Aprenda cómo mejorar el control y la garantía de calidad en la industria alimentaria con las soluciones digitales de Augmentir.

Seguir los procedimientos de control de calidad (CC) y aseguramiento de la calidad en la industria alimentaria es fundamental para garantizar la calidad del producto y la satisfacción del consumidor. Los consumidores actuales exigen productos seguros y confiables que cumplan con todos los protocolos de inspección de calidad. Lo último que desea es que un producto sea retirado del mercado debido a posibles riesgos para la salud.

De acuerdo a Fabricación de alimentosEl control de calidad es uno de los aspectos más importantes de la industria de alimentos y bebidas. Los fabricantes que realizan inspecciones rutinarias de sus productos durante cada etapa del proceso de producción aumentan significativamente sus posibilidades de entregar productos libres de riesgos para la salud y responsabilidades. Pero además de evitar estas preocupaciones, estandarización y digitalización de la calidad Los procedimientos benefician a toda la operación.

En definitiva, prevenir y detectar problemas de calidad puede mejorar la calidad del producto, reducir el desperdicio, aumentar las ganancias, mejorar la reputación de la marca y evitar desastres mediáticos o relacionados con la seguridad alimentaria. Aprenda más sobre el control de calidad y la garantía en la industria alimentaria y cómo mejorarlos mientras analizamos:

- Tipos de medidas de control de calidad a tomar

- Cómo mejorar los procedimientos de control de calidad y aseguramiento en la producción de alimentos

- Cómo Augmentir ayuda con el control y aseguramiento de la calidad

Tipos de medidas de control de calidad a tomar

Existen ciertas medidas de control de calidad que puede implementar para garantizar que todos los productos cumplan con los estándares de calidad, desde inspecciones periódicas de las máquinas hasta la capacitación de los trabajadores. Estas medidas se dividen en dos categorías generales: preventivas y reactivas.

Control de calidad preventivo (proactivo)Minimizar el número de deficiencias comienza con la implementación de soluciones preventivas de control de calidad. Cuando los trabajadores pueden detectar errores antes de que ocurran, previenen defectos en los productos. Las medidas preventivas de control de calidad deben implementarse de forma rutinaria y pueden abarcar desde la inspección de máquinas y equipos hasta la capacitación de los empleados. Al proporcionar a los trabajadores información y orientación en tiempo real a través de soluciones móviles y conectadas, los fabricantes les permiten tomar mejores decisiones sobre la calidad de los productos, reduciendo el riesgo de errores e identificando posibles problemas de calidad antes de que los productos se envíen a los clientes, reduciendo así el riesgo de retiradas de productos y preservando la confianza del consumidor.

Control de calidad reactivoDetectar todos los defectos en la planta de producción es casi imposible, incluso con las estrategias más infalibles. Por eso, crear un plan de acción antes de una crisis puede ayudar a resolver los problemas de calidad en cuanto surgen.

Lo que incluya en su plan dependerá de los posibles problemas. Por ejemplo, puede incluir instrucciones específicas sobre qué hacer si la maquinaria se avería o se detiene inesperadamente. Es fundamental recopilar todos los datos en esta etapa. Analizarlos puede ayudarle a mejorar el control de calidad preventivo en el futuro para garantizar que los mismos problemas no se repitan.

