As a leader in the connected worker software market, we have experienced the highs and the lows that the pandemic has brought to the industrial frontline worker market. One area that stands out in particular is the equipment field service space. Equipment OEMs typically support the installation, startup, maintenance, and repair of their products through […]

As a leader in the connected worker software market, we have experienced the highs and the lows that the pandemic has brought to the industrial frontline worker market. One area that stands out in particular is the equipment field service space. Equipment OEMs typically support the installation, startup, maintenance, and repair of their products through some combination of a direct service force, a dealer service network, or their customers. This created a real problem when the COVID pandemic spread since the “instructions” available to support these services were designed for technicians who already knew how to perform the work, and much of the equipment was highly sophisticated requiring visits to the customer site. OEMs had to quickly find a way to project some type of virtual presence or ‘remote expert’ solution, to mimic being on-site as closely as possible.

This led to a rush to implement either industrial remote expert tools, enterprise collaboration products like Cisco Webex and Microsoft Teams, or consumer products like FaceTime to support field service activities.

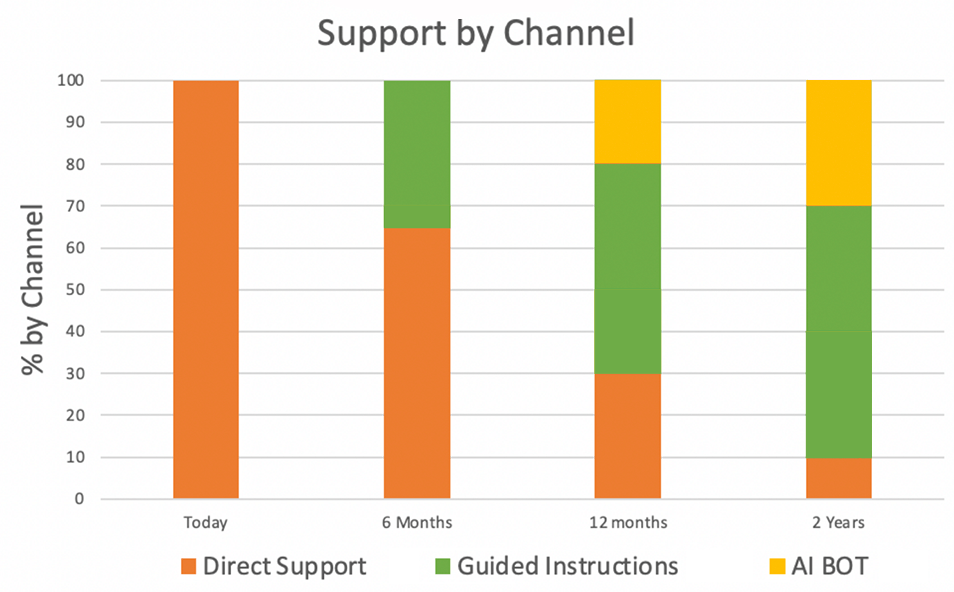

While these solutions have been good at providing a short-term band-aid to relieve the symptom, they don’t really address the underlying problem – the lack of rich, interactive workflows that are able to guide technicians with a wide range of skills to perform these tasks safely, correctly, and at an acceptable level of productivity. It’s a similar scenario to taking aspirin to treat a fever from an infection – aspirin may provide short-term relief, but ultimately it masks the presence and reduces the urgency to treat the underlying cause. Without looking forward and taking the next step in the connected worker journey, OEM’s will forever be required to provide 100%, synchronous, live support to make sure these tasks are done correctly and that customers are satisfied.

Achieving Digital Maturity to Reduce Support Costs and Improve Customer Satisfaction

At Augmentir, we see “Digitally Mature” organizations as those that are continually moving forward on the digital continuum and have the ability to drive continuous improvement through the adoption of tools that help digitally connect their workforce.

For equipment OEMs, we see digital maturity happening over four stages of the connected worker journey:

Step 1 – Remote Expert and Assistance

Industrial AR-based remote assistance and remote expert solutions that provide worker guidance and support are a simple first step in the connected worker journey. Designed to be used by field service technicians or customers, these industrial solutions allow companies to provide remote expert support via rich interactive (chat, voice, video) mediums to field techs or customers to solve an immediate need.

Step 2 – Augmented, Guided Instructions

With a connected workforce, equipment OEMs can drive greater efficiency by digitizing paper-based work instructions and maintenance/repair procedures. Digital work instructions help intelligently guide technicians (or customers) of all skill levels to complete these tasks independently and correctly.

In this field service scenario, remote expert and assistance plays a supporting role (as it should) to ensure customer satisfaction. Customers have higher satisfaction rates because the work is done on their time schedule and OEMs see a reduction in their direct support costs.

Step 3 – AI Support Bots

OEMs can drive further service optimization through AI support bots that provide autonomous, digital assistance.

Service technicians that require additional support can benefit from AI bots that autonomously deliver answers to questions, digital content such as drawings, pictures and videos, and rich sets of digital work instructions, to help workers resolve issues and complete the work independently. This allows a portion of customer remote assist requests to be handled autonomously, further increasing customer satisfaction and reducing direct support costs.

Step 4 – AI-based Opportunity Insights

According to LNS Research, as workers become more connected, companies have access to a new rich source of activity, execution, and tribal data, and with proper AI tools, can gain insights into areas where the largest improvement opportunities exist for their service delivery. Artificial Intelligence lays a data-driven foundation for continuous improvement in the areas of productivity, quality, and workforce development, setting the stage to address the needs of a constantly changing workforce.

For example, after Augmentir is deployed for a number of months, our AI engine will start identifying patterns in the data that will allow you to focus your efforts on the areas that have the biggest customer satisfaction, productivity, and field service workforce development opportunities. This will allow you to answer questions such as:

- Where should I invest to get the biggest improvement in customer satisfaction?

- What service tasks have the largest productivity or quality opportunity?

- Where would targeted training give me the biggest return?

Augmentir’s True Opportunity™ engine continuously updates its insights to enable companies to focus on their largest areas of opportunity, enabling you to deliver year over year improvements in key customer service metrics.

What is Your Digital Maturity?

Imagine, as you move forward on your connected worker journey, increasing customer satisfaction while reducing support costs, all while making your service delivery more productive – across your direct staff, dealers, or end customers.

Contact us today to take our digital maturity assessment and start your journey towards a digitally connected enterprise.