Augmentir CEO Russ Fadel had the opportunity to be interviewed recently by Ann Wyatt, Industry 4.0 and IIoT Enthusiast, for the OnRamp Manufacturing Conference.

Earlier this month, Russ Fadel had the opportunity to be interviewed by Ann Wyatt, Industry 4.0 and IIoT Enthusiast, for the OnRamp Manufacturing Conference. OnRamp Manufacturing is the leading conference for manufacturing innovation that brings together the manufacturing industry’s leading corporations, investors, and startups. The conference highlighted innovations disrupting the manufacturing industry, the leaders making such innovations possible, and how new technologies and business models will reinvent the industry. In this exciting interview, Ann and Russ discussed some of the top challenges that today’s manufacturers face, and how technology such as AI and connected worker solutions that recognize the variability in today’s workforce are empowering workers by giving them tools and resources that will set them up for success.

The following is a recap of some of the highlights of the discussion.

The great resignation is upon us now

The consistent story of the manufacturing workforce is that there is an aging workforce and 30-40% of that workforce will leave within the next 5 years, taking valuable, hard to capture tribal knowledge with them. Many manufacturers were under the misconception that the remitting workforce would pass down their knowledge to the next generation as they did before. However, this was a big misconception. Even prior to Covid, the dynamics of the workforce themself have changed. In the last 5 years, the tenure of manufacturing workers is down to 17% and that decrease escalated even more as a result of the pandemic.

The stability of the workforce has decreased in the past 8 years. Old work processes were designed during a more stable time and unfortunately aren’t applicable for this generation of workers. Today’s workers are in the factory less frequently, don’t stay as long, and due to Covid, may be out for short periods of time, resulting in the need for a more dynamic workforce. To deal with this rapidly changing workforce, manufacturers will need a more data-driven approach powered by AI to empower their workforce.

A highly effective, cross functioning workforce

Over the years, the manufacturing industry has done a really good job of connecting machines into the fabric of the business and giving operators the necessary data to help run those machines better. Our frontline workers, the last piece of connectivity, are the least connected set of workers in the company. Frontline workers should be fully integrated into the fabric of the business from a collaboration standpoint so that they can access the data they need as well. Secondly, when they are working, it needs to be understood what workers are doing well and what they are struggling with, so we can match people with the tasks that they already excel at.

Top trends and key challenges in today’s workforce

At the highest level, everyone is talking about the disruption of the mobile supply chain. The role of the manufacturer is to put supply into the supply chain and to safely build products at acceptable quality and productivity levels, matching today’s workforce with today’s task load.

The new dynamics of the workforce (lots of turnover, shorter tenure, people leaving abruptly) are at odds with what manufacturers are trying to do, which is to be a stable source of supply to the global supply network. Technology today, specifically AI, lets us understand at a data-driven level and in real time how workers can perform at their individual best, based on their training experience and raw ability for a specific task.

How Hybrid Work is impacting the manufacturing workforce

With Covid came an immediate need for remote presence, but the real issue is the idea that a subject matter expert needed to be on site for support. This way of working is now a thing of the past. When we think about having frontline workers fully connected to the organization, at any moment in time, they should have direct access to the tools and resources that would help them do their job better. Connected work in the future means using AI to allow frontline workers to have access to internal and external resources that are appropriate for them at their fingertips.

Another interesting statistic resulting from Covid is that employee engagement is down almost 20% from pre-Covid times. Manufacturers are always concerned about employee engagement, particularly with certain jobs that might be repetitive. AI is extremely helpful in measuring signals of engagement but also provides tools to the organization to increase the level of engagement of frontline workers. One thing that causes a reduction in engagement is when a worker feels like they can’t perform a job so they become frustrated.

Using AI to give frontline workers the tools and information they need when they need it is one way to help increase engagement. The other way is to let them feel connected to the actual importance of their work.

Hiring, Training & Reskilling

The new workforce dynamics and the nature of hybrid work are also now forcing manufacturers to re-think employee onboarding and training.

