Discover how Connected Worker platforms like Augmentir are transforming safety compliance in manufacturing and industrial sectors. From digitized SOPs to AI-powered insights, learn 5 powerful ways to improve EH&S.

In industries like manufacturing, energy, pharmaceuticals, and construction, Environmental, Health & Safety (EH&S) is not just a regulatory requirement—it’s central to operational integrity, workforce well-being, and brand trust. Yet many organizations still rely on outdated paper processes, static training programs, and fragmented safety communication systems.

As digital transformation accelerates across frontline operations, a new class of solutions is emerging: Connected Worker platforms. These tools empower industrial workers with mobile access to the information, training, and communication they need—exactly when and where they need it. When integrated into EH&S programs, they don’t just make safety easier to manage—they make it smarter, more scalable, and more resilient.

Backed by AI and real-time data, platforms like Augmentir are helping companies move from reactive safety management to proactive risk prevention.

Here are the top 5 ways Connected Worker tools are improving safety compliance in 2025 and beyond:

1. Digitizing and Standardizing Safety Procedures

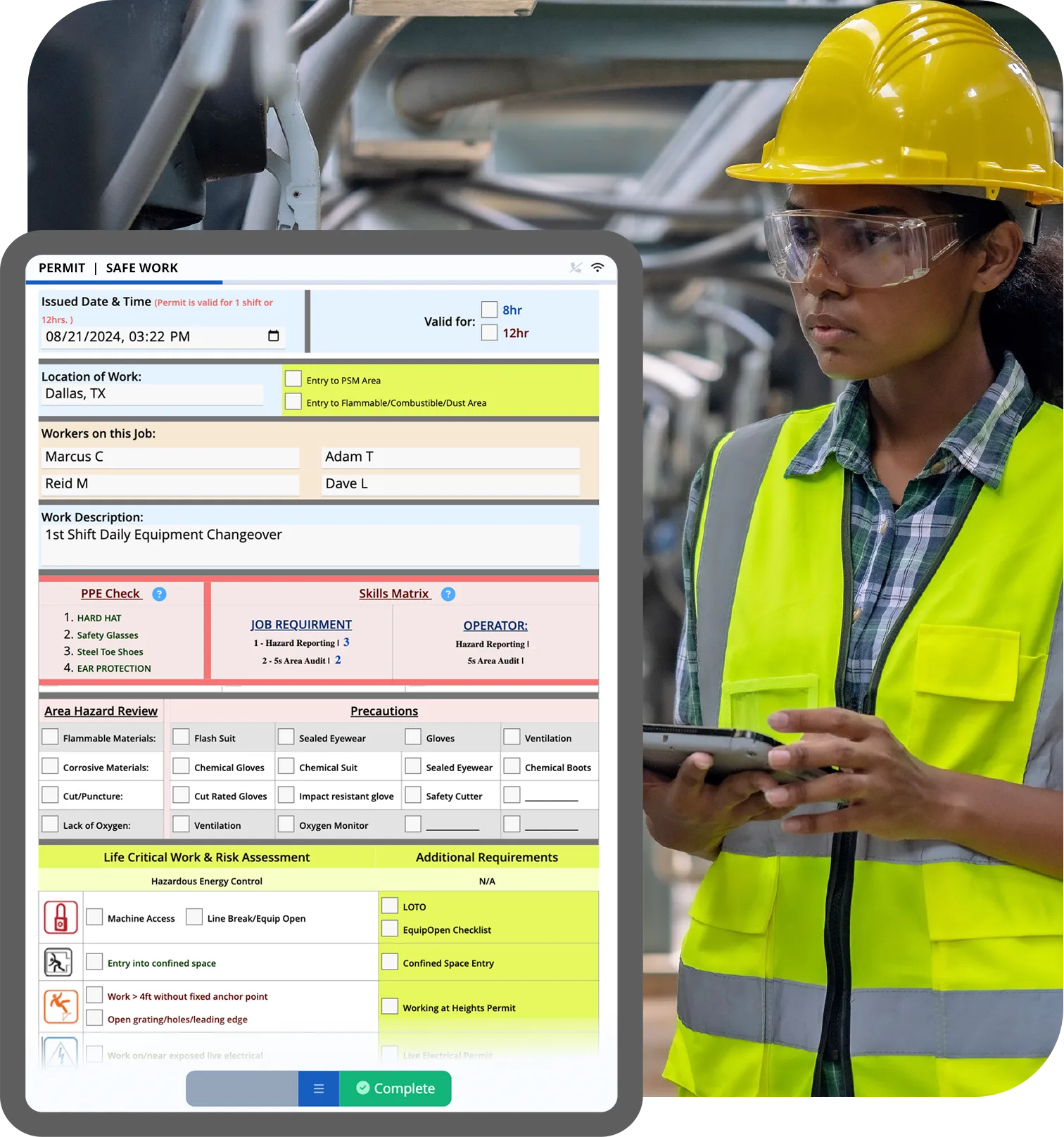

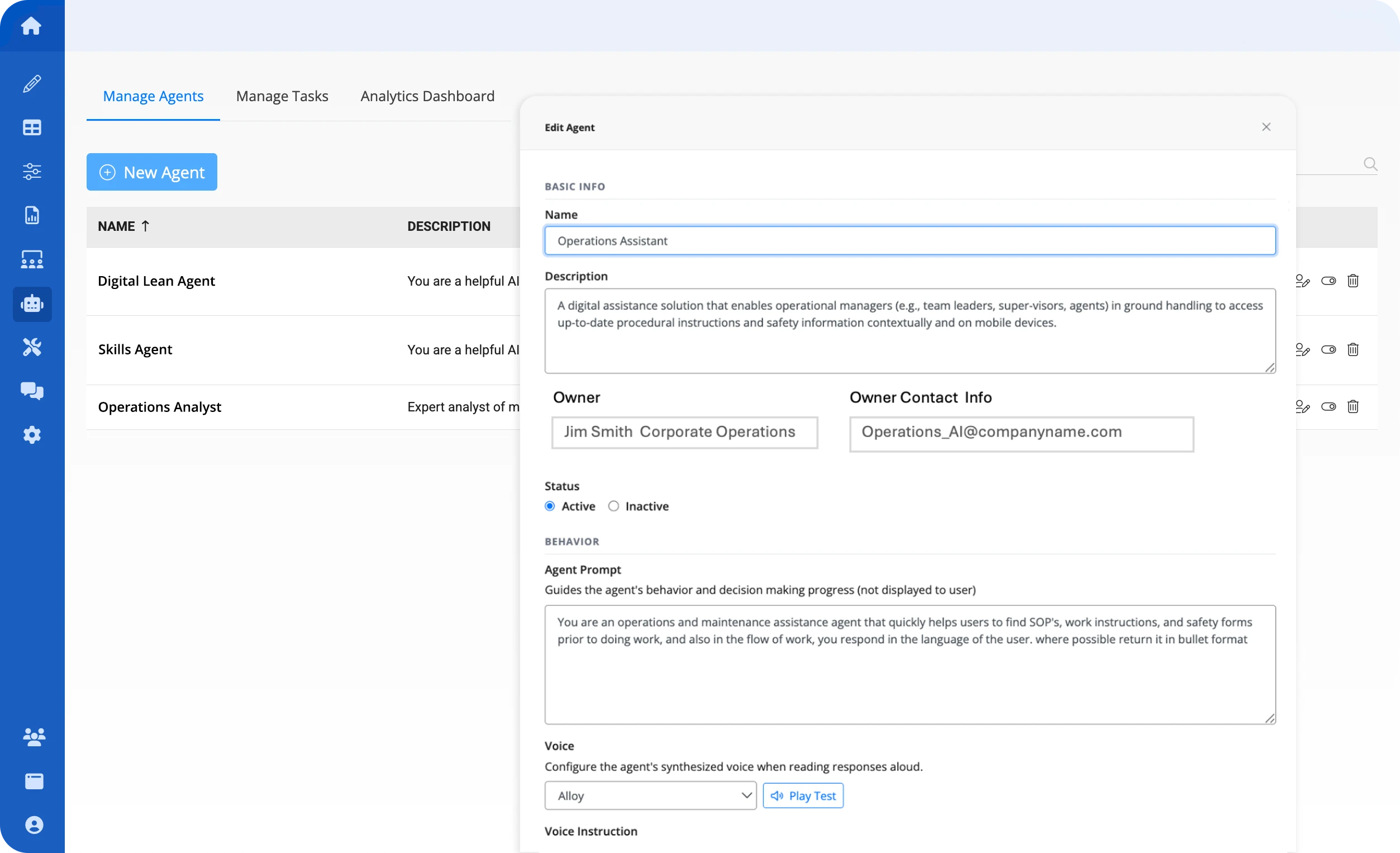

Outdated SOPs, missing forms, manual permit to work processes, and inconsistent training delivery can all lead to non-compliance and unsafe conditions. Connected Worker tools eliminate these gaps by fully digitizing safety workflows—creating a single source of truth for the entire workforce.

Whether it’s a job safety analysis, equipment inspection, permit to work, or Lockout Tagout (LOTO) checklist, mobile connected worker applications ensure every worker has access to real-time, validated instructions. No printing. No ambiguity. Just operational consistency.

Impact: Reduced procedural deviations, increased inspection completion rates, and simplified regulatory reporting.

