El software de gestión de habilidades inteligentes está ayudando a los fabricantes a cerrar la brecha entre la capacitación, las habilidades y el trabajo para construir una fuerza laboral más resiliente y ágil.

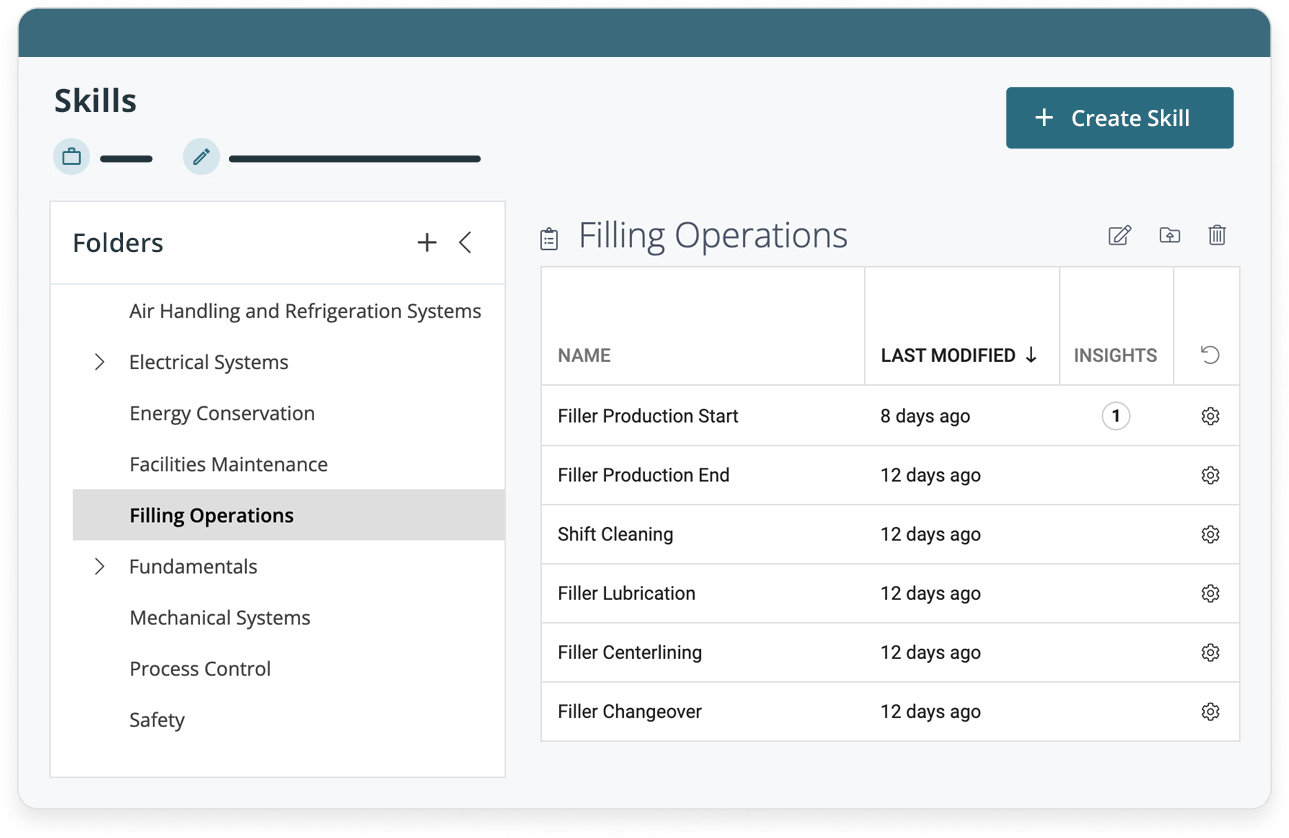

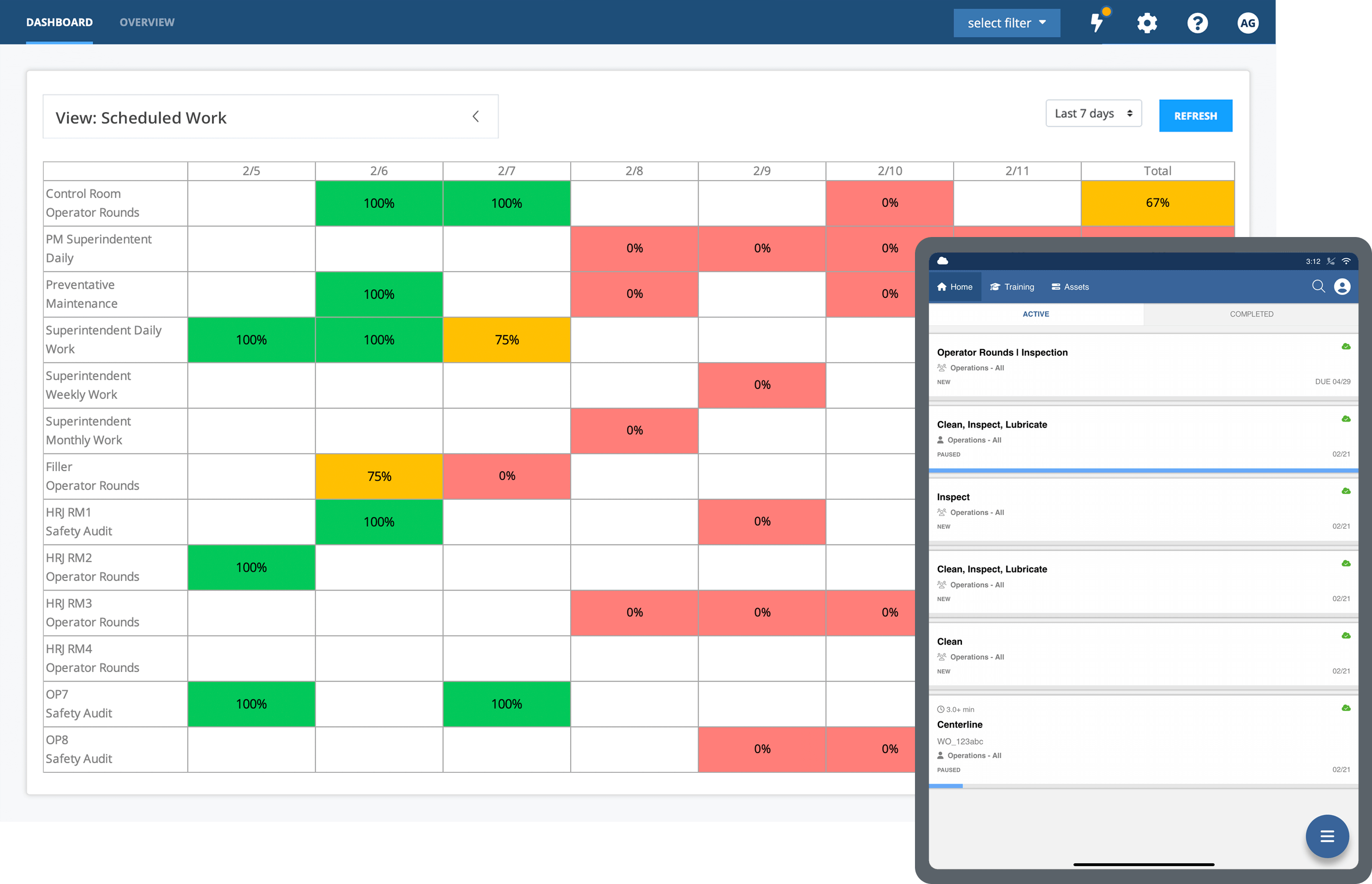

¿En qué etapa se encuentra en su proceso de adopción de tecnologías nuevas y emergentes? Muchos fabricantes se están sumando a la tendencia de las herramientas más recientes que brindan orientación digital a los trabajadores. Quizás decidió implementar instrucciones de trabajo digitales para ayudar a los trabajadores a realizar tareas de forma segura y eficiente. O tal vez ha comprado... software de gestión de habilidades Para ayudarte a catalogar y organizar las habilidades y capacidades de los diferentes trabajadores. Pero ¿alguna de estas opciones es suficiente por sí sola para alcanzar todos tus objetivos de producción? Posiblemente, pero poco probable.

