Total Productive Maintenance

Total Productive Maintenance (TPM) is a proactive maintenance approach that engages all employees to maximize equipment efficiency, prevent breakdowns, and improve productivity through regular, planned maintenance and continuous improvement.

Manufacturers are always looking for ways to maximize equipment performance while reducing the risk of machine failure and lost production time. This is where Total Productive Maintenance comes in. The TPM methodology empowers businesses to maintain their production lines by boosting equipment effectiveness and leveraging the benefits of digital, data-driven solutions.

If you want to learn more about TPM and its advantages, read on about the following topics:

What is total productive maintenance?

Total productive maintenance (TPM) is an approach designed to optimize equipment availability and performance. It is a foundational aspect of any lean manufacturing environment, which strives to eliminate waste and elevate worker productivity.

The TPM philosophy stresses the importance of using equipment, employees, and supporting processes to maintain and improve the safety, quality, and integrity of production in manufacturing.

In manufacturing, production is highly dependent on equipment and workers. Production losses can occur throughout the assembly process due to equipment downtime, poor worker effectiveness, and inefficient procedures.

Total productive maintenance strives to reduce workplace losses by placing the responsibility of basic maintenance upkeep on the primary equipment user: the machine operator.

Operators maintain their equipment using autonomous maintenance techniques (cleaning, safety checks, etc.) and other preventative maintenance practices.

Over time, TPM can impact your overall equipment effectiveness (OEE), the gold standard for measuring how well a manufacturing process is applied. TPM is a key component of operational excellence in manufacturing, as well as a core piece of integrated work systems (IWS).

TPM strives to achieve perfect production by having:

