Round Led by Pritzker Group Venture Capital with Participation by Lerer Hippeau and HOLT Ventures Validates the Industry’s Need for Artificial Intelligence (AI) based Technology that Supports the Frontline Workforce

HORSHAM, PA – JULY 16, 2019 – Augmentir, Inc., a leading provider of augmented worker software for industrial companies, today announced it has closed an oversubscribed funding round. The round was led by Pritzker Group Venture Capital, with participation from Lerer Hippeau, current investors, and HOLT Ventures, the strategic venture capital arm of HOLT CAT.

“The closing of this round with the participation of these leading venture capital firms further validates our unique AI-first approach to improving the productivity of frontline workforces,” said Russ Fadel, Co-founder and CEO of Augmentir. “This funding will enable us to expand our global footprint, further increase the functionality of the platform, and make it even more accessible to companies across the small, mid-sized and large spectrum, and we look forward to reaching even more companies while defining the future of work.”

Ty Findley, Vice President at Pritzker Group Venture Capital, added, “With our thematic focus on Industry4.0, we are excited to be working with a company that is accelerating the industrial sector evolution using AI and AR to support frontline workers. From founding efforts at Wonderware, Lighthammer, and ThingWorx, the Augmentir team has a proven track record and domain experience delivering software innovation to the manufacturing and industrial market, and we are eager to participate as Augmentir continues to shape the frontline workforce of the future.”

“We are excited to be working with Augmentir and believe that the platform provides our Caterpillar dealership with the opportunity to standardize our workflow across multiple operations in order to deliver improved consistency to our customers,” added Meg Paulus, Partner at HOLT Ventures. “Augmentir’s AI engine will help us gain better real time and global insights to our operations to drive increased efficiency and technician training and enablement throughout our territory which spans from the Red River to the Rio Grande.”