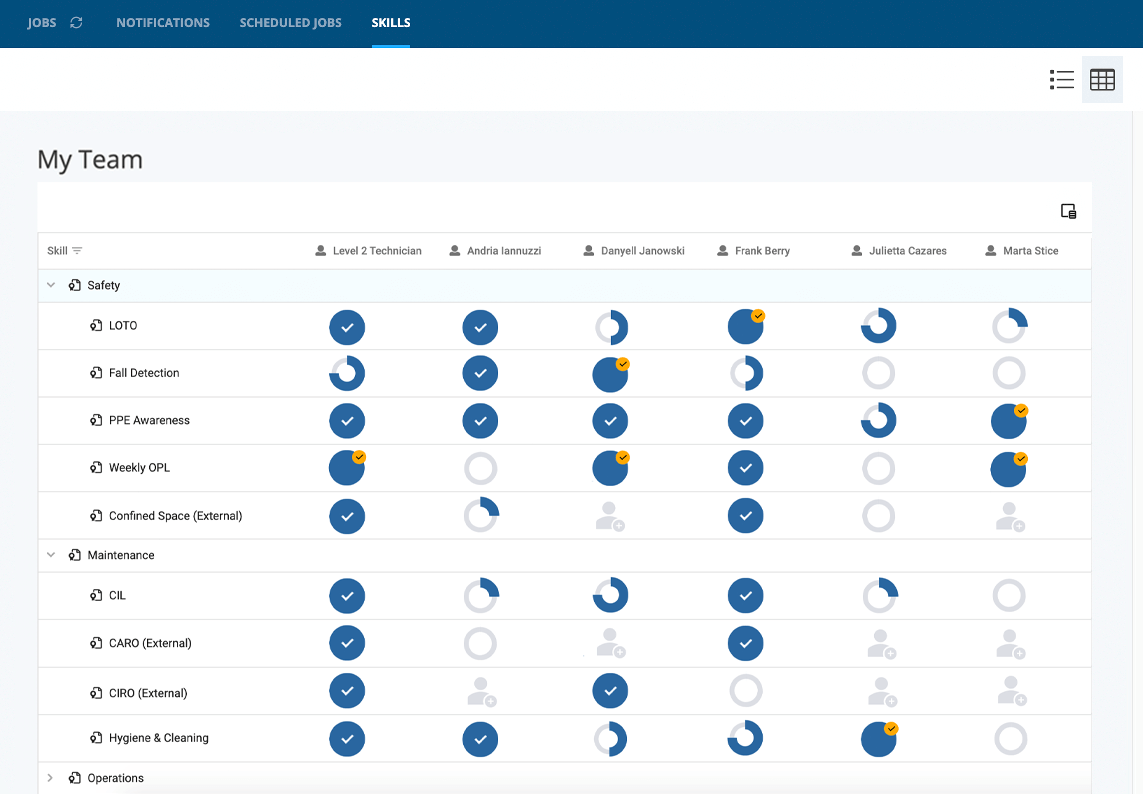

Instrucciones de trabajo digitales por su propia cuenta trabajo estándar Las directrices no consideran las habilidades únicas de cada trabajador. Los programas independientes de gestión de habilidades pueden ofrecer un resumen de las habilidades y certificaciones de sus trabajadores, pero no capturan el desempeño en tiempo real para brindar evaluaciones precisas. Tampoco ofrecen el contenido de capacitación personalizado necesario para garantizar que los trabajadores rindan al máximo. ¿Podemos entonces estar de acuerdo en que estas dos características deben ir de la mano?

Uno no puede existir sin el otro: combinar habilidades en el flujo de trabajo

En el pasado, independiente sistemas de gestión de habilidades fueron suficientes porque:

- La rotación era poco frecuente, por lo que los supervisores de línea conocían a todos los miembros de su equipo y sus habilidades y avales actuales, lo que facilitaba que el supervisor asignara el trabajo de manera segura y óptima.