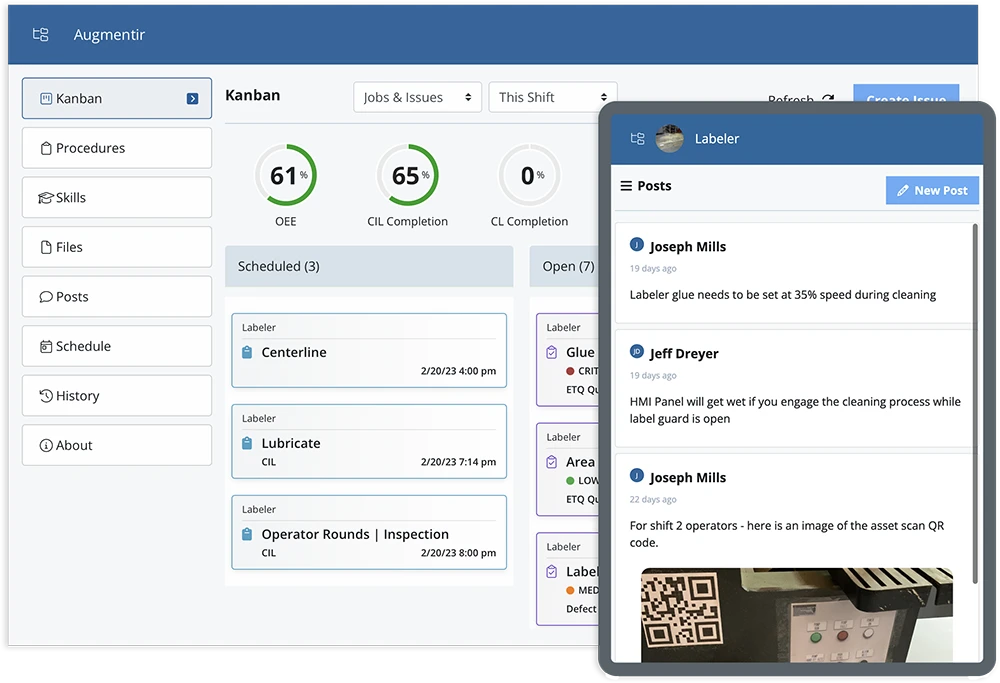

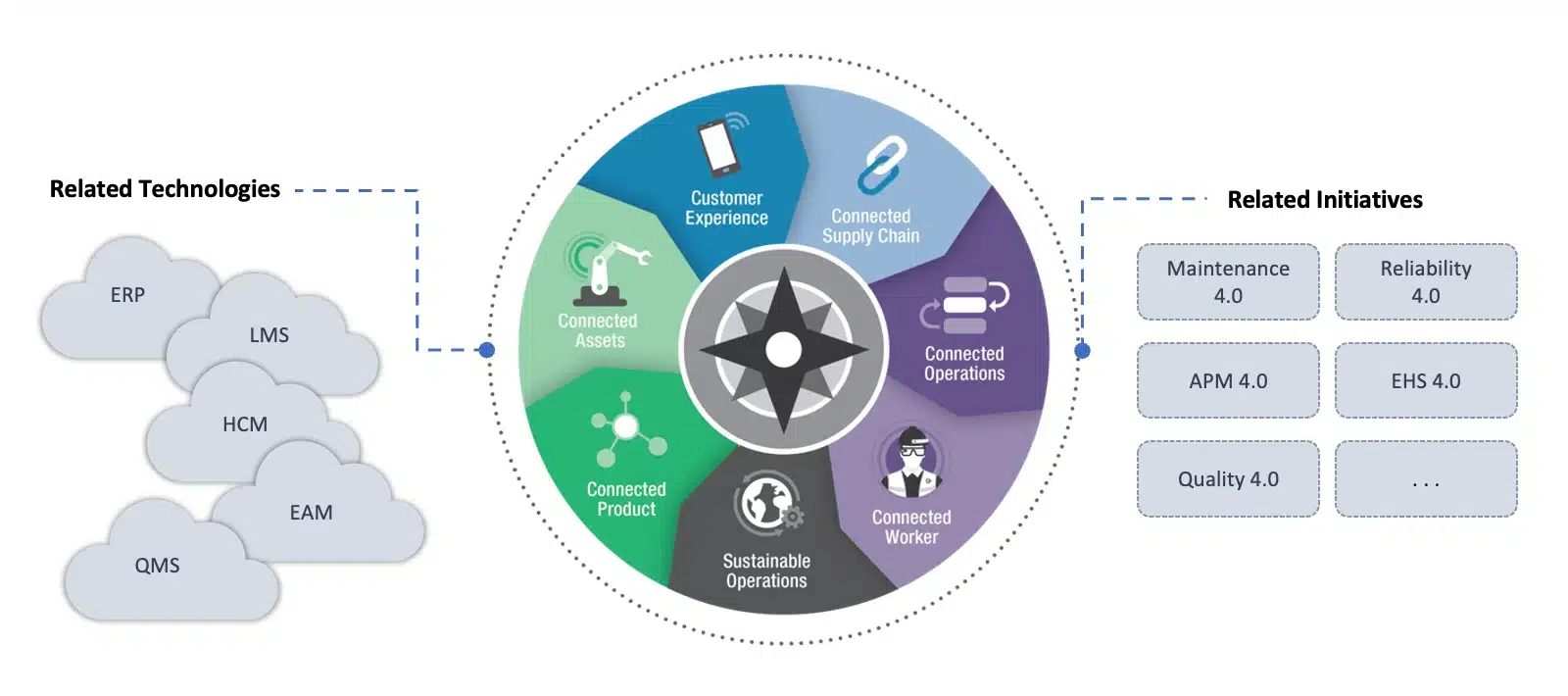

Al utilizar inteligencia artificial y tecnologías digitales modernas, las empresas pueden conectar, involucrar y empoderar a los trabajadores de primera línea para impulsar mejoras de calidad, resolver problemas de calidad más rápidamente y compartir información oportuna con equipos de toda la cadena de valor.

