Discover how to optimize shift startup performance during the golden hour in manufacturing – boost efficiency and drive productivity with connected worker technology.

The Golden Hour in Manufacturing refers to the first hour of production after a shift begins, a line is restarted, or a process is changed over. It is a critical window of time where performance, quality, and productivity are closely monitored to ensure a strong, stable start to the shift.

AI-powered connected worker solutions give you the digital tools to create a reliable, transparent, and data-driven shift handover — making your Golden Hour truly golden. No more missed info, no more guesswork, just smooth startups and better shift-to-shift alignment.

Read our article below to learn more about the Golden Hour in Manufacturing:

- What is the Golden Hour in Manufacturing?

- Golden Hour: A Bottleneck and an Opportunity

- The Impact Golden Hour has on Overall Daily Productivity

- How Smart Connected Worker Technology Improves the Golden Hour

- Optimizing the Golden Hour with Augmentir

What is the Golden Hour in Manufacturing?

The Golden Hour in manufacturing is the crucial first hour at the start of a production shift, changeover, or restart. This period is treated as a high-priority window to verify that machines, materials, personnel, and processes are all operating correctly and efficiently. During this time, supervisors and frontline workers focus on identifying and resolving any early-stage issues—such as quality defects, equipment malfunctions, or supply shortages—before they can affect the rest of the shift. The goal is to ensure a smooth, consistent startup that sets the stage for high productivity and minimal waste.

