Discover how Augmentir’s AI transforms the connected worker journey—boosting training, productivity, and continuous improvement across operations.

In an era defined by digital transformation and workforce disruption, industrial companies are reimagining how they support their frontline teams. At the heart of this shift is the Connected Worker—a worker empowered by technology to perform safely, efficiently, and with confidence.

But enabling a connected workforce requires more than just digitizing procedures or implementing standalone tools. It demands intelligence embedded throughout the entire worker lifecycle.

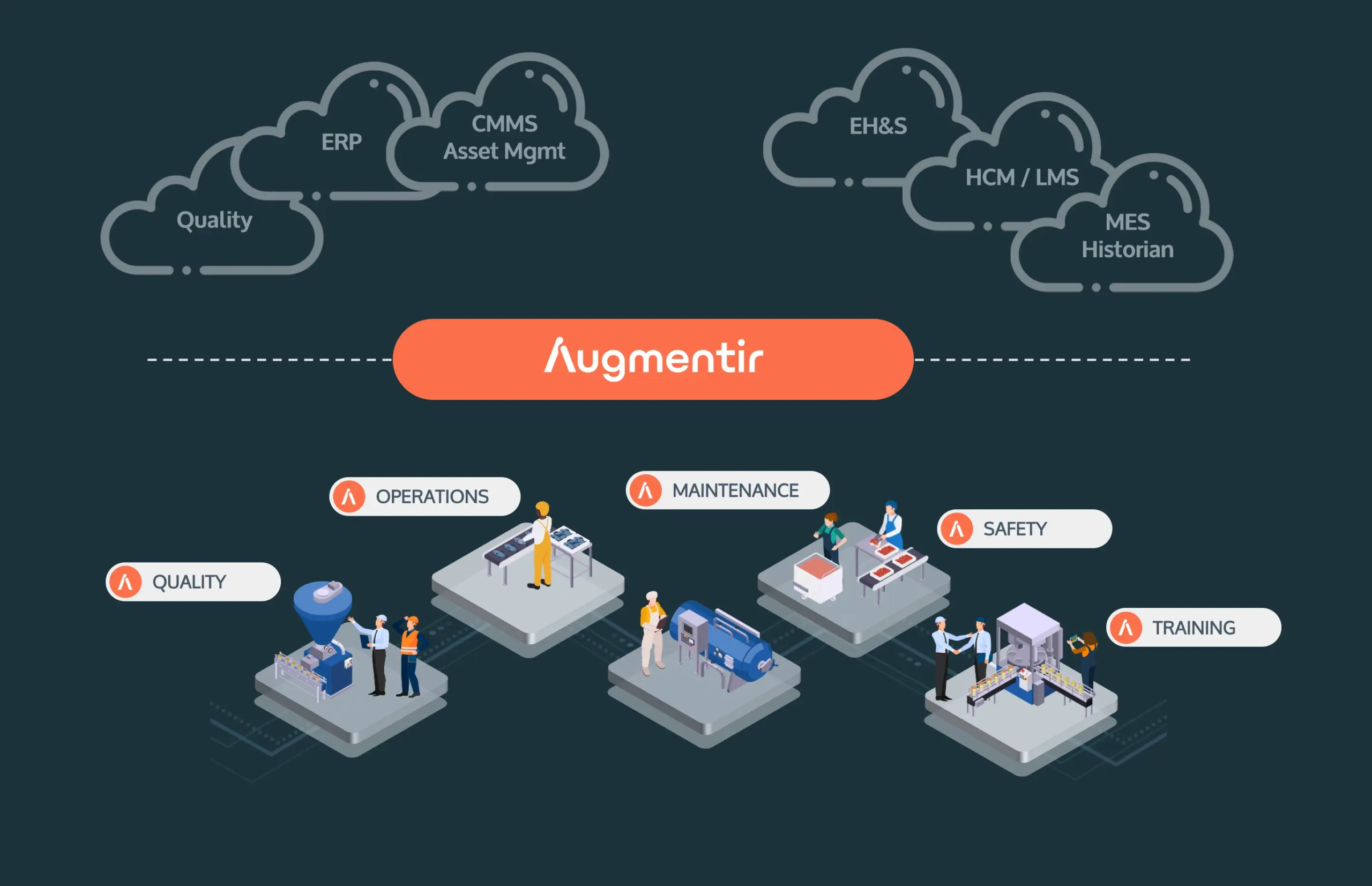

That’s where Augmentir’s AI-powered Connected Worker platform shines. By infusing intelligence into every phase of the connected worker journey—from content creation to onboarding, daily operations, and continuous improvement—Augmentir delivers measurable gains in productivity, safety, and workforce engagement.

A Framework for Transformation: The Connected Worker Journey

The Connected Worker Journey consists of four critical, interrelated stages:

- Content Conversion & Creation

- Worker Onboarding & Training

- Operational Excellence

- Continuous Improvement

At each phase, Augmentir’s embedded AI transforms outdated processes into intelligent workflows—helping organizations streamline deployment, scale training, and drive continuous value.

Let’s explore how.

