Learn how to track employee skills in manufacturing and discover modern approaches to effective skills tracking.

In today’s manufacturing environment, it is daunting and time-consuming to keep track of employee skill levels across the many different job tasks. With the constantly accelerating rate of turnover in the workforce, Excel or paper-based skills tracking in manufacturing has become obsolete.

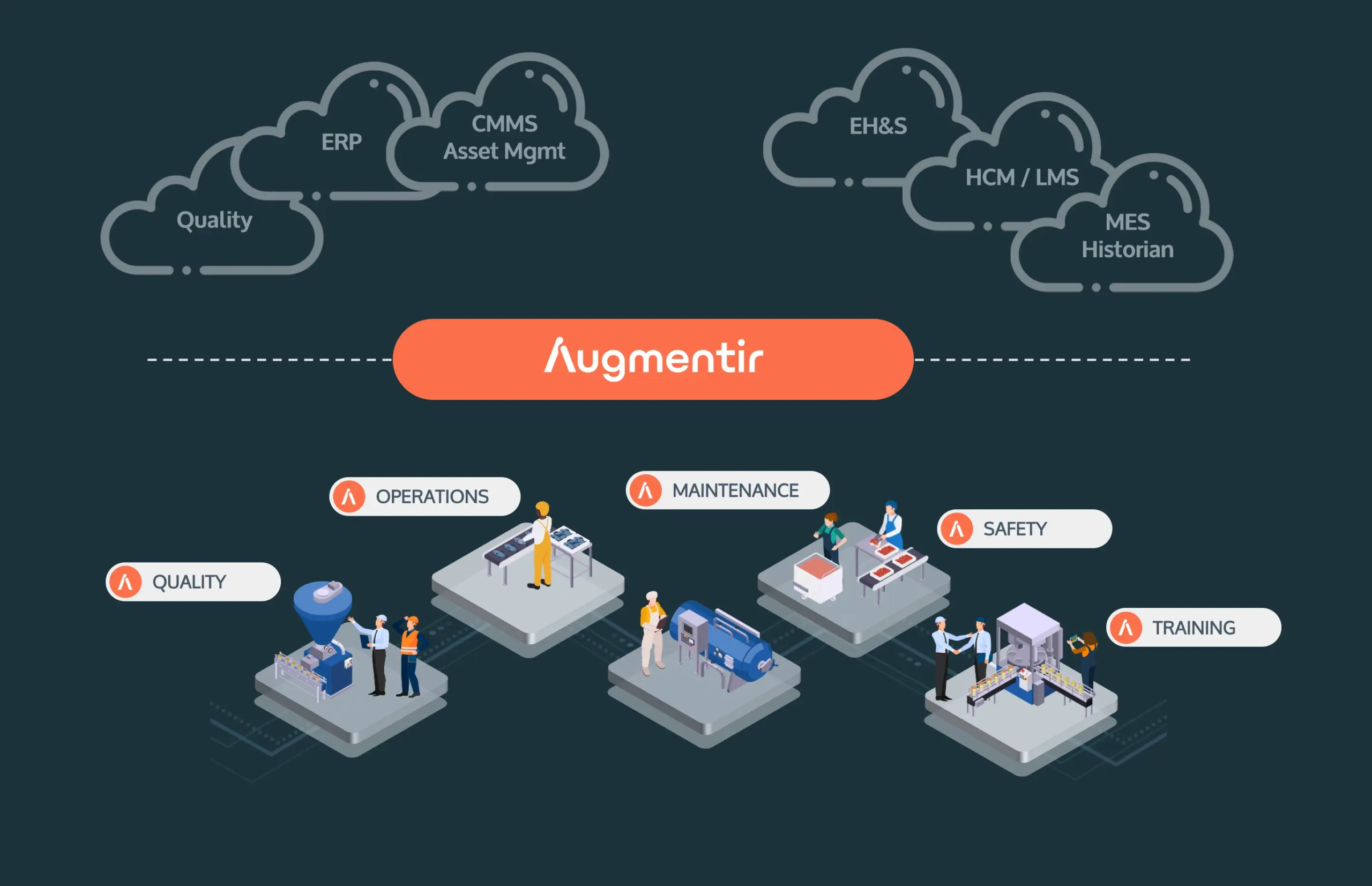

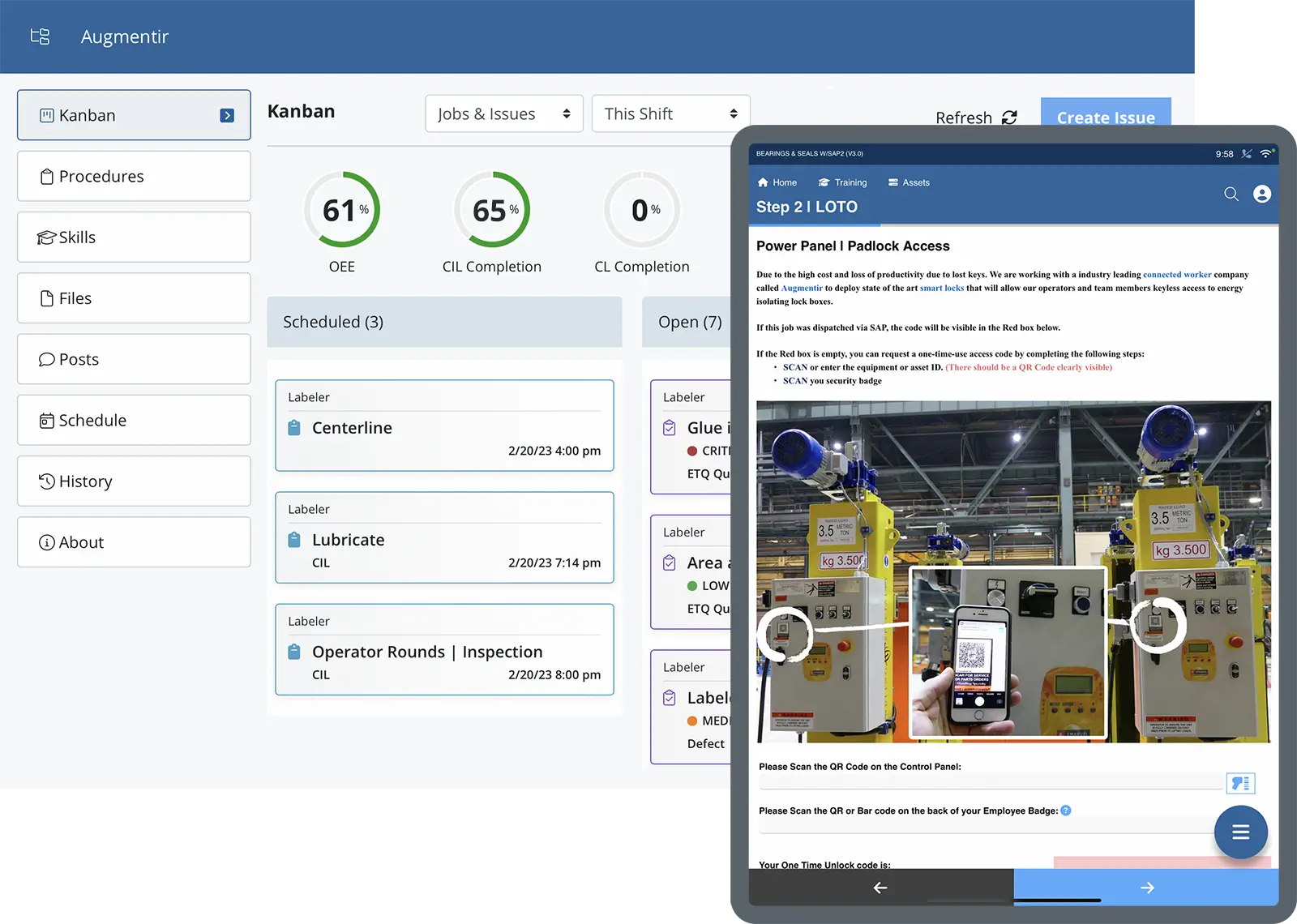

Leading manufacturers are now turning to smart digital technology to streamline skills tracking and connect it with frontline operations, giving them a competitive edge and boosting workplace safety productivity. Skills tracking software can be a great help to identify workers’ current skills and find any gaps. In a nutshell, such a tool helps automate, organize and simplify the process of evaluating employees’ skills and better understanding your workforce.

Learn more about how skills tracking is changing and the importance of integrating skills management into the flow of work by exploring the following topics:

- Five approaches to effective skills tracking in manufacturing

- Benefits of tracking skills in manufacturing

- Features to look for in skills tracking software

Five approaches to effective skills tracking in manufacturing

According to a recent survey by McKinsey & Company, companies reported that tracking and validating skills and competencies was their top talent challenge.

