New report by Gartner recognizes innovative companies in manufacturing operations solutions.

Horsham, PA September 13, 2022 – Augmentir, the provider of the world’s only smart connected worker suite, today announced that it has been named a “Cool Vendor” in the August 2022 Cool Vendors™ in Manufacturing Operations report by Gartner, Inc.

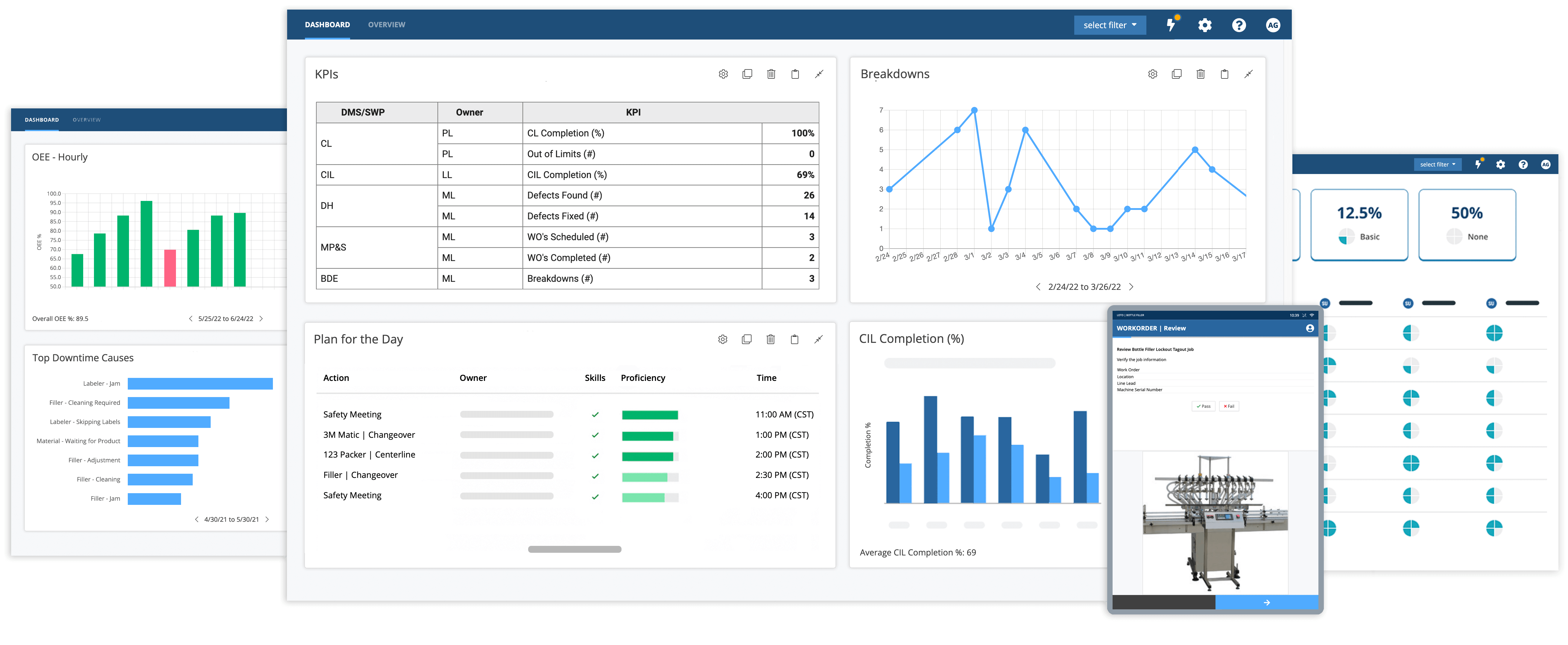

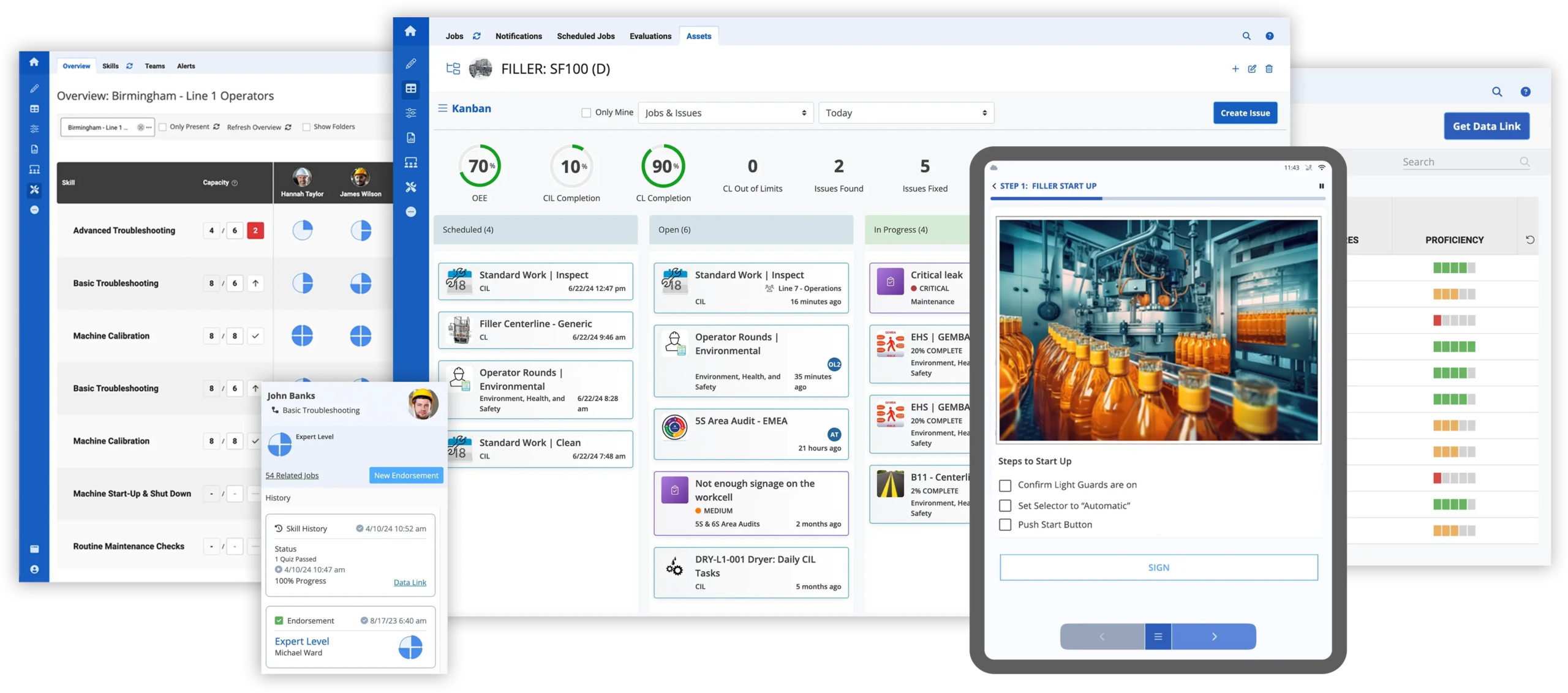

Augmentir is known for its unique AI-based connected worker technology. The company’s solution is used to digitize and optimize frontline work based on worker capability and task complexity and add precision to workforce development by helping manufacturers identify opportunities to improve training and optimize upskilling and reskilling programs.

Gartner’s Cool Vendor research is “designed to highlight interesting, new and innovative vendors, products, and services.” This year’s Cool Vendors in Manufacturing Operations report showcases solutions for manufacturing operations leaders seeking to improve digitization, supply chain visibility, and operational excellence.