1. Content Conversion & Creation

Laying the Foundation for Frontline Intelligence

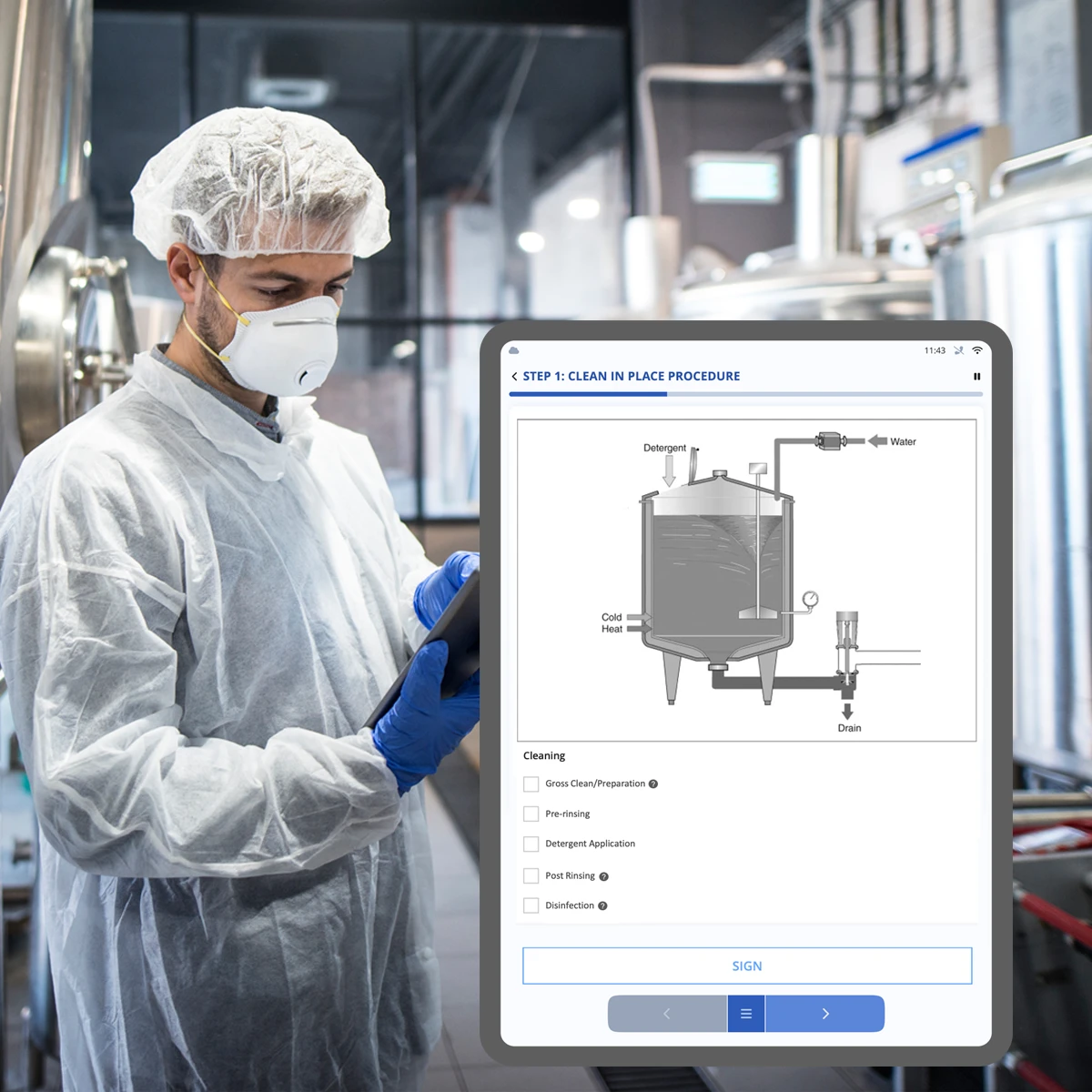

Deploying modern Connected Worker software delivers ROI through a combination of features that support data collection, compliance, auditability, and data visibility for enabling continuous improvement.

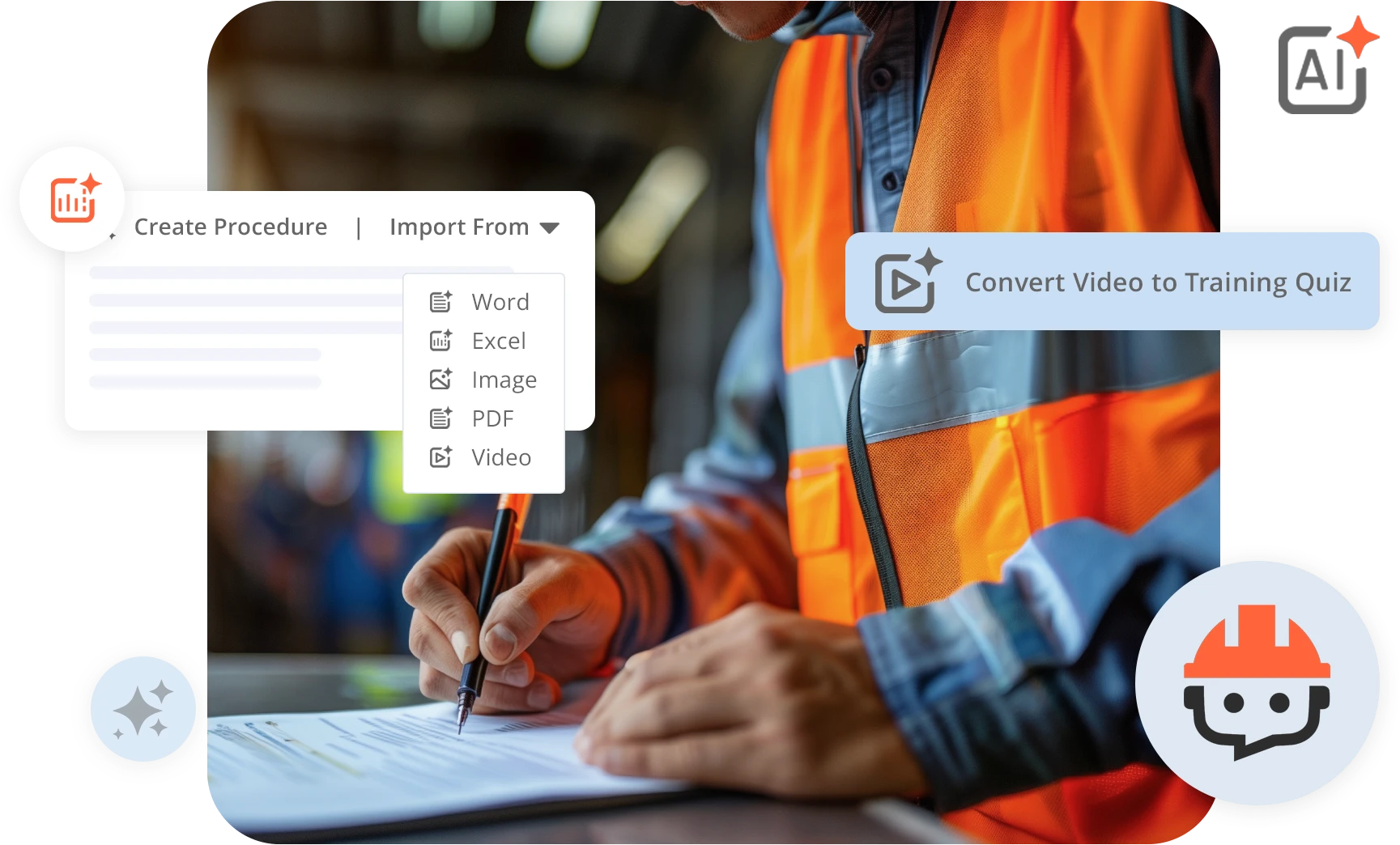

For all companies, the Connected Worker journey begins with transforming legacy documents—SOPs, work instructions, training manuals, checklists, videos, and more—into structured, digital-ready formats that support the requirements above.

This means converting thousands (to tens of thousands) of legacy documents trapped in PDFs, Word docs, Excel files, Powerpoints, videos, and proprietary systems, all while trying to preserve their structure, intent, and compliance relevance. In the past, this process was typically manual, becoming one of the costliest and longest phases in the Connected Worker journey.

