Learn how to reduce changeover time in manufacturing and the benefits of doing so to maximize production processes.

Providing quality products consistently and on time is at the forefront of customer satisfaction. In today’s competitive market, manufacturers must execute production runs quickly and efficiently to meet customer demand. But equipment and workers can’t operate 24/7. Machines must be properly maintained, workstations require cleaning and employees need rest. This is where optimizing changeover time comes in.

Changeover time is the period that it takes for workers to adjust machines or for assembly lines to start the next product run. A changeover usually includes swapping parts, sanitizing equipment, and preparing it for the next cycle. A good rule of thumb is to keep the changeover period down to less than 10 minutes. You can keep track of your organization’s changeover time by capturing how long it takes to produce each product.

Keeping an eye on your changeover time can help you maximize production and improve processes. Learn more about how you can reduce changeover time in manufacturing by exploring the following topics:

- Three steps for reducing changeover time

- Step 1: Assess your present changeover method.

- Step 2: Implement Single-Minute Exchange of Dies (SMED)

- Step 3: Create standard changeover procedures

- Benefits of reducing changeover time

- How digitization can help reduce changeover time

Three steps for reducing changeover time

Minimizing changeover time is a key component of lean manufacturing, a production method aimed at minimizing waste while increasing worker productivity. Implementation of this process of quick changeover can help manufacturers maximize uptime and cut down on waste caused by downtime.

Although there are various steps you can take to reduce it, here are some essential steps to help you get started:

Step 1: Assess your present changeover method.

It’s crucial to look at your existing changeover protocol before taking action to modify it. Try to identify which processes need optimization in order to cut down on the time between inventory runs.

Step 2: Implement single-minute exchange of dies (SMED).

Single-minute exchange of dies is a tool used in lean manufacturing to reduce changeover time to single digits. This means that a successful assembly run should be less than 10 minutes.

It’s helpful if workers have some idea of how long each task (such as switching parts, cleaning, etc.) takes during the production process. This awareness can be cultivated the more they familiarize themselves with procedures and day-to-day routines.

Step 3: Create standard changeover procedures.

Creating standard operating procedures (SOPs) and standardizing work can help with the changeover process. If there aren’t centralized procedures, changeover times will vary based on the employee, how long it takes them to clean up, set up and begin a new production run.

It’s important for procedures to contain explicit directions on how to perform successful changeovers. This can include highlighting which equipment needs to be calibrated and other machinery-related tasks.

