How AI, HR, and operations come together to support frontline workers. Key insights from the HR Happy Hour podcast, featuring Chris Kuntz from Augmentir on skills, training, and connected work.

Augmentir’s VP of Marketing, Chris Kuntz, recently joined Steve Boese on the System of Record podcast from the HR Happy Hour Network to talk about a topic that doesn’t get nearly enough attention: how AI, operations, and HR come together to support the frontline workforce.

While much of the AI-at-work conversation focuses on desk and knowledge workers, Chris and Steve shifted the spotlight to the 65% of the workforce who work on factory floors, in distribution centers, and out in the field—and how technology can be used to augment and empower, not replace, them.

Below are the key themes and insights from the conversation.

The Missing Link in Industrial Transformation: People

Chris shared his background in industrial and emerging technologies, including his work helping pioneer Industrial IoT at ThingWorx. After years of making machines smarter and more connected, his team recognized a critical gap in Industry 4.0 and 5.0 initiatives:

Humans were the missing piece.

Frontline workers—despite being essential to safety, quality, and productivity—have historically been underserved by technology. Post-pandemic workforce shifts have only intensified the challenge, with:

- Shorter average tenure

- Less experience on the job

- Higher early attrition rates

These trends make traditional six-month onboarding models unsustainable and force organizations to rethink how they support and develop frontline talent.