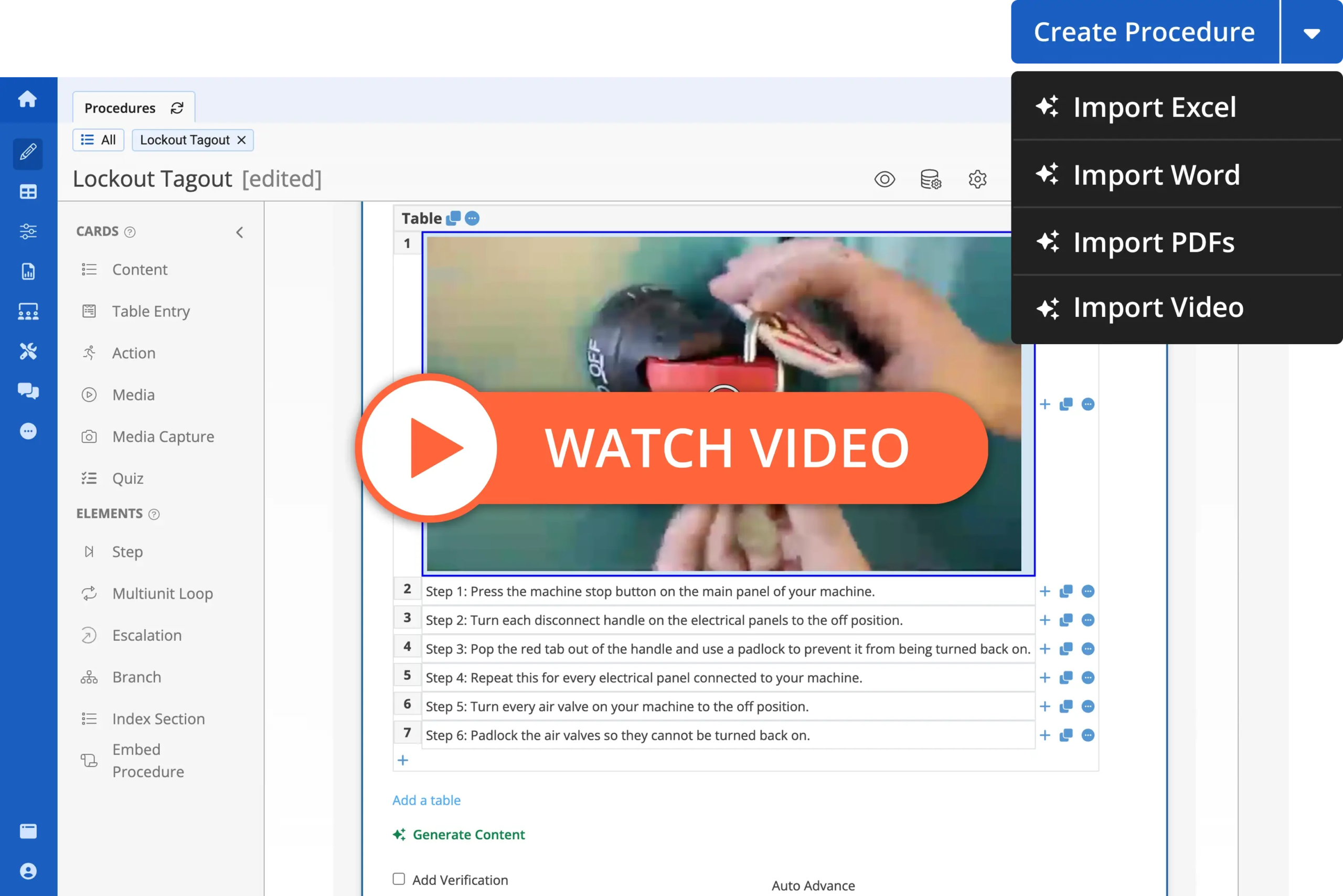

Augmentir, even prior to Generative AI (GenAI) era, has been a pioneer in providing tools to significantly reduce this effort even while meeting the three fundamental requirements of conversion:

- Maintain the integrity of the form design: the format of legacy documents did not arrive by chance, rather they were the result of serious considerations for human factors. Arbitrarily changing these designs results in significant retraining of the frontline workforce, loss of usability, and potentially, significant operational qualification costs in regulated use cases.

- Simplify the addition of data collection: make incorporating data collection throughout the form simple, efficient, and smart. Data collection offers the opportunity for smart validation, data driven conditional workflows, escalation, and continuous improvement.

- Embed granular event tracking: Connected Worker ROI depends on the ability to provide compliance and auditability, which is enabled through granular event tracking. Additionally, continuous improvement relies on AI-optimized data from digital time and motion studies, which is automatically captured and processed through Augmentir’s patented True Productivity™ algorithm.

Today, general purpose GenAI tools offer the tantalizing vision that they can transform this process by accelerating the conversion of legacy digital content into, structured content suitable for Connected Worker use cases. There are examples where GenAI has been demonstrated as a general purpose solution to performing these conversions. Unfortunately, in each of the examples that Augmentir has reviewed, these tools met none of the fundamental conversion requirements.

Included in Augmentir’s suite of Industrial GenAI tools, is Augie™ Content Assistant, which is purpose-built for Connected Worker use cases. Augie has been built with domain specific tooling which, when combined with advanced large language models (LLMs), delivers intelligent content that meets the foundational requirements of the Connected Worker space.

With the Augie Content Assistant, Augmentir turns the challenge of content digitization into a fast, AI-driven advantage:

- 91% faster content conversion: What used to take hours now takes just minutes to convert a single document. When scaled across an organization’s entire repository of SOPs, work instructions, training materials, and more, this reduces the overall content conversion effort from months down to days.

- Multi-format compatibility: Word, Excel, PowerPoint, PDFs, images, and narrated videos are seamlessly converted into native Augmentir content, complete with data collection and high resolution embedded event tracking.

- Fidelity preserved: Structure, logic, and intent are maintained through AI-optimized prompts. This ensures that converted content mirrors the original format workers are familiar with—helping reduce change fatigue and making it easier for frontline teams to adopt digital workflows with minimal disruption.

- Instant translation: Localize content quickly without compromising compliance or clarity.

This is more than digitization—it’s intelligent transformation that enables data collection, auditability, and operational scalability from day one.