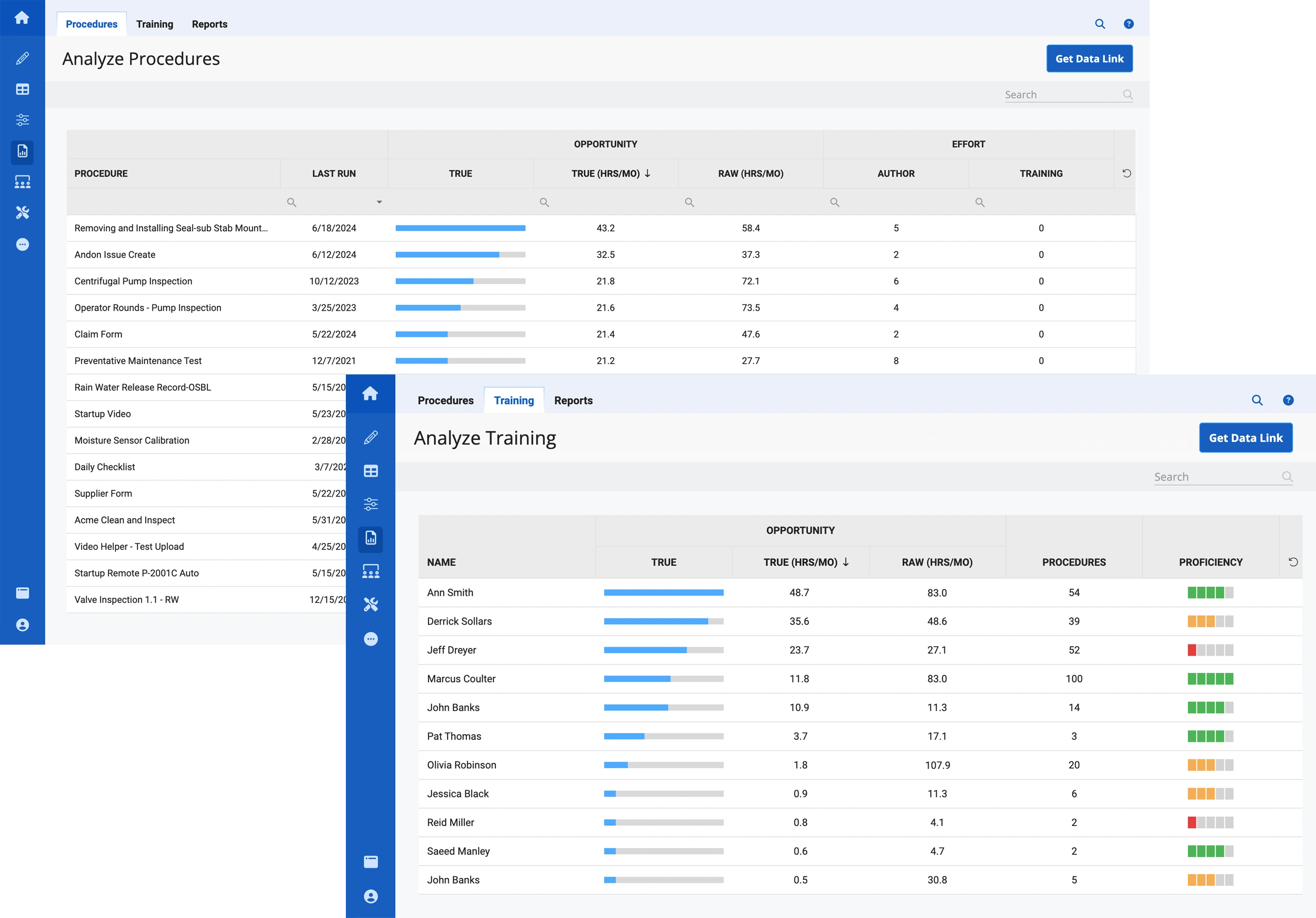

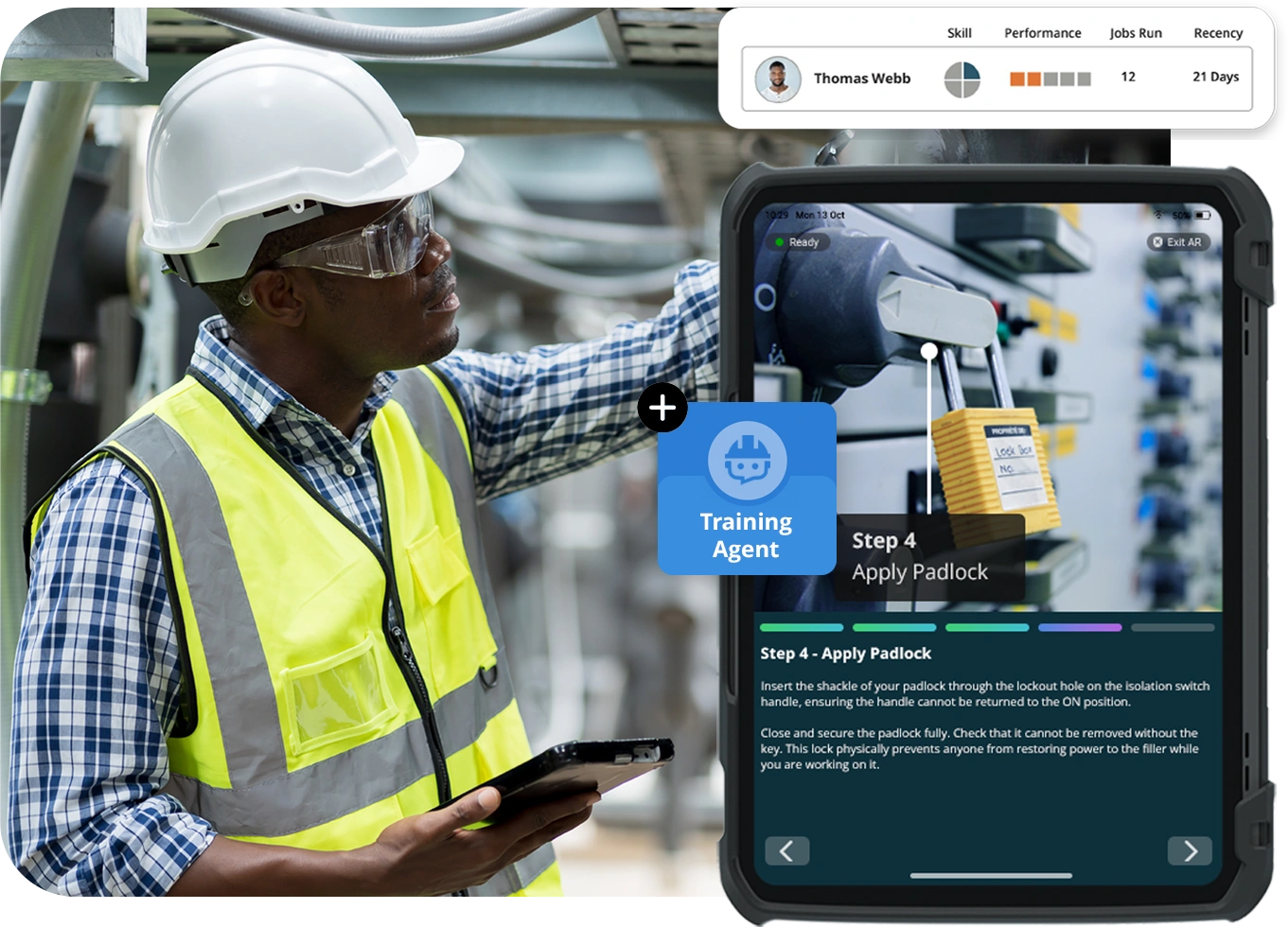

This latest round of funding will allow Augmentir to further expand its reach in the industrial sector, including oil and gas, mining, field service, and manufacturing industries, and continue to provide solutions that will shape the future of the industrial workforce. The company is the first to deliver an “AI-first” enterprise platform for the industrial sector that combines augmented reality (AR) with artificial intelligence and machine learning (AI/ML). Augmentir’s Augmented Operations™ platform allows industrial companies to support their frontline workforce with augmented procedures and step-by-step work instructions, remote assistance capabilities, and drive continuous improvement through AI-driven insights.

###

About Augmentir

Augmentir is a leading provider of augmented worker software for industrial companies. Its flagship offering, the Augmented Operations™ platform, is the first of its kind to combine enterprise augmented reality (AR) with artificial intelligence and machine learning (AI/ML), empowering frontline workers to perform their jobs with higher quality and increased productivity while driving continuous improvement across the organization. For more information, please visit www.augmentir.com.

About Pritzker Group Venture Capital

Pritzker Group Venture Capital (PGVC) helps entrepreneurs build market-leading technology companies at the early stages of their growth. Since its founding in 1996, the firm has worked side-by-side with entrepreneurs at more than 200 companies, building partnerships based on trust and integrity. The firm has built a unique investment platform consisting of a team of experienced investment professionals and world-class operating partners combined with a vast network of strategic relationships. PGVC invests in enterprise technology and consumer internet companies, typically in their seed and Series A rounds. For more information, visit www.pritzkergroup.com/venture-capital/.

About Lerer Hippeau

Lerer Hippeau is the most active early-stage venture capital fund in New York City with investments in leading consumer and enterprise companies, including Allbirds, Casper, Guideline, and Group Nine Media. The firm invests across all sectors, backing founders with product vision, customer insight, and a keen instinct for brand building. For more information please visit www.lererhippeau.com.

About HOLT Ventures

The Holt family has a long legacy of innovation in the industrial business space, dating back to the early 1900’s when Benjamin Holt invented the track-type tractor, which was later named the Caterpillar. Today, the Holt family works alongside Caterpillar Inc. to deliver market-leading solutions through their heavy equipment dealership, HOLT CAT®, which is the largest Cat® tractor and engine dealer in the United States. HOLT Ventures strives to continue the legacy of innovation by investing in technologies and bright minds that are focused on solving challenges in our business. Current investments include Interplay Learning, Ranger Health, and SmartPicture/PLNAR. For more information visit www.holtventures.com.