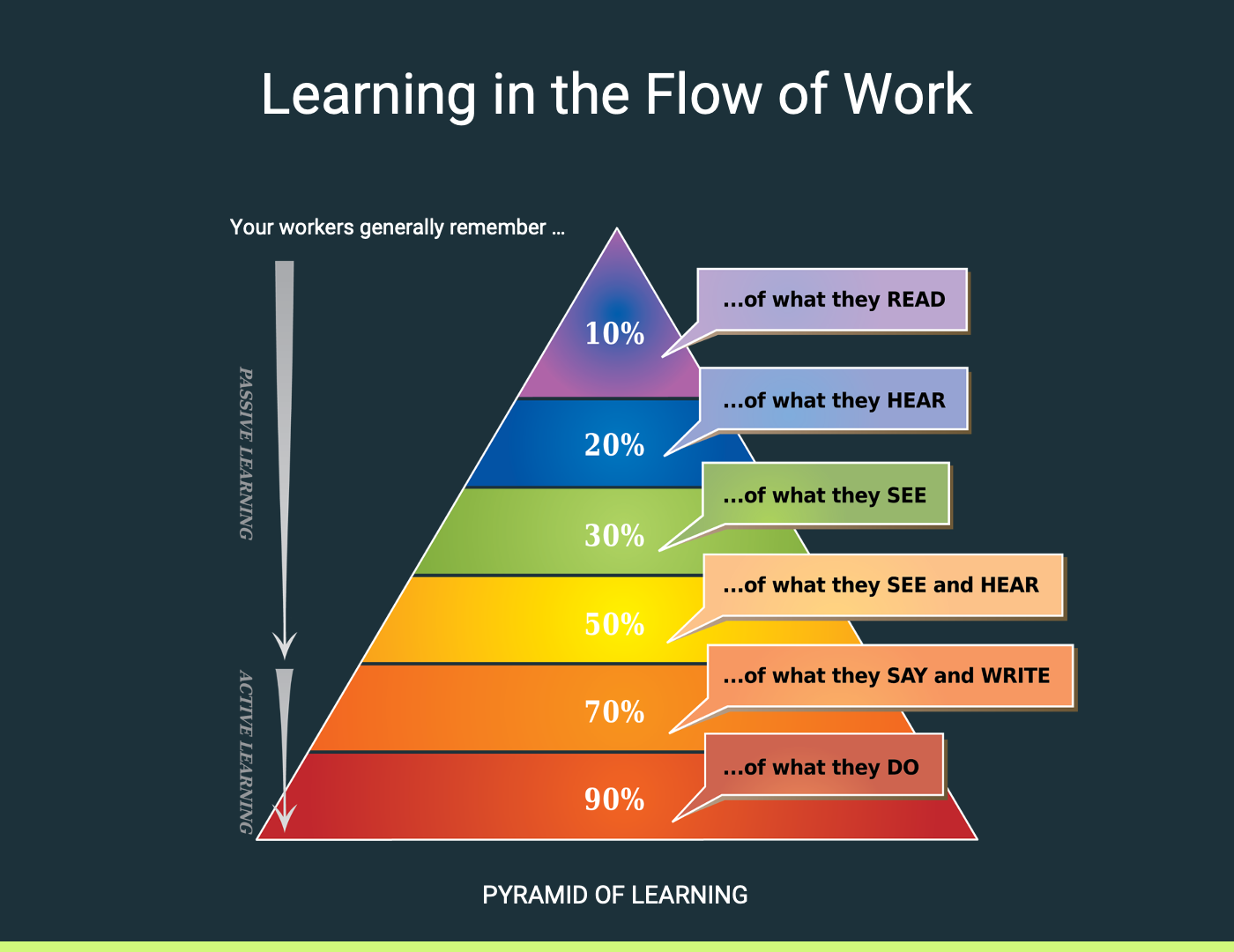

The historic methods of onboarding and training taught workers everything they could “possibly” do which resulted in overtraining. The data-driven era we’re entering into is one of continuous learning and development powered by AI. Training shifts from the things frontline workers are possibly going to do to what they are probably going to do. This results in reduced training times, continuous learning and development, and the ability to upskill at any point as needed. Learning is always available, training content is available to the worker on the shop floor at the time of need. Reducing the initial onboarding training and allowing training to occur at the moment of need, coupled with AI for scoring, provides insights into the most effective training modules as well as what needs to improve based on demonstrated execution.

Transforming Today’s Workforce with AI & Connected Worker Tools

One challenge with connected worker data is that it’s inherently noisy. In many cases, up to 37% of the signals that come back are not representative of what is actually happening. Fortunately, AI excels at recognizing patterns in noisy data, so we can use that to focus companies on the work processes that have the most opportunity, allowing organizations to understand their actual proficiency at any procedure or job. This helps them understand current workforce skills, what areas need to be connected or improved, and where they should invest if they want to get the largest return, with AI being the driving technology that unlocks those signals in noisy data.

AI is largely embedded in most aspects of our lives and it will play an equally large role in helping the connected workforce progress and become part of the 21st-century solution and the next generation of how people work. Adopting these methodologies early on will make the overall digital transformation process a lot easier for manufacturers.