2. Real-Time Communication of Hazards and Safety Updates

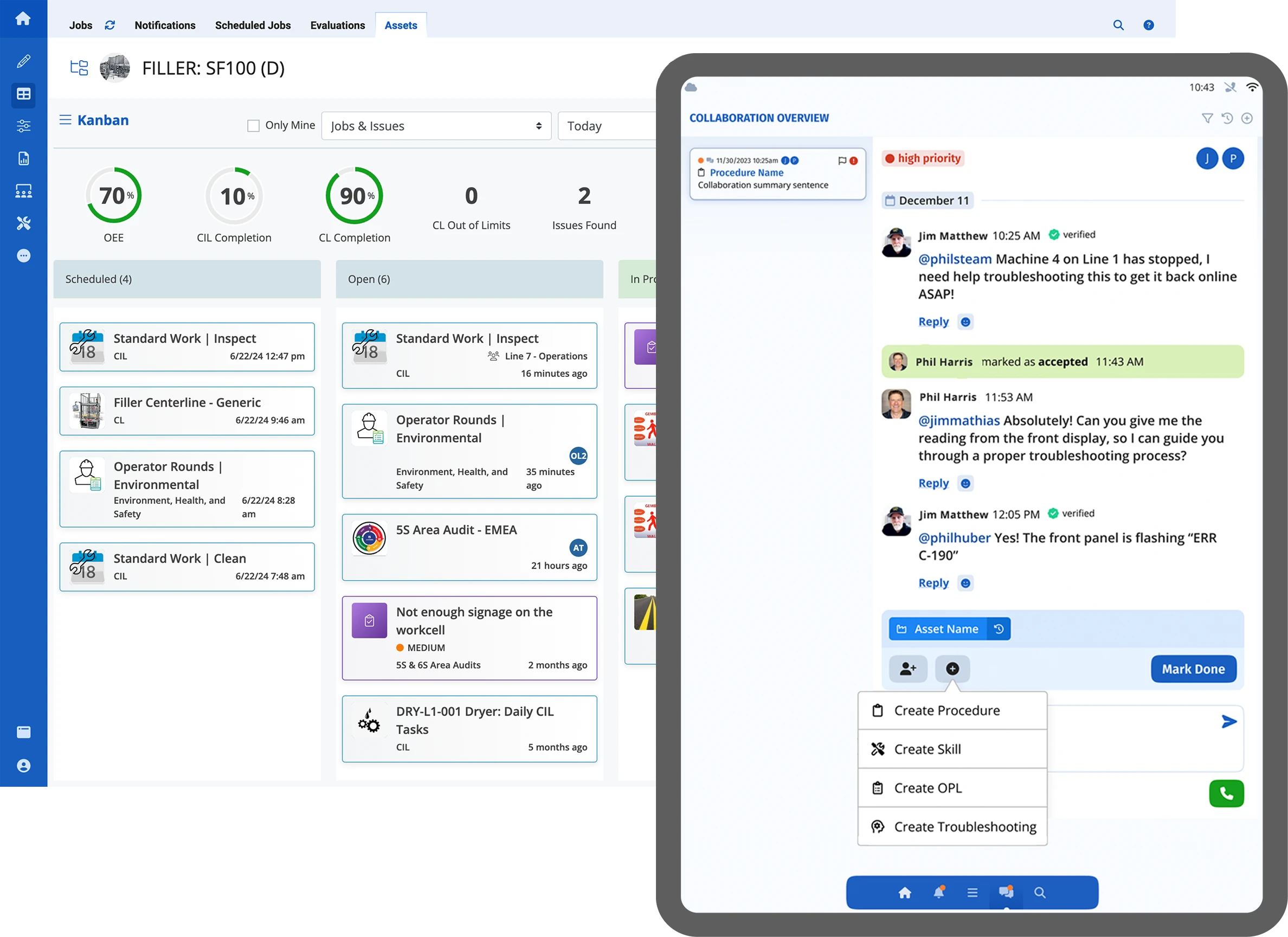

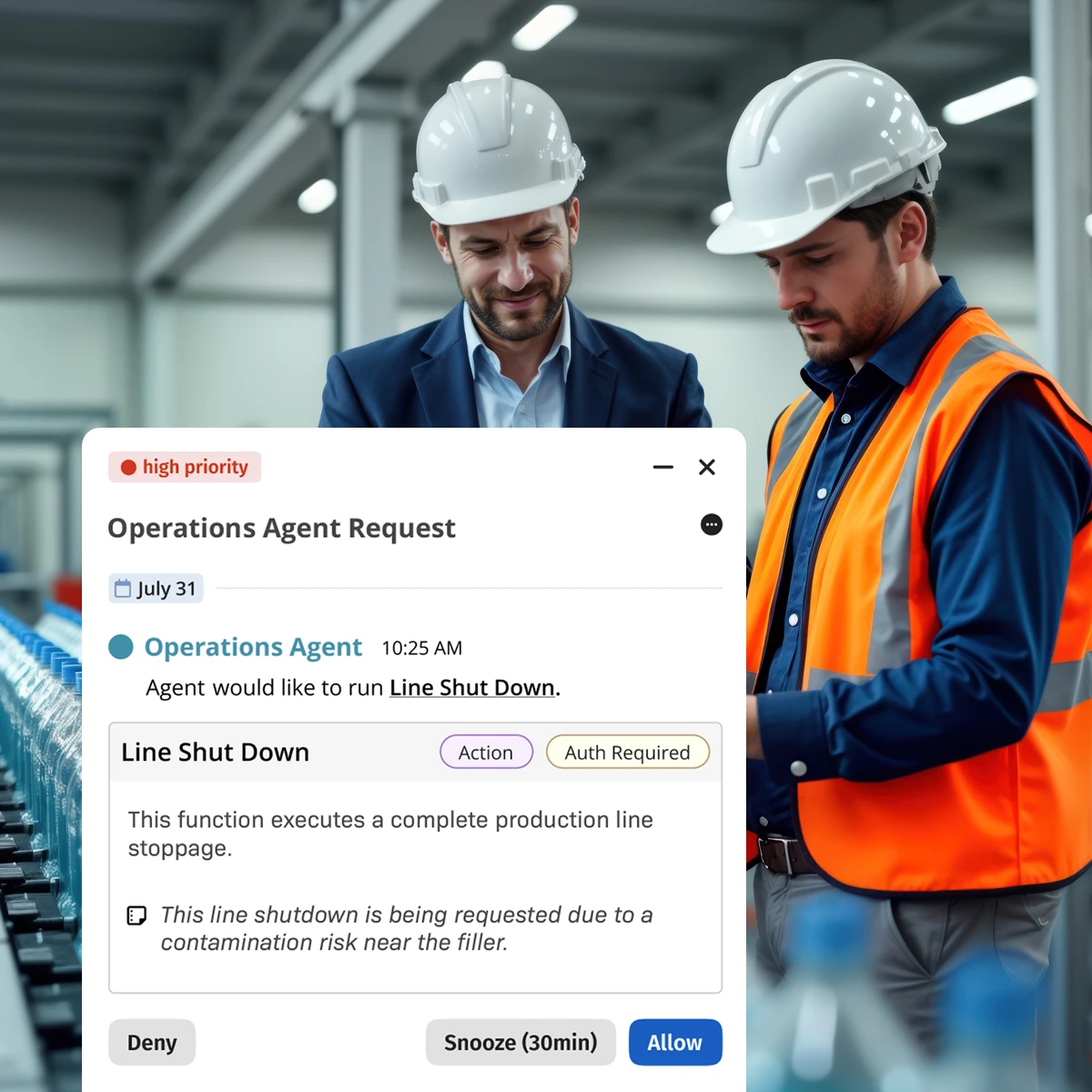

Many industrial incidents are the result of slow or ineffective communication. Connected Worker platforms enhance situational awareness by enabling real-time messaging, collaboration, alerts, and escalation workflows.

If an unexpected hazard arises—say, a chemical leak or equipment fault—managers can instantly notify affected personnel, reroute workflows, or push emergency protocols. Workers, in turn, can report near misses, unsafe conditions, or noncompliance through voice commands, forms, or photos directly from the floor.

Result: A faster, closed-loop system for identifying and addressing safety risks before they escalate.