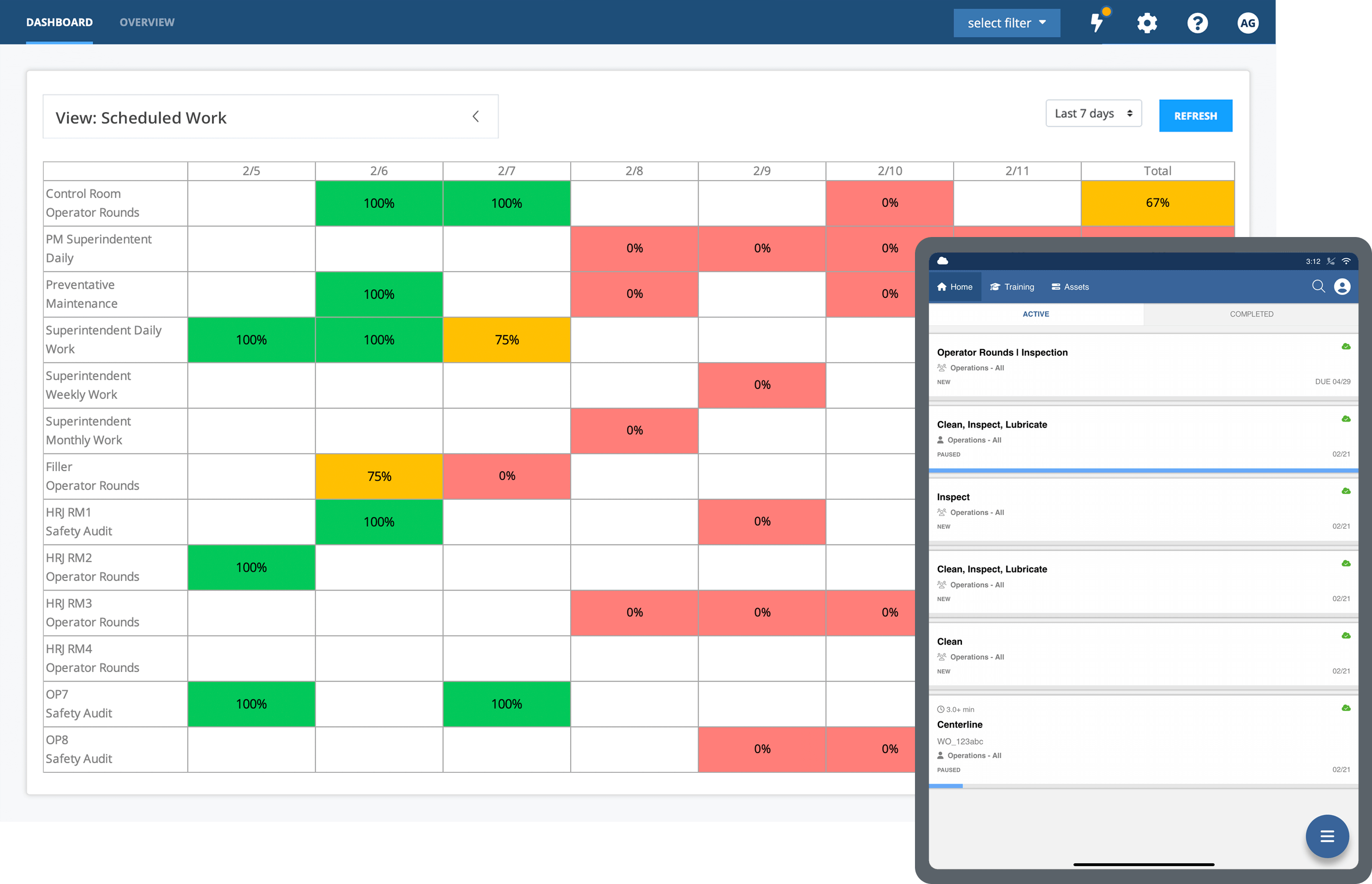

This concept aligns closely with lean manufacturing principles, emphasizing proactive problem-solving, first-time quality, and continuous improvement. By closely monitoring performance metrics like first pass yield, cycle time, changeover time (a key performance indicator for quick changeover), and downtime during the Golden Hour, teams can make real-time adjustments and prevent small issues from becoming larger operational setbacks. Many manufacturers also use digital tools and connected worker platforms to standardize Golden Hour checklists, track startup performance, and support operator communication—turning this critical hour into a strategic advantage.

Using digital tools and connected worker technology can help to standardize and optimize Golden Hour checklists, track startup performance, and support operator communication—turning this critical hour into a strategic advantage.

Golden Hour: a Bottleneck and an Opportunity

The Golden Hour is a deceptively small window with an outsized impact. It’s when frontline workers receive their marching orders, assess equipment, respond to unresolved issues from the previous shift, and set the tone for productivity, safety, and quality. But for many manufacturers, this hour can be plagued by inefficiencies.

Bottleneck: Where the Golden Hour Goes Wrong

Here’s how the Golden Hour can become a liability:

1. Incomplete Shift Handover

Most shift changes rely on manual notes, whiteboard updates, or verbal exchanges. These are often:

- Inconsistent or outdated

- Lacking context (e.g., root causes, downtime justifications)

- Not actionable for incoming workers

This creates information gaps that lead to confusion, delays, or rework.

2. Delayed Startup and Lost Time

Operators may spend 30–60 minutes just getting oriented:

- Locating tools or materials

- Checking machine status

- Figuring out which tasks are highest priority

This lost time is rarely tracked, but it compounds over shifts, weeks, and quarters—significantly reducing overall equipment effectiveness (OEE).

3. Unresolved Issues Carry Over

When maintenance issues, quality concerns, or safety risks go undocumented or unaddressed, they often resurface during the next shift—now harder to track and fix.

4. Disengaged or Underprepared Workers

According to Gallup, employee engagement in the U.S. fell to its lowest level in over a decade in 2024, with only 31% of employees reporting being actively engaged at work. In manufacturing environments, this disengagement is especially visible during shift transitions—particularly among new or cross-trained workers. These employees often enter their shifts unsure of what’s expected of them, especially during the critical first hour. Without clear direction, proper onboarding, or real-time support, their uncertainty can quickly lead to avoidable errors, increased dependency on supervisors, and a noticeable drop in confidence and morale. This not only affects individual performance but can disrupt the flow of the entire operation.

Opportunity: A Strategic Window for Gains

When managed well, the Golden Hour becomes a strategic advantage that sets the foundation for a high-performance day.

1. Accelerated Ramp-Up Time

With the right systems in place, workers can:

- Receive task assignments instantly

- Access personalized, digital instructions

- Know the status of machines and ongoing work within minutes

This cuts wasted time and increases output from the get-go.