Augmentir’s Focus: Closing the Skills and Experience Gap

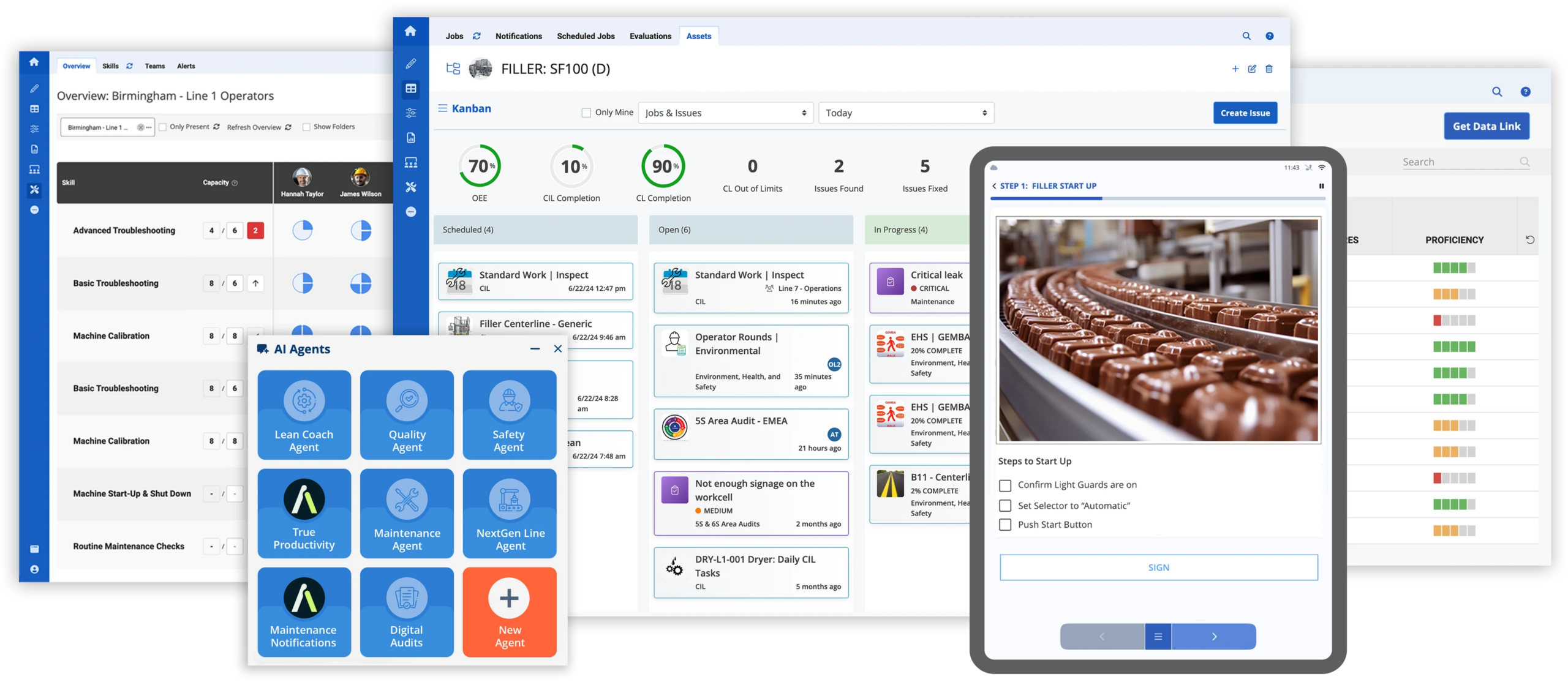

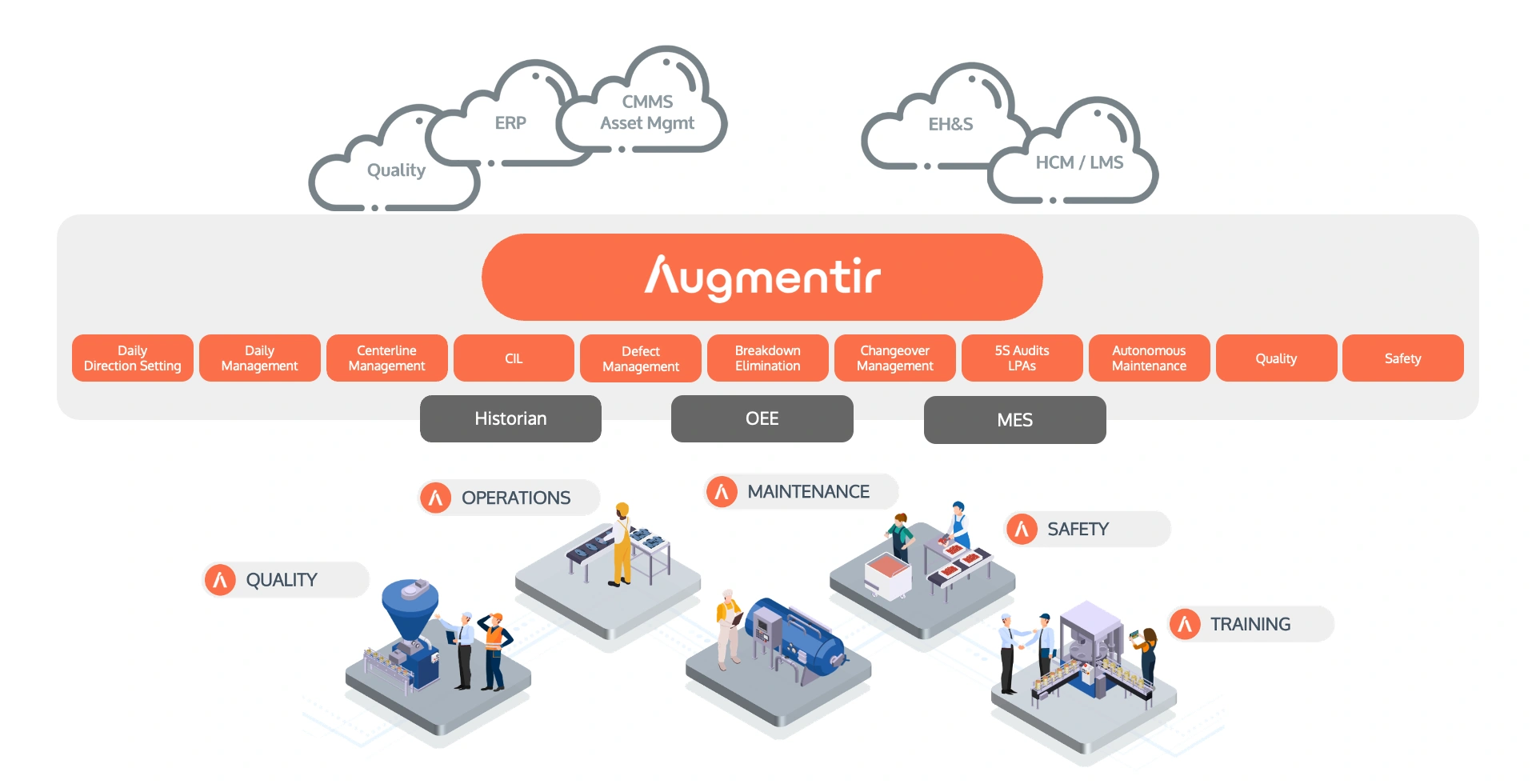

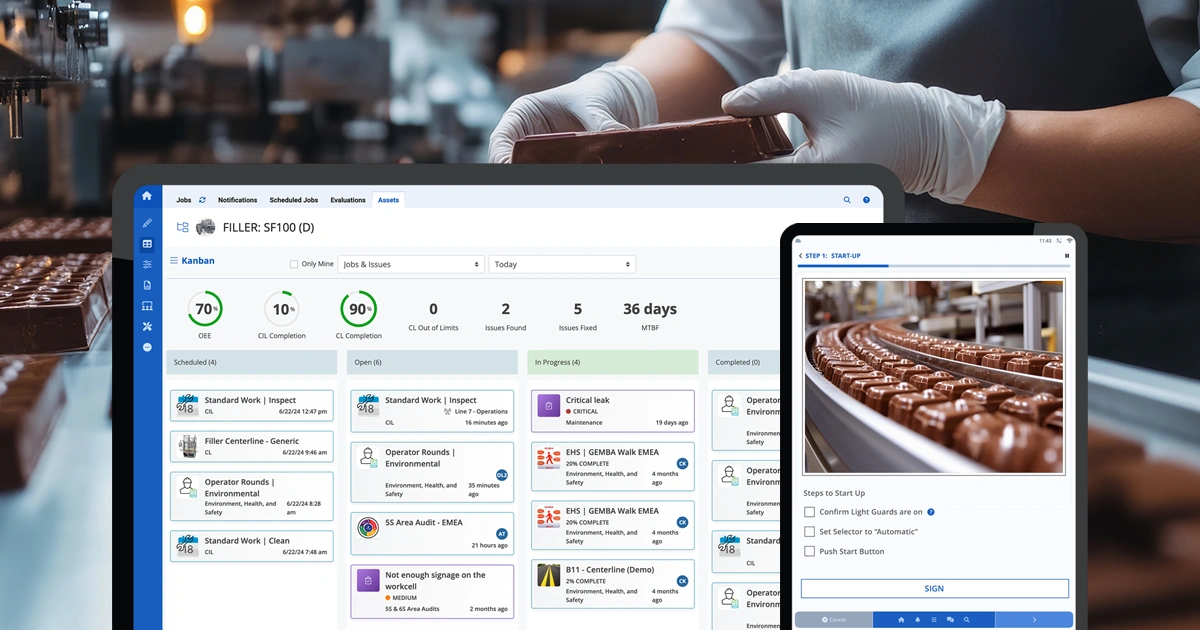

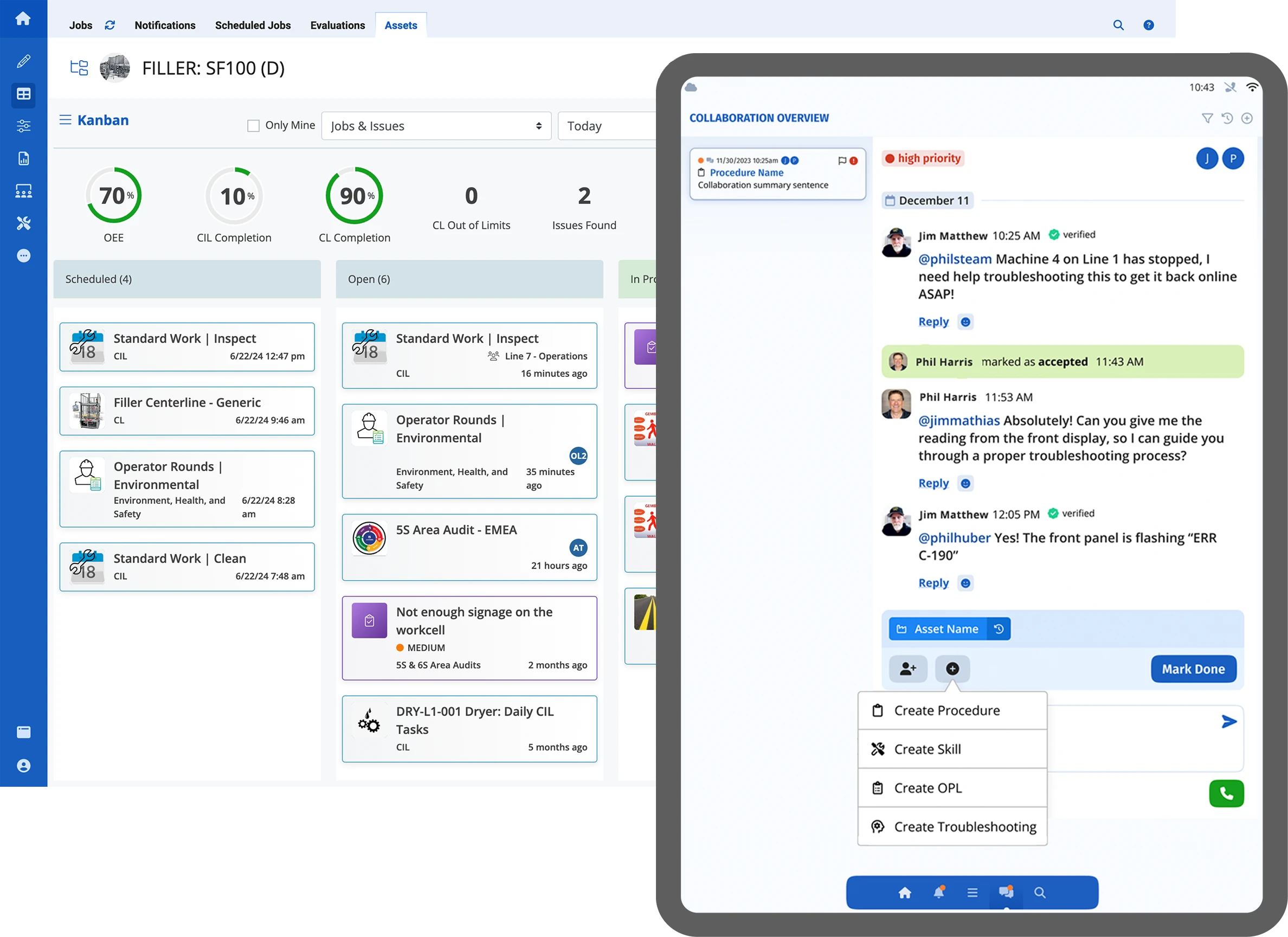

Founded in 2018, Augmentir is an AI-first connected worker platform designed to address what Chris calls the most critical problem in manufacturing today: the combination of labor shortages, skills gaps, and experience gaps.

Rather than treating frontline technology as just digitized paperwork, Augmentir connects workers directly to the digital thread of the business, integrating:

