The impact of COVID-19 has changed the manufacturing landscape permanently, and clear changes are necessary for manufacturing leaders in order to stay competitive and succeed in this new normal. This was the focus in the recently published Gartner Hype Cycle for Manufacturing Operations Strategy, which focused on a portfolio of enabling capabilities and technologies, and […]

The impact of COVID-19 has changed the manufacturing landscape permanently, and clear changes are necessary for manufacturing leaders in order to stay competitive and succeed in this new normal. This was the focus in the recently published Gartner Hype Cycle for Manufacturing Operations Strategy, which focused on a portfolio of enabling capabilities and technologies, and their potential business impacts. The goal of this Hype Cycle report was to provide a holistic view of key concepts that can guide manufacturers when defining both short-term and long-term strategies for growth.

Augmentir was recognized as an important player for Connected Factory Worker technology and Immersive Experiences in Manufacturing.

Emerging Technologies in Manufacturing

According to Gartner, a dynamic and volatile market environment is changing the face of manufacturing operations. This Gartner Hype Cycle report on manufacturing operations strategy will help inform future approaches, create roadmaps, align investments, and educate peers.

It is not business as usual in 2020. The impact of COVID-19, and changes in how factories are located, staffed, managed and digitized are placing pressure on manufacturing operations leaders. Technologies such as artificial intelligence (AI) and augmented reality (AR) based remote collaboration are central now to the corporate innovation portfolio of any business leader and crucial to boosting productivity at a time when enterprises most need it. This hype cycle highlights these, as well as other key mature and emerging technologies, including the following:

- Connected Factory Worker: Connected factory workers use various digital tools to improve the safety, quality, and productivity of the jobs they perform. This technology helps connect workers to the “digital fabric” of the business, providing insight into the tasks they perform so that they can be optimized and continually improved on.

- Immersive Experiences in Manufacturing Operations: According to Gartner, immersive experiences refer to enabling the perception of being physically present in a nonphysical world or enriching people’s presence in the physical world with content from the virtual world. Gartner sees using immersive experiences for quality and maintenance tasks, connecting with employees that are not able to be on-site, or wearables for safety management.

Augmentir is recognized in the context of Connected Factory Workers and Immersive Experiences in Manufacturing Operations as a software and solution provider.

Augmentir’s Approach to Connected Factory Workers and Immersive Experiences in Manufacturing

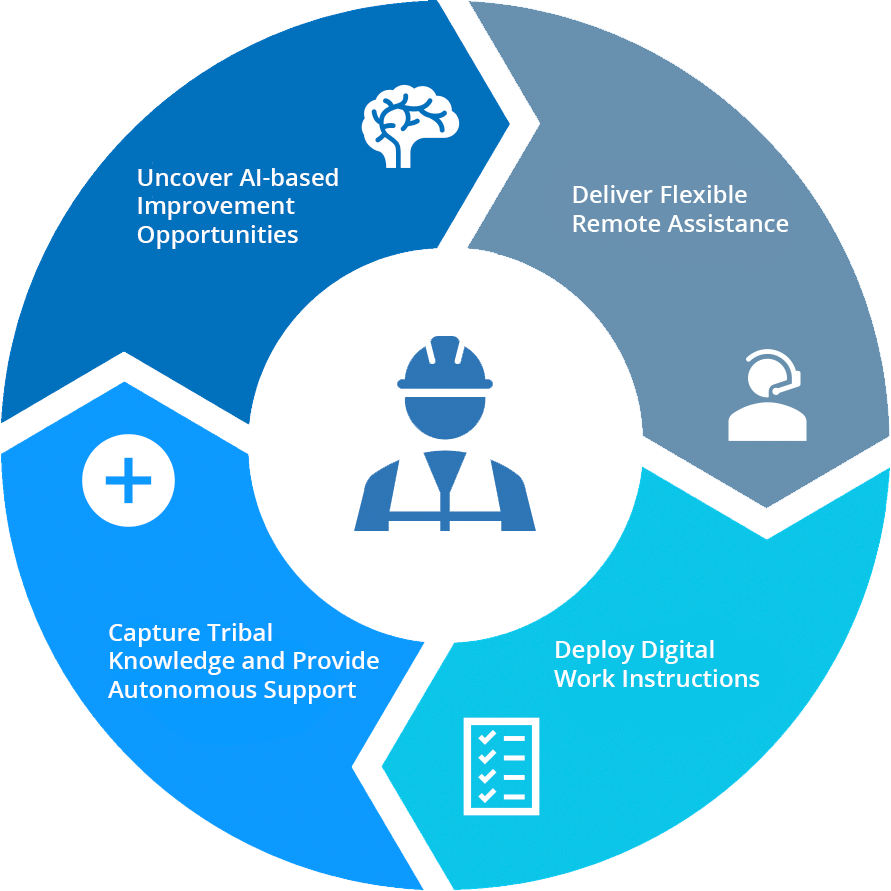

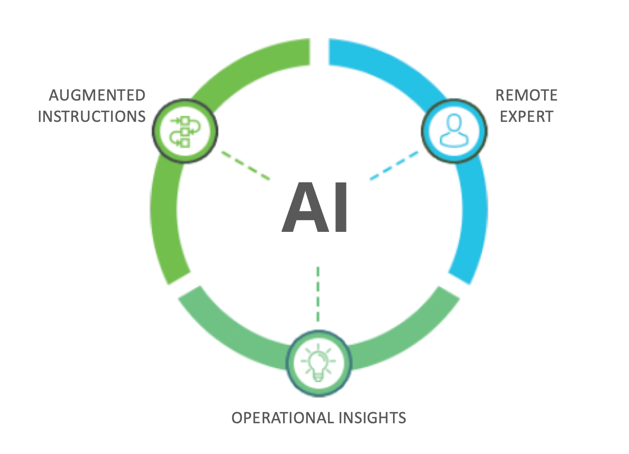

Augmentir sits at the intersection of these innovation profiles, using artificial intelligence and machine learning (AI/ML) to amplify the value that digital technologies bring to the connected worker.

Digitized workflows and augmented work instructions help guide connected workers with visual aids and contextual information. AI is used to personalize the instructions to each worker’s proficiency level, which helps intelligently close the skills gap and enable workers to perform at their best.

Remote Expert guidance helps workers resolve issues faster by leveraging collaboration with remote subject matter experts. Integrated chat allows one expert to support multiple workers. Multi-level escalation helps connected workers solve problems faster.

Augmentir’s AI-based “True Opportunity” system uses granular data to identify the largest opportunities in improving the skills of the frontline workforce and helps to drive continuous improvement throughout the organization.

At Augmentir, our AI identifies patterns and generates insights based on analyzing data from connected workers. These insights improve worker performance as well as provide positive impact on training, operational workflows, and quality. According to Gartner, “The possibility of predicting performance is extremely attractive for manufacturers. This is driving the strong interest in ML. ML is an essential enabler of artificial intelligence (AI), smart factories and intelligent automation”.

Our view at Augmentir is that the purpose of a connected worker platform isn’t simply to deliver instructions and remote support to a frontline worker, but rather to optimize the performance of the connected worker ecosystem. Artificial intelligence is uniquely able to address the fundamental macrotrends of growing skills gaps and the loss of tribal knowledge. With an ecosystem of content authors, frontline workers, subject matter experts, operations managers, continuous improvement engineers, and quality specialists, there are were dozens of opportunities to improve performance.

If you’d like to see how our AI is able to uncover and rank “True Opportunities” across your workforce and improve overall worker performance or drive continuous improvement, schedule a demo today.