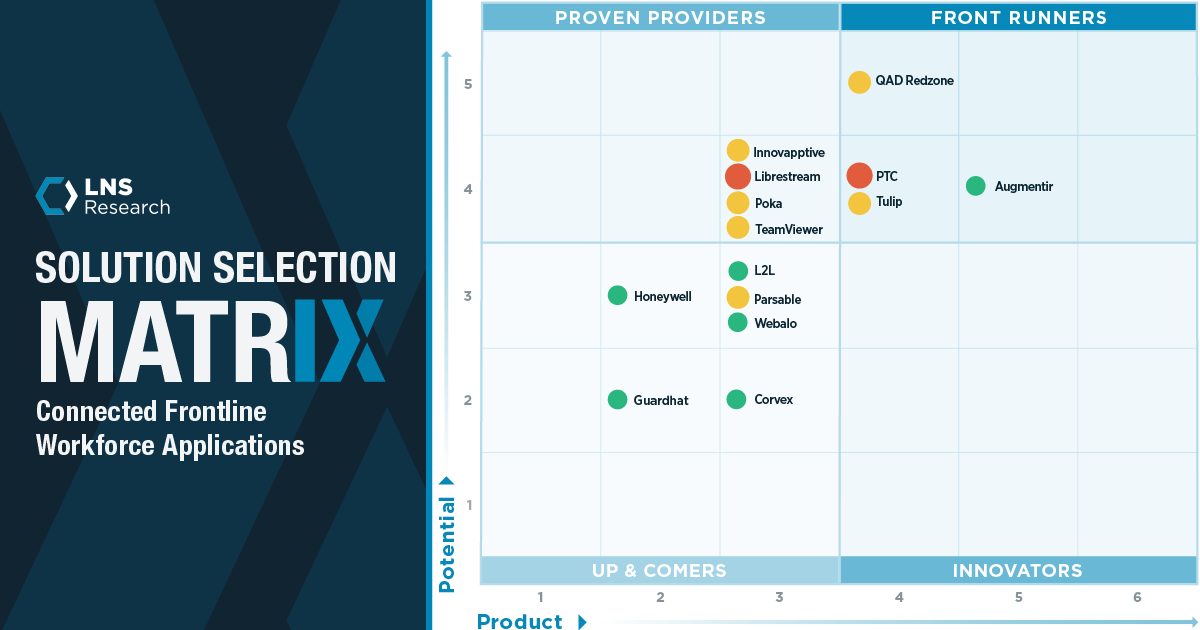

“We are honored to be included as a Cool Vendor in Gartner’s Cool Vendors in Manufacturing Operations report this year,” said Russ Fadel, CEO and Co-Founder of Augmentir. “At a time when labor shortages and workforce disruptions are at an all-time high, more and more companies are turning to smart digitization to help optimize the productivity of their frontline teams. Our suite of AI-based, smart connected worker tools helps manufacturers digitally transform skills, work execution, and collaboration for their teams. We believe this recognition by Gartner reinforces our position as a market-leader in smart digital solutions for industrial frontline work.”

Augmentir’s suite of AI-powered connected worker tools helps industrial companies deliver effective skills management, training, digital workflow, and collaboration for today’s more dynamic industrial workforce. These capabilities, built on top of Augmentir’s patented “Smart” AI foundation, close the loop between training and work execution to deliver the data and in-line insights necessary to continuously improve operational excellence day-over-day, year-over-year.

To learn more about Augmentir, please visit www.augmentir.com.

# # #

Gartner “Cool Vendors in Manufacturing Operations” by Rick Franzosa, Simon Jacobson, Scot Kim, Tuong Nguyen; August 17, 2022

Disclaimer: Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose. Gartner and Cool Vendors are registered trademarks and service marks of Gartner, Inc. and/or its affiliates in the U.S. and internationally and are used herein with permission. All rights reserved.

About Augmentir

Augmentir™ is the world’s only Smart Connected Worker suite. Augmentir’s software is a complete suite of connected worker tools that helps industrial companies digitize and optimize processes that support frontline workforces from “hire to retire”. Companies in manufacturing, service, energy, and construction leverage Augmentir’s suite of tools to deliver more intelligent skills management, training, collaboration, and on the job support for today’s more dynamic, more flexible industrial workforce. For more information, please visit www.augmentir.com.