- Las inversiones en capacitación, reciclaje y mejora de las competencias se realizaron con un enfoque único para todos o mediante un enfoque puramente subjetivo o anecdótico.

Hoy en día, sin embargo, existe una situación diferente.

Los supervisores de línea lidian con miembros del equipo que no conocen bien, nuevos empleados que se incorporan cada día y experimentados que se marchan. Esto genera problemas de seguridad y dificulta la asignación óptima de tareas, ya que no solo los trabajadores son variables, sino que sus niveles de habilidades y certificaciones son un objetivo en constante evolución.

Un sistema integrado y de circuito cerrado de gestión de habilidades es la solución para esta era de alta rotación de personal y ausentismo.

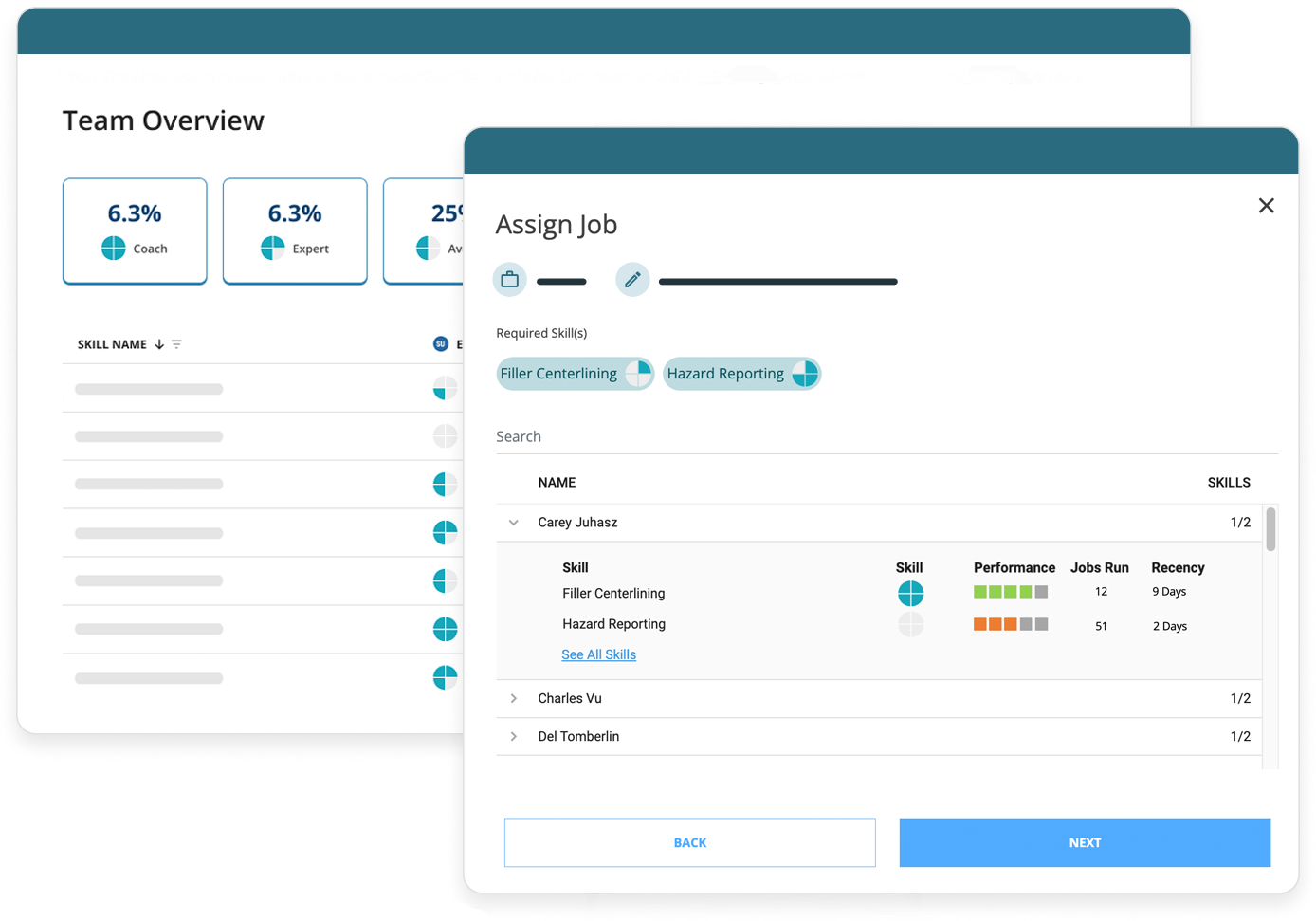

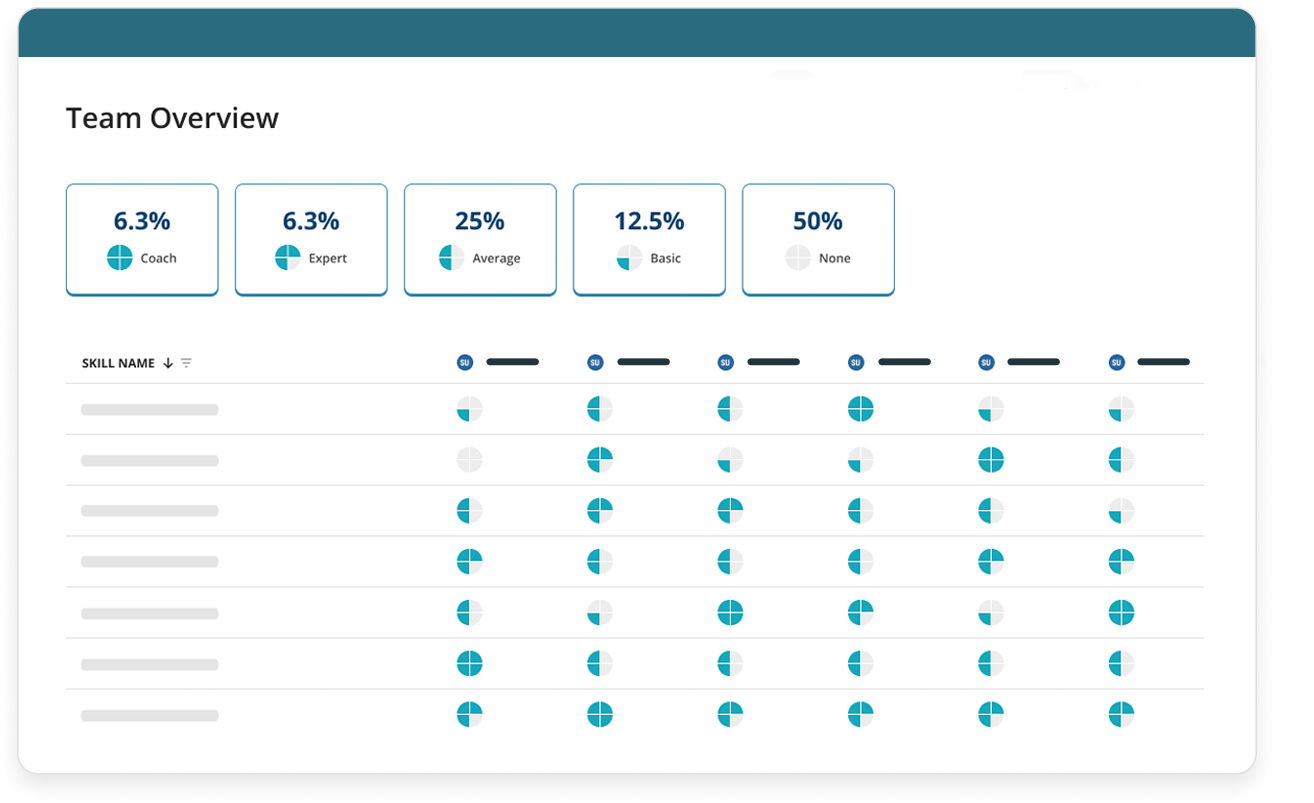

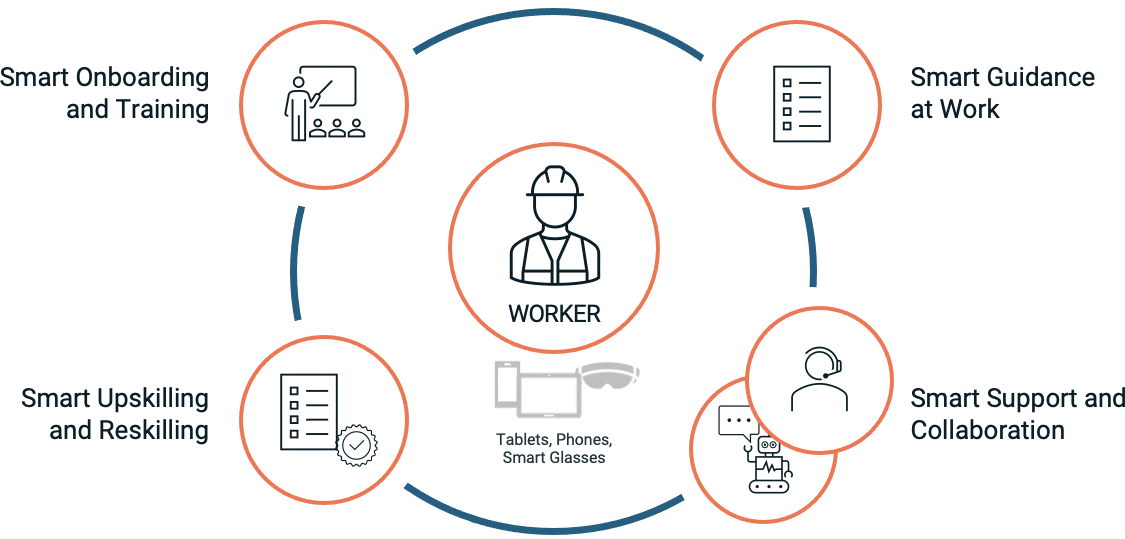

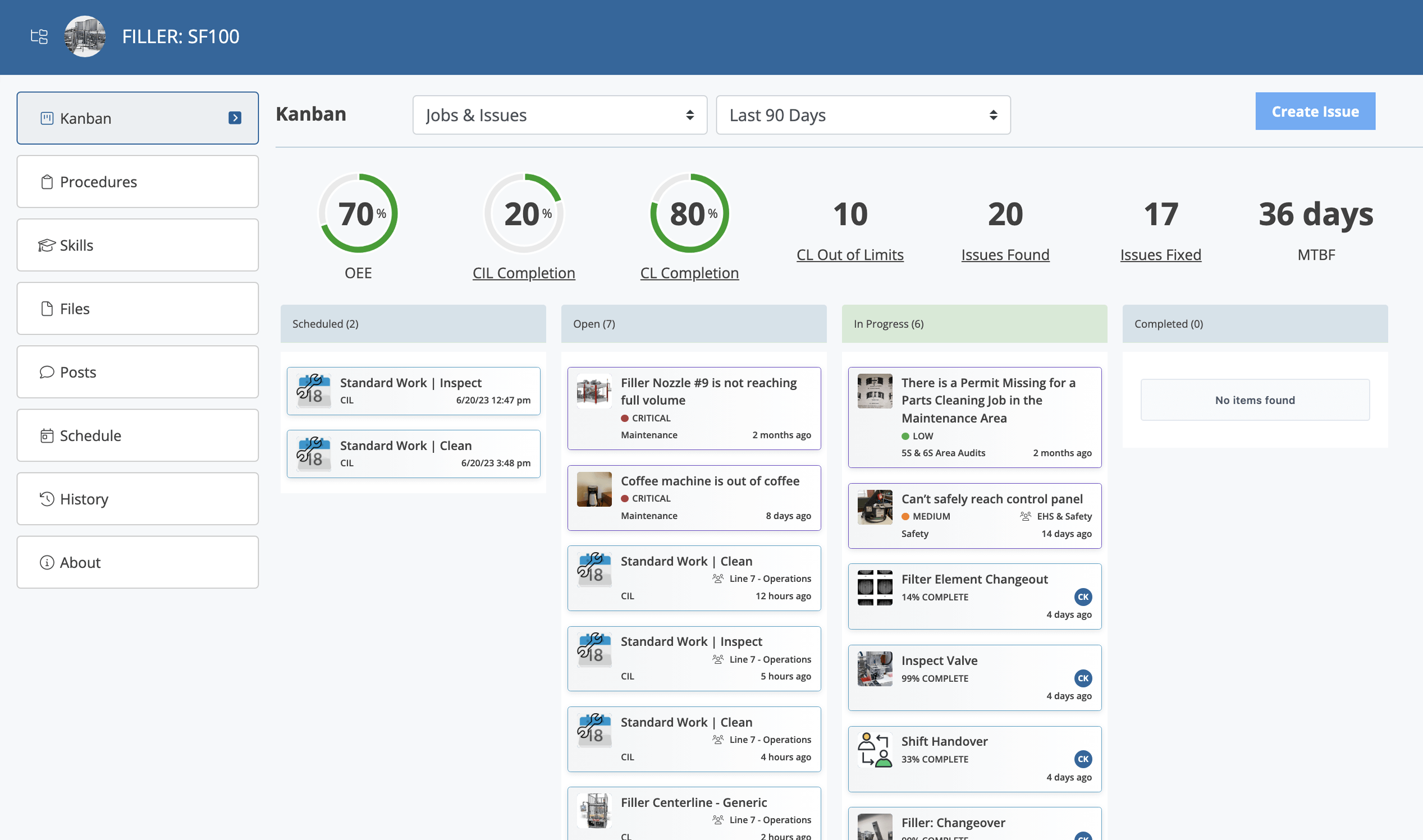

Soluciones de gestión de habilidades Las herramientas que combinan funciones de seguimiento de habilidades con tecnología para trabajadores conectados y orientación digital en el trabajo pueden aportar un valor añadido significativo. Los datos del desempeño laboral real pueden fundamentar las iniciativas de desarrollo de la fuerza laboral, lo que le permite orientar sus esfuerzos de capacitación, reciclaje y perfeccionamiento de habilidades donde tengan el mayor impacto.

Puede generar una gran cantidad de datos valiosos para brindar capacitación personalizada, acreditaciones de habilidades e identificar oportunidades laborales. ¿Qué más se puede hacer? Imagine reducir los costos de capacitación, optimizar la programación de tareas, aumentar la seguridad y mejorar la productividad. Y ahora piense en lo que sucederá al agregar tecnología inteligente a este paquete integral.

¡El poder de la digitalización inteligente! La gestión de habilidades y las instrucciones de trabajo digitales impulsan la productividad.