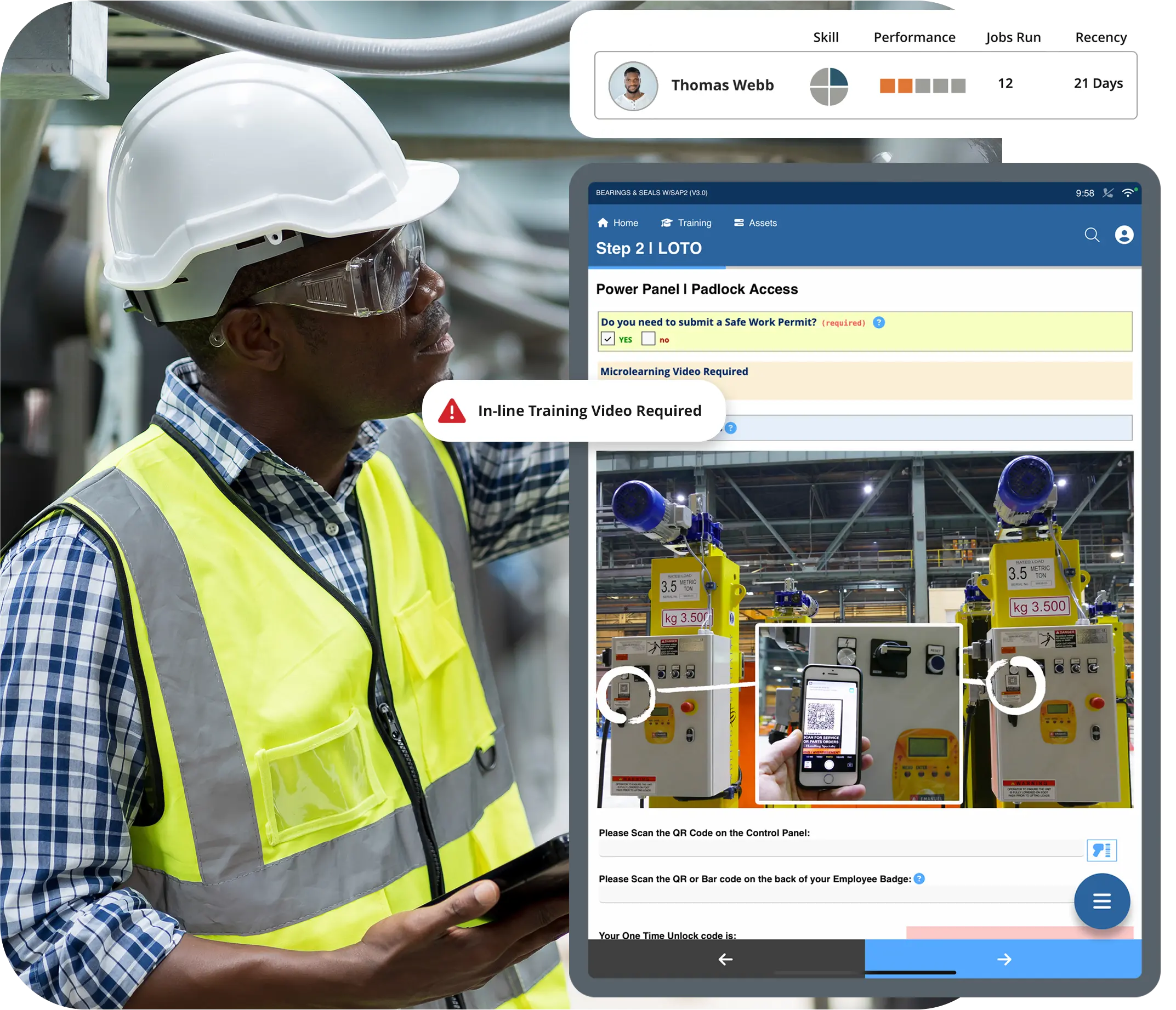

3. Delivering Embedded, Adaptive Safety Training

Traditional EH&S training is periodic, generic, and disconnected from actual work. In contrast, Connected Worker tools bring adaptive, on-demand microlearning directly into the flow of work.

Using Augmentir’s AI-powered connected worker platform, safety refreshers, toolbox talks, and task-specific training modules are delivered at the point of need—tailored to the worker’s skill level, recent behavior, or even risk profile.

Why it matters: Personalized safety education builds long-term retention and reduces costly retraining cycles.

4. Automating Safety Documentation and Compliance Readiness

Compliance is only as strong as its documentation. But manual reporting systems often result in incomplete records, delayed submissions, or errors that surface during audits.

Connected Worker platforms solve this by automatically capturing who did what, when, and how—across inspections, sign-offs, observations, and more. Every action is time-stamped, traceable, and ready for regulatory review, whether you’re governed by OSHA, ISO 45001, or industry-specific protocols.

Compliance advantage: Be audit-ready in minutes, not months.

