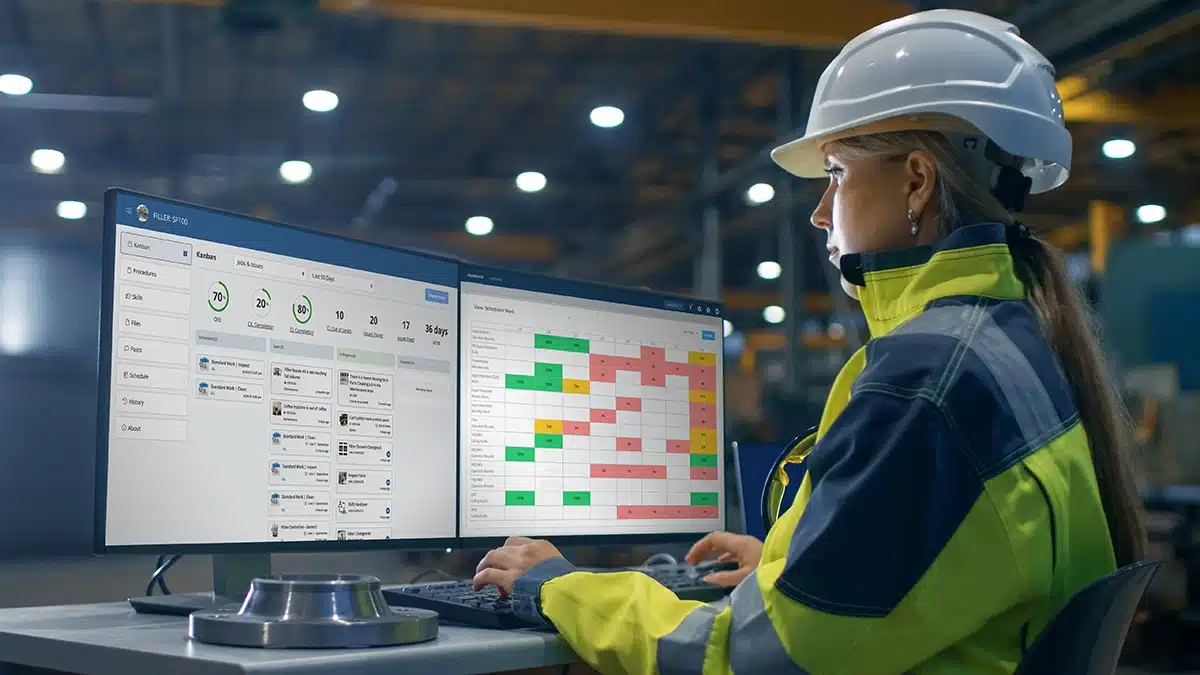

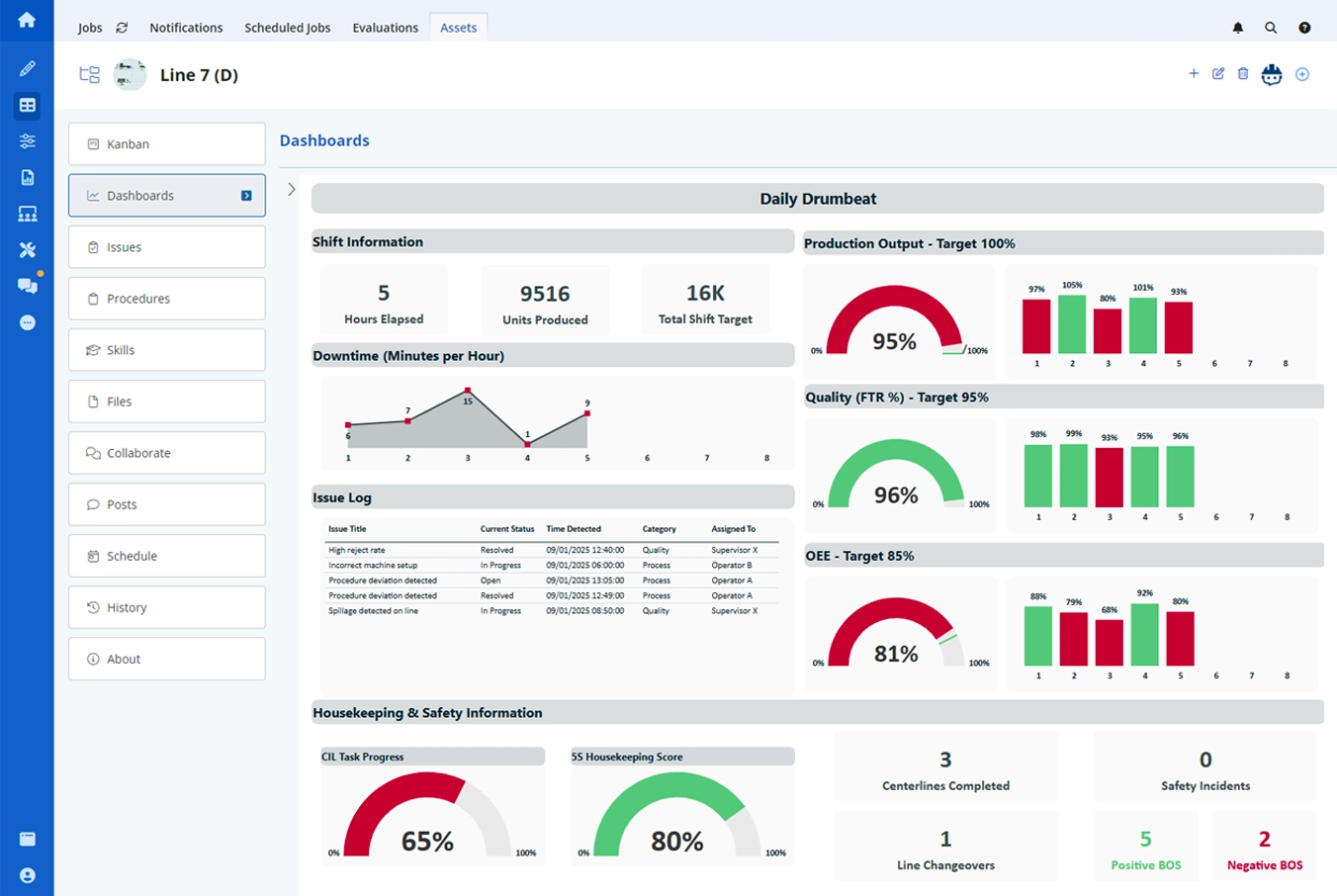

Augmentir supports a company’s Integrated Work System (IWS) strategy by enhancing key elements of frontline operations such as daily management, direction setting, and shift handovers. By digitizing and standardizing these workflows, Augmentir ensures that critical information is captured, shared, and acted upon consistently across teams and shifts. This not only drives operational discipline but also aligns frontline activity with strategic objectives.

Daily direction setting becomes significantly more effective with Augmentir’s digital tools. Supervisors can rapidly communicate goals, identify production variances, and prioritize actions using real-time data from the shop floor. Augmentir’s connected worker platform ensures that frontline teams are equipped with clear, up-to-date instructions that reflect current conditions, reducing downtime and enabling more agile responses to issues.

Additionally, Augmentir streamlines shift handovers by providing a structured, digital record of shift activities, issues, and resolutions. This eliminates the information gaps and miscommunications that often occur during manual handovers, ensuring continuity and faster problem resolution.

By integrating seamlessly into IWS frameworks, Augmentir empowers companies to build a more proactive, data-driven, and aligned frontline workforce.

Unlock Continuous Improvement with Data and AI

IWS relies on data to drive informed decision-making and continuous improvement. Augmentir captures rich, real-time data from every task completed by your frontline teams. Its AI engine then analyzes this data to uncover hidden inefficiencies, suggest targeted improvements, and recommend actions that directly impact OEE and operational KPIs.

Instead of relying on assumptions or static audits, Augmentir enables a dynamic, data-driven improvement loop — where insights are generated in real time, and decisions are based on actual shop floor behavior.

A Foundation for Sustainable Operational Excellence

An IWS strategy is not a one-time project — it’s a long-term commitment to operational excellence. Augmentir helps sustain that journey by aligning your people, processes, and technology through a single, AI-driven platform. By providing data visibility, enabling a culture of ownership, and continuously optimizing workflows, Augmentir ensures that your IWS system doesn’t just run — it evolves.

Start Building a Smarter IWS with Augmentir

Whether you’re just beginning your IWS journey or looking to accelerate existing initiatives, Augmentir gives you the digital backbone you need. From standard work and skills development to continuous improvement and performance tracking, Augmentir is purpose-built to support and scale IWS strategies in modern manufacturing environments.