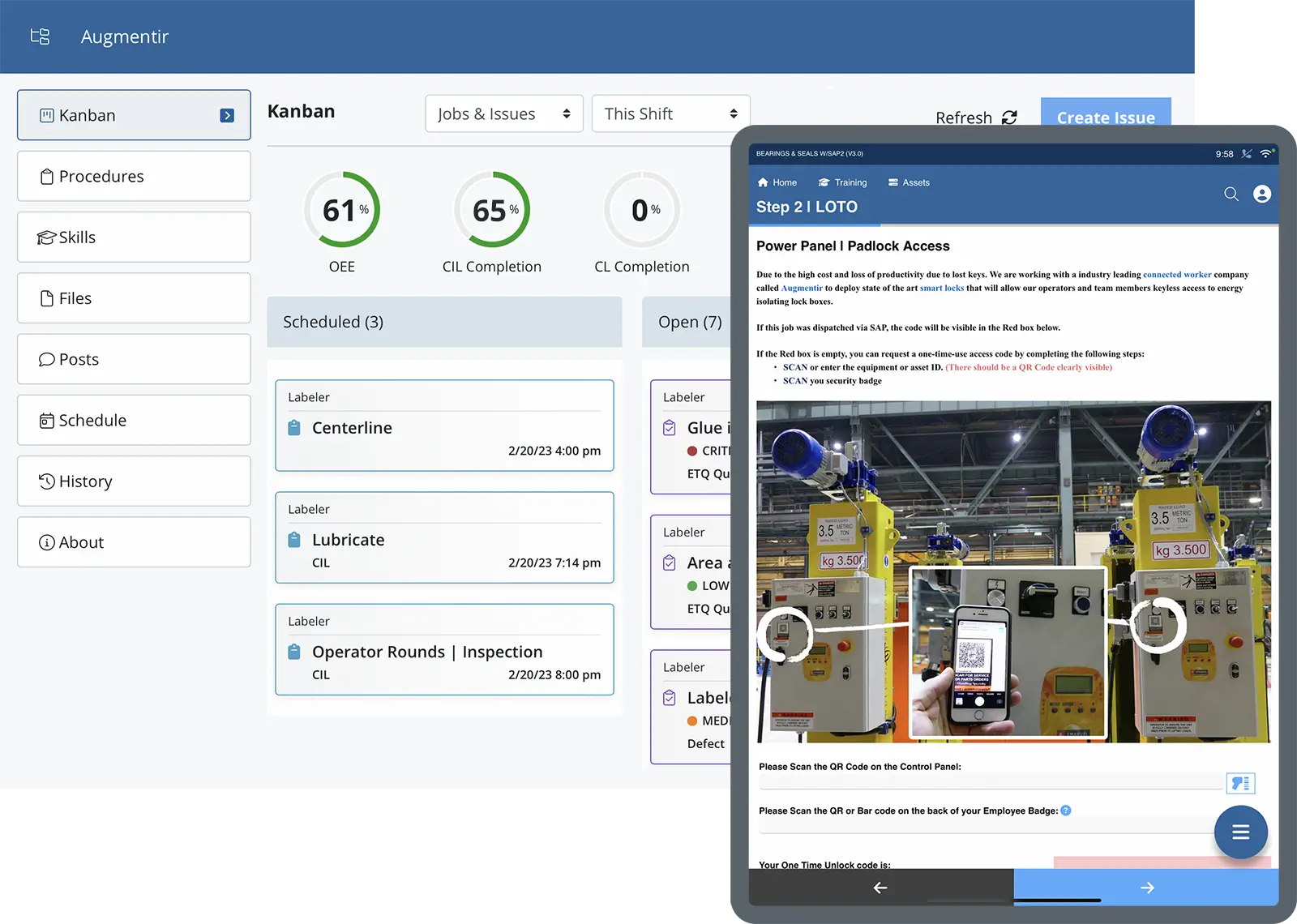

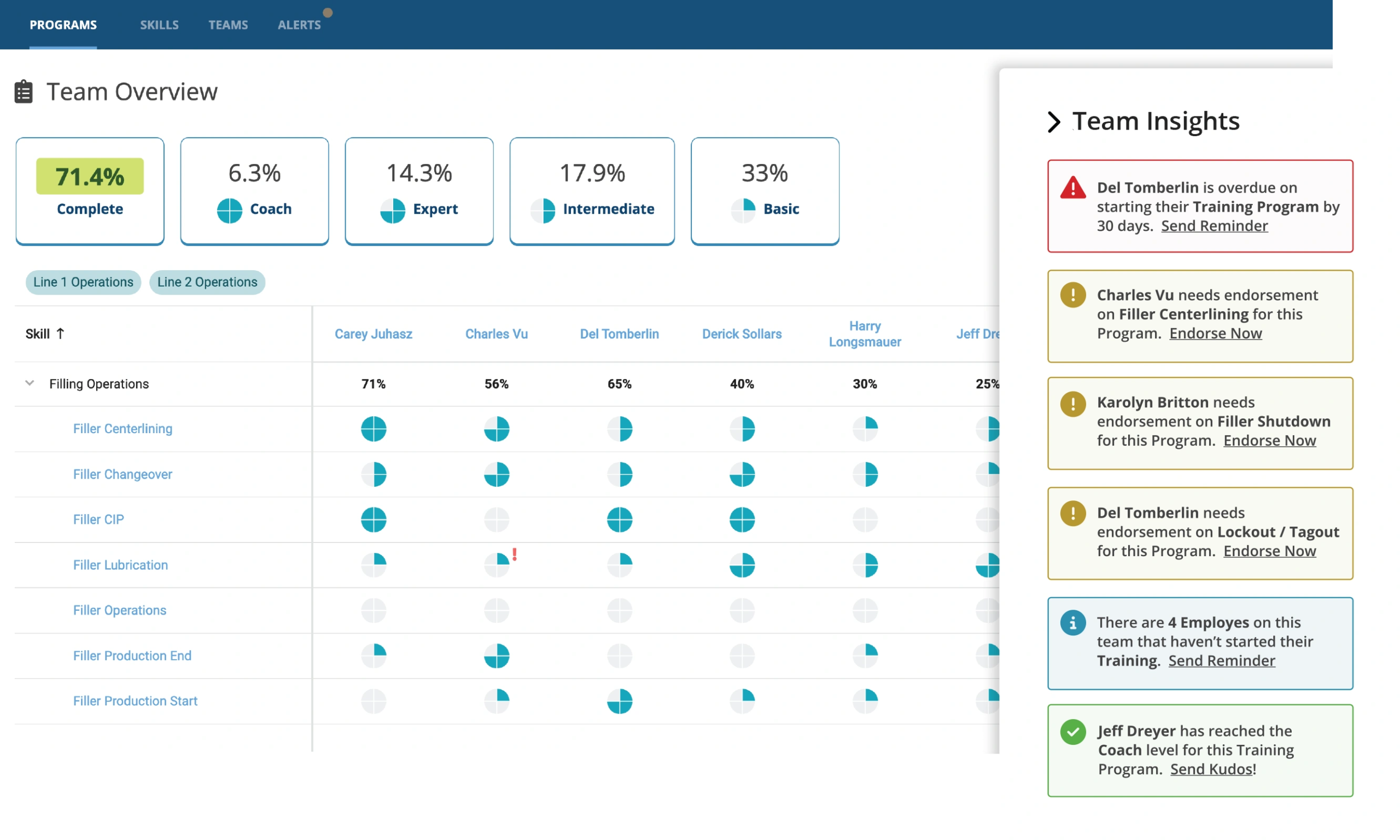

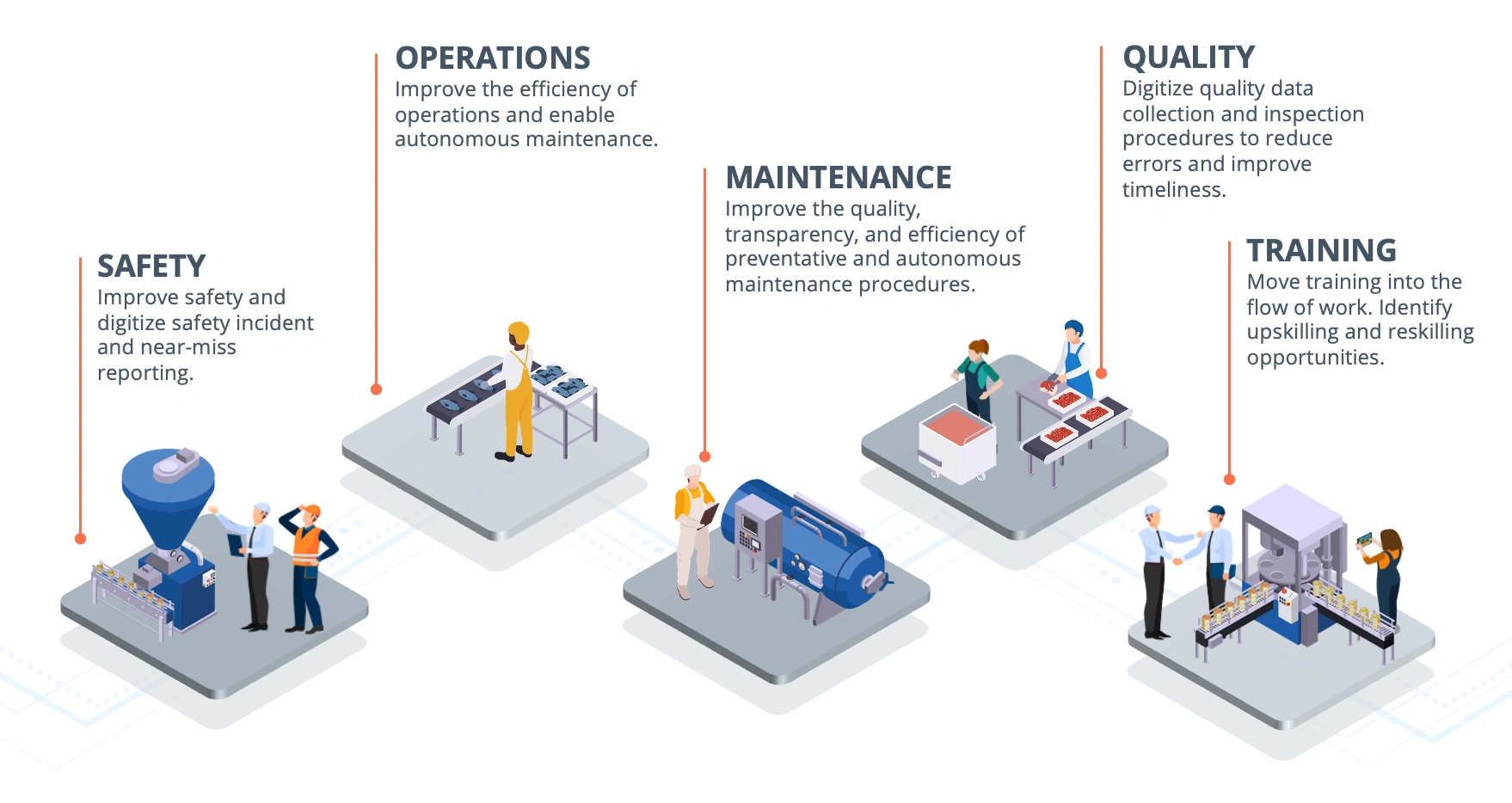

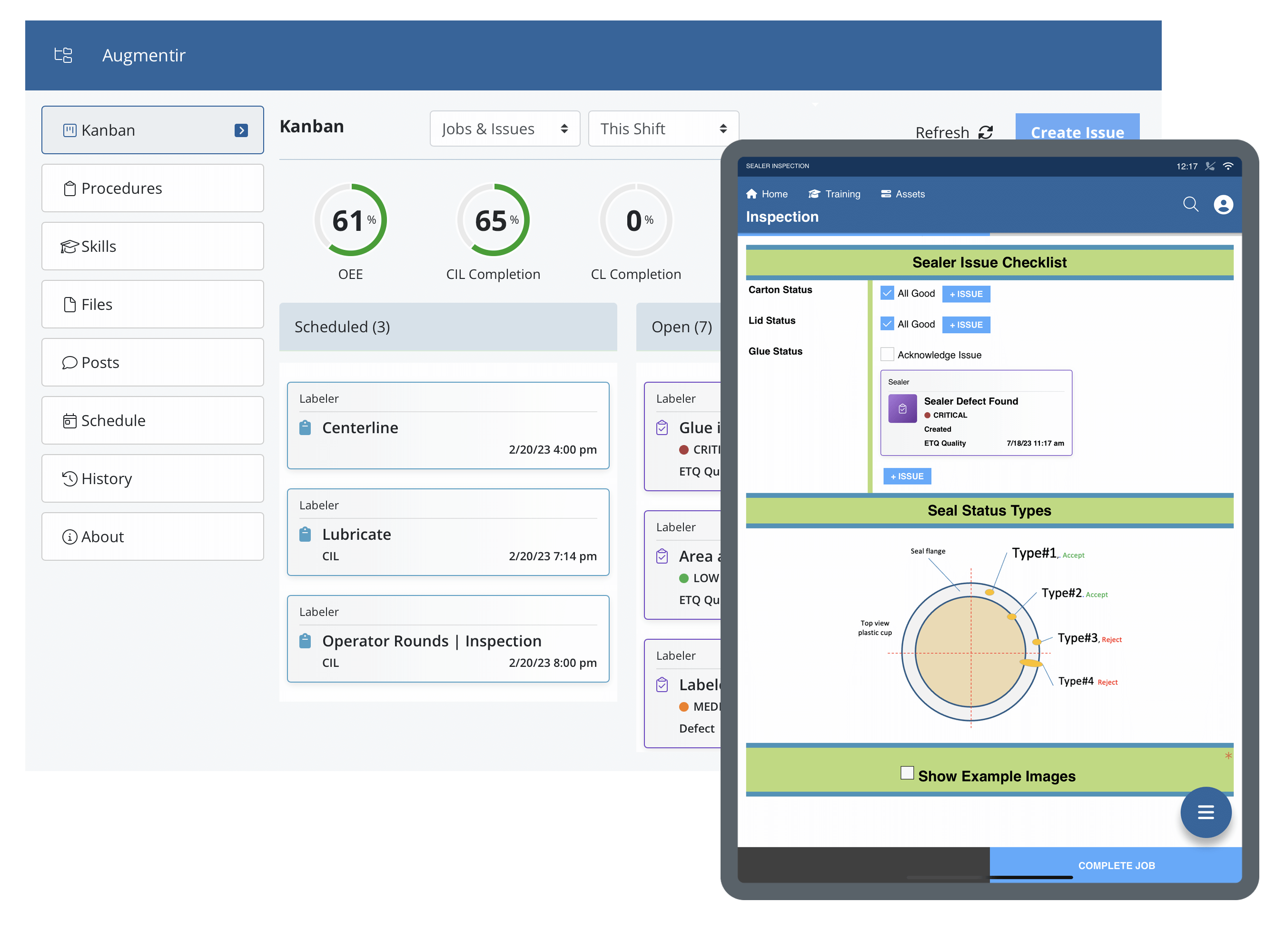