2. Worker Onboarding & Training

Adaptive Support That Accelerates Learning

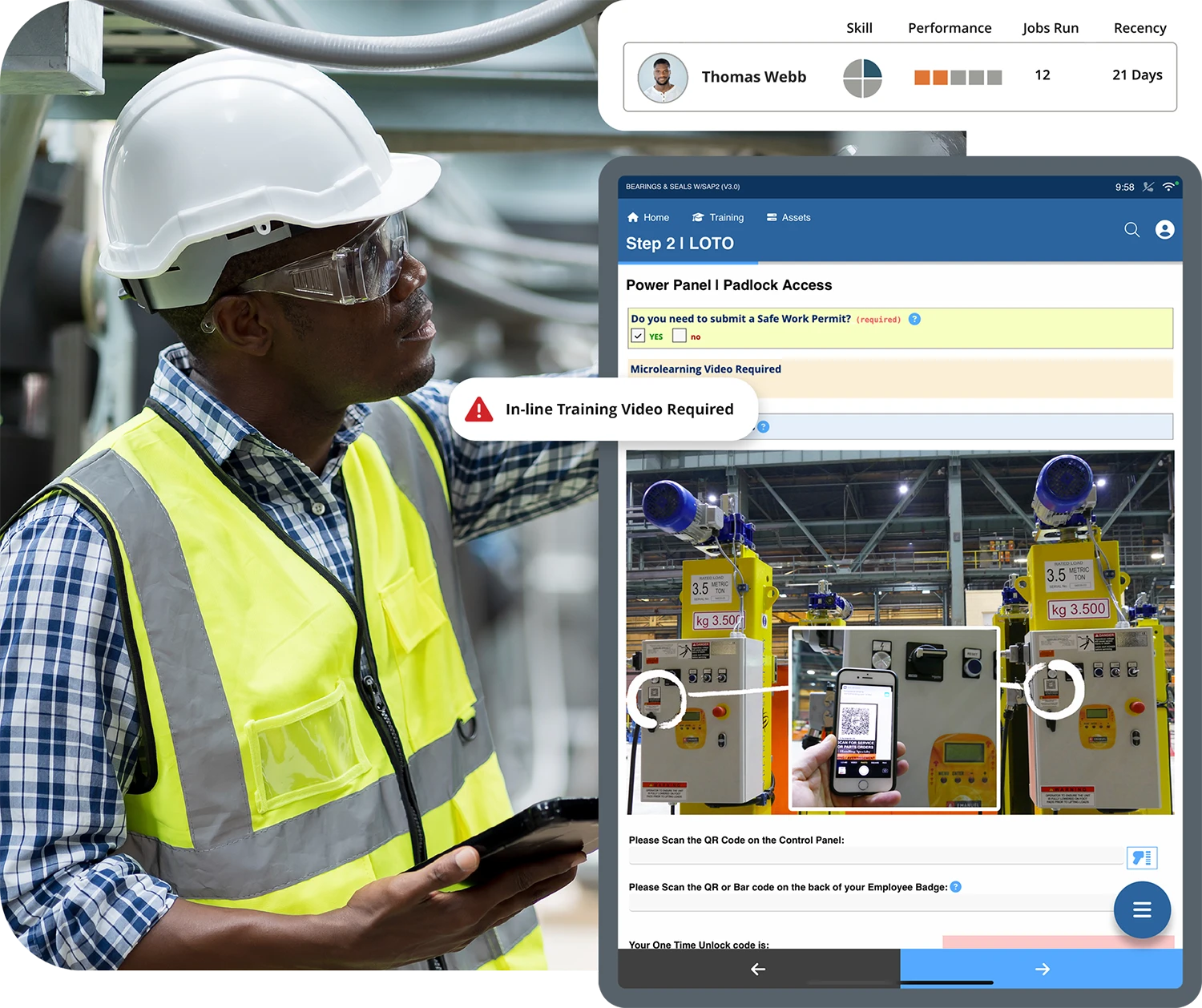

Once your content foundation is in place, the next challenge is onboarding and upskilling your workforce. Traditional methods are static, generic, and fail to reflect real-time needs.