Tenga en cuenta que el control de calidad en la industria alimentaria debe formar parte de cada proceso de fabricación, desde la concepción y el desarrollo del producto hasta la producción y la entrega. Los problemas pueden surgir en cualquier momento, por lo que es fundamental seguir los protocolos en cada etapa de la producción para evitar incluso el más mínimo error.

Todos los trabajadores también deben respetar los protocolos de control de calidad y garantía en sus tareas diarias para garantizar la mejora continua del producto.

Una mejor organización de los equipos también puede ayudar a los trabajadores a comprender cómo la acción de uno afecta al otro para resolver posibles problemas. Esta es otra ventaja de integrar la jerarquía de activos con una solución para trabajadores conectados. En resumen, unas jerarquías sólidas son una base sólida para una gestión adecuada del mantenimiento y la fiabilidad.

Cómo mejorar los procedimientos de control de calidad y aseguramiento en la producción de alimentos

Los procedimientos eficaces de control y aseguramiento de la calidad evitan que productos alimenticios defectuosos lleguen a tiendas de comestibles y hogares. Por eso, los fabricantes deben documentar la calidad de sus productos en cada etapa del proceso operativo. Estrategias como los planes de calidad a la primera (FTQ), o "first time right", junto con soluciones inteligentes y conectadas, ayudan a reducir las deficiencias de los productos y a aumentar la satisfacción del cliente.

Las empresas manufactureras de la industria alimentaria deben cumplir con los requisitos específicos establecidos por la Administración de Alimentos y Medicamentos (FDA), el sistema de Buenas Prácticas de Manufactura (BPM) y el Análisis de Peligros y Puntos Críticos de Control (APPCC). Las directrices establecidas por estos organismos reguladores pueden brindar a las empresas una mejor idea de cómo deben ser sus procesos y qué datos deben recopilar y reportar.

Se deben recopilar datos para los procesos de producción en tiempo real. Estos varían según el producto, pero pueden abarcar desde el enfriamiento y el procesamiento térmico hasta el análisis de toxinas metálicas y otros depósitos químicos en las materias primas.

Los siguientes pasos proporcionan una hoja de ruta sobre cómo mejorar el control de calidad en la industria alimentaria.

Paso 1: Consigue los ingredientes correctos

Una cadena de montaje exitosa comienza con la búsqueda y el uso de los ingredientes correctos. Algunos aspectos a considerar al elegir los ingredientes: dónde se obtuvo la materia prima, cuándo y en qué estado se encuentra.

Paso 2: Incluya una lista de proveedores aprobados

Asegúrese de que cada ingrediente cuente con una lista de proveedores aprobados. Una buena regla general es incluir tres proveedores por ingrediente y registrar el ingrediente con el nombre, la dirección y el código de cada proveedor en la lista. Cuanta más información incluya, mejor. Contar con una lista de proveedores aprobados garantiza que todas las partes sean debidamente verificadas por la empresa fabricante y cumplan con sus requisitos de calidad y distribución.

Paso 3: Documentar la creación de productos y recetas

Documentar la elaboración de cada alimento y su receta ayuda a establecer los estándares de calidad de los productos terminados. Esta documentación también puede ser útil para mejorar el desarrollo de productos en el futuro. El documento debe incluir los tipos de ingredientes utilizados, sus códigos, el rendimiento del lote, la fórmula porcentual y más.

Paso 4: Procedimientos de producción del catálogo

También es fundamental registrar todos los detalles de un proceso de producción, incluyendo cómo deben entregarse los materiales, las condiciones apropiadas para almacenar los alimentos, en qué orden debe añadirse cada ingrediente al lote, qué herramientas se necesitan y quién está a cargo de cada tarea.