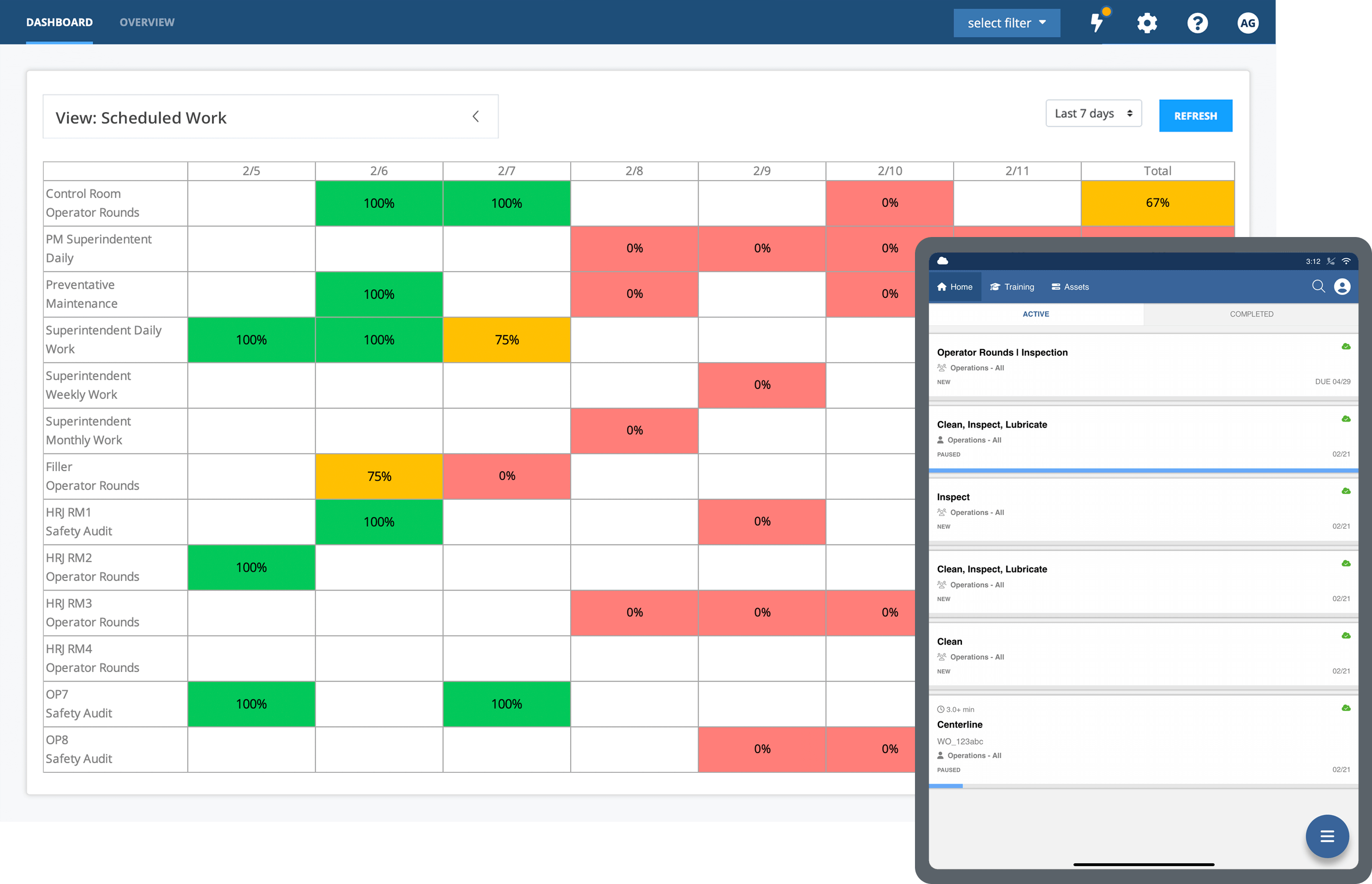

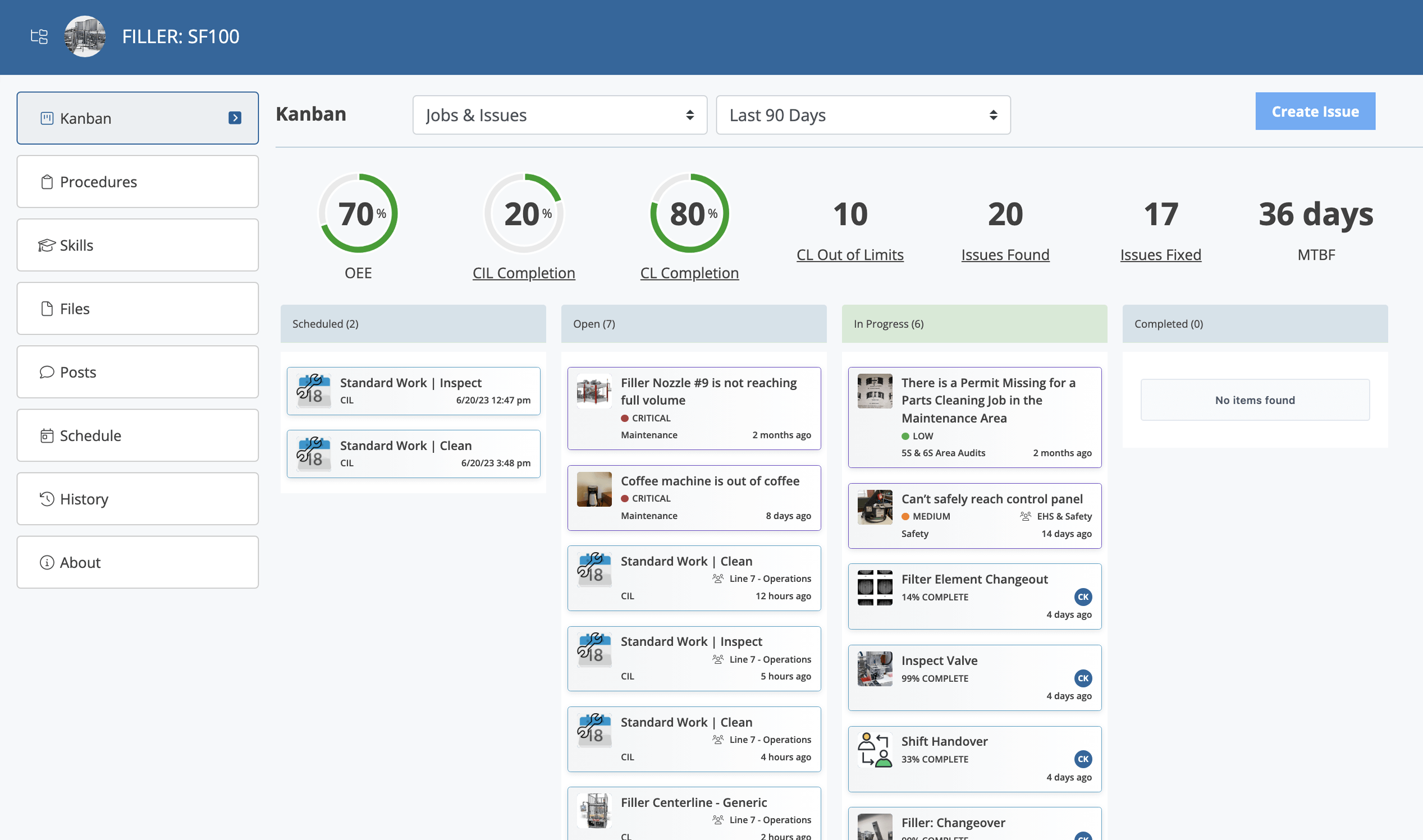

Digitizing changeover procedures can offer several benefits that enhance the overall efficiency, safety, and effectiveness of the changeover process. Digital procedures can be accessed by frontline workers through a mobile device or wearable technology, and help improve accessibility, accountability, standardization, as well as provide visual aids to less-experienced workers performing the task.

In a nutshell, having clear instructions makes it easier for workers to know what to expect when it’s time for a changeover.