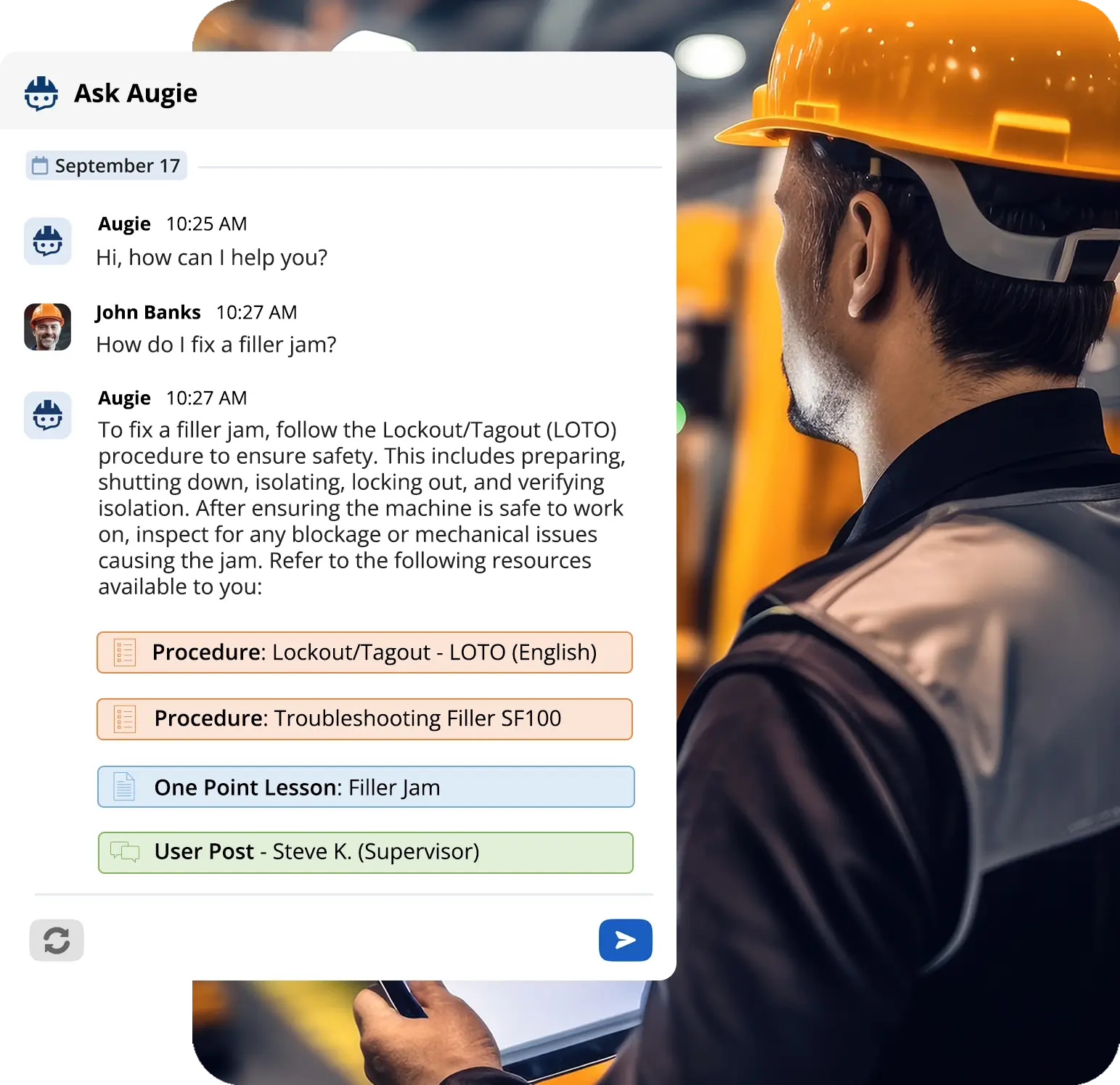

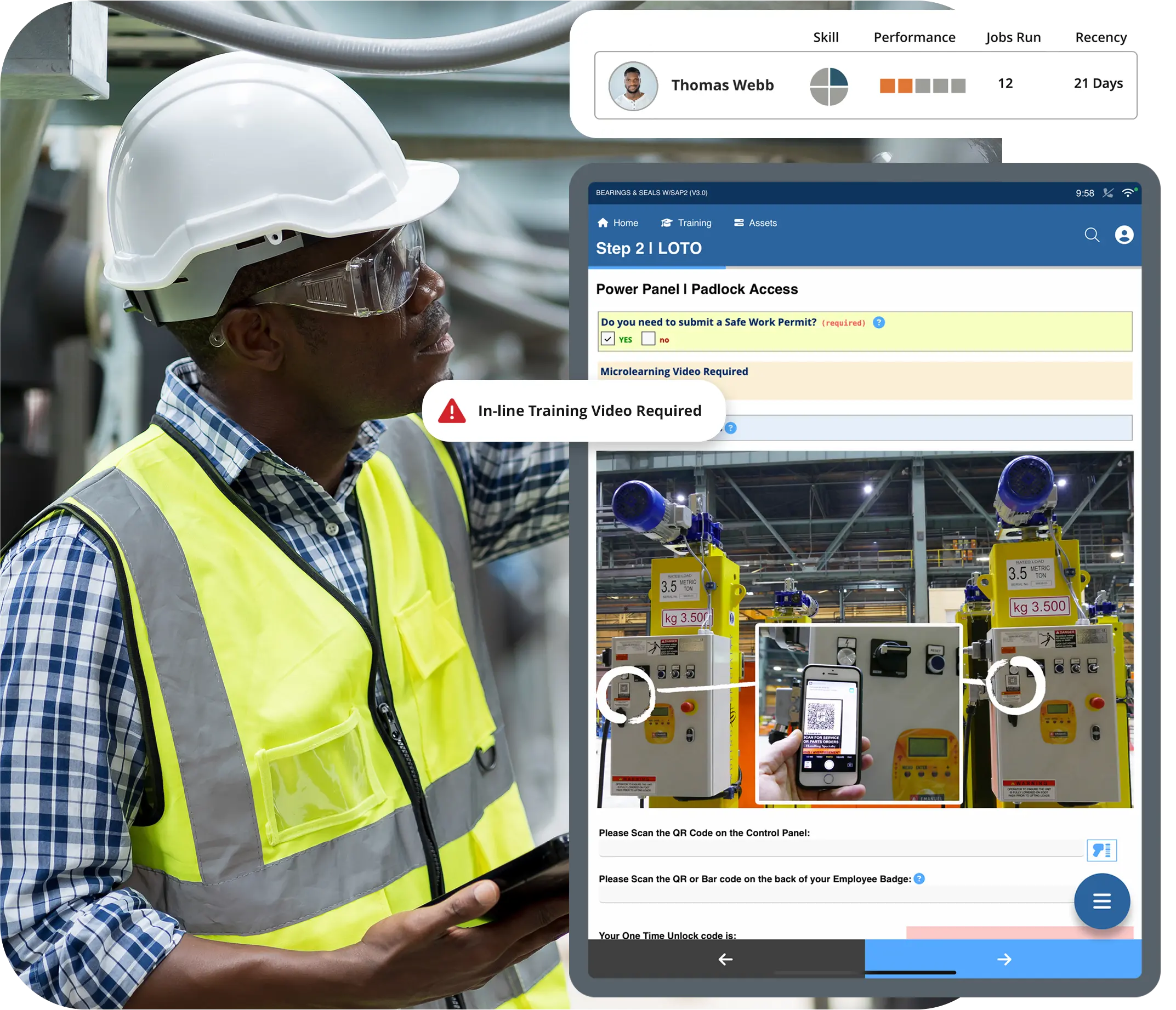

With Augmentir’s Augie Training Assistant and AI Agents, onboarding becomes a personalized, dynamic experience:

- Tailored workflows: New hires are guided step-by-step based on their role, skill level, and assigned tasks.

- Training in the flow of work: Instruction happens in real time, with guidance delivered during actual task execution.

- Digital assistants ensure worker safety and compliance: Workers have natural language access to digital assistants to guide and support them while they work—enforcing safety, quality, and best practices.

- Continuous adaptation: Augmentir’s True Opportunity™ AI continuously monitors skilling and reskilling performance and adjusts training content based on worker feedback and progression.

This ensures faster ramp-up times, better comprehension, and more confident employees from day one.