- Operational systems (ERP, MES, QMS)

- Learning and training platforms

- HR systems and skills data

This creates a single interface where workers are active participants in the digital ecosystem—while giving leaders unprecedented visibility into performance, skills, and improvement opportunities.

From Paper Procedures to Continuous Improvement

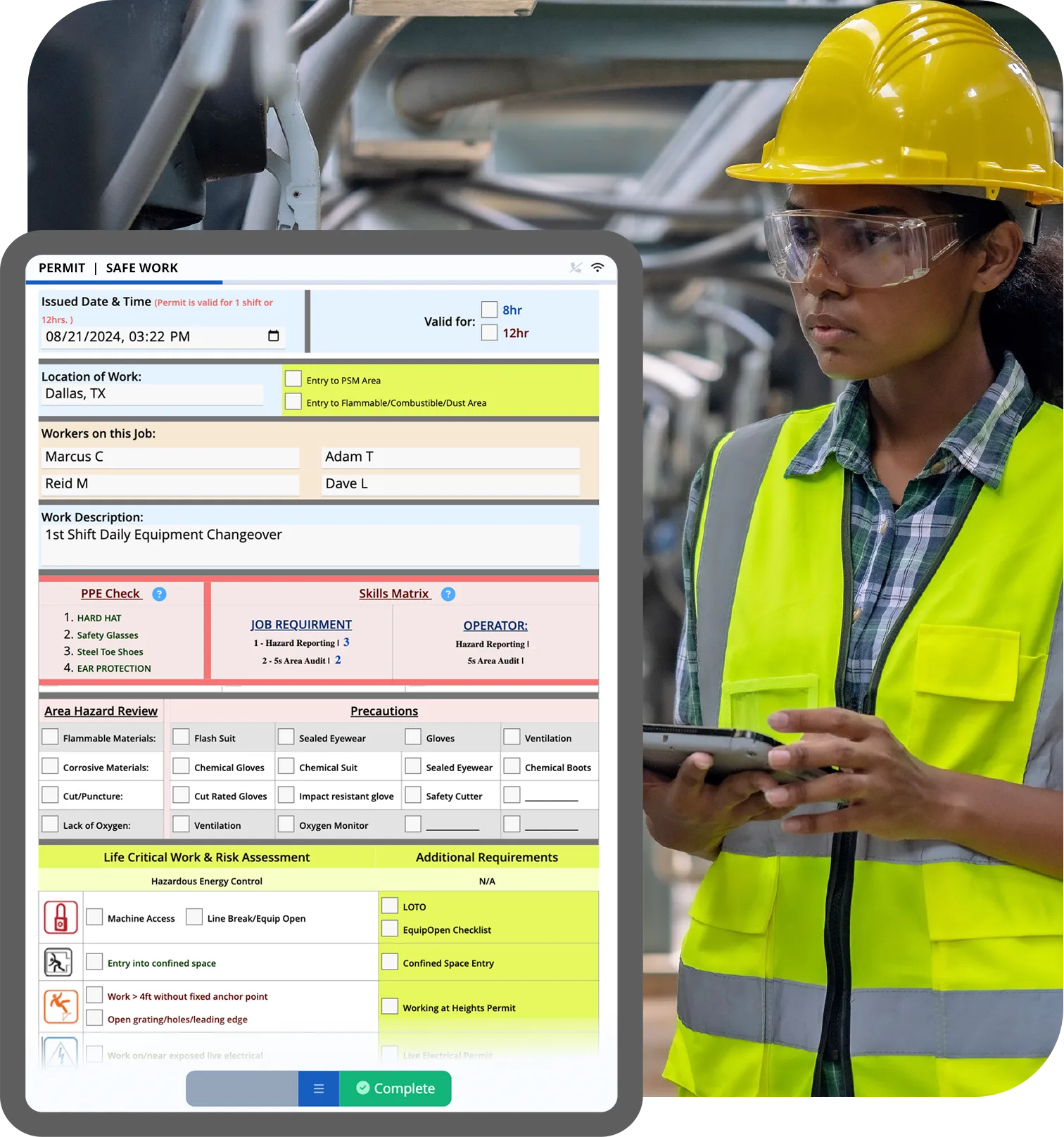

Chris described how many industrial processes have historically relied on paper instructions or tribal knowledge. By digitizing standard work and connecting workers digitally, organizations can:

