Say hello to the newest addition to the Augmentir platform, Augie – the GenAI powered digital assistant for manufacturing.

Say hello to the future of work in manufacturing with the latest addition to Augmentir’s suite of connected worker tools, Augie™.

Augie is a digital assistant for frontline operations that utilizes Generative AI and proprietary fit-for-purpose, pre-trained Large Language Models (LLMs) to enhance operational efficiency, problem-solving, and decision-making for today’s less experienced frontline industrial workers. It leverages enterprise-wide data, provides instant access to relevant information, closes skills gaps with personalized support, offers insights into standard work and skills inventory, and identifies opportunities for continuous improvement.

Augie is a result of our dedication to empowering frontline workers, leveraging AI to support manufacturing operations, and giving manufacturing workers better tools to do their jobs safely and more efficiently.

Continue reading below to learn more about how Augie works and how it can benefit your frontline workforce and manufacturing operations:

- How our GenAI Powered Assistant Works

- How Augie Benefits Your Frontline Workforce

- Improve Operational Efficiency with Augie and Augmentir

How our GenAI Powered Assistant Works

Generative AI-powered smart manufacturing assistants are designed to provide secure, role-based, personalized assistance to frontline workers, engineers, and managers in various industries, including manufacturing.

They work by leveraging artificial intelligence and integrations across different software systems, providing guidance and assistance in various tasks to enhance productivity and performance. This includes providing data insights, recommendations on actions to improve performance, and the ability to create analyses and dashboards with a natural language-based assistant.

A majority of smart manufacturing assistants only draw their information from manufacturing execution systems (MES), without tying in other important systems necessary for frontline manufacturing success.

Augie, however, is different. It leverages enterprise-wide data tying in information from a wide range of platforms including operational data, training and workforce management data, connected worker and engineering data, as well as information from enterprise systems.

How Augie Benefits Your Frontline Workforce

Augie is unique among other smart manufacturing assistants. It leverages proprietary fit-for-purpose, pre-trained LLMs and generative AI, coupled with robust security and permissions, to help factory managers, operators, and engineers improve efficiency, resolve issues faster, and prevent downtime.