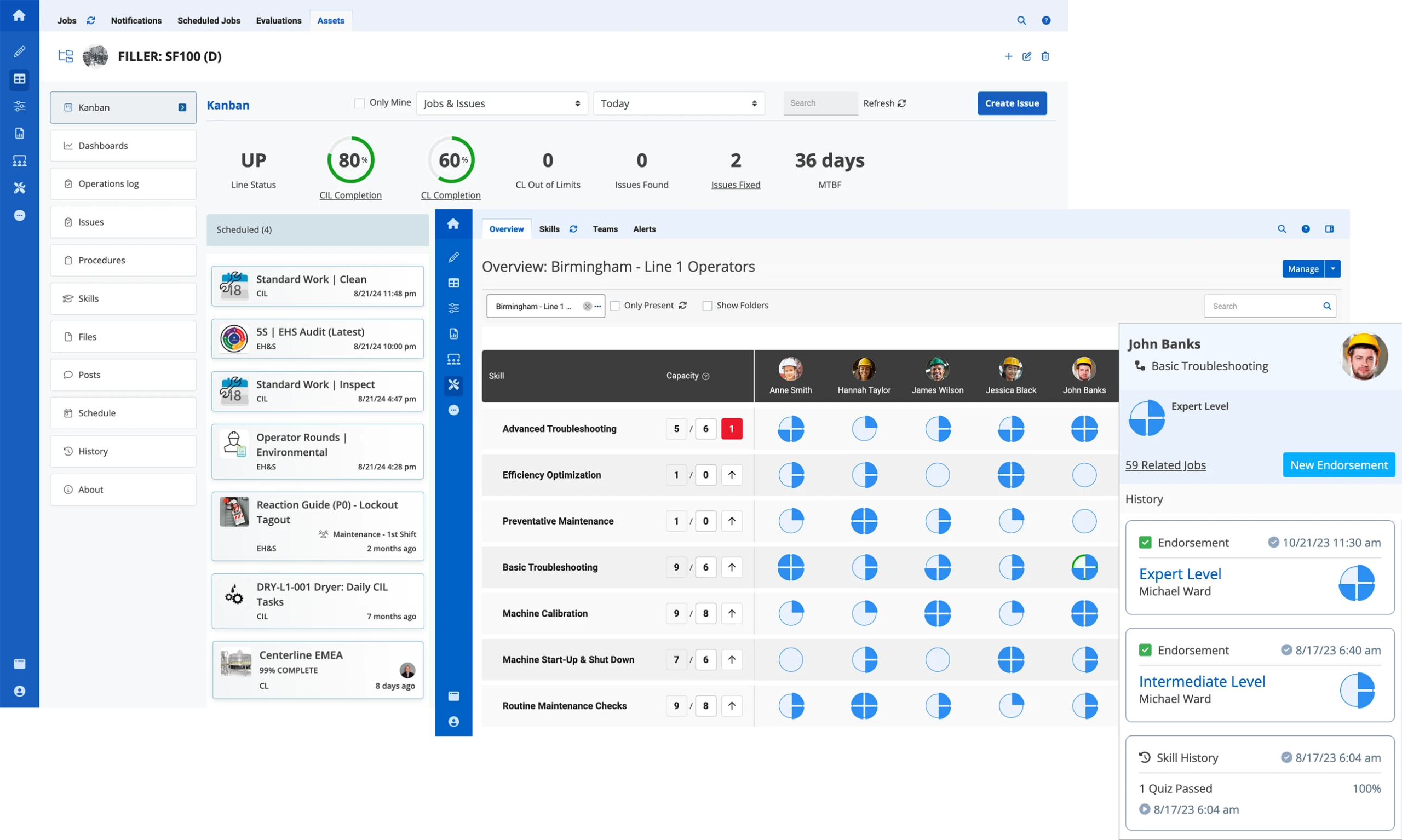

3. Operational Excellence

Smarter, Safer, More Productive Frontline Work

With your workforce engaged and trained, the next step is supporting them during everyday operations. Here, Augmentir’s AI becomes a digital copilot—delivering real-time, personalized support in the flow of work.