- Capture real-time performance data

- Identify skill gaps and training needs

- Reduce safety incidents, rework, and downtime

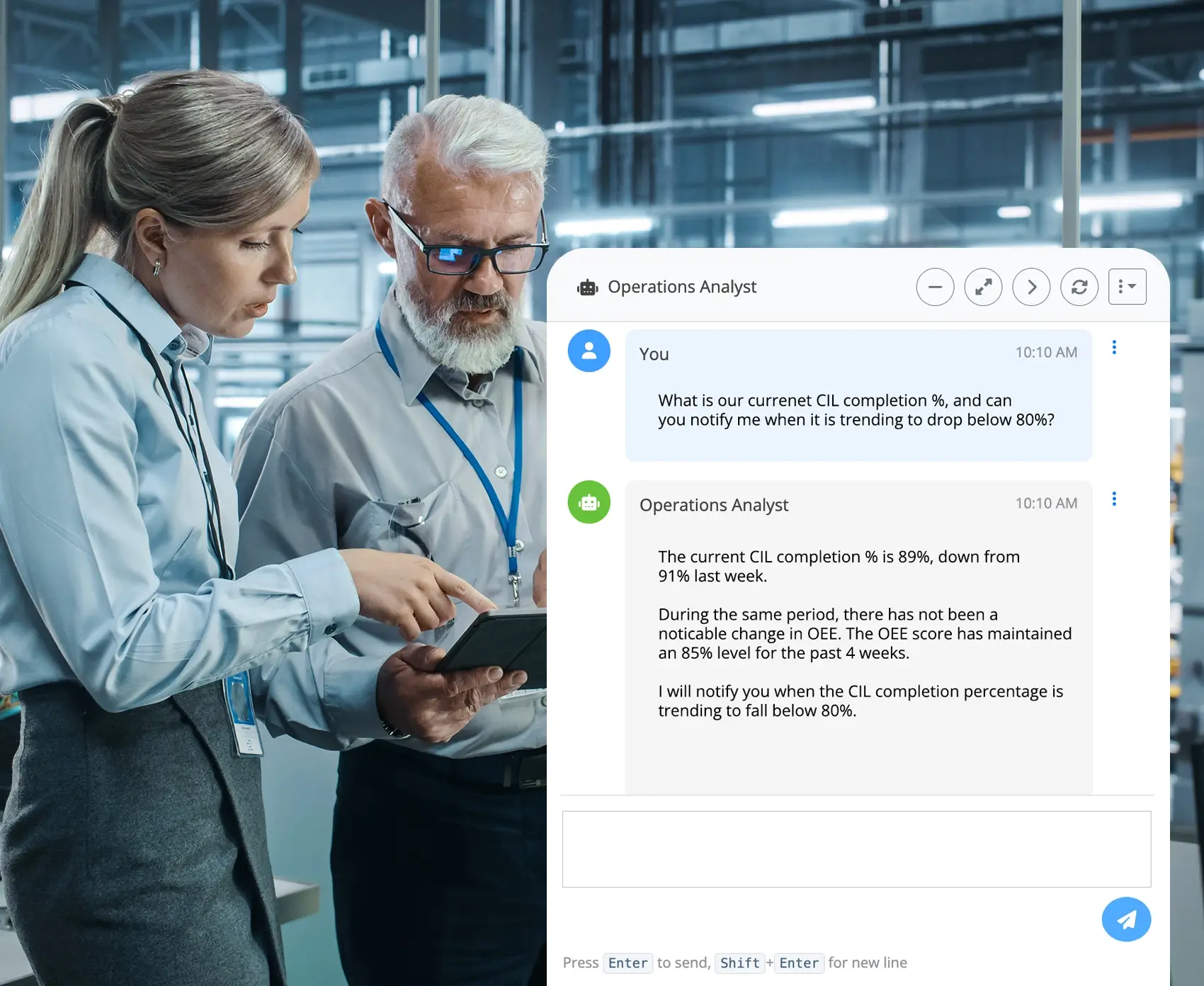

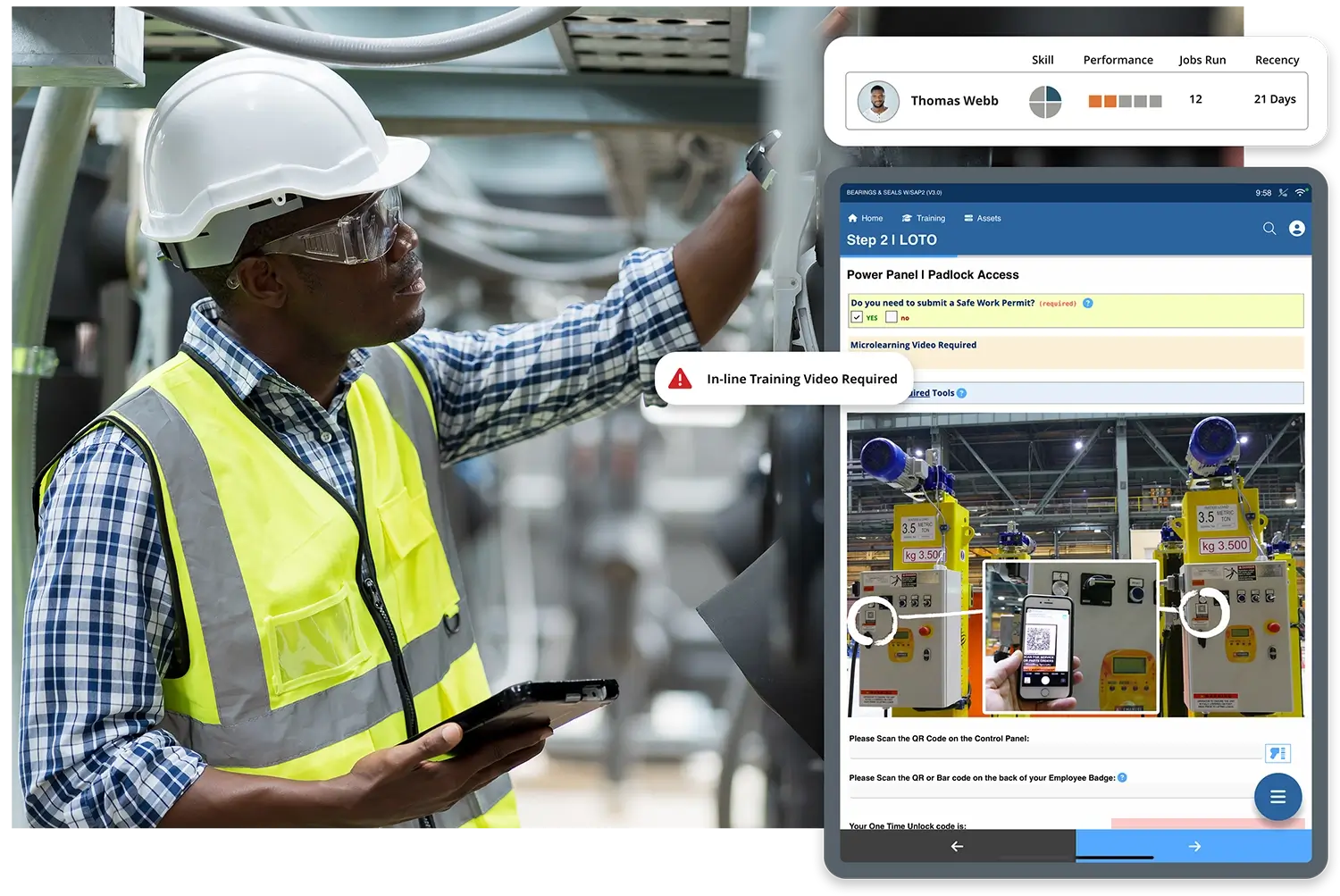

Augmentir applies machine learning to analyze hundreds of data points—from task duration to error rates—to surface insights such as:

- Where individuals may need targeted training

- Where processes or content need improvement

- How onboarding and training programs are performing

For plant managers and operations leaders, this replaces backward-looking reports with actionable, real-time decision support.