Effective skills tracking can improve safety, productivity, and worker performance by helping match the right people with the right tasks. For any organization, there are multiple methods and tools that can be used to track the skills of your workforce:

1. Direct assessment

This approach focuses on one employee directly assessing another. This may be done as a form of peer review between employees or by a manager.

2. Self-assessment

This approach consists of employees conducting self-assessments of their skills and qualifications through surveys every few months.

3. Anonymous peer assessment

This approach involves coworkers anonymously assessing each other’s performance on projects or other tasks.

4. Skill assessment using HR or learning systems

This type of assessment can be done using an HR system (or a Learning Management System) to assess and update employee profiles based on training completed. For example, workers can report any courses finished, track their training data or report new certificates.

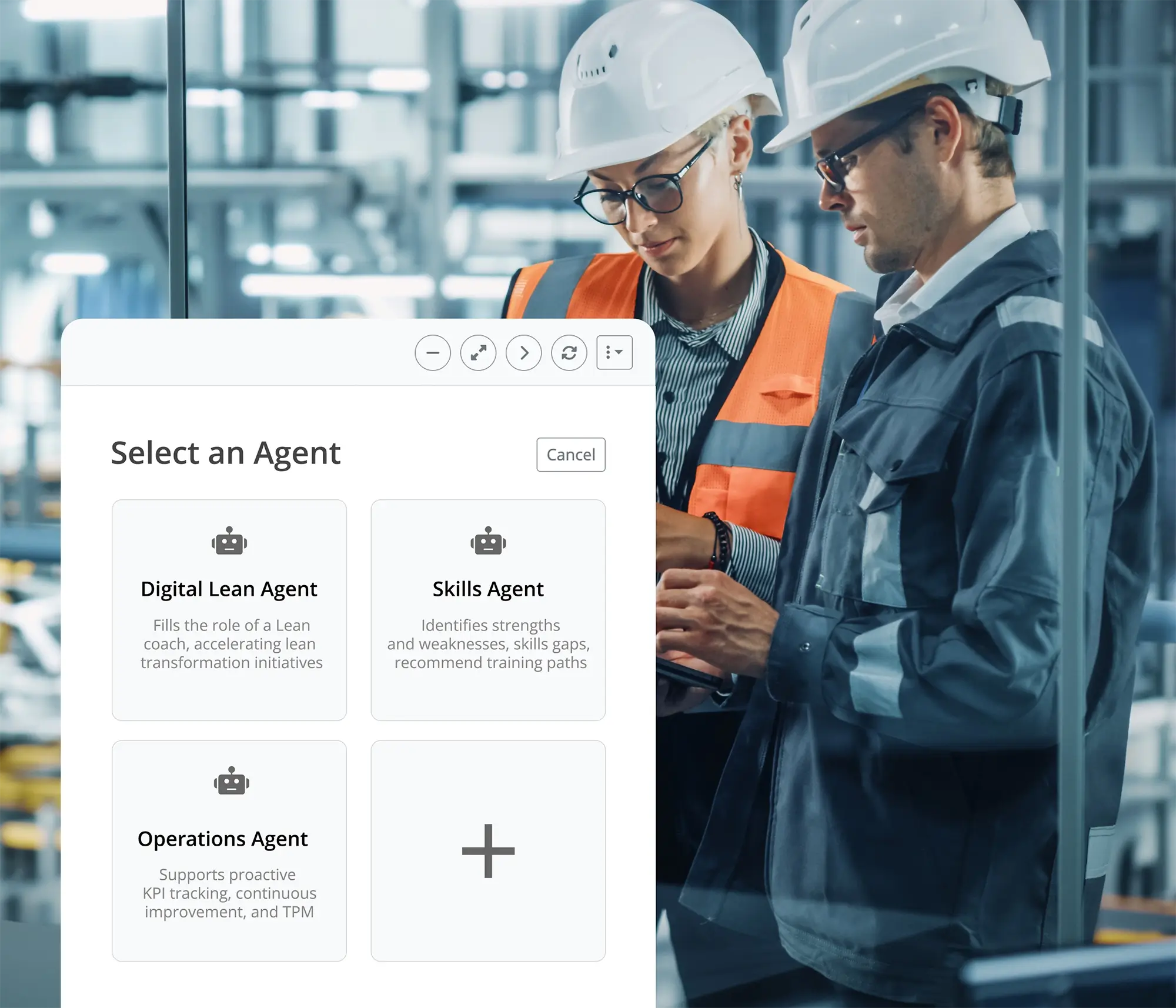

5. AI-based skills tracking software

Any of the above 4 methods are commonly used, however, the increasing workforce variability, absenteeism, and turnover is forcing new requirements. Increasingly, manufacturers are turning to AI-based software solutions to help digitally track and manage skills, and connect them with work execution.

