Learn about the best practices for optimal asset maintenance performance and how to track your assets to ensure that everything is in working condition.

Asset maintenance refers to everything that goes into keeping your manufacturing assets in tip-top shape. With machinery, for example, asset maintenance means conducting frequent inspections and repairs. With office space, this term involves maintaining a clean, safe, and productive workplace. With products, it includes checking finished goods for any deficiencies or errors.

In a nutshell, asset maintenance helps prolong the performance and lifespan of equipment, machinery, goods, and more. Performing this strategy ensures that your essential business resources continue functioning smoothly and properly.

Learn the best practices for increasing asset maintenance performance:

- Best practices for optimal asset maintenance performance

- Advantages of asset maintenance

- Asset maintenance tools and how Augmentir can help

Best practices for optimal asset maintenance performance

Implementing key best practices can improve asset maintenance in manufacturing. We’ve put together five crucial strategies to ensure your manufacturing firm is performing at its best while minimizing costs:

1. Gather as much info as possible

Gathering data on assets can help management make better informed production decisions. Asset tracking is a great technique to accomplish this.

2. Create a preventive maintenance schedule

The data that’s been collected will make it easier to create a preventive maintenance schedule. To create one, start by organizing asset data and analyzing the info you’ve amassed (e.g., how often each item must be checked and maintained). Lastly, prioritize your most important assets and allocate funds to maintain them.

3. Train workers

Investing in your employees pays off. Procedural documentation and training will help ensure that all maintenance work is thoroughly performed and recorded. Skills management software can help with ongoing management and tracking of employee skills and training requirements.

4. Apply an inventory tracking system

There is nothing worse than beginning a project only to find out that you don’t have all the moving parts to complete it. An inventory system helps reduce the chances of missing crucial product information and enables you to better track company assets.