Worker Empowerment, Not Surveillance

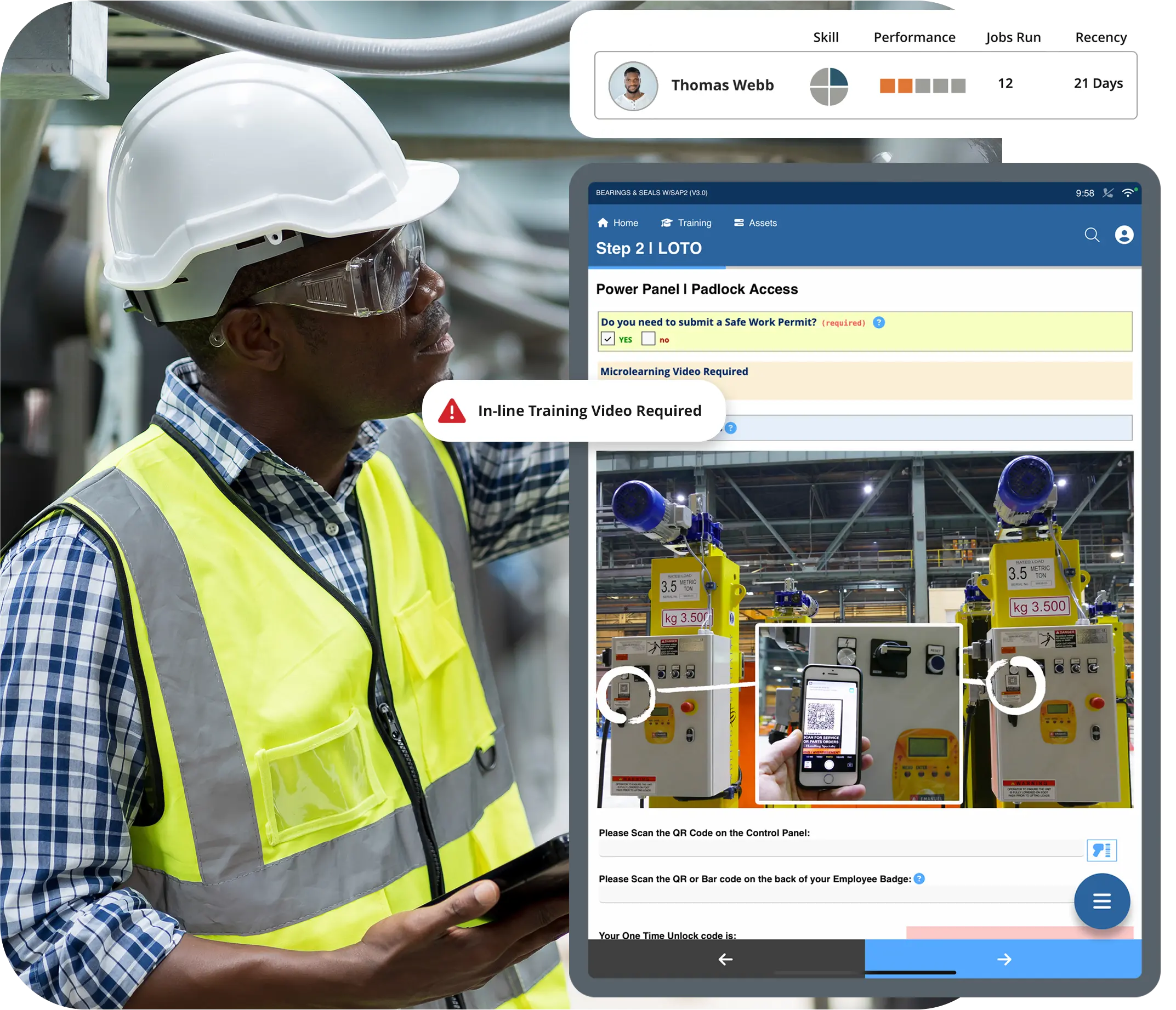

A key part of the discussion focused on worker trust and experience. Chris emphasized that successful connected worker initiatives are grounded in empowerment, not micromanagement.

When frontline employees are involved early in the rollout and change management process, the technology is seen as a tool that:

- Helps them do their jobs safely and correctly

- Reduces frustration and guesswork

- Recognizes and rewards positive behaviors

From reporting safety issues to improving efficiency, these signals also provide valuable engagement insights for HR—bridging a gap that has long existed between HR and operations.