2. Stronger Communication Between Shifts

Digitized, real-time shift reports ensure continuity by:

- Highlighting unresolved issues

- Providing historical context for recurring problems

- Aligning everyone on goals and priorities

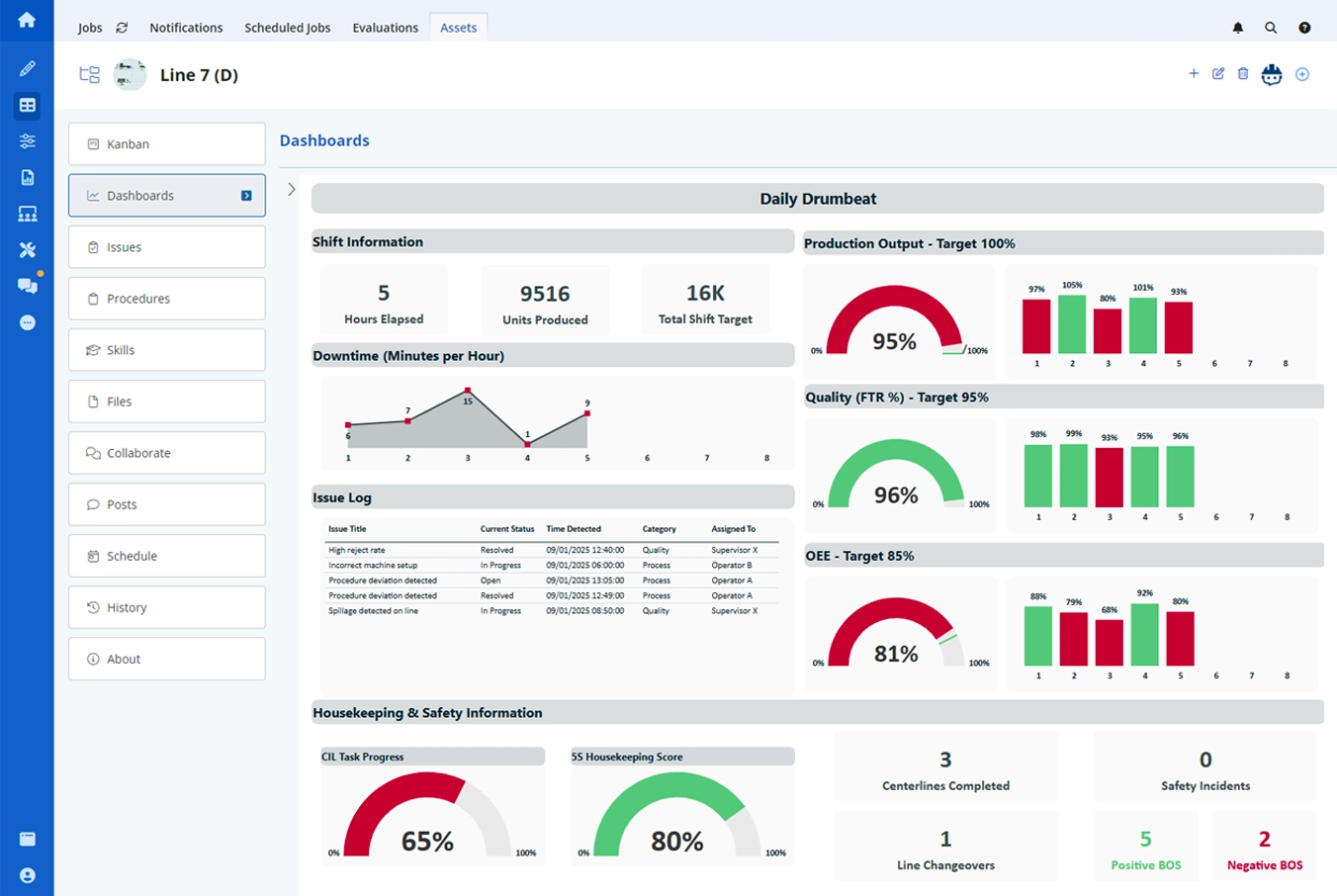

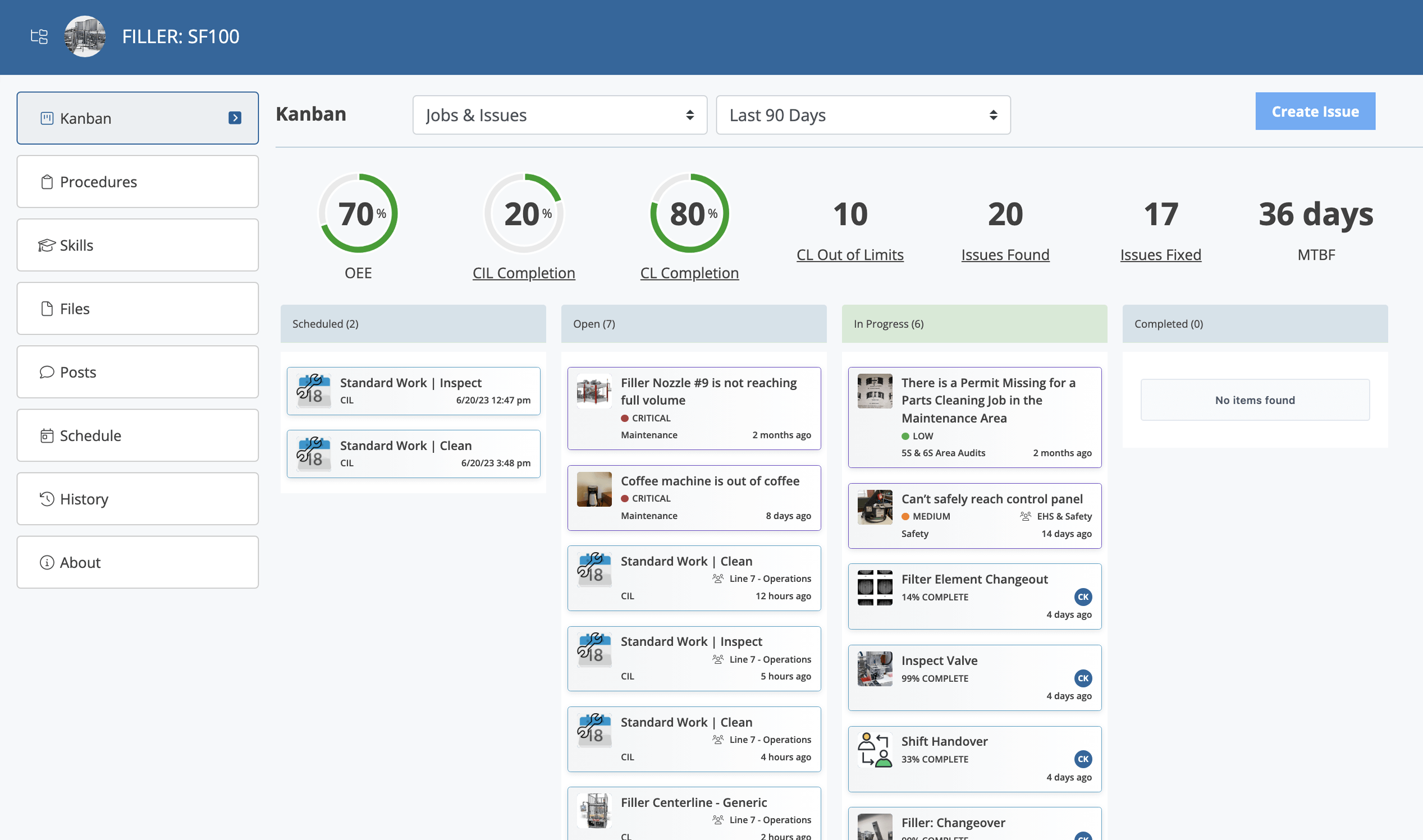

Shift Handover Report using Augmentir’s Connected Worker Platform

This minimizes miscommunication and helps to improve shift handover.

3. Data-Driven Decision-Making

Supervisors and plant managers gain instant visibility into:

- What happened last shift

- What’s planned this shift

- Where attention is needed now

These insights help allocate resources more effectively during the most time-sensitive part of the day.

4. Proactive Quality and Safety Checks

The first hour is a prime window to:

- Identify anomalies before full-scale production starts

- Catch quality issues early

- Perform standardized safety walkthroughs

This proactive approach leads to fewer defects, reduced scrap, and improved compliance.

5. Frontline Worker Empowerment

When workers are equipped with the tools, context, and clarity they need right away, they feel:

- More confident

- More engaged

- More likely to solve problems independently

The Impact Golden Hour has on Daily Productivity

The Golden Hour in manufacturing plays a crucial role in shaping daily productivity by establishing a strong operational foundation right at the start of the shift. When this first hour is managed effectively—through proper machine checks, material readiness, and operator alignment—it minimizes early disruptions and ensures that production ramps up efficiently. This proactive approach helps prevent issues from escalating, allowing teams to maintain a steady workflow and hit performance targets more consistently throughout the day.