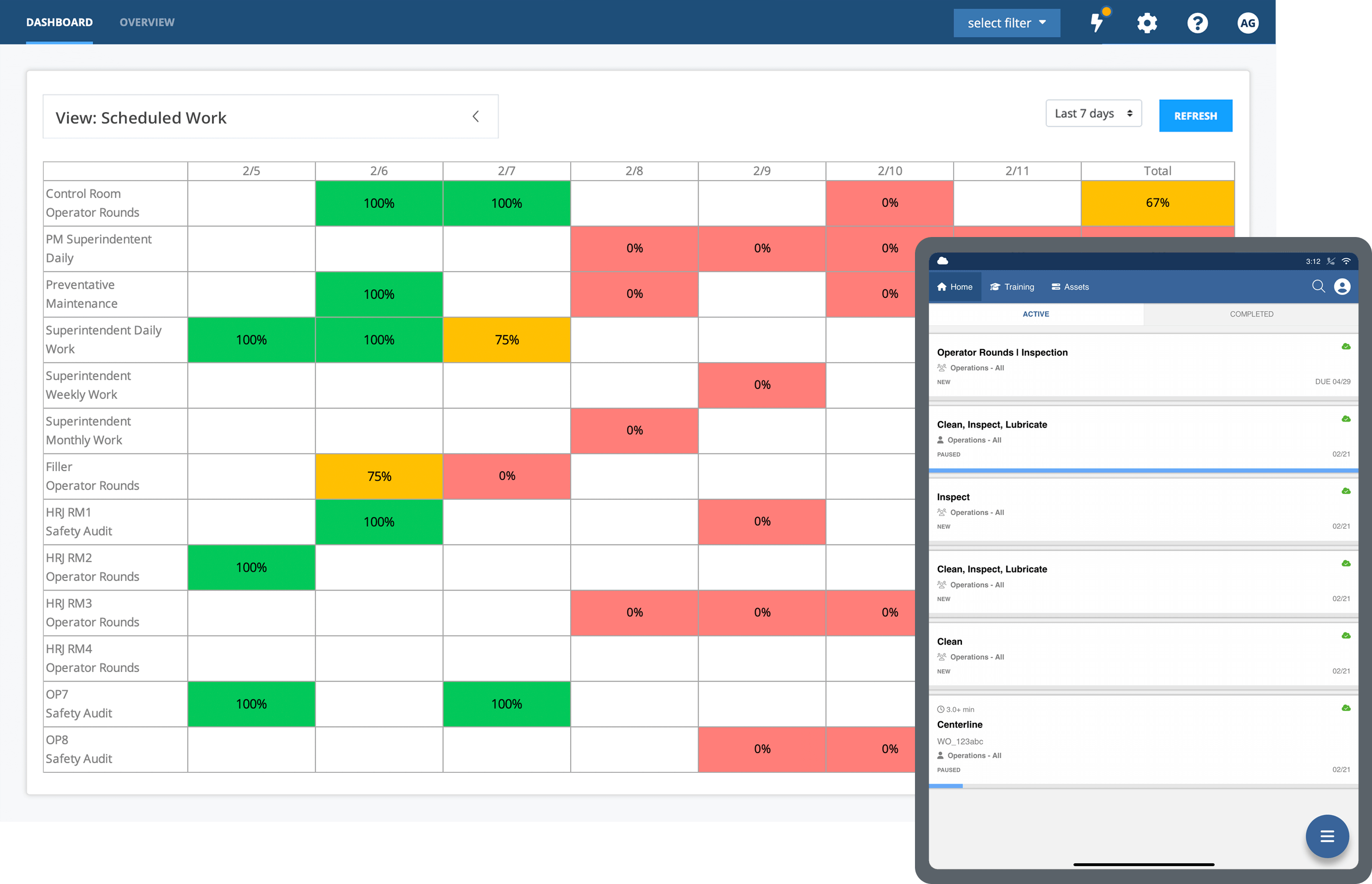

5. Track asset maintenance key performance indicators (KPIs)

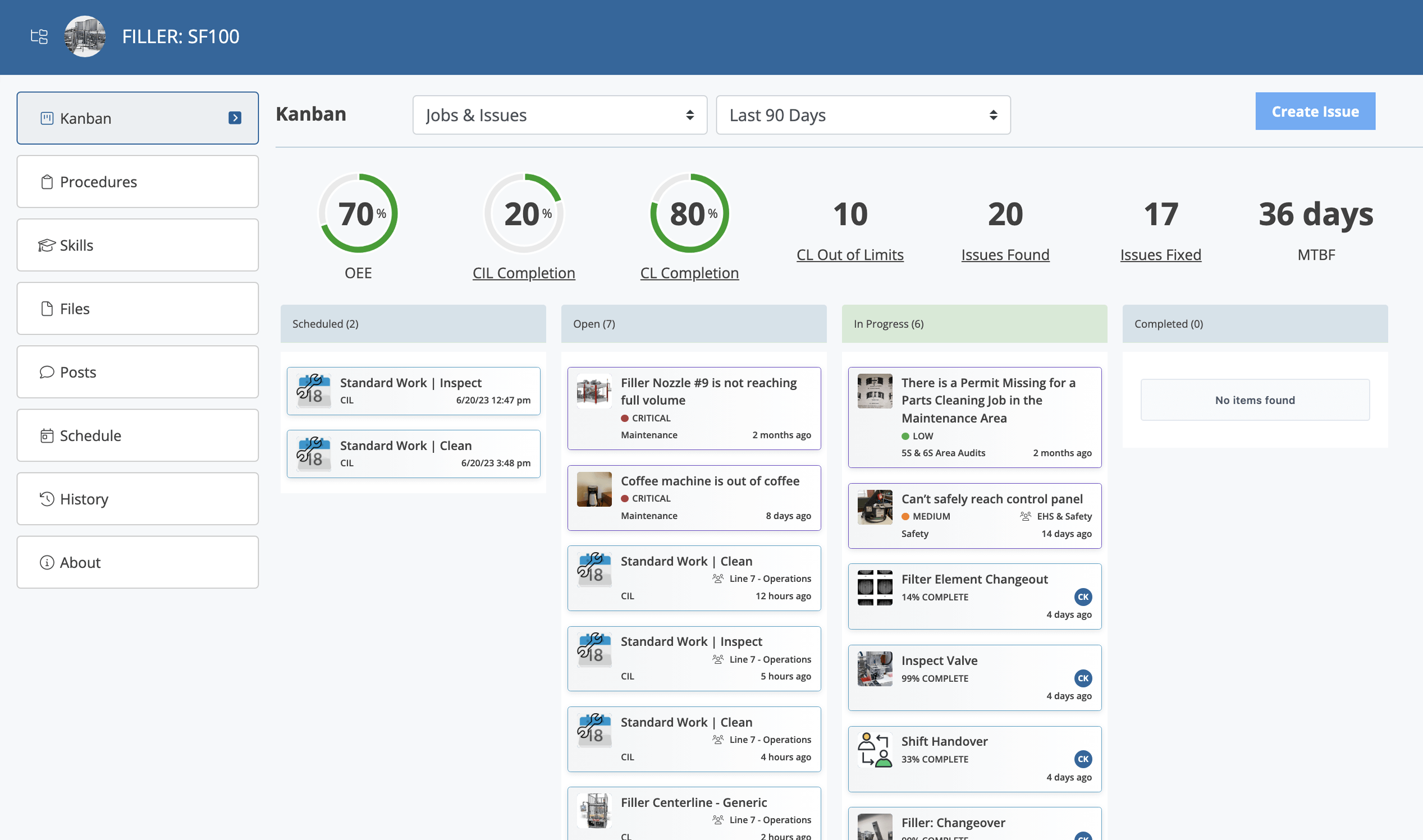

KPIs such as mean time between failures (MTBF), overall equipment effectiveness (OEE), and work order resolution time can give a performance review on how well your assets are doing. They’re also great at pinpointing which areas could benefit from predictive maintenance, the process of checking for deficiencies to avoid future machine breakdowns.