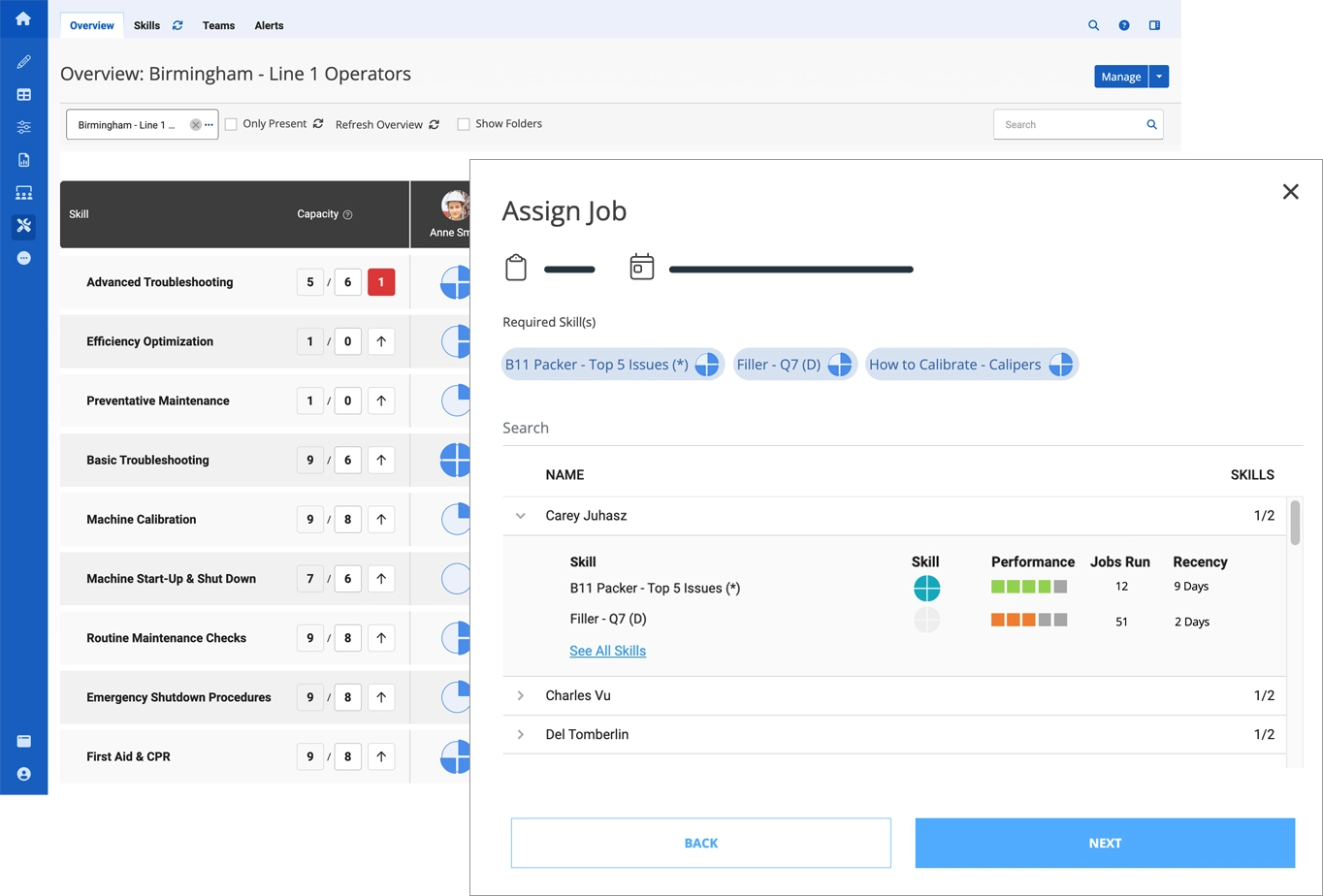

Bridging HR and Operations

One of the most compelling themes was the disconnect between HR systems and day-to-day operations. Skills matrices, certifications, and training data often live in HR tools that operations leaders can’t easily access.

By bringing skills and competency data directly into operational workflows, organizations can:

- Schedule work based on real capabilities

- Identify reskilling and upskilling needs

- Measure the effectiveness of training programs

For HR leaders, this turns training ROI from a “black box” into something measurable and defensible.