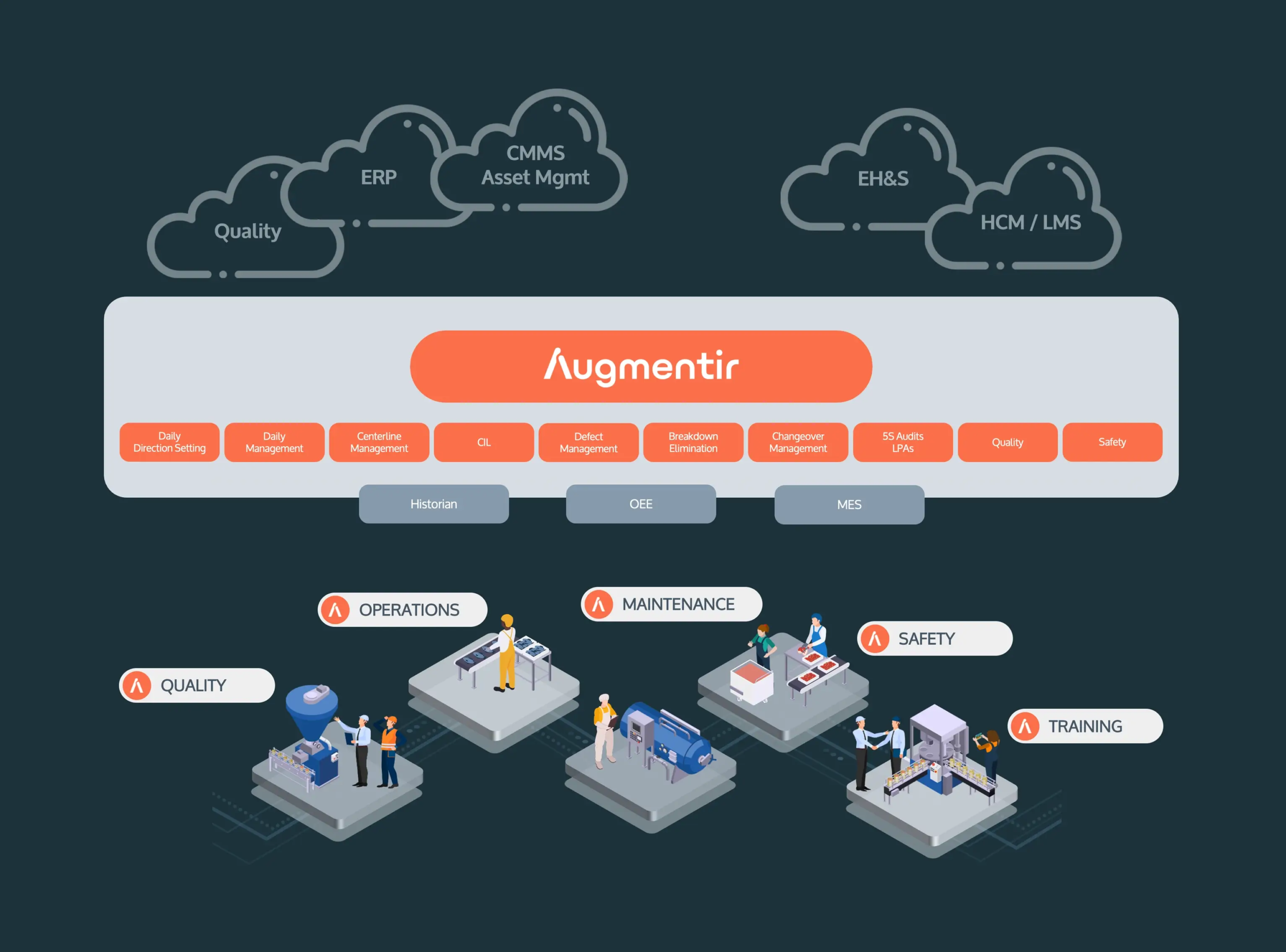

Augmentir supports your IWS strategy by acting as a single pane of glass for your frontline operations. With Augmentir, you can digitize, manage, and optimize all aspects of your frontline operation:

- Daily Direction Setting (DDS)

- Daily Management System (DMS)

- Centerline Management

- Clean, Inspect, Lubricate processes

- Defect Management

- Breakdown Elimination

- Changeover Management

- Shift Handover

- 5S and Layered Process Audits

- Quality Management on the Shop Floor

- Safety

- Maintenance

Let Augmentir be your partner in transforming how work gets done — and in unlocking the full potential of your IWS strategy.