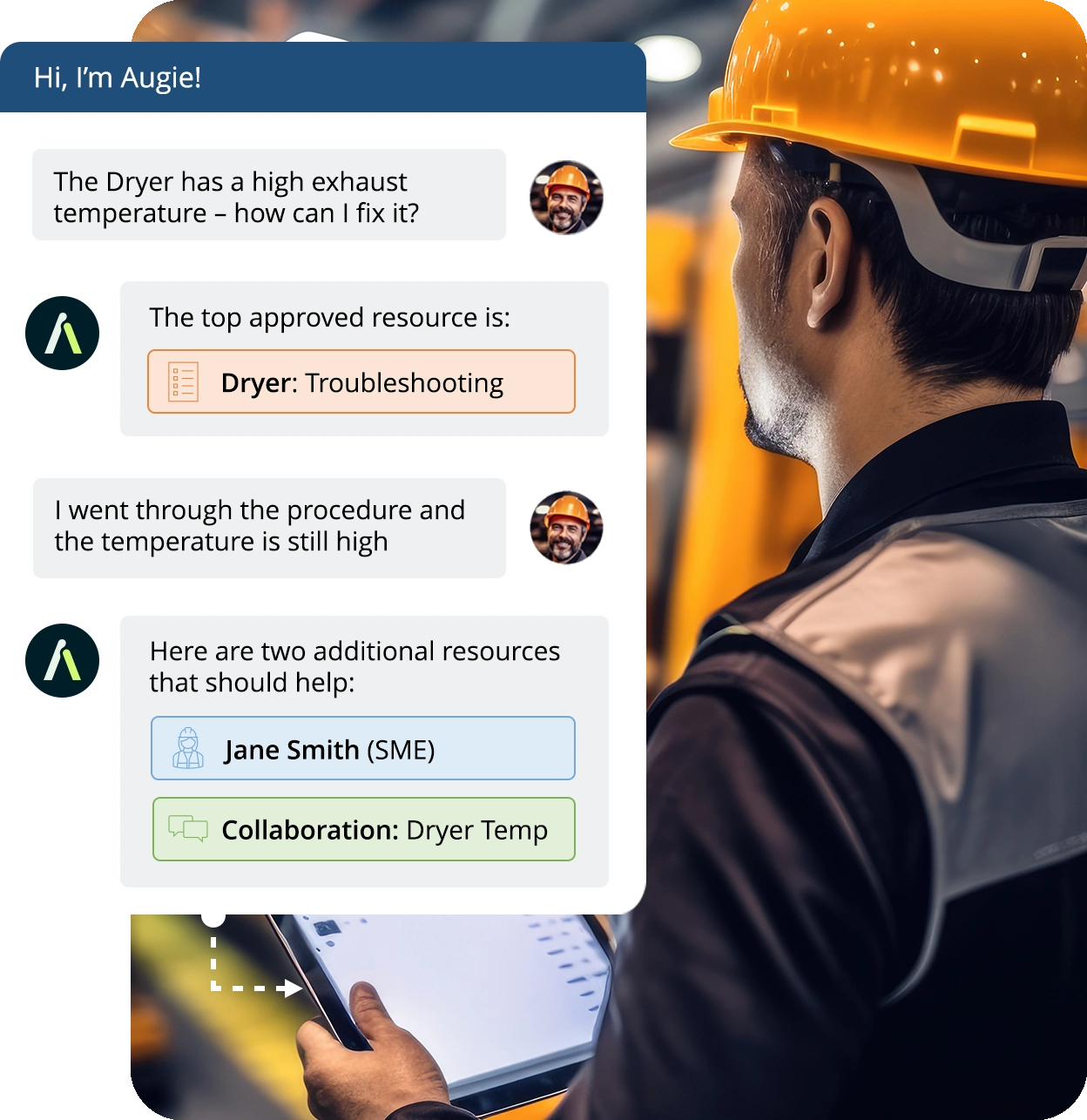

With information readily available via Augie, frontline workers can make decisions faster, reduce downtime, and improve troubleshooting with instant access to summarized facts relevant to a job or task. Additionally, Augie is multi-modal, meaning it can return actionable information in the form of work procedures, training videos, recorded collaborations, engineering documents and SOPs, as well as tribal knowledge.

Through Augie, manufacturers can instantly:

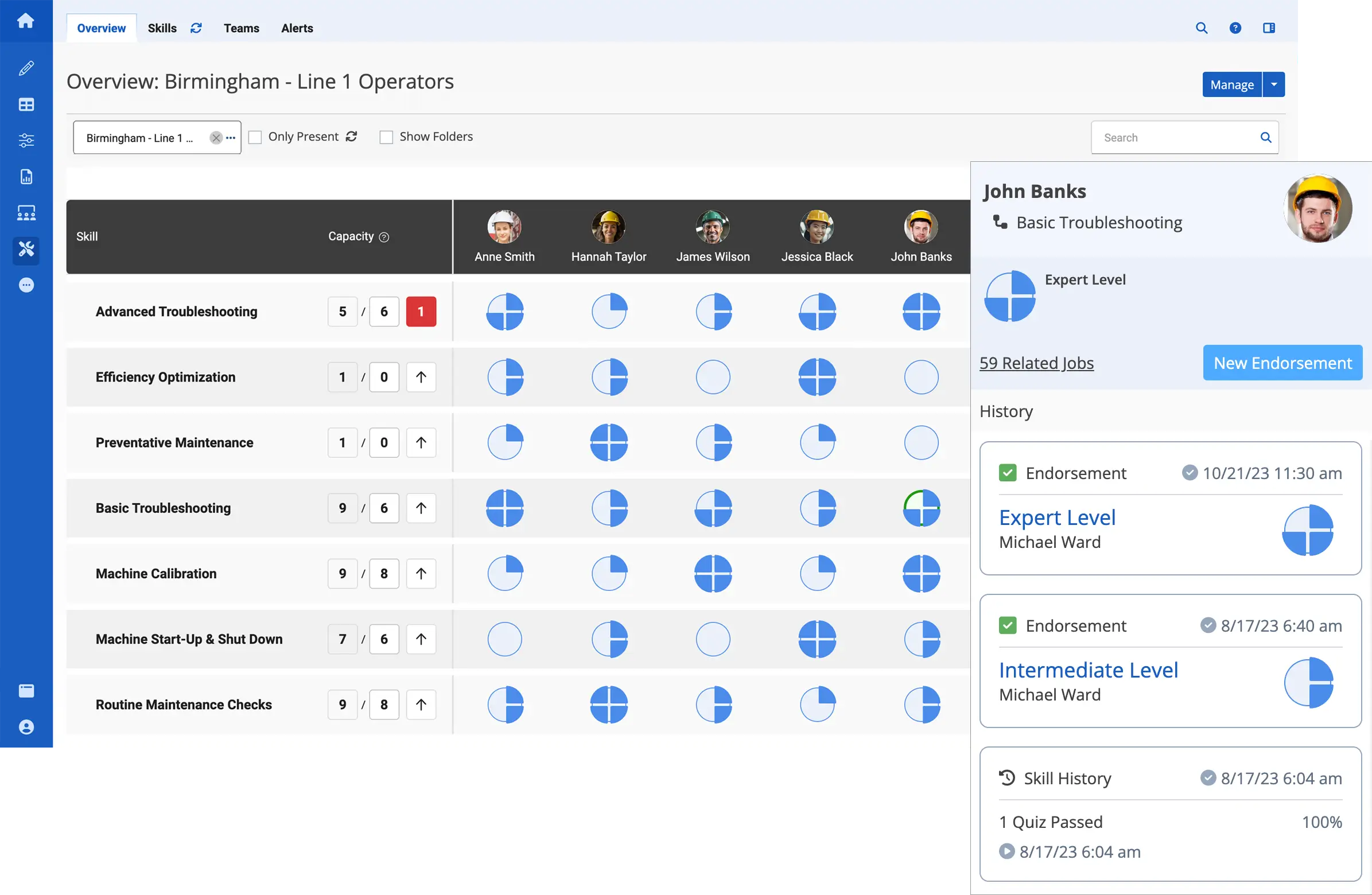

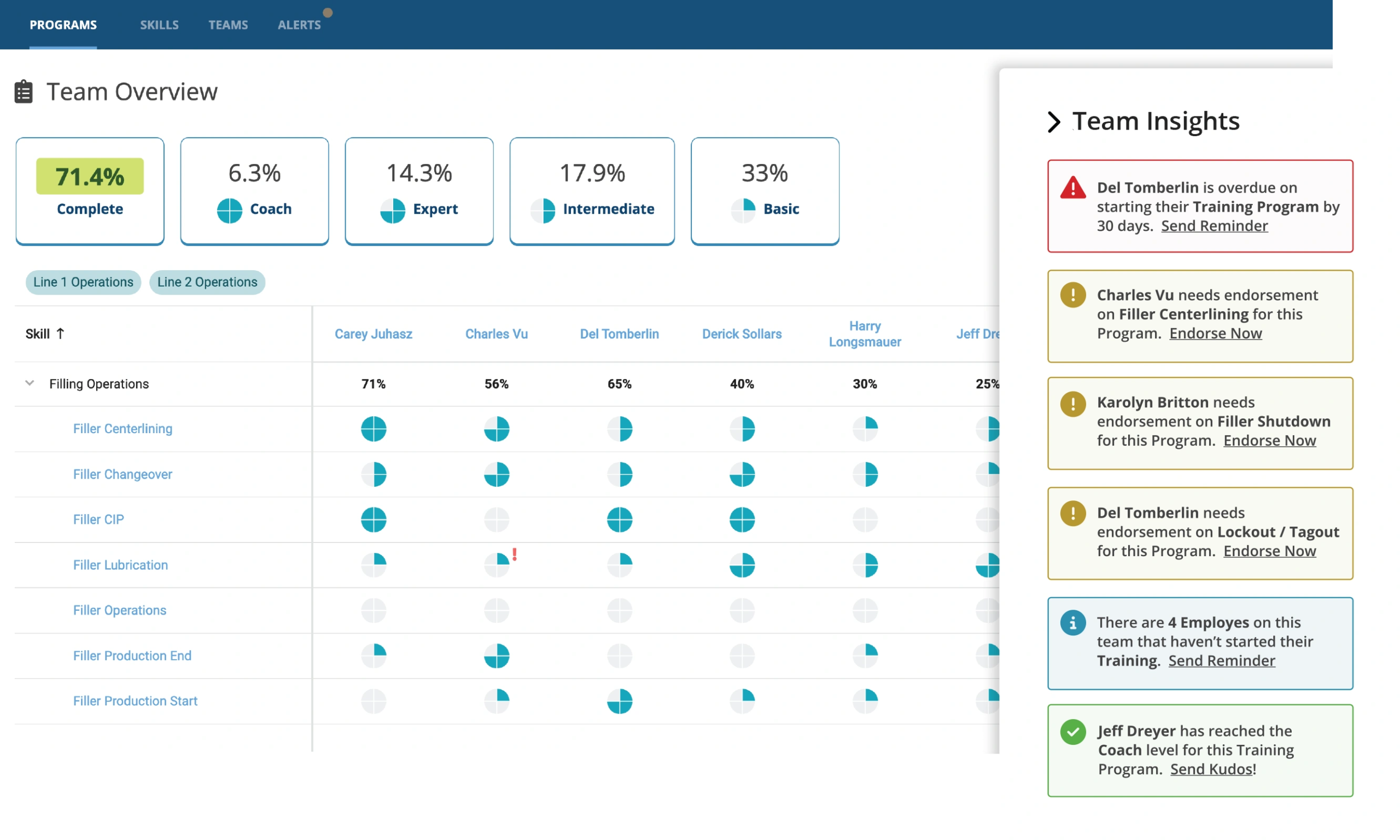

- Close skills and experience gaps with personalized support

- Gain insights into Leader Standard Work

- Gain new insights into skills inventories

- Convert Tribal Knowledge into Digital Corporate Assets

- Identify opportunities for continuous improvement

- Forecast potential operational issues

With Augie by your side, you can streamline manufacturing operations, optimize performance, empower your frontline workforces, and stay ahead in today’s rapidly evolving and competitive landscape.

Webinar

6 Ways Manufacturers Can Use GenAI Today

On-Demand

Improve Operational Efficiency with Augie and Augmentir

The digitization of frontline processes has become a must-have to keep up with the velocity of change – but not just digitization … smart digitization. Recently, Deloitte found that 86% of manufacturing executives believe smart factory solutions will be the primary drivers of competitiveness in the next five years. Leveraging smart, AI-driven connected worker solutions that allow industrial organizations to best support their frontline workforces and optimize processes to make them safer and more efficient is critical to overall enterprise success.

At Augmentir, we have been met with continued success in our efforts to transform manufacturing operations. Our patented Smart AI foundation helps manufacturing organizations close the loop between training and work execution, delivering the data and in-line insights necessary to continuously improve operational excellence day-over-day, year-over-year. Augmentir is the world’s leading connected worker solution, combining smart connected worker and GenAI technologies to drive continuous improvement and enhance performance management initiatives in manufacturing.

The addition of Augie to our platform is a game-changer for factory floor and other frontline workers, allowing for quick reference troubleshooting and useful, contextualized information to be delivered at the moment of need. Furthermore, with Augie, less experienced workers are provided with additional support and individualized guidance based on the job or task needs.

With patented AI-driven insights that digitize and optimize manufacturing workflows, training and development, workforce allocation, and operational excellence, Augmentir is trusted by manufacturing leaders as a digital transformation partner delivering measurable results across operations. Schedule a live demo today to learn more.