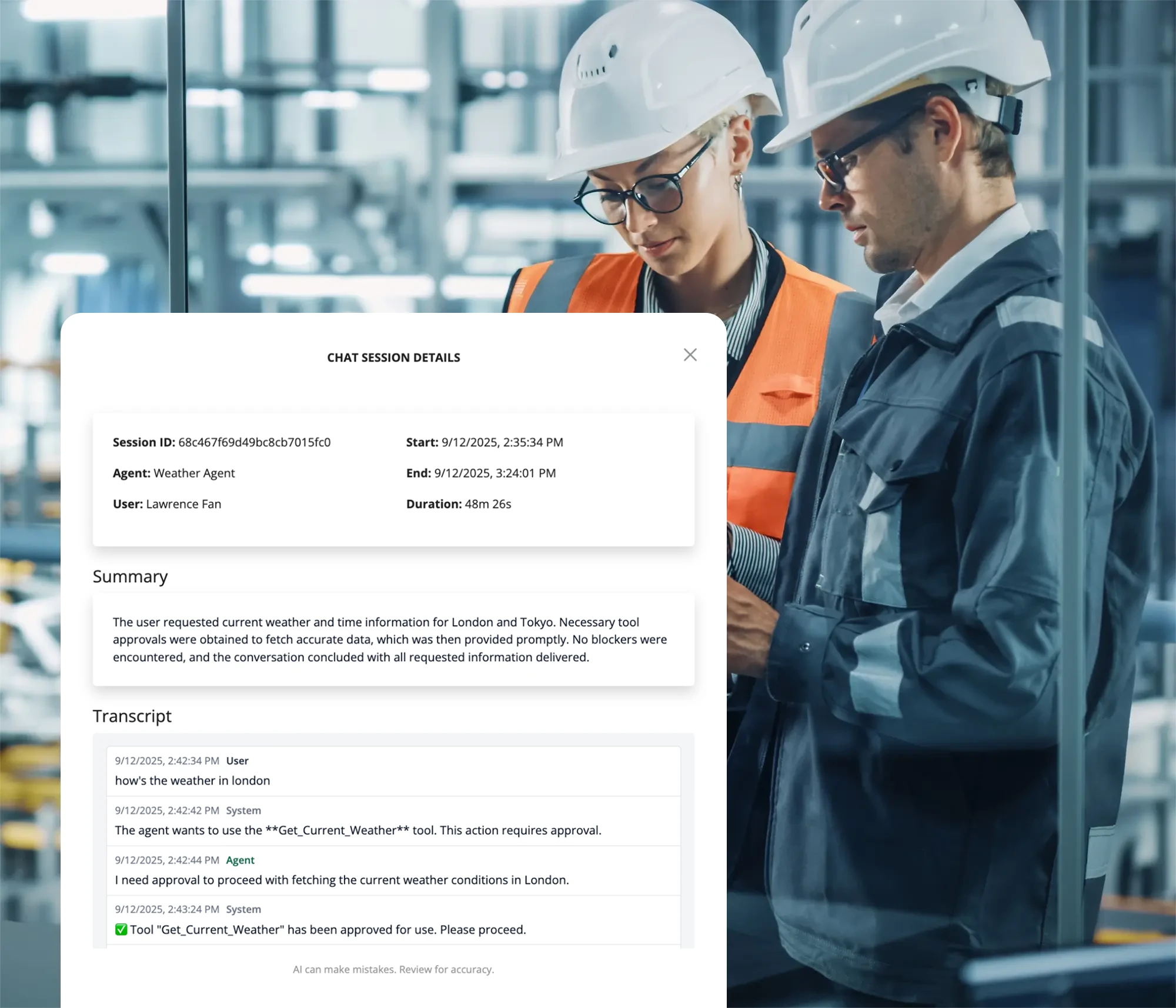

5. Unlocking Predictive Safety Insights Through AI

EH&S leaders need to do more than react—they need to predict. With Connected Worker platforms, operational data becomes a strategic asset. Augmentir uses AI and machine learning to analyze safety behaviors, flag leading indicators of risk, and recommend interventions—before incidents occur.

This includes identifying trends such as repeated safety violations on a particular shift, increasing near-misses on certain equipment, or declining task proficiency in a subgroup of workers.

Forward-looking benefit: Transition from lagging indicators (like incident rates) to leading indicators that drive a culture of safety excellence.

How Augmentir is Revolutionizing Safety Compliance

Augmentir’s platform is at the forefront of transforming how industrial companies manage EH&S. By embedding safety into daily operations, it helps organizations go beyond compliance to create a culture of safety ownership.

Key innovations Augmentir brings to safety compliance:

- AI-driven Safety Intelligence: Augmentir’s AI identifies risk trends across tasks, teams, and sites, helping safety leaders implement targeted improvements.

- Smart Workflows: Every safety-critical task is embedded into digital workflows that adapt to individual performance and conditions in real time.

- Continuous Worker Feedback: Built-in feedback loops ensure workers can raise issues, suggest improvements, and stay engaged with safety practices.

- Performance-Linked Safety Coaching: Augmentir correlates safety metrics with individual skill profiles, prompting personalized coaching to address gaps before they become incidents.

Augmentir doesn’t just digitize safety—it makes it dynamic, intelligent, and fully integrated with operational execution. As a result, companies can achieve higher compliance rates, fewer incidents, and a more empowered frontline workforce.

Final Thoughts: EH&S in the Connected Era

LNS Research, a thought leader in the industrial space, recently identified EH&S as one of the most strategic areas impacted by Connected Worker technologies. As expectations rise—for safety, sustainability, and operational agility—the need to modernize your EH&S approach becomes non-negotiable.

Augmentir’s Connected Worker platform enables industrial companies to embed safety into every task, every worker, and every workflow. It’s time to stop managing safety in silos and start integrating it into the core of your operations.

Let’s talk: Request a demo to see how Augmentir can elevate your EH&S strategy.