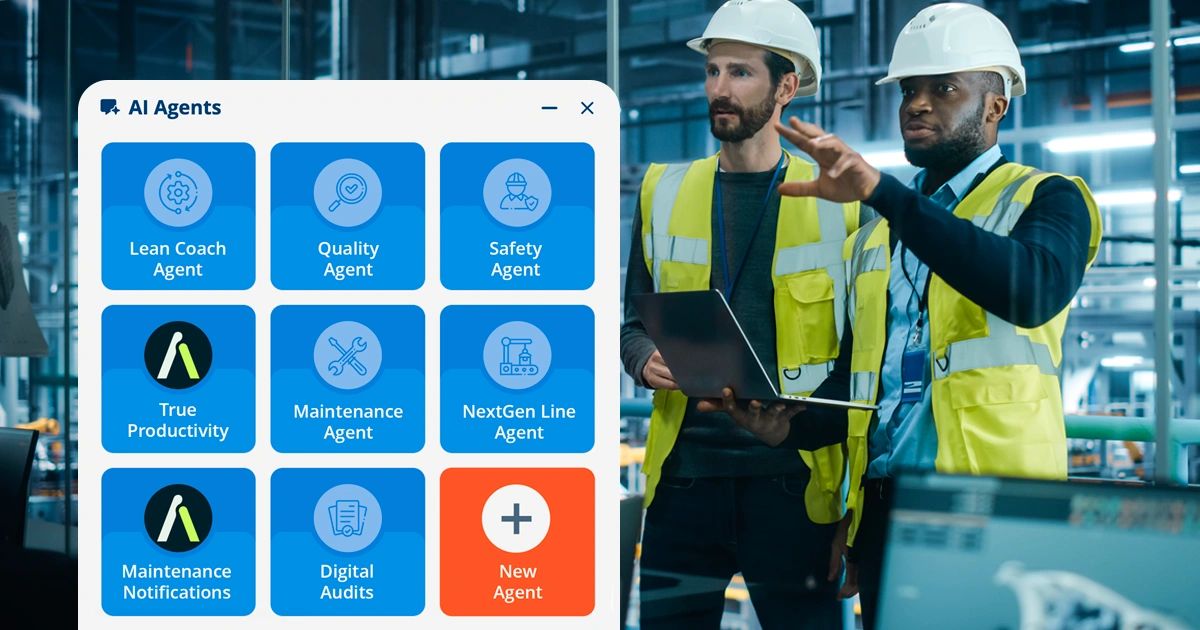

Asset management software like Augmentir’s Connected Worker Solution helps you simplify the operations and maintenance of your facility. Manage work and maintenance procedures, skill requirements, training, KPIs, and preventive maintenance schedules all through a visual interface. Connected worker solutions help integrate your CMMS with your shop floor operations.

Advantages of asset maintenance

The maintenance of assets in manufacturing consists of regularly inspecting, repairing, and replacing equipment and other assets to confirm that everything is in workable condition.

Advantages of asset maintenance:

- Enhanced workplace safety

- Greater equipment reliability

- Longer machine lifespan

- Lower maintenance costs

- Improved productivity

- Better regulatory compliance

Asset maintenance tools and how Augmentir can help

Manufacturers are encouraged to manage and track assets to limit product flaws, prevent machine failure, and improve overall productivity. However, in today’s digital age, especially with more mobile devices, complex cloud-based technologies, and software updates, handling assets has become much more complicated.

This is where Augmentir’s AI-powered connected worker solution, or asset management software, comes in. Our solution allows manufacturing facilities to better monitor their assets and manage them effectively with easy-to-use customizable dashboards and real-time insights.

Ours is the world’s only connected worker suite that provides an overarching view of an asset’s life cycle. Accurate digital asset records can help manufacturers with resource planning. In addition, our tool helps with asset record keeping so that you don’t have to worry about not meeting regulatory compliance requirements.

Though a manufacturing firm could use a spreadsheet to track its assets, our digital solution gives workers the ability to evaluate asset-specific data and make better decisions about how to manage each one.

Transform how your company runs its maintenance operations. Request a live demo today!