Benefits of reducing changeover time

Reducing changeover time can yield a number of benefits, especially for companies producing a large number of products on a day-to-day basis.

Some of the advantages include:

- Makes it easier to transition between production processes

- Creates a more productive work environment

- Helps to reduce equipment downtime

- Gets products to customers faster

How digitization can help

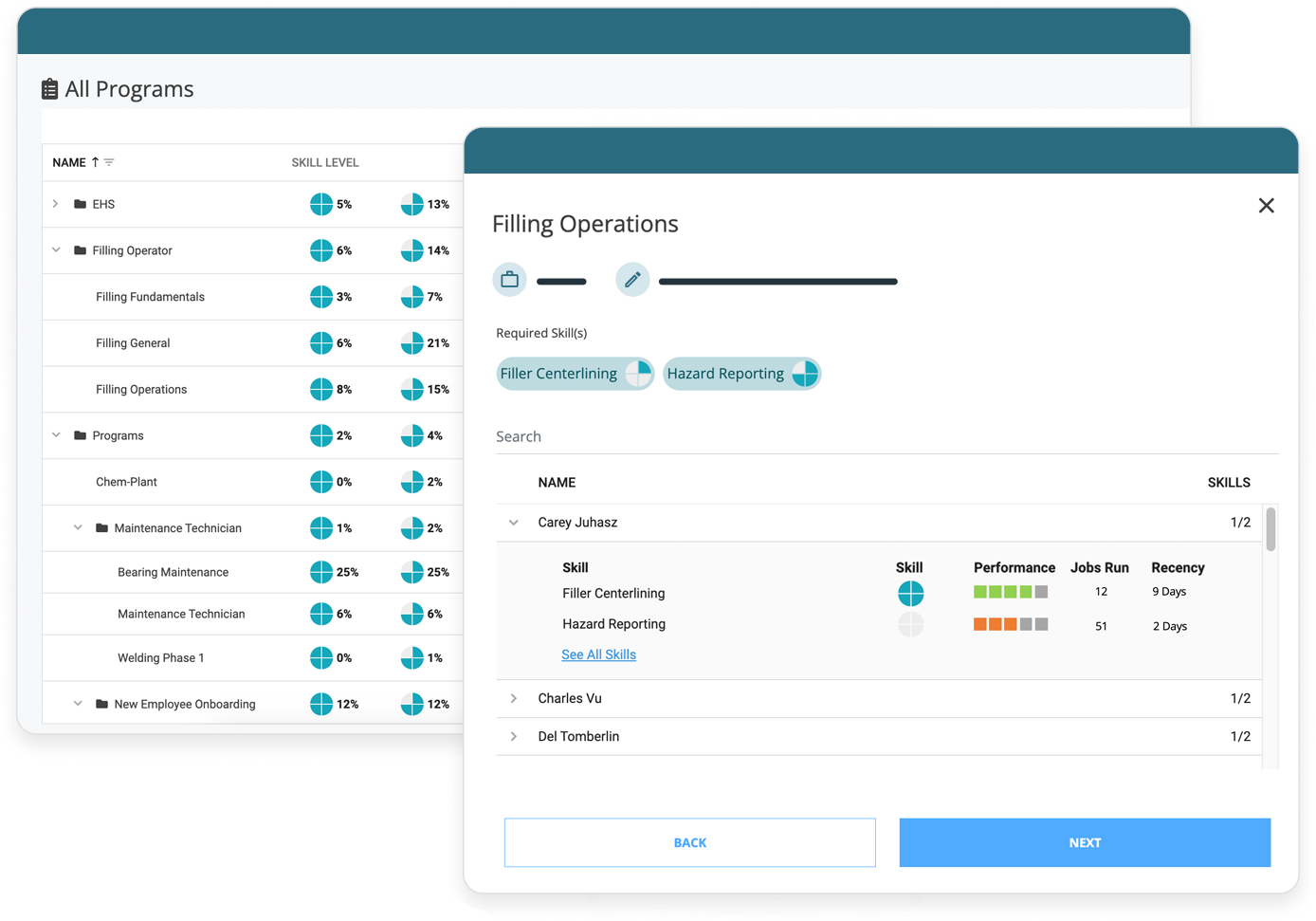

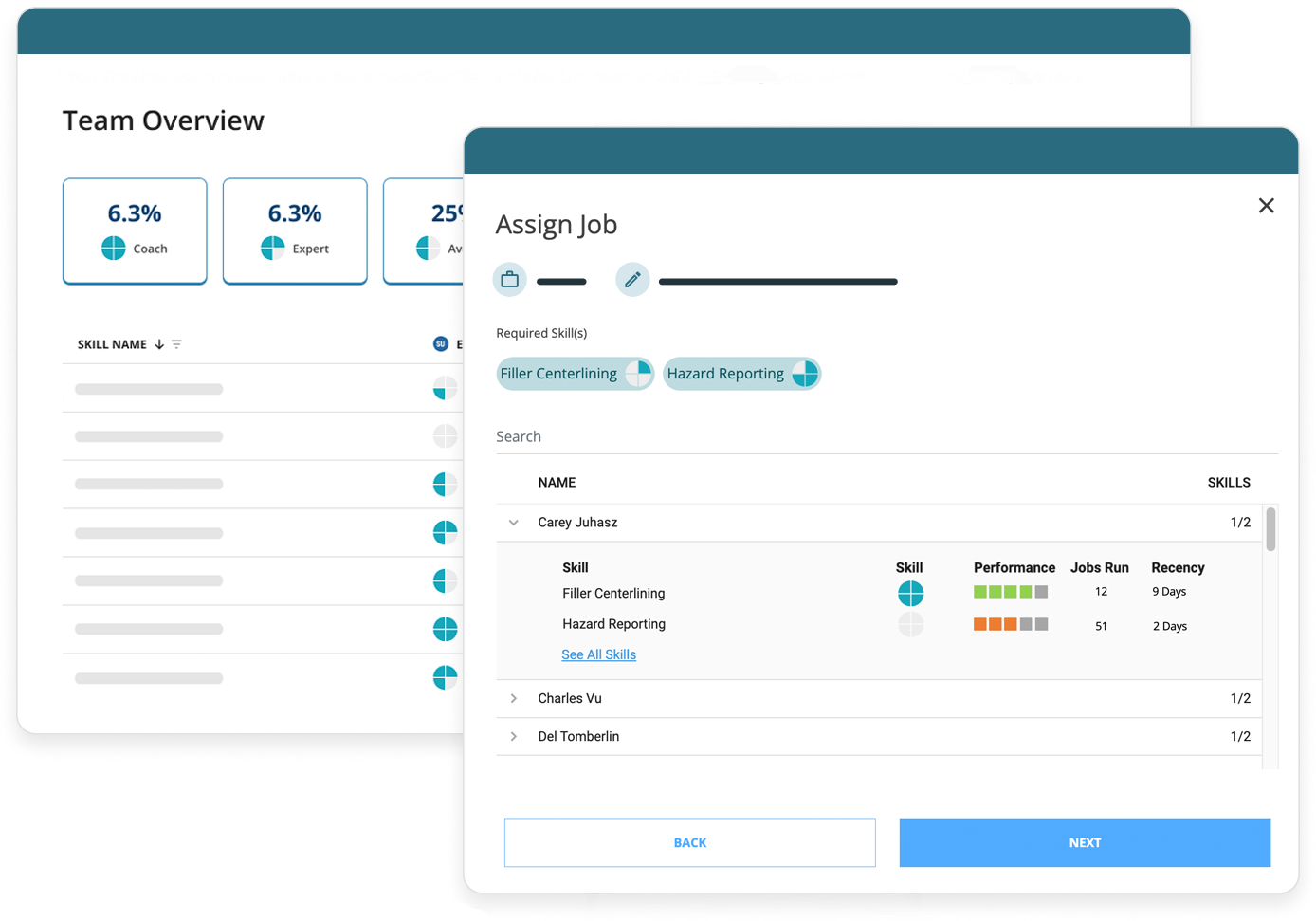

Implementing connected worker solutions that digitize and optimize changeover processes can help reduce the time each changeover takes by providing explicit digital instructions customized to any given task, machine, or worker.

Digital work instructions are electronic versions of work instructions, quality manuals, or SOPs that provide necessary visual aids and real-time contextual information to help guide workers through complex tasks. These digital work instructions intelligently deliver guidance and streamline changeover processes with images, videos, augmented reality experiences, and live support from colleagues or subject matter experts.

Augmentir is the world’s first AI-powered connected worker platform that helps industrial frontline workers reduce changeover time in manufacturing using smart technology. Learn how world class manufacturers are using Augmentir to drive improvements across their industrial operations – contact us for a demo today!