- No breakdowns

- No stops or running slowly

- No defects

- No accidents

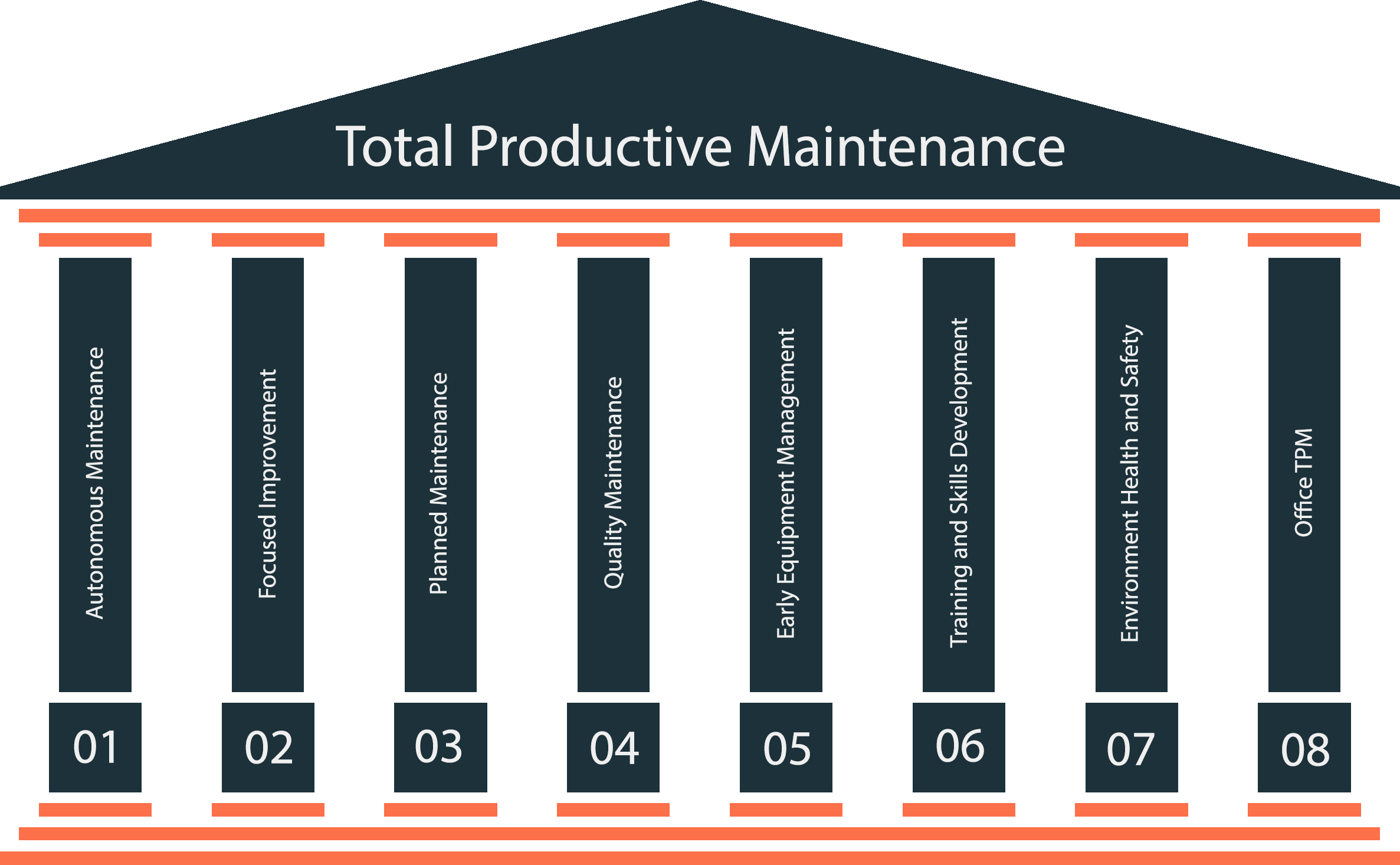

The 8 pillars of TPM

The eight pillars of TPM focus on preventive practices to help improve equipment reliability. They’re based on the 5S system (sort, set in order, shine, standardize and sustain) for organizing work spaces so tasks can be performed efficiently.

The eight pillars are:

1. Autonomous maintenance

Autonomous maintenance is an approach to maintenance that involves giving machine operators responsibility for basic maintenance and upkeep tasks, allowing dedicated technicians to focus on more complex maintenance jobs. This strategy is a pillar of TPM, an approach designed to optimize equipment performance and a foundational aspect of lean manufacturing.

Autonomous maintenance (AM) grants operators more control over cleaning, lubricating, and inspecting their own equipment – and helps to identify equipment issues early on before they become failures.

Successful AM requires that manufacturers provide their operators with the appropriate digital tools and knowledge to perform these tasks independently. This involves digitizing standard operating procedures (SOPs) for cleaning, lubricating, and inspections, and providing operators with easy access to training and a knowledge base of information.

Total productive maintenance and autonomous maintenance are key components of Integrated Work Systems. Integrated work systems (IWS) are an example of a strategy for improving operational excellence in manufacturing. Integrated work systems bring together the core principles of people, process, and technology to drive higher levels of manufacturing performance and continuous improvement.

2. Focused improvement

Focused improvement involves leveraging small teams into the mindset of regularly working together to implement improvements.

3. Planned maintenance

Planned maintenance includes scheduled preventative maintenance (PM) of equipment and assets in order to keep them operational and prevent unplanned downtime.

4. Quality management

The quality management pillar focuses on incorporating error detection and root cause analysis into the production process and includes regular, proactive inspections and quality control checks.

5. Early equipment management

This pillar focuses on creating a system for managing product and equipment development.

6. Training and skills development

The training and skills development pillar of TPM ensures that equipment operators and maintenance teams are equipped with the proper knowledge of TPM and specifically how to perform quality, inspection, and maintenance tasks.

Training and education are increasingly shifting to on-the-job support at the time of need. This includes using modern digital tools to train and guide operators during maintenance tasks. Connected worker platforms that incorporate digital skills tracking, digital work instructions, and on-the-job training, including one-point lessons, help sharpen job-related knowledge and enable operators to be successful at regular maintenance tasks. This can help prevent further deterioration of the equipment.

Once operators are trained and have access to digital information to help guide them through the maintenance processes, they are able to perform tasks independently and at an optimal level of safety and quality.

7. Environmental health and safety

Safety-oriented tasks are performed by equipment operators in order to maintain a safe work environment.

8. Office TPM

This pillar includes extending TPM benefits beyond the plant floor and applying TPM principles to administrative functions, including order processing, procurement, and scheduling.

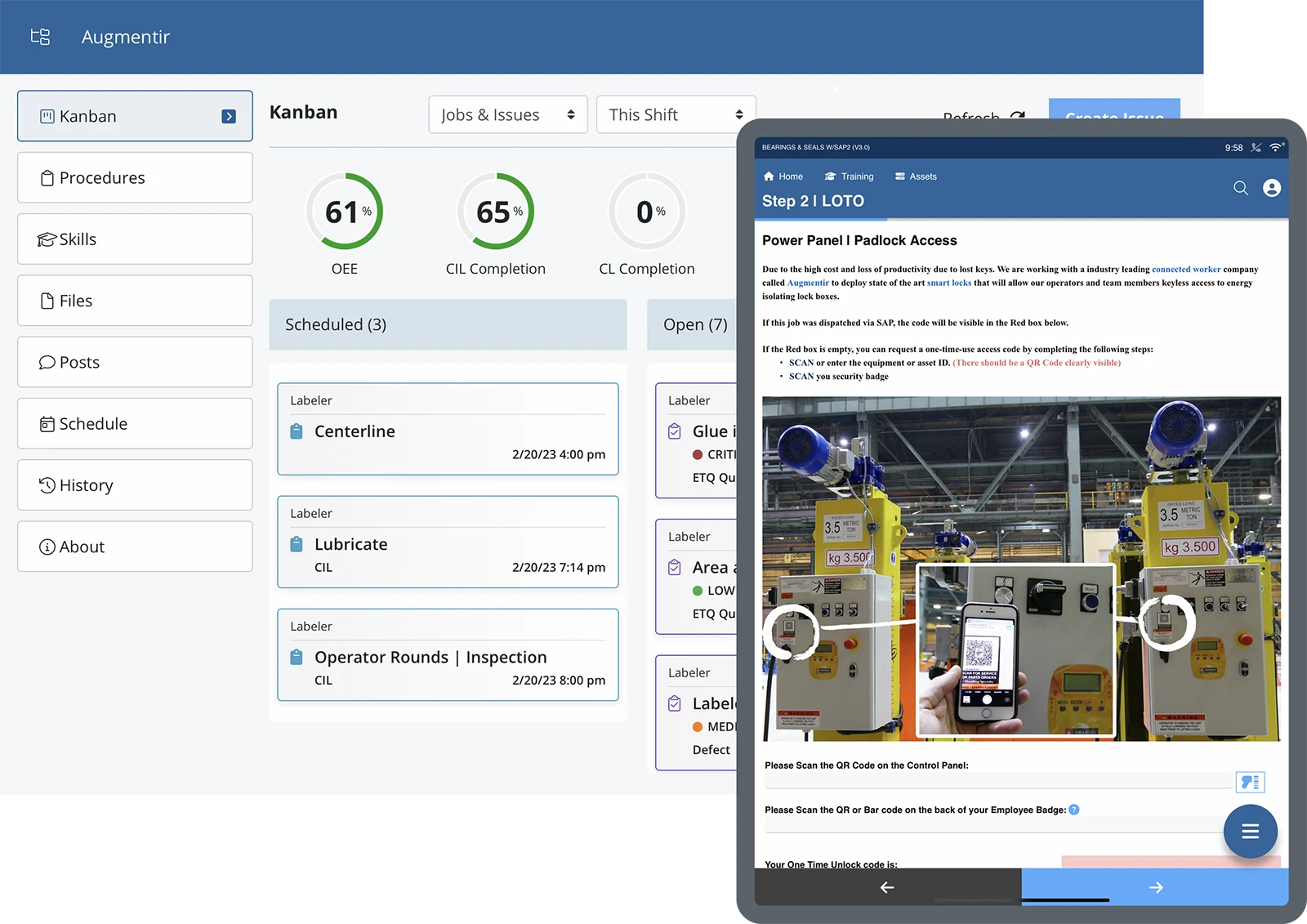

Digitizing and sustaining TPM with AI-powered connected worker tools

Connected worker platforms are digital software tools that can help standardize and improve the way operators perform maintenance tasks. They are used to improve communication, collaboration, guidance, and support for the operators.

Connected worker platforms are used to create, assign, and manage the maintenance tasks being done. Through a combination of digital work instructions and real-time collaboration tools, operators can independently complete maintenance tasks at peak performance.

Furthermore, connected worker solutions that are built on an AI foundation are also being used to support continuous improvement and lean initiatives in the workplace.

With the foundational elements of digitized SOPs and remote expert guidance in place, manufacturing companies can guide their operators with contextual information to help them perform jobs at peak efficiency and solve problems faster.

This also allows organizations to capture valuable data not just on the work that is performed, but also how workers are carrying out their jobs and what activities or interactions are contributing to the success or performance of certain jobs.

Interested in learning how Augmentir can help you digitize and sustain TPM within your organization? Get in touch with us for a free demo.

Frequently Asked Questions (FAQ)

What is Total Productive Maintenance (TPM)?

Total Productive Maintenance (TPM) is a proactive maintenance strategy that aims to maximize the effectiveness of equipment by involving all employees—from operators to management—in maintaining and improving manufacturing performance. TPM focuses on minimizing downtime, reducing defects, and ensuring equipment reliability.

What are the pillars of Total Productive Maintenance?

The core pillars of TPM typically include Autonomous Maintenance, Planned Maintenance, Quality Maintenance, Focused Improvement, Early Equipment Management, Training and Education, Safety/Environment, and TPM in Office Functions. These pillars drive continuous improvement and equipment effectiveness.

Why is TPM important in manufacturing?

TPM helps manufacturers reduce unplanned downtime, extend equipment life, improve product quality, and boost employee ownership of equipment performance. It aligns with lean manufacturing principles and supports operational excellence initiatives.

How does TPM improve equipment effectiveness?

TPM improves equipment effectiveness by targeting the six big losses: equipment failure, setup and adjustment, idling and minor stops, reduced speed, process defects, and reduced yield. This leads to higher Overall Equipment Effectiveness (OEE).

How can digital tools support TPM in manufacturing?

Digital tools—such as AI-powered connected worker platforms—support TPM by standardizing maintenance procedures, tracking real-time equipment data, enabling predictive maintenance, and empowering frontline workers with digital work instructions and collaboration tools.

What is the difference between TPM and preventive maintenance?

Preventive maintenance is a scheduled approach to servicing equipment before failure occurs. TPM goes further by involving the entire workforce in equipment care and focusing on continuous improvement, quality, and ownership.

How does Augmentir support Total Productive Maintenance?

Augmentir supports TPM through its AI-powered connected worker platform, which helps digitize and optimize maintenance workflows, improve workforce engagement, and capture critical operational data for continuous improvement.