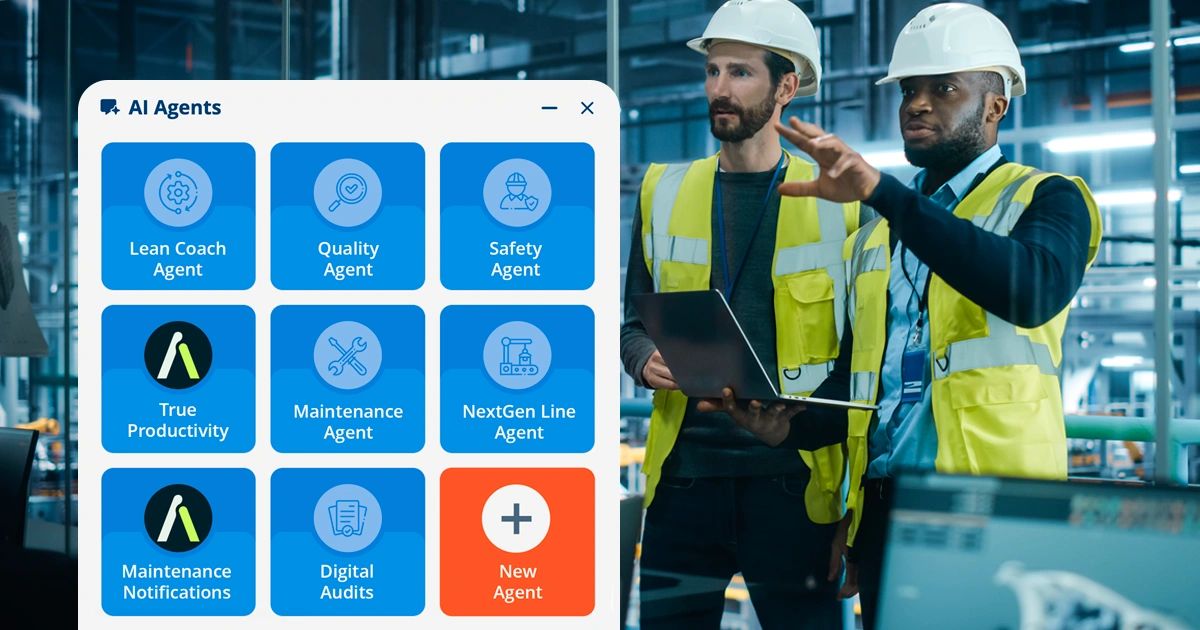

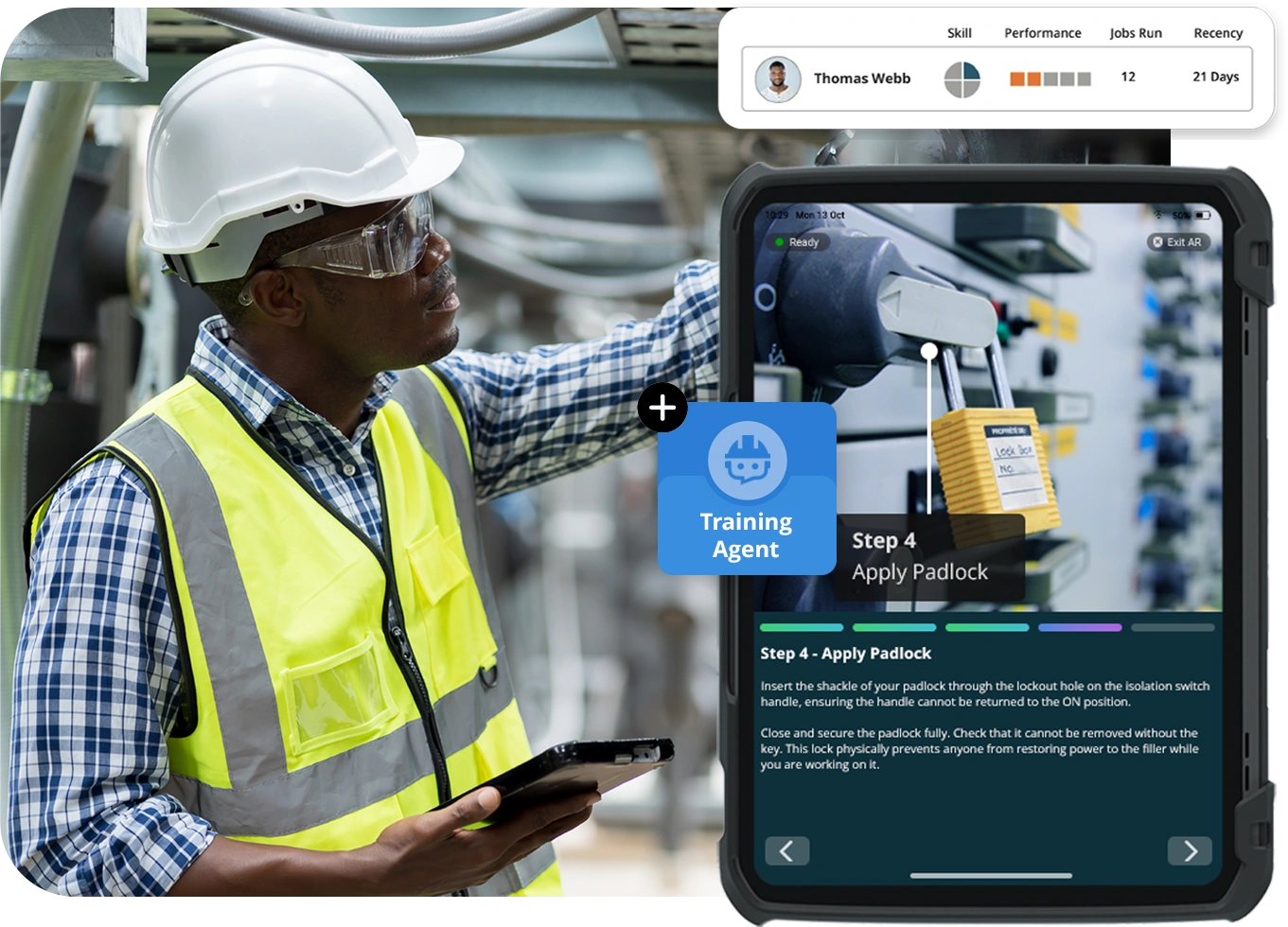

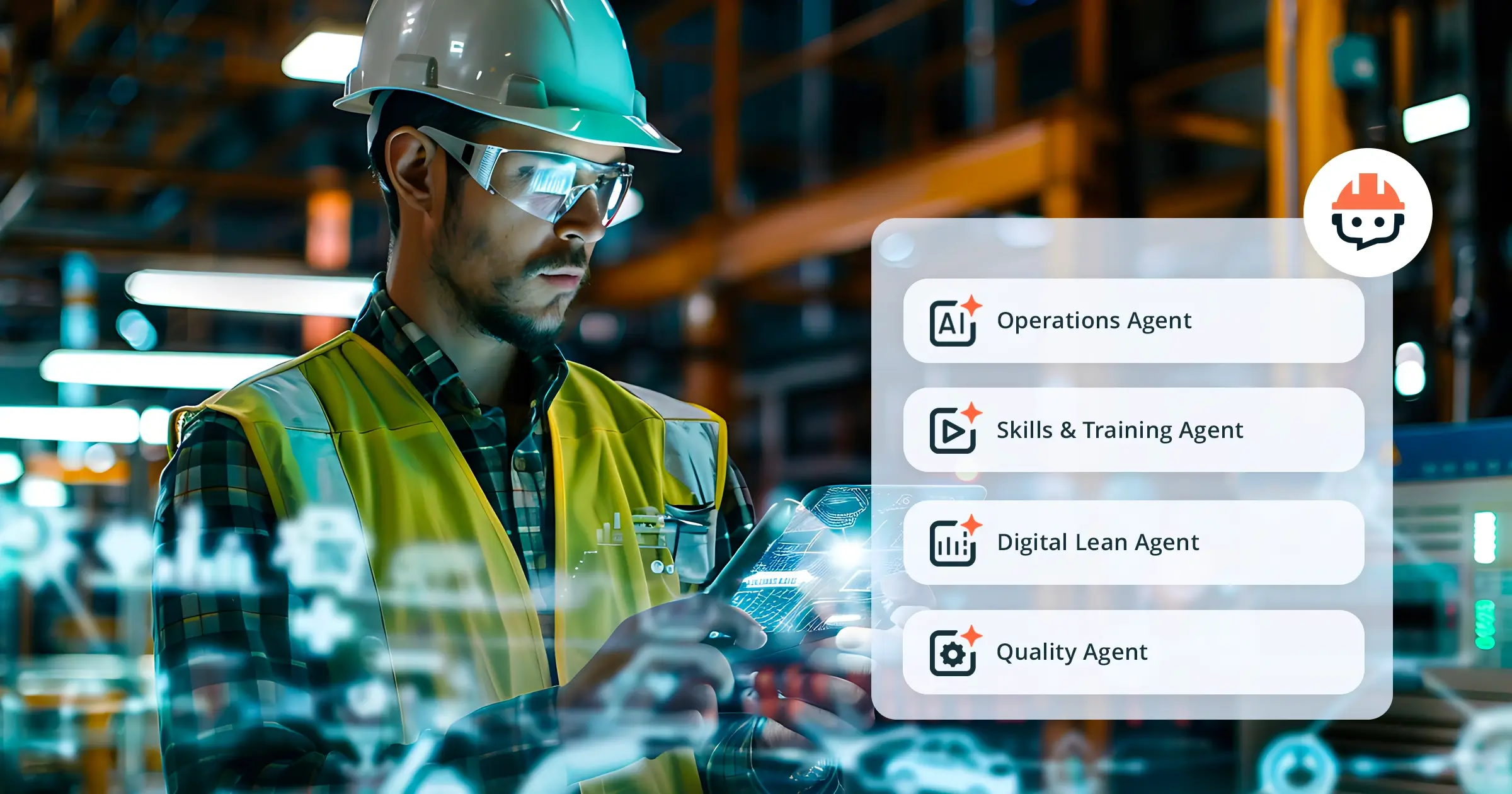

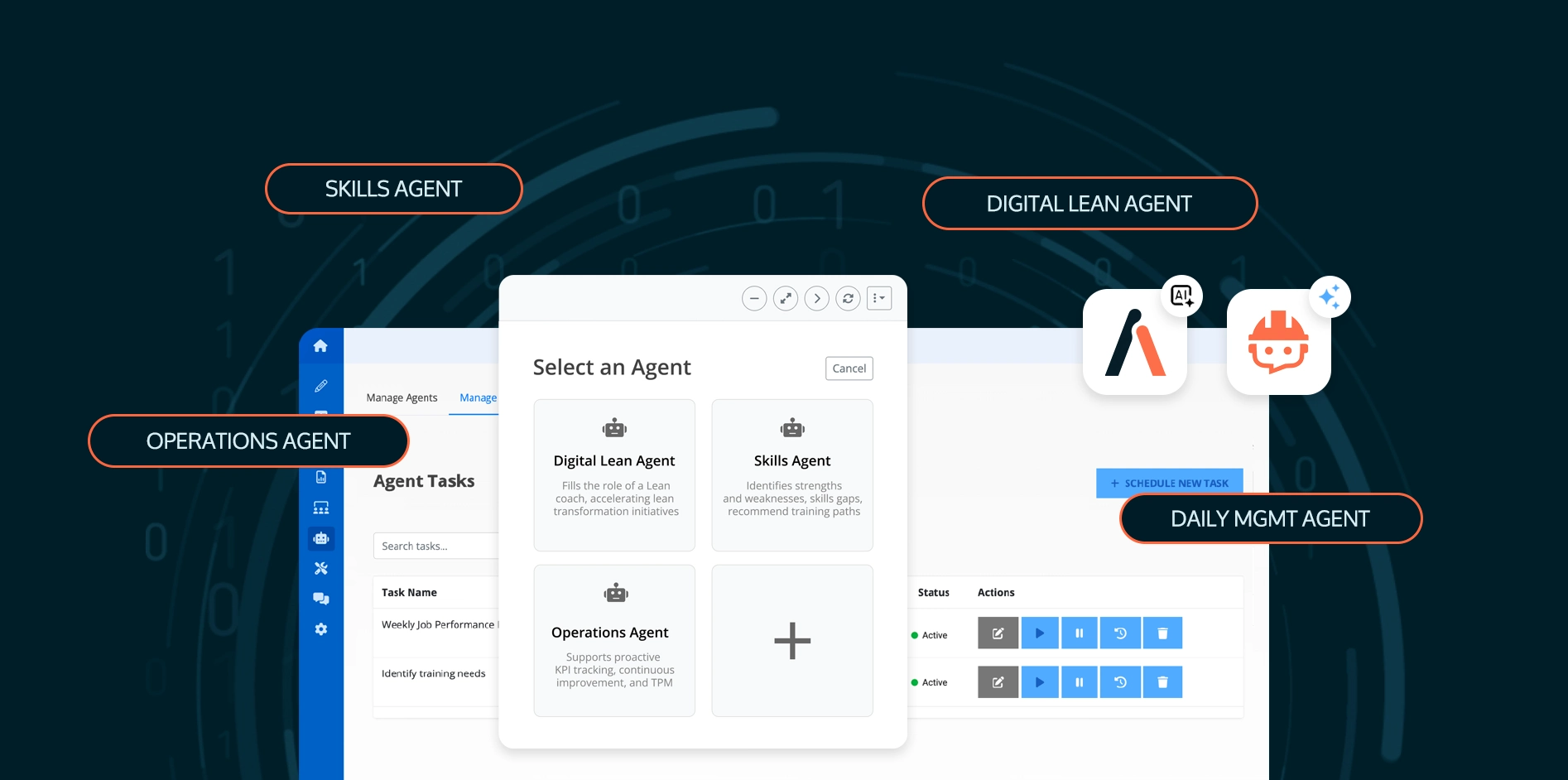

The Rise of AI Agents on the Frontline

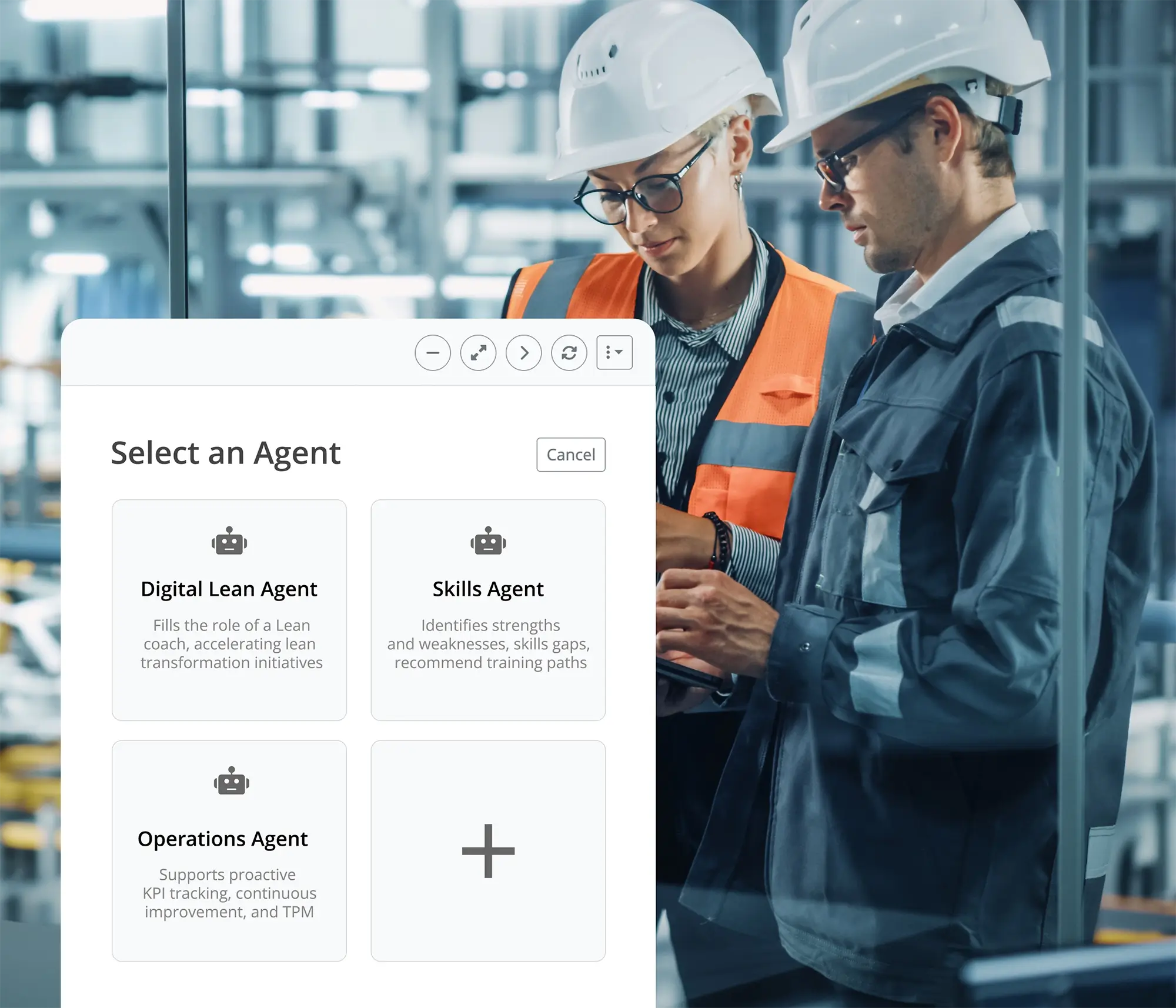

Chris also shared how Augmentir evolved beyond analytics into AI assistants and agents. From its generative AI factory assistant Augie to emerging agentic use cases, the vision includes:

- Digital lean coaches

- Training and skills agents

- Root cause analysis (“5 Whys”) agents

- Quality agents

- Safety agents

Importantly, Augmentir has established clear guardrails—such as human-in-the-loop approvals and deterministic logic for safety-critical tasks—to ensure AI supports workers responsibly; these principles are codified in Augmentir’s Six Laws of Agents.

What’s Next: A Human-Centered Future of Work

Looking ahead, Chris highlighted how leading manufacturers like Colgate-Palmolive and Hershey are creating new roles that blend HR and operations, focused on people capability and performance excellence.

The most exciting trend?

Companies are using technology to make frontline work better—faster onboarding, skills development in the flow of work, higher retention, and a stronger sense of purpose for workers.

By truly aligning people, process, and technology, these organizations are redefining what frontline work can look like.

Listen to the Full Conversation

To hear the full discussion on connecting HR, operations, and AI for the frontline workforce, check out the System of Record podcast on the HR Happy Hour Network.

Request a demo to learn more about Augmentir or connect with Chris Kuntz on LinkedIn to continue the conversation.