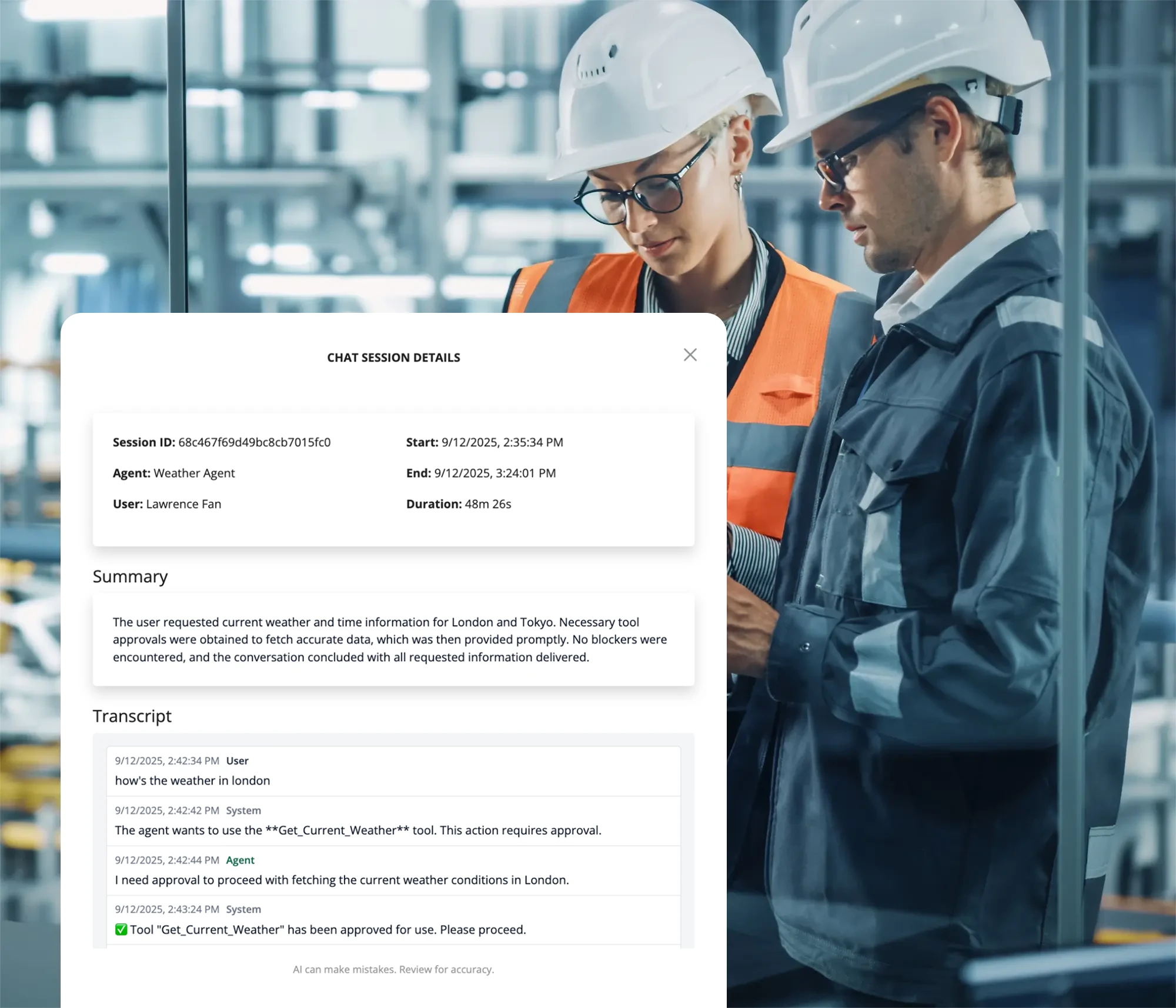

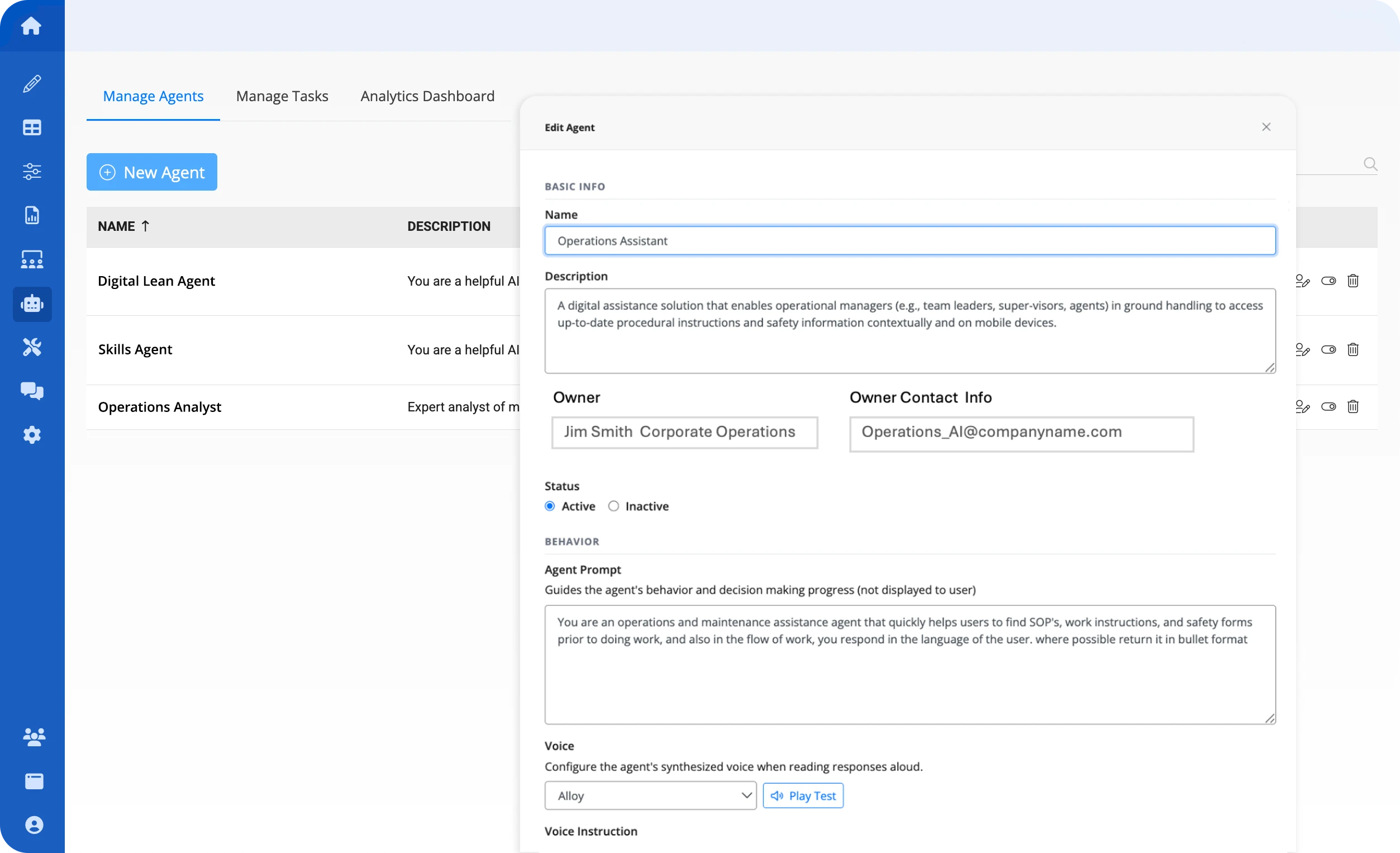

With your workforce engaged and trained, the next step is supporting them during everyday operations. Here, Augie Work Assistant, which is fully customizable and extensible by customers, becomes a role-specific digital copilot—delivering real-time, personalized support in the flow of work.

Key capabilities include:

- Task-specific guidance: Augie delivers insight tailored to the person, the task, and the real-time conditions.

- Role-Specific Digital SME: The Augie Work Assistant can be configured at the role level, provides always-on expertise that is tuned to needs to each person in each role—answering questions, flagging issues, and improving accuracy.

- AI-powered integration: Embedded AI APIs automate documentation, resolve issues in real time, and enable intelligent quality checks.

The result? Fewer errors, faster resolutions, and safer, more confident workers.