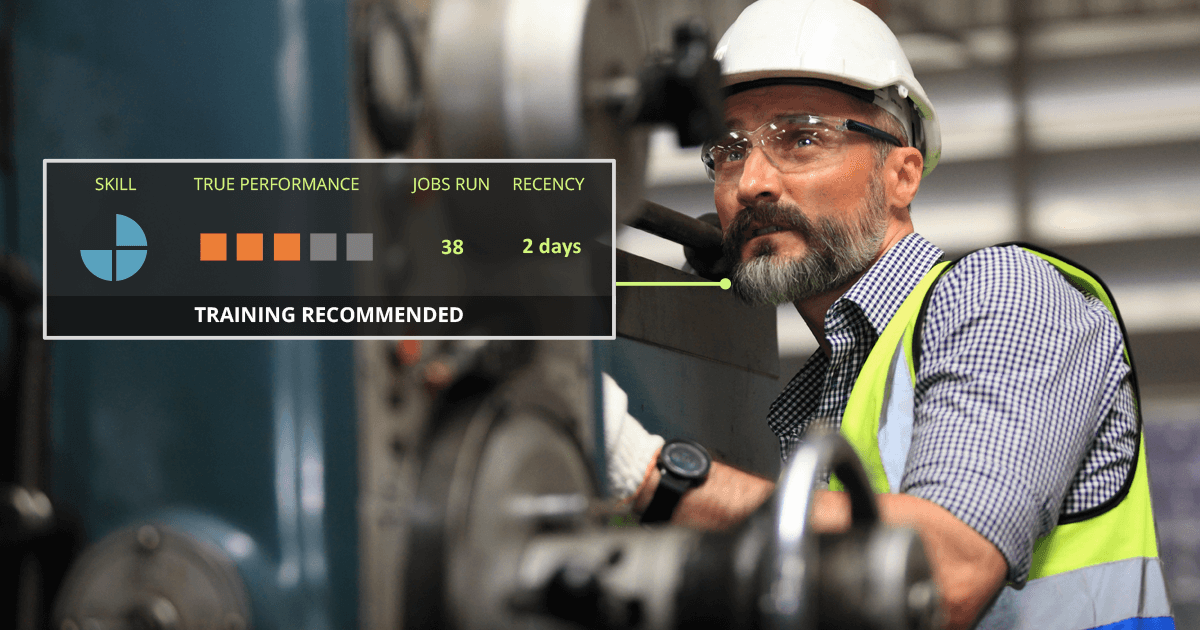

HR/Learning systems or standalone skills tracking software solutions that attempt to automate skills tracking fall short of meeting the needs of today’s manufacturers because they do not connect the “skills that workers know” with the “work being done”. These standalone solutions may have been ideal for the stable, unchanging workforce of the past, but they are not suited for today’s era of high workforce variability.