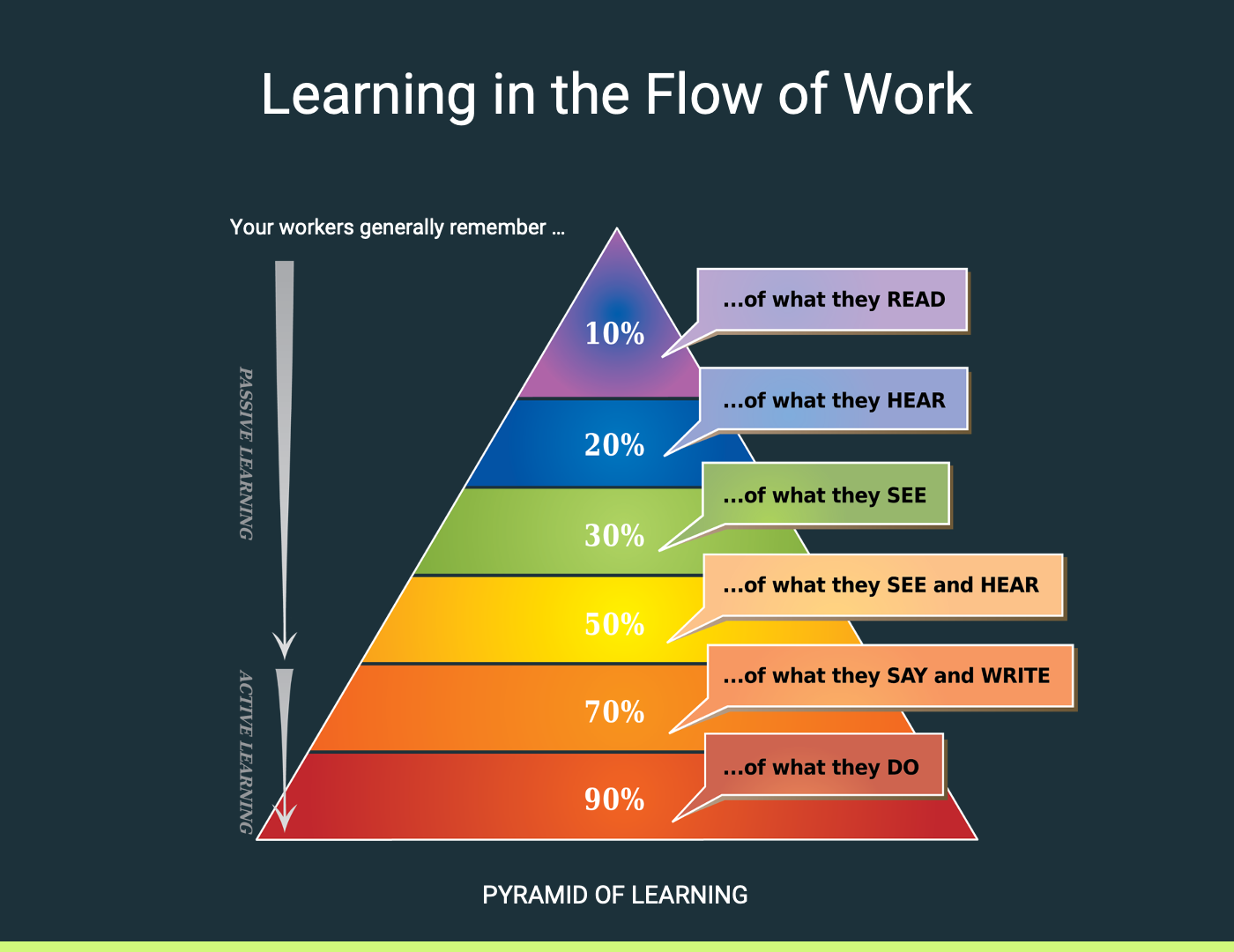

De acuerdo a DeloitteLas organizaciones están adoptando un enfoque basado en habilidades para satisfacer la demanda de agilidad, autonomía y equidad. Las soluciones para trabajadores conectados, que combinan la gestión de habilidades con instrucciones de trabajo digitales, colaboración y gestión del conocimiento, son ideales para optimizar la fuerza laboral actual, que es variable. La información generada por IA se extrae de patrones identificados en toda la actividad laboral en tiempo real. Esta información identifica dónde los trabajadores, tanto nuevos como experimentados, pueden beneficiarse de la actualización o el perfeccionamiento de sus habilidades.

Esta combinación de tecnología digital inteligente también puede aprovechar sus recursos de capacitación, como videos instructivos, instrucciones escritas o acceso a expertos remotos, para brindar orientación personalizada que permita al trabajador rendir al máximo. Estas herramientas trabajan juntas de forma inteligente para ayudarle a asignar a los trabajadores a los procedimientos según los niveles de habilidad requeridos. ¡Sin dudas! Augmentir es la única Solución para trabajadores inteligentes conectados entrelazar estas herramientas de gestión con la IA convirtiéndola en una potencia para optimizar sus operaciones y alcanzar los objetivos de producción.