Learn how to write manufacturing SOPs and the benefits of having standard operating procedures in a manufacturing operation.

Standard operating procedures, or SOPs, will change the way you run your manufacturing operations.

SOPs are imperative to a properly organized management structure. They are step-by-step guidelines workers must follow when carrying out tasks to standardize work and are designed to meet industry regulations.

Essentially, they provide general info about assignments, including the tools, methods, or machinery needed to complete projects. SOPs indicate what the task is, who will perform it, how it should be completed, and when it should be completed.

For example, manufacturers may write SOPs for employee training to reduce risk and injury. Leadership may also use procedures to assign goals and measure employee performance.

Read on to find out more about the benefits of manufacturing SOPs and how to write them by exploring the following topics:

- Advantages of Implementing Standard Operating Procedures

- How to Write a Manufacturing SOP

- Why SOPs are Important in Manufacturing

- Improving SOPs with Digital Technology and Connected Worker Solutions

Advantages of Implementing Standard Operating Procedures

According to Forbes, a comprehensive SOP keeps workers on the same page and improves efficiency and accuracy. Without documented procedures, there is no way to set proper standardized processes and workers might try to complete jobs in non-standard methods, which leads to disruptions in the production processes and causes all sorts of quality issues in a manufacturing environment. Thankfully, SOPs work to prevent that from happening.

Some of the advantages of using SOPs include:

- Meets regulatory compliance: Product inspectors constantly ask to review SOPs when conducting audits. These serve as the point of reference for whether specific measures followed meet industry guidelines.

- Standardizes tasks: The point of written procedures is to establish a standard way of completing tasks. They enable tasks to be performed in the same way across the company.

- Improves accountability and tracking: SOPs define who is responsible for a work order, maintenance check or inspection. This reporting can improve accountability across departments. If a task wasn’t completed accordingly or a procedure was missed, management can take necessary steps to prevent it from happening again.

Digitized SOPs can further improve tracking and traceability features, helping manufacturers comply with regulations and quality standards. With digital SOPs it becomes easier to maintain records of every step in the production process, including who performed each task and when.

How to write a manufacturing SOP

Writing a comprehensive set of SOPs can help workers perform tasks in the safest and most efficient way possible. Although there isn’t an official way to write procedures, you can follow certain steps to make them more effective:

Step 1: Establish a goal.

It’s important to think about what you want your SOP to accomplish. Regardless if you’re starting a new process or improving an existing one, figuring out the end goal will make it easier to complete the document.

Step 2: Pick a format.

There are different formats you can use to write your document: step-by-step, hierarchical, narrative, etc. We recommend the sequential step-by-step format for its straightforwardness.

Step 3: Write the procedures.

Make sure your procedures are clear, concise, current, consistent, and complete.

Step 4: Review and update.

It’s important to review your SOP for any discrepancies and update them if necessary. Consider asking fellow leaders knowledgeable in procedure creation to read them over.

Why SOPs are Important in Manufacturing

Compliance with manufacturing SOPs is crucial for a number of reasons, including:

- Prevents accidents and ensures worker safety

- Promotes worker consistency

- Improves product quality

- Protects your business’s reputation

SOPs are a critical component of manufacturing operations because they provide a structured framework for achieving consistent quality, safety, and efficiency in the production process. They help manufacturers meet regulatory requirements, reduce errors, and ensure that employees are trained to perform tasks consistently and safely.

Digitizing Manufacturing SOPs with Connected Worker Solutions

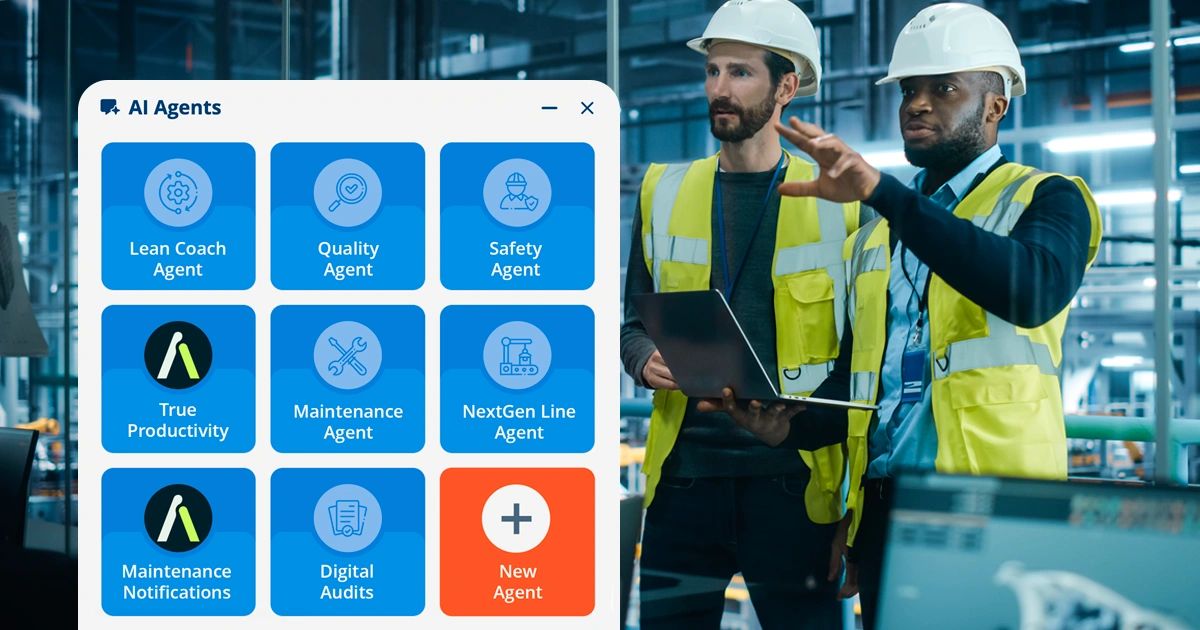

Using connected worker technologies to create digital SOPs can significantly improve their impact on manufacturing by enhancing accessibility, effectiveness, and overall utility.

Through digitization and smart, connected worker technology manufacturers can improve SOPs with features like real-time access, remote collaboration and guidance, data-driven insights, workflow automation, enhanced training, traceability and compliance, and more. Essentially, with these advanced technologies, manufacturing organizations can augment and support their workers with optimized processes and SOPs creating an environment of continuous improvement.

Augmentir offers customized AI-powered connected worker solutions that transform how you write and create manufacturing standard operating procedures. Request a live demo today to learn more about why leading manufacturers are choosing our solutions to improve their manufacturing processes.