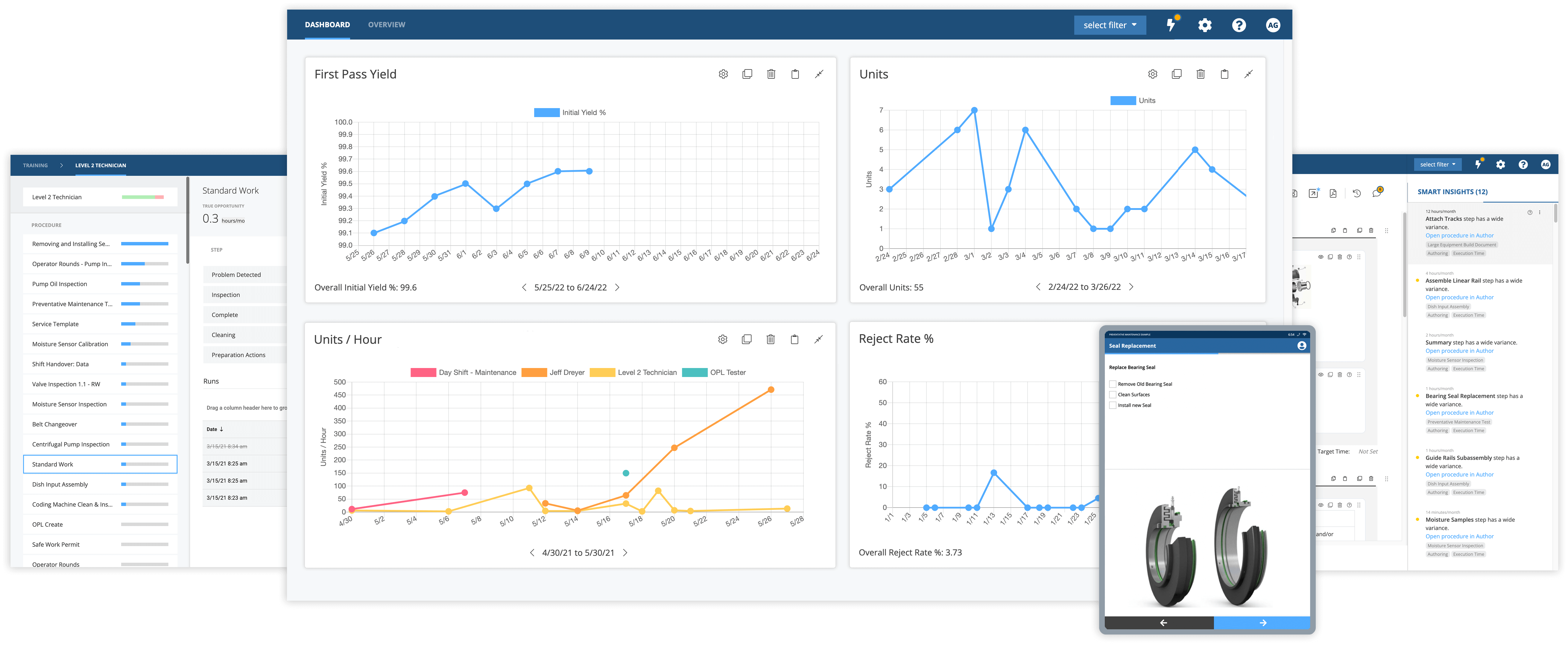

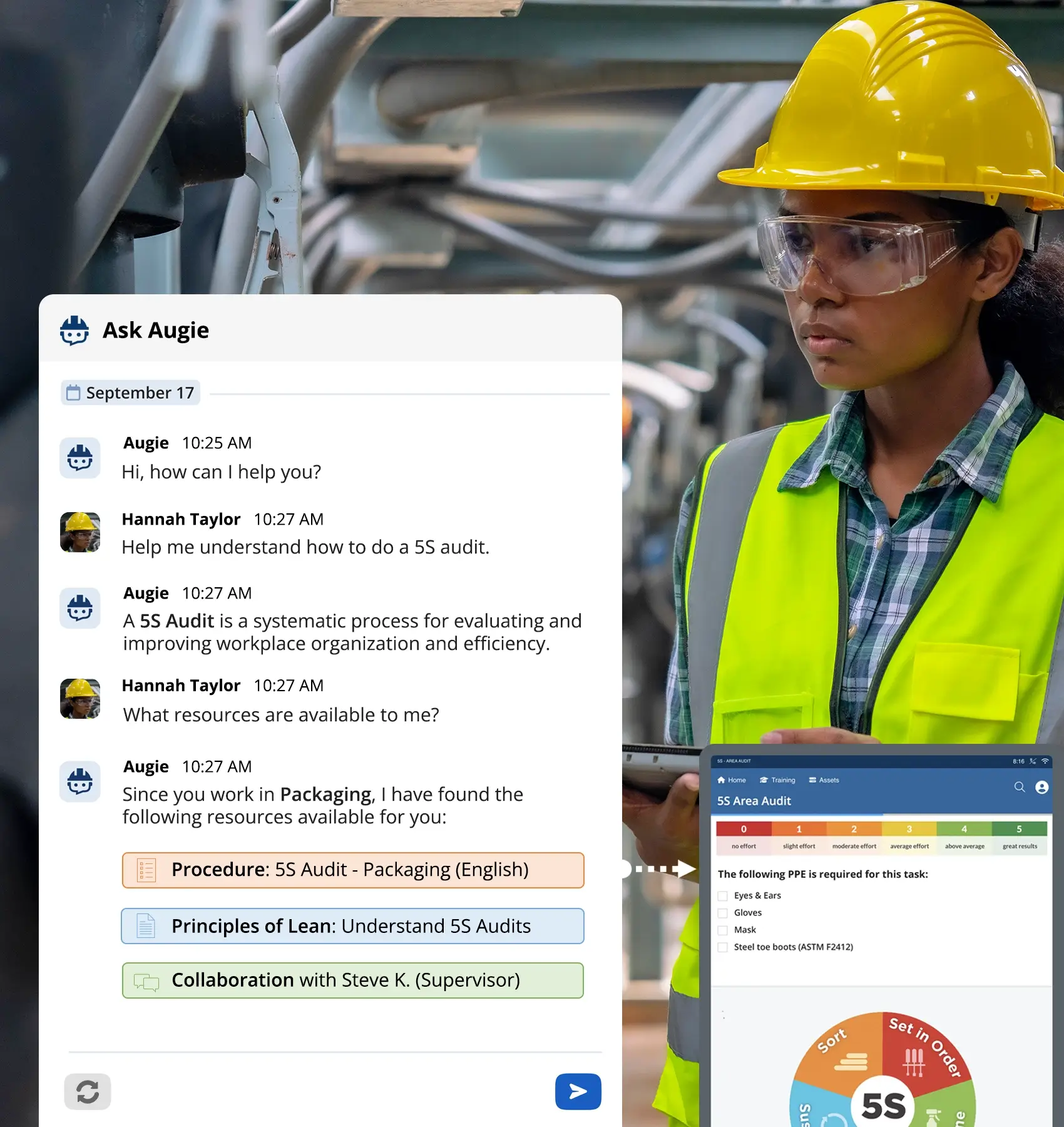

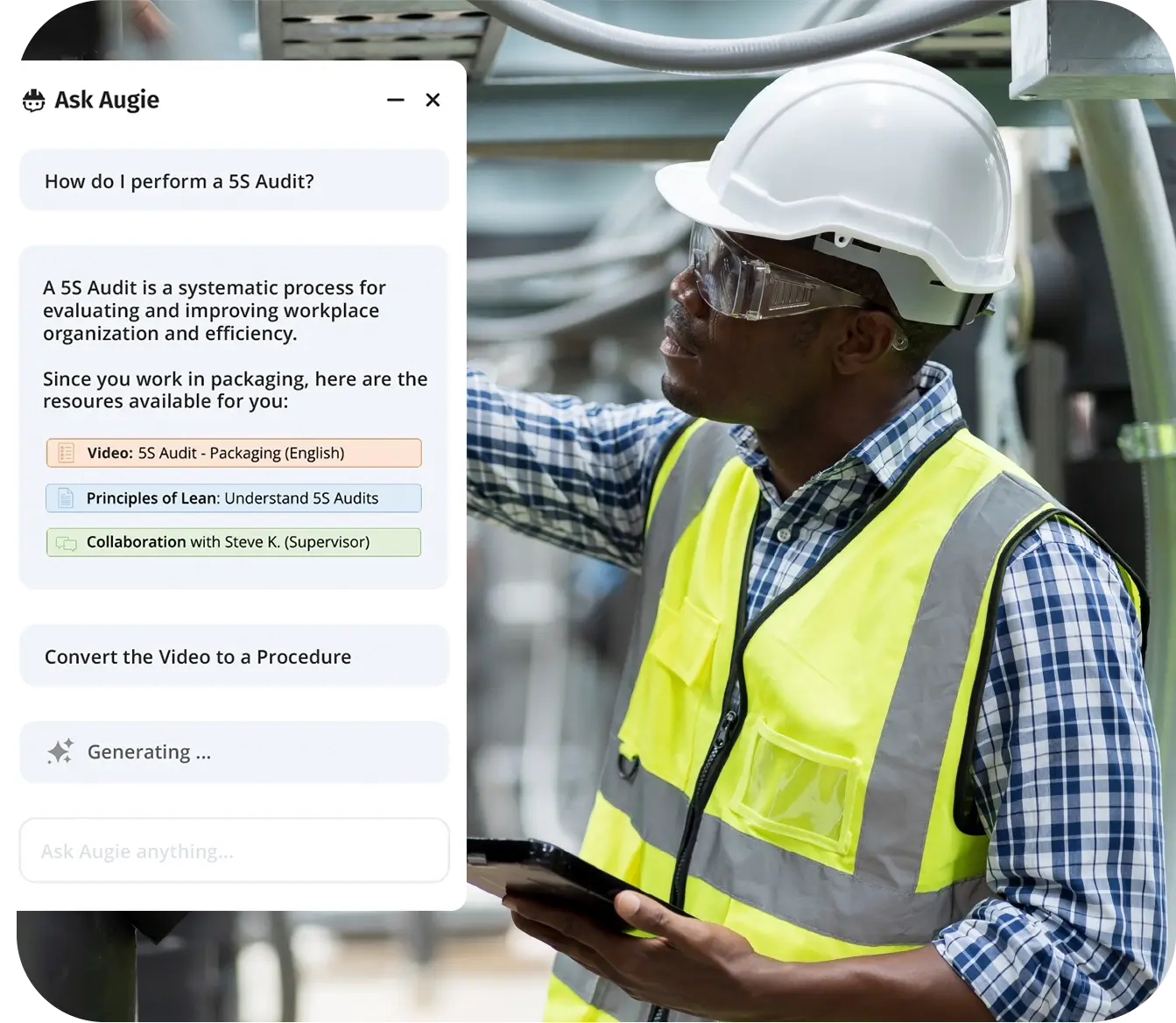

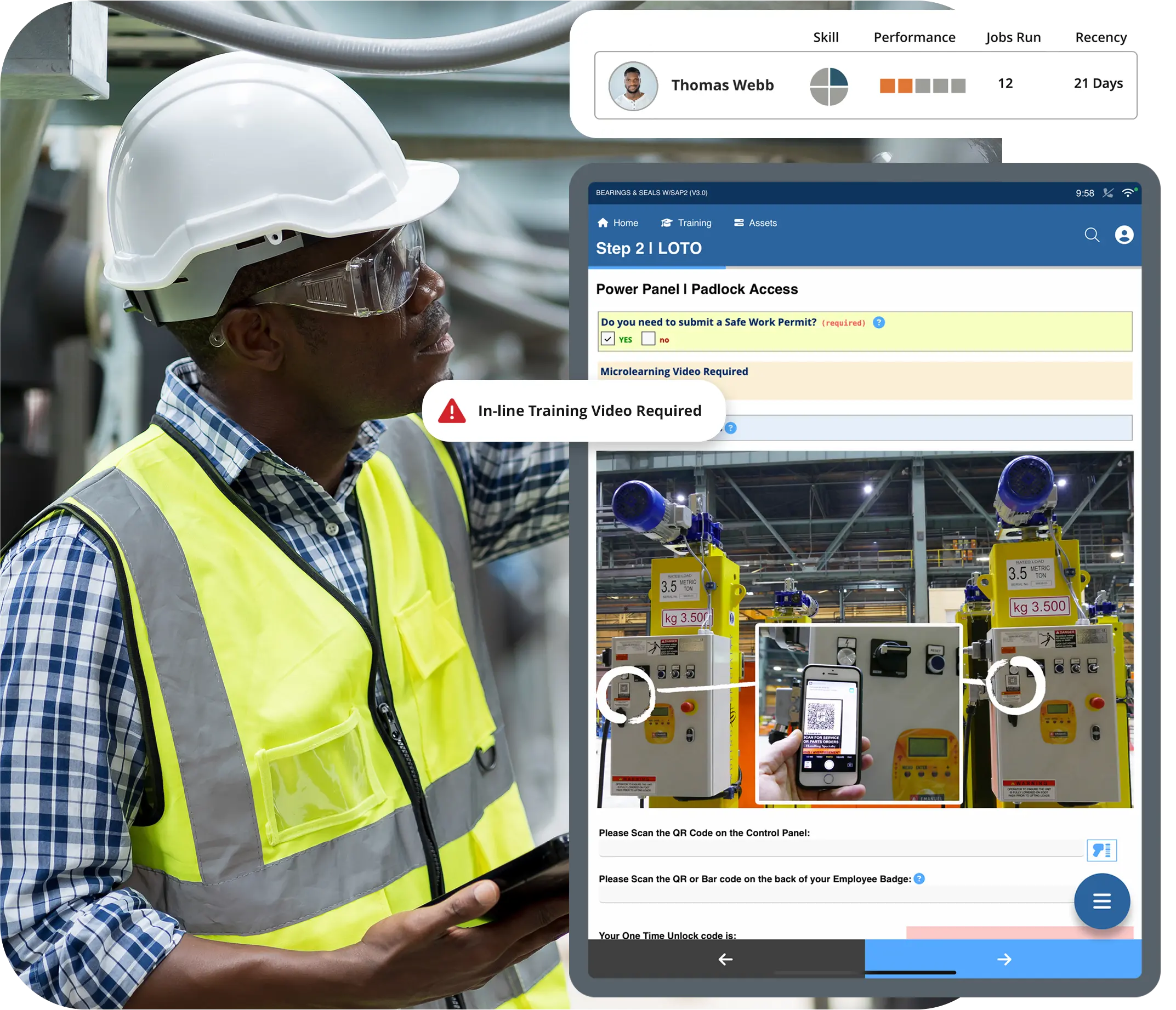

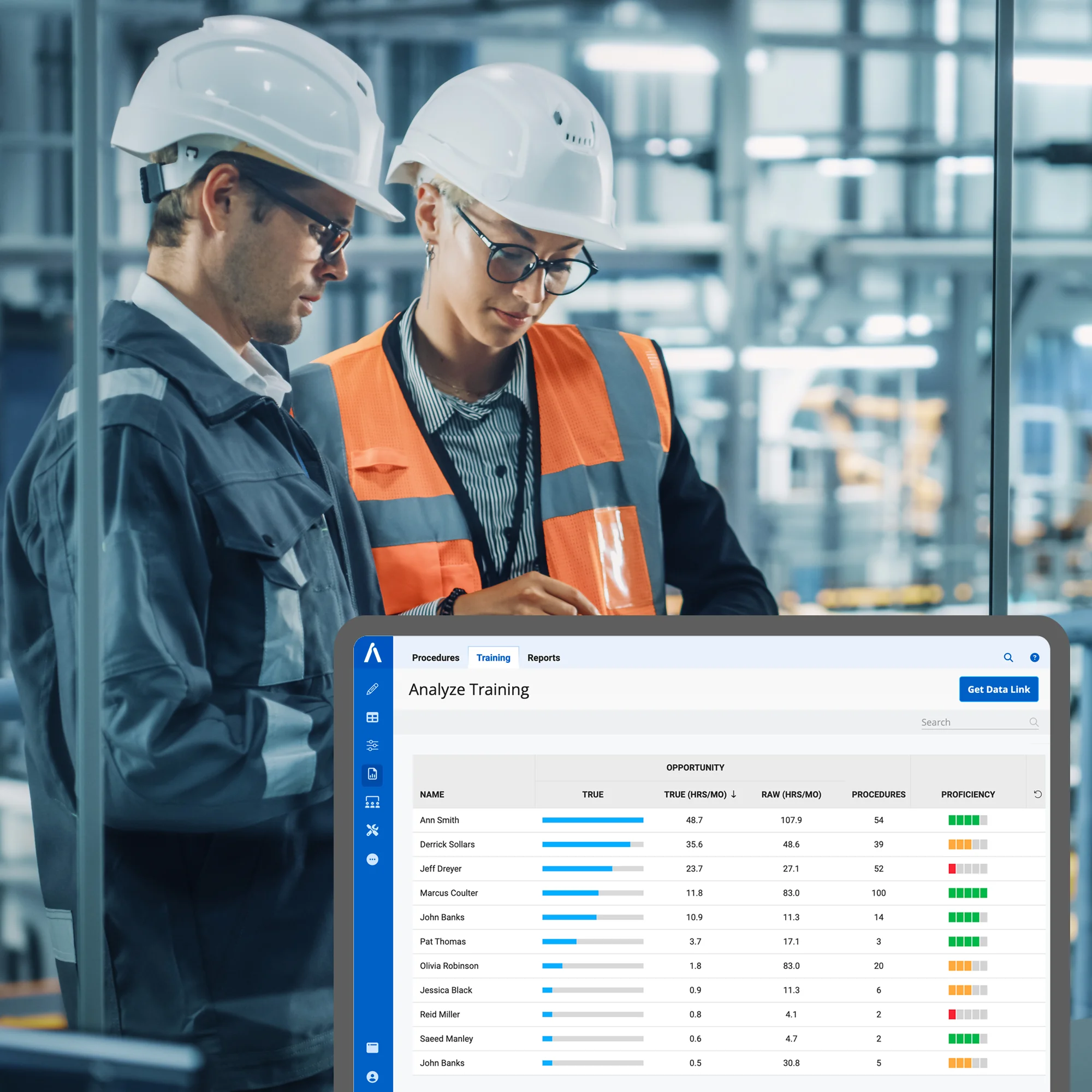

An integrated, closed-loop skills management system is the solution for this era of high workforce turnover and absenteeism. Skills management solutions that combine skills tracking capabilities with AI-based connected worker technology and on-the-job training can deliver significant additional value. Data from actual work performance can inform workforce development investments allowing you to target you training, reskilling, and upskilling efforts where they have the largest impact.

Benefits of skills tracking in manufacturing

Tracking skills in manufacturing can help identify the skills your employees already hold and those they still need to learn to properly do their jobs. Furthermore, using AI-based connected worker solutions, organizations can digitize and easily manage skills tracking and training programs and connect them with frontline operations.

Some benefits of tracking your employees’ skills using this approach include:

1. Boosts productivity on the shop floor

An organization’s commitment to cultivating its team’s skills can influence their attitudes toward the job. A worker is likelier to perform better when valued and appreciated. Skills tracking also ensures that workers are qualified to perform their job.