Conversely, if problems arise during the Golden Hour—such as equipment malfunctions, quality defects, or unclear communication—they often cause delays and require rework, which can drag down productivity for the entire shift. By treating the Golden Hour as a focused period for startup optimization and problem-solving, manufacturers can reduce downtime, improve first-pass yield, and drive a more productive and predictable day on the shop floor.

How Smart Connected Worker Technology Improves the Golden Hour

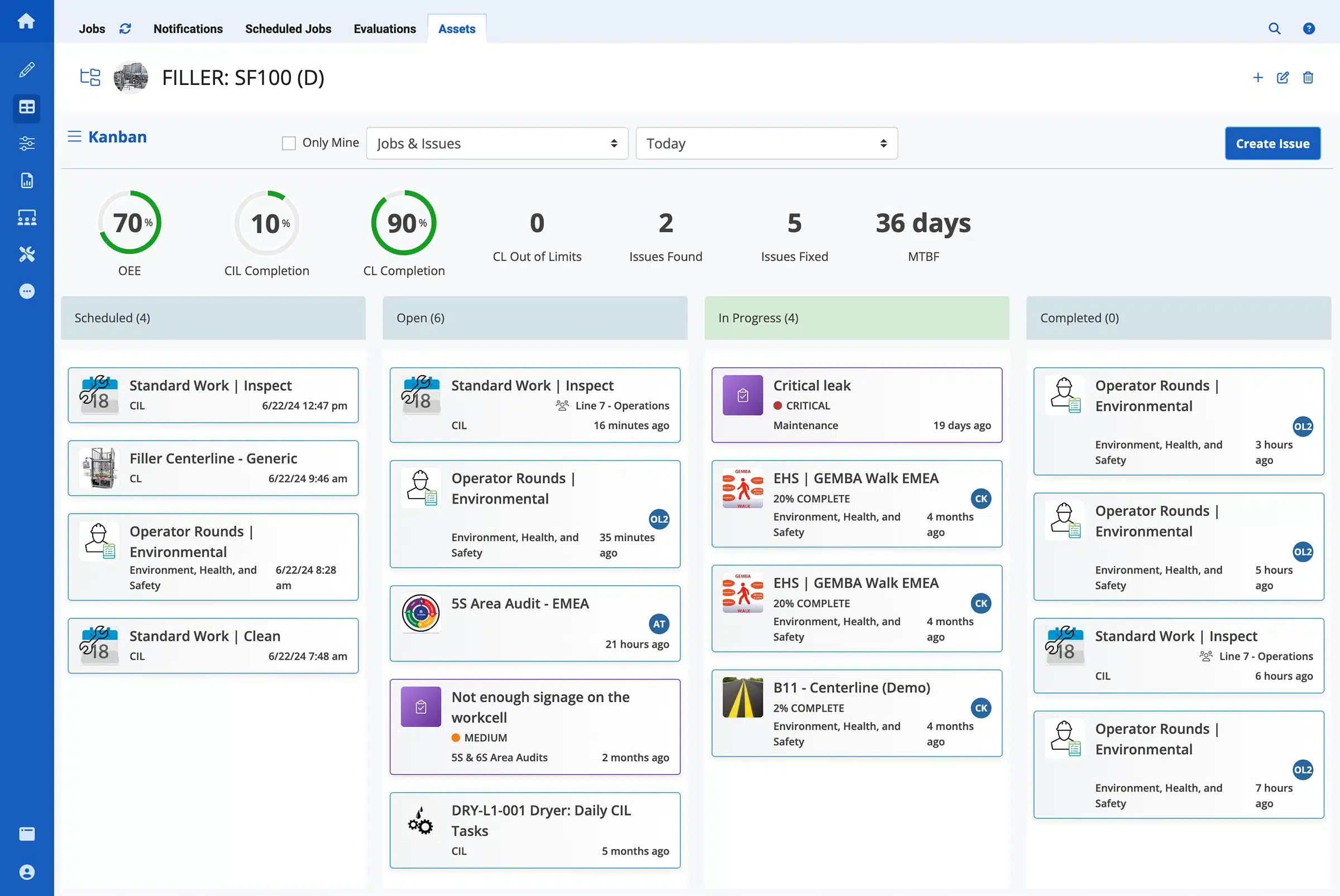

Connected worker platforms digitize and enhance frontline workflows, enabling smarter, faster shift transitions. Here’s how:

1. Digital Shift Handover Logs

Replace static whiteboards and paper notes with real-time digital logs that:

- Capture key insights from the previous shift

- Automatically assign tasks

- Flag unresolved issues or maintenance alerts

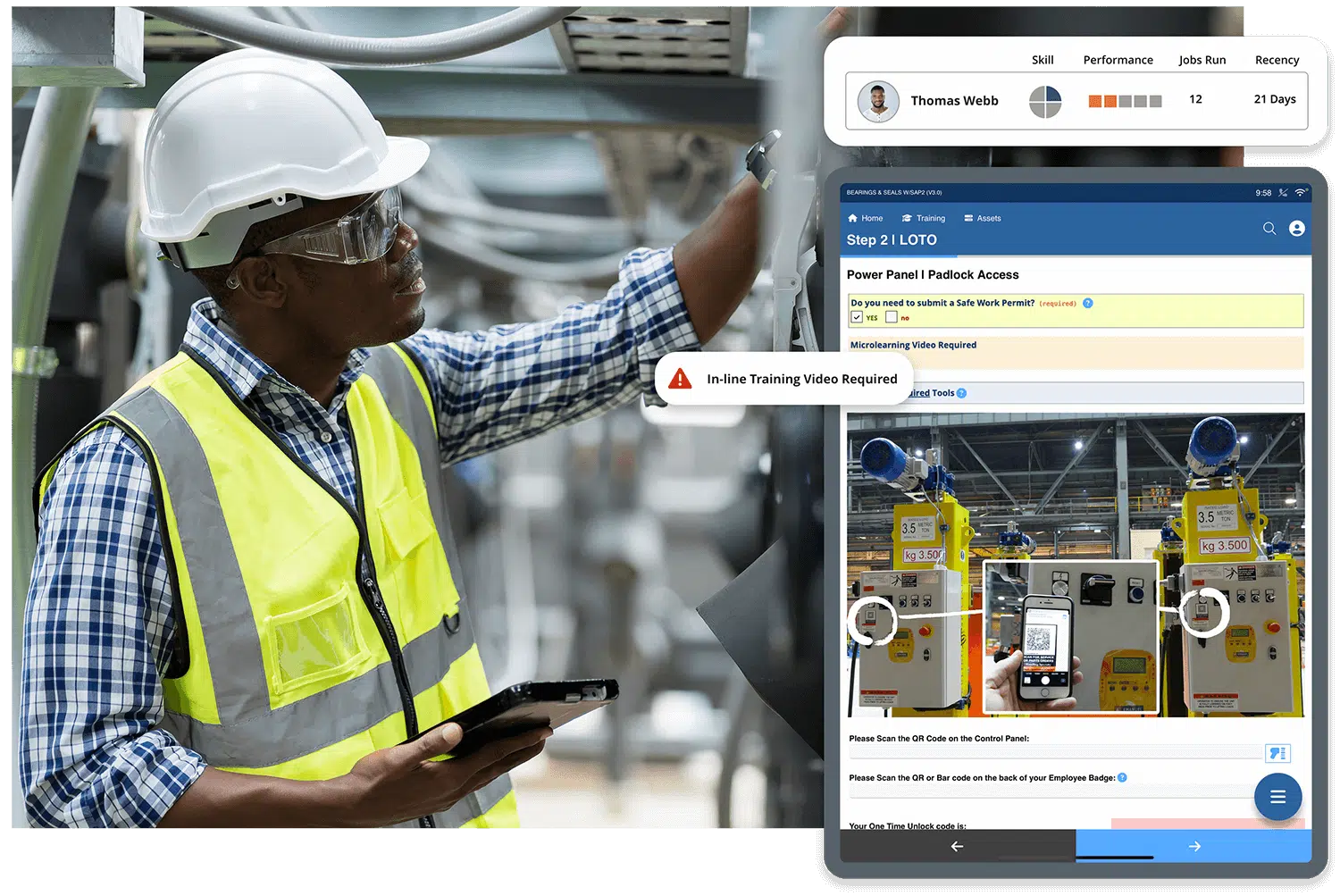