Tenga en cuenta que este paso es diferente de documentar el desarrollo del producto y la receta, ya que incluye las instrucciones para cada procedimiento. Por ejemplo, se le puede pedir a un trabajador que precaliente el horno a una temperatura determinada para garantizar que la comida esté lista para su distribución al cliente.

Paso 4: Registrar procesos en tiempo real

Los operadores de máquinas deben registrar en tiempo real cada detalle de la creación de los productos durante la producción. Esto puede incluir factores como el tamaño del producto, el peso, la fecha de caducidad, el estado del equipo, etc.

Paso 5: Digitalizar los procesos de aseguramiento e inspección

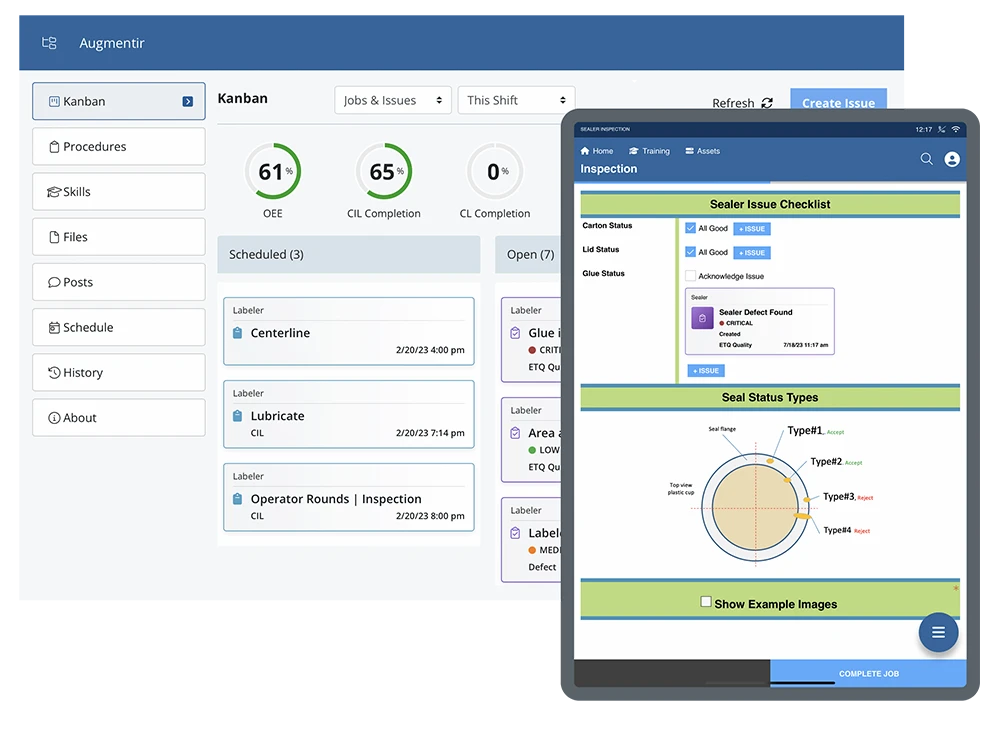

La IA y los sistemas de trabajadores inteligentes y conectados ayudan a digitalizar y vincular las inspecciones y otros procedimientos de control de calidad. Esto crea una capa adicional de defensa, protegiendo a los clientes y previniendo problemas de calidad antes de que afecten la producción.