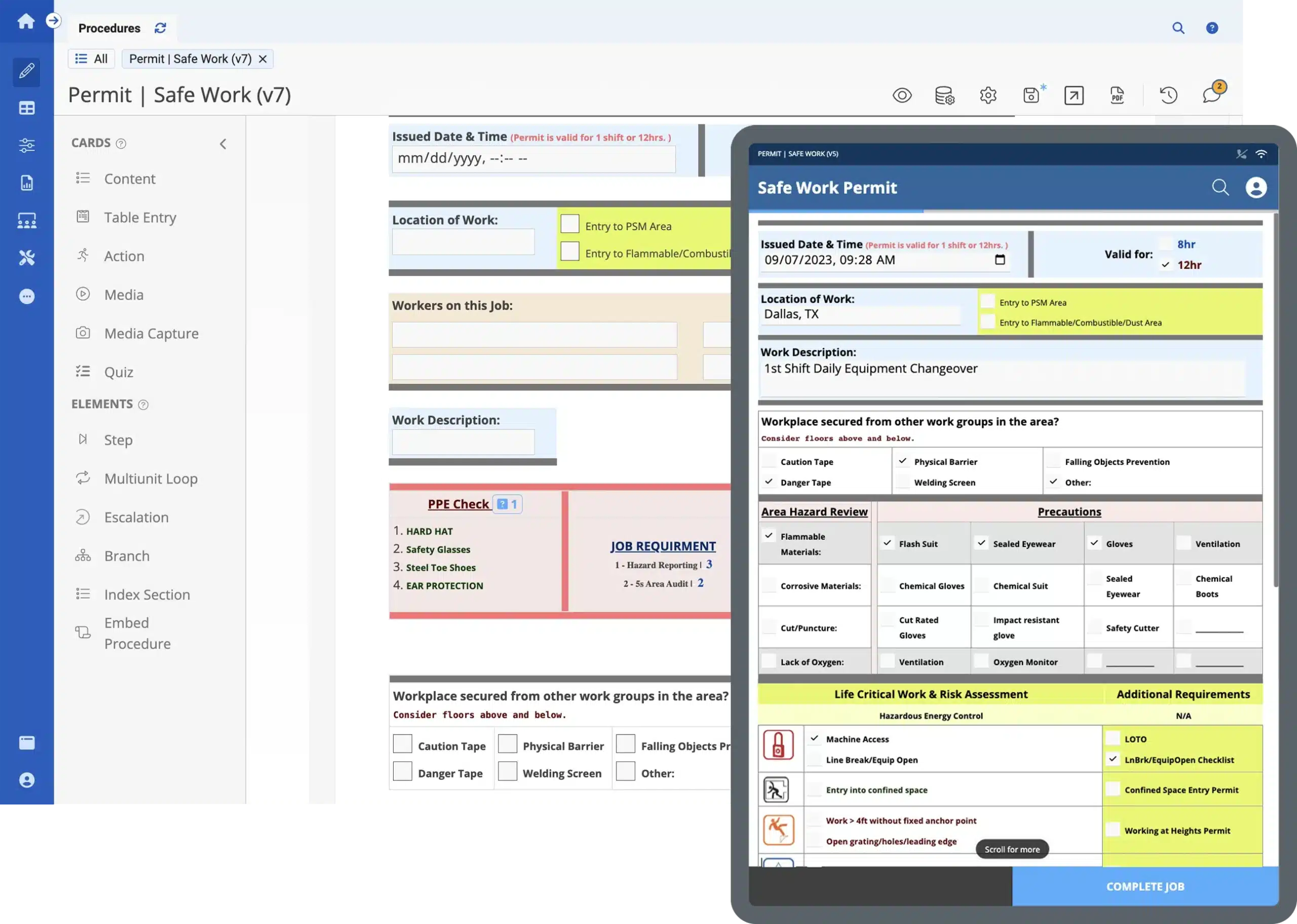

2. Ensure safety

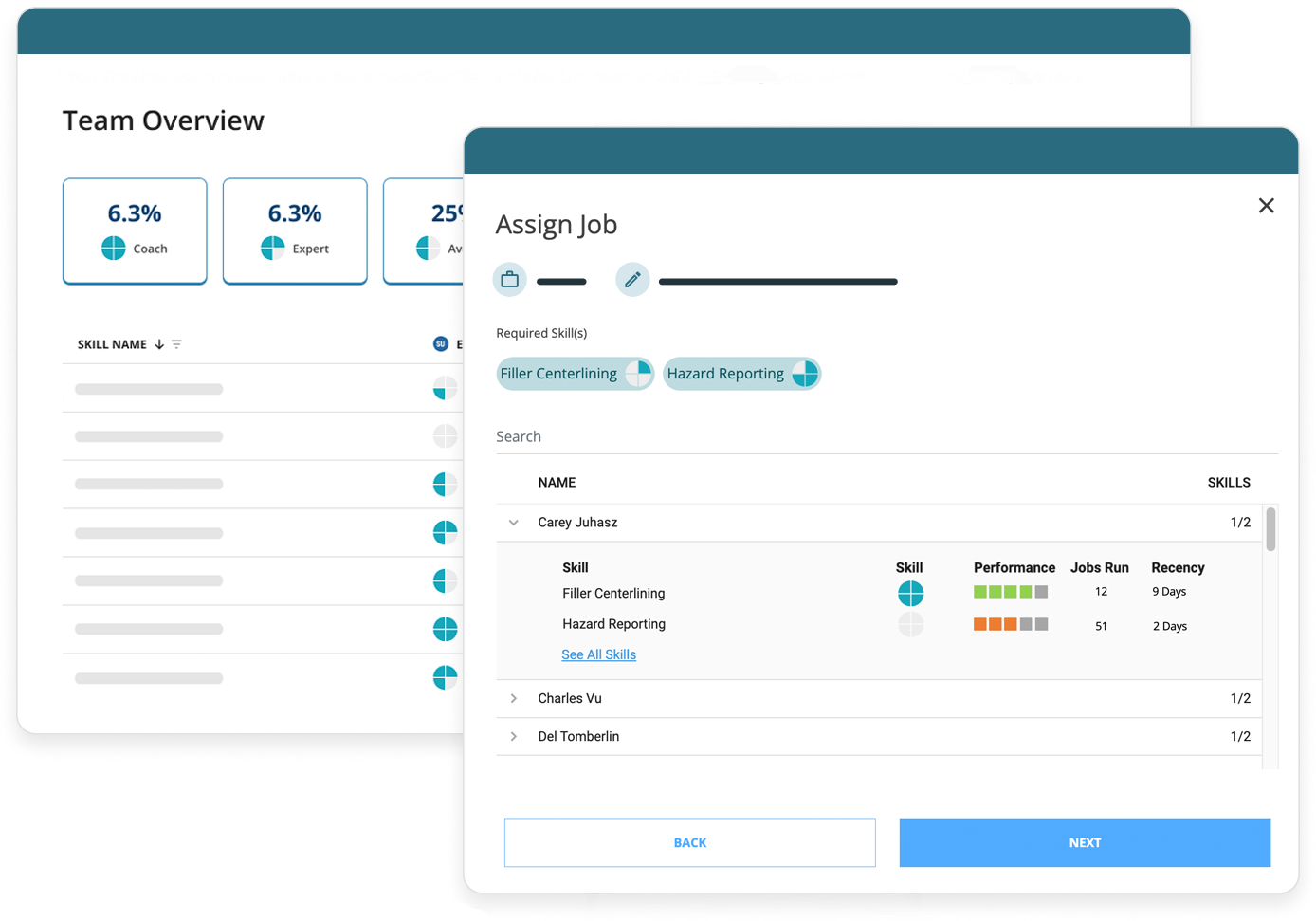

Solutions that close the loop between training/skills and the work being done allow organizations to validate at the time of work assignment who has the skill level to safely perform a specific task. This helps to mitigate risk and ensure safety.

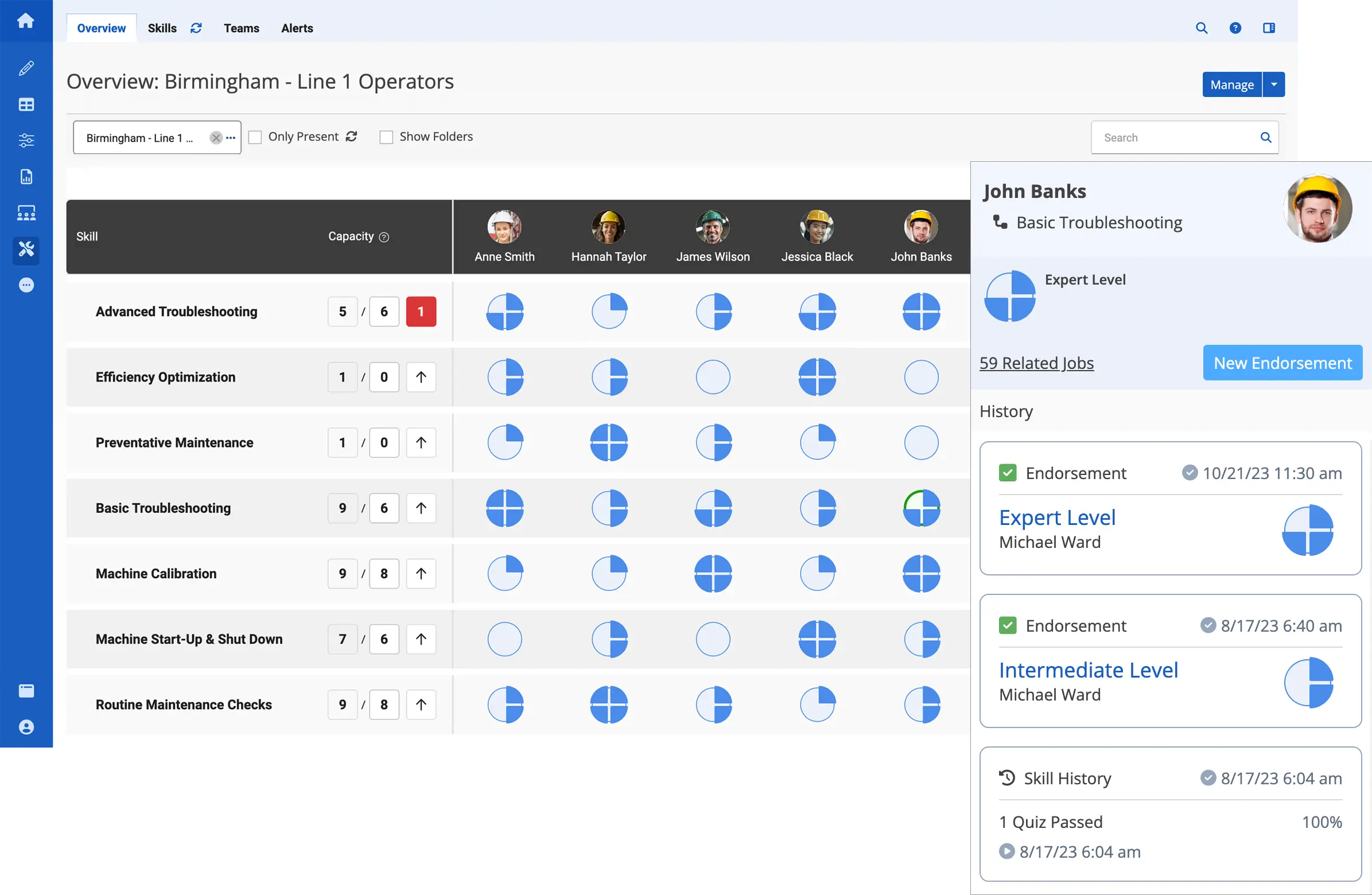

3. Intelligently assigning work

Ensure the right person is assigned to the right job. Manage work assignments based on skill level, endorsements, and actual job performance.