4. Continuous Improvement

Closing the Loop with Actionable Insights

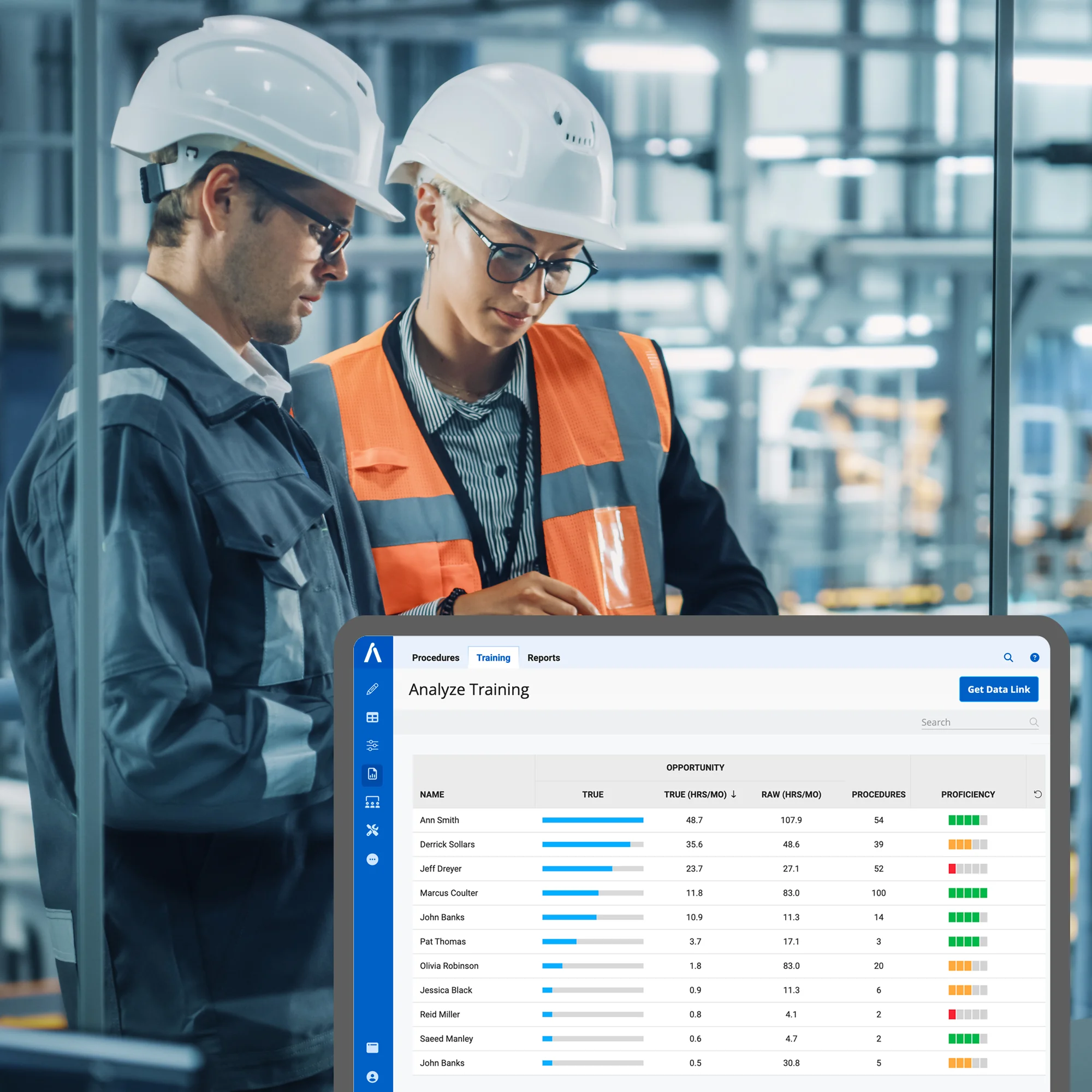

Continuous improvement (CI) doesn’t just happen—it requires the right data, insights, and tools to identify what matters most. Augmentir empowers teams to move from guesswork to precision by surfacing opportunities directly from real-world operations.

AI-powered tools include:

- True Proficiency: Aligns training and performance data to uncover skill gaps and enhance learning programs.

- True Opportunity: Pinpoints the highest-impact areas for improving quality, productivity, and safety.

- Augie Data Assistant: Enables natural-language queries to quickly reveal trends, inefficiencies, or outliers.

- Augie Content Assistant: Capture & Convert tribal knowledge embedded in informal collaboration into formal, reusable SOPs.

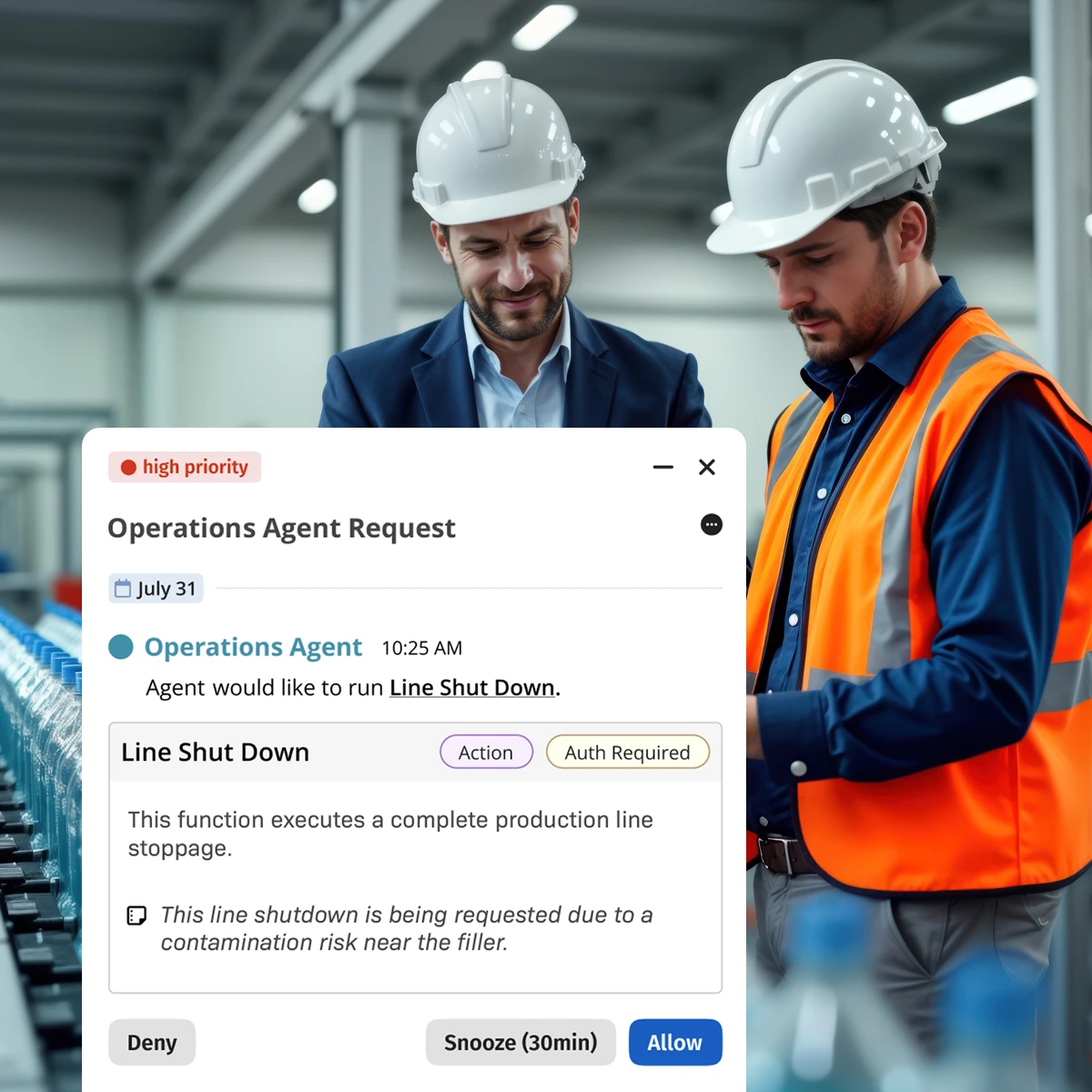

- Augie Autonomous Agents: Automate repetitive tasks, monitor KPIs, and trigger proactive CI actions.

Together, these tools ensure that continuous improvement isn’t a periodic initiative—it’s built into the fabric of daily operations.

AI That Delivers Real-World Value

Augmentir’s AI doesn’t just digitize work—it reimagines it. By embedding intelligence throughout the entire Connected Worker Journey, the platform empowers frontline teams to:

- Onboard faster

- Work safer and smarter

- Learn continuously

- Drive real business outcomes

With Augmentir, companies move beyond digital transformation toward AI-driven workforce transformation—turning every worker into a connected, empowered, and continuously improving contributor to operational excellence.