Cómo Augmentir ayuda con el control y aseguramiento de la calidad

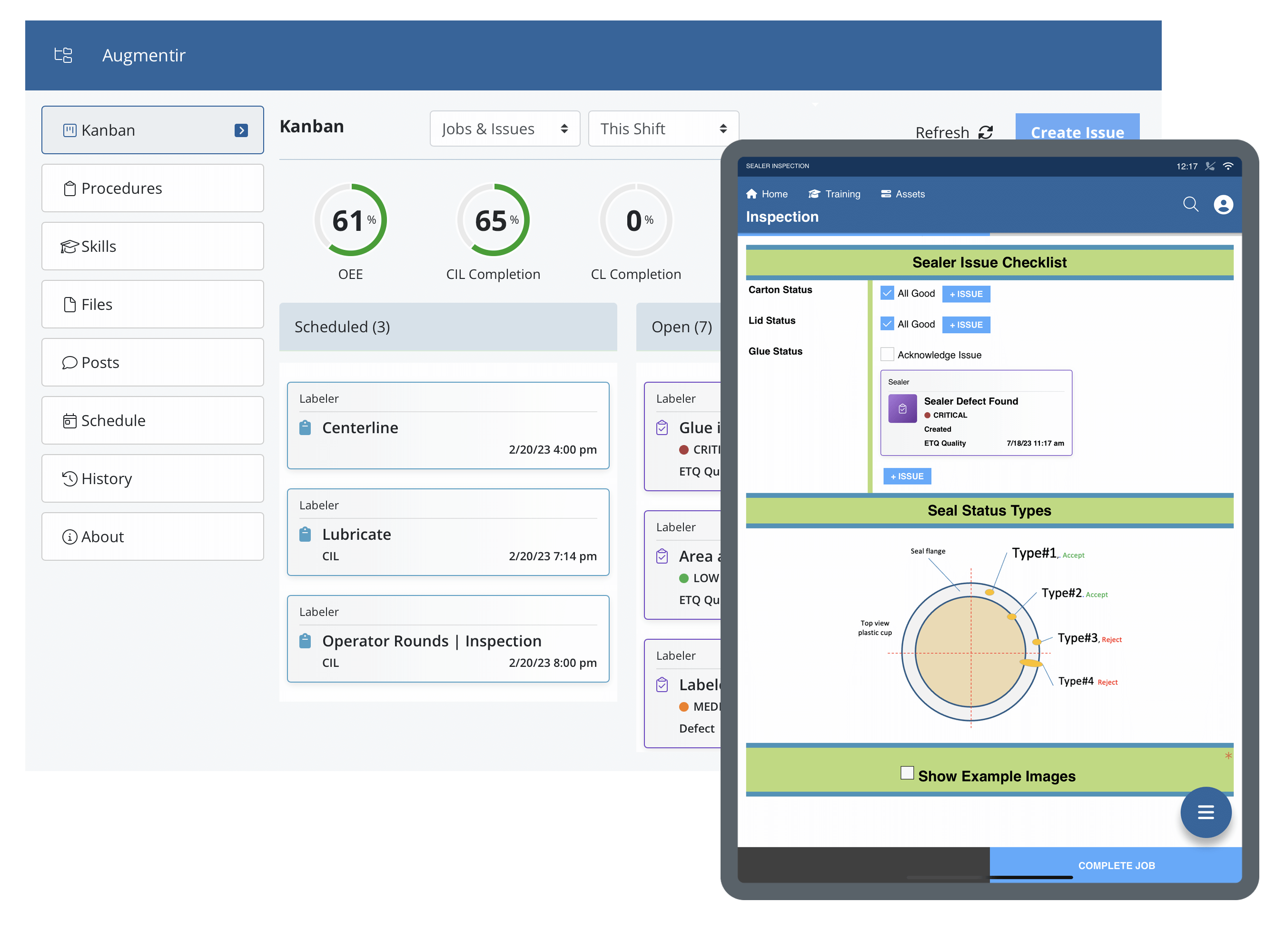

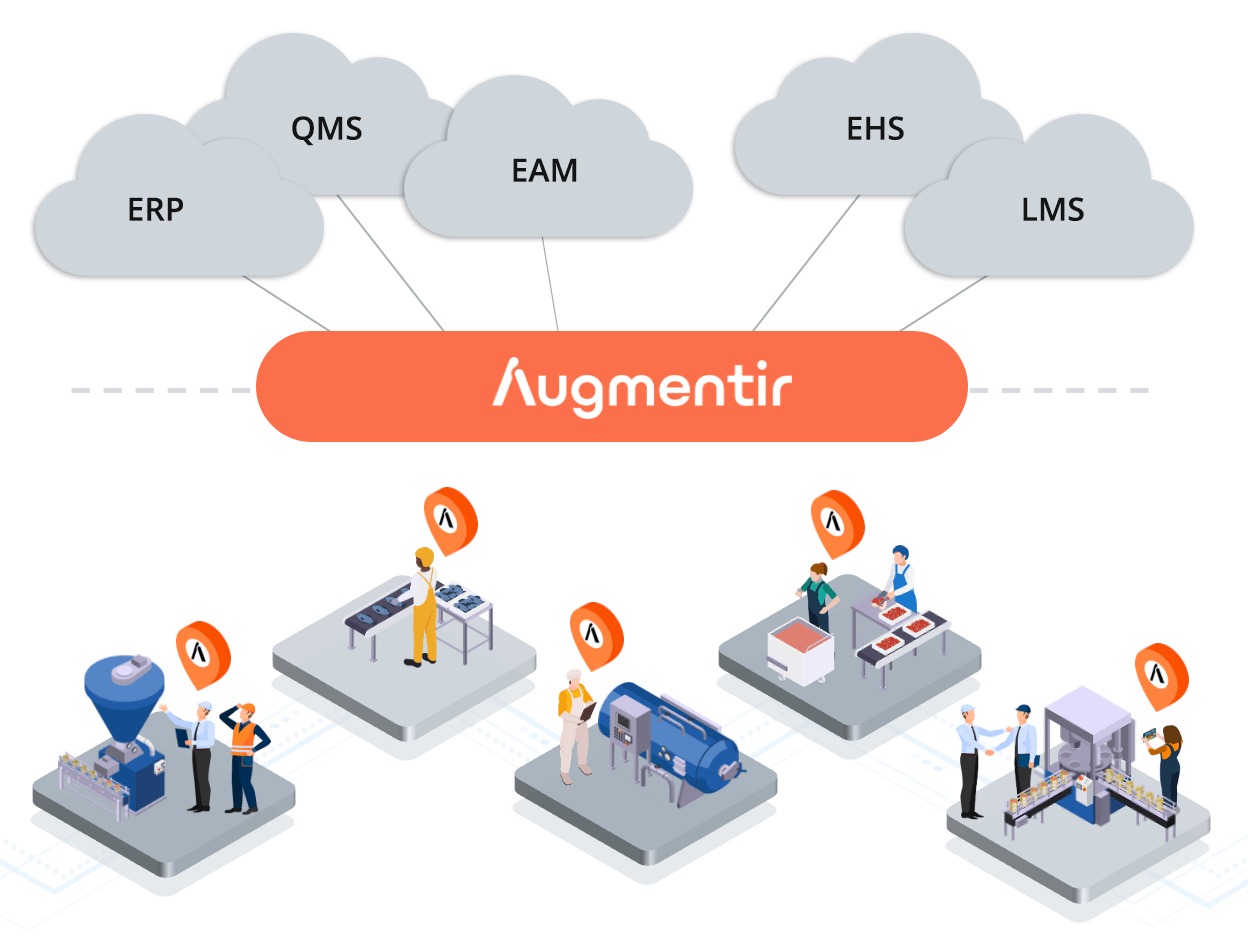

Augmentir ofrece una forma más inteligente de mejorar el control de calidad en la industria alimentaria mediante la estandarización y optimización eficaz de los procedimientos de control de calidad e inspección para todos los trabajadores de primera línea. Con nuestras soluciones inteligentes y conectadas, junto con software basado en IA, los fabricantes de alimentos han mejorado el control y el aseguramiento de la calidad mediante:

- Seguimiento y análisis de datos para identificar tendencias y oportunidades de mejora

- Reducir el error humano en las inspecciones mediante la estandarización y mejora de los procedimientos y procesos de capacitación

- Transformar a los trabajadores conectados en sensores humanos que puedan abordar de forma proactiva los eventos de calidad y seguridad que surgen durante las operaciones de fabricación.

Nuestras soluciones para trabajadores conectados impulsadas por IA brindan instrucciones de trabajo digitales para ayudar a los empleados a realizar mejores controles de inspección y reducir la cantidad de errores de producción y reelaboración.

Estas soluciones personalizadas también incluyen:

- Procedimientos operativos estándar digitales Procedimientos Operativos Estándar (POE) para completar las tareas de la línea de montaje. Estas instrucciones paso a paso pueden mejorar considerablemente la eficiencia del flujo de trabajo, aumentar el cumplimiento normativo y reducir los errores en el taller.

- Flujos de trabajo digitales que convierten sus procesos en papel en instrucciones de trabajo digitales y las personalizan según las necesidades de cada trabajador.

- Mejore la trazabilidad del producto para reducir el tiempo de configuración del equipo, reducir las inconsistencias en el proceso y satisfacer mejor las expectativas del cliente. Nuestras instrucciones digitales le ayudan a rastrear fácilmente los materiales desde la cadena de suministro, el inventario y en cada proceso de producción.

Si está interesado en saber por qué las empresas eligen Augmentir para ayudar a mejorar sus procesos de control y garantía de calidad, consulte nuestra casos de uso de calidad – o comuníquese para programar una demostración en vivo.