4. Closes the skills gap

Tracking skills is a great way to identify gaps between the skills employees already have and the skills they need. With this information, the company can arrange for additional training or other ways to invest in their employees. Keep in mind that as your manufacturing organization evolves and grows, so should your employee skillset.

5. Boosts internal communications

Employers who actively develop their employees’ skill levels are likelier to retain them. Tracking skills can also motivate and spur connections with team members.

6. Identify upskilling or reskilling opportunities

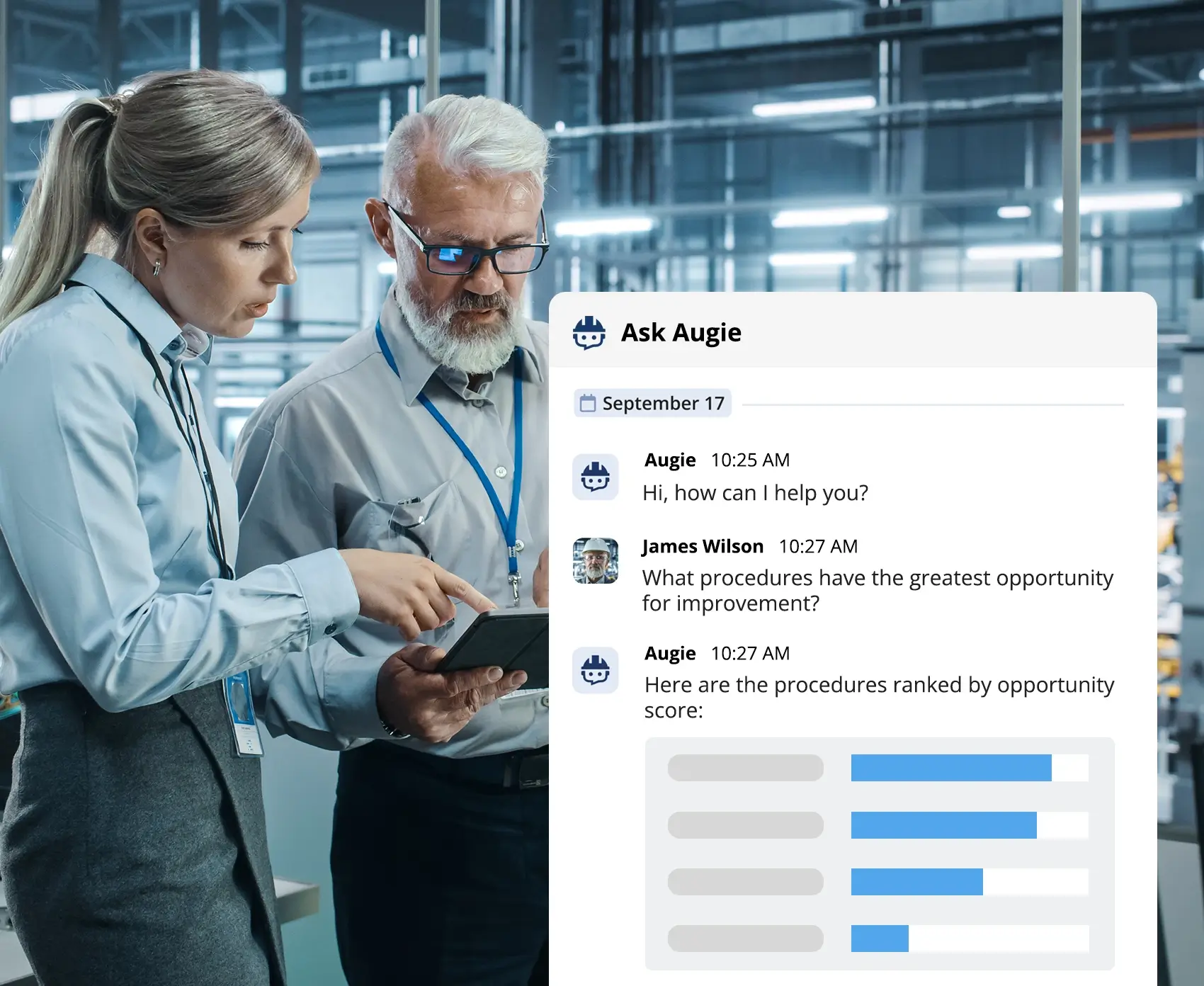

Use data from actual work performance, combined with an employee’s current skills and endorsements to inform your reskilling and upskilling decisions.

7. Enhances competitive edge

Although the purpose of effective skills tracking is to aid in worker growth and development, a byproduct is a stronger, more competitive organization as a whole. Knowing where improvements need to be made can close any learning gaps and boost the overall success of a company. Optimizing your workforce can help improve productivity in every department, giving your company a competitive edge in today’s market.

Features to look for in skills tracking software

Having the right features for skills tracking in manufacturing can help a company be more productive and efficient. This type of software should help manufacturing facilities no only identify, assess, track and cultivate employee skills, but also improve operational safety and performance.

It’s important to look for the following features when deciding which software is right for you:

Training management

This feature helps businesses see how their teams are progressing and evaluate whether training opportunities are making an impact. It helps store employee training records for real-time access and evaluation, and measure training effectiveness based on actual job performance.

Certifications management

This feature helps employers manage employee certifications. If a worker’s certification is expiring, the software’s tracking functions should easily notify the parties involved.

Skills tracking integrated into the flow of work

Skill levels and current endorsements ensure that workers can perform tasks safely and correctly and, therefore need to be considered at the moment of work assignment and again at the moment of work execution.

Live dashboard

Skills tracking software with customizable dashboards offer a real-time view of employee skills, qualifications, and any skill gaps that may exist. Managers will have a better idea of where to allocate resources to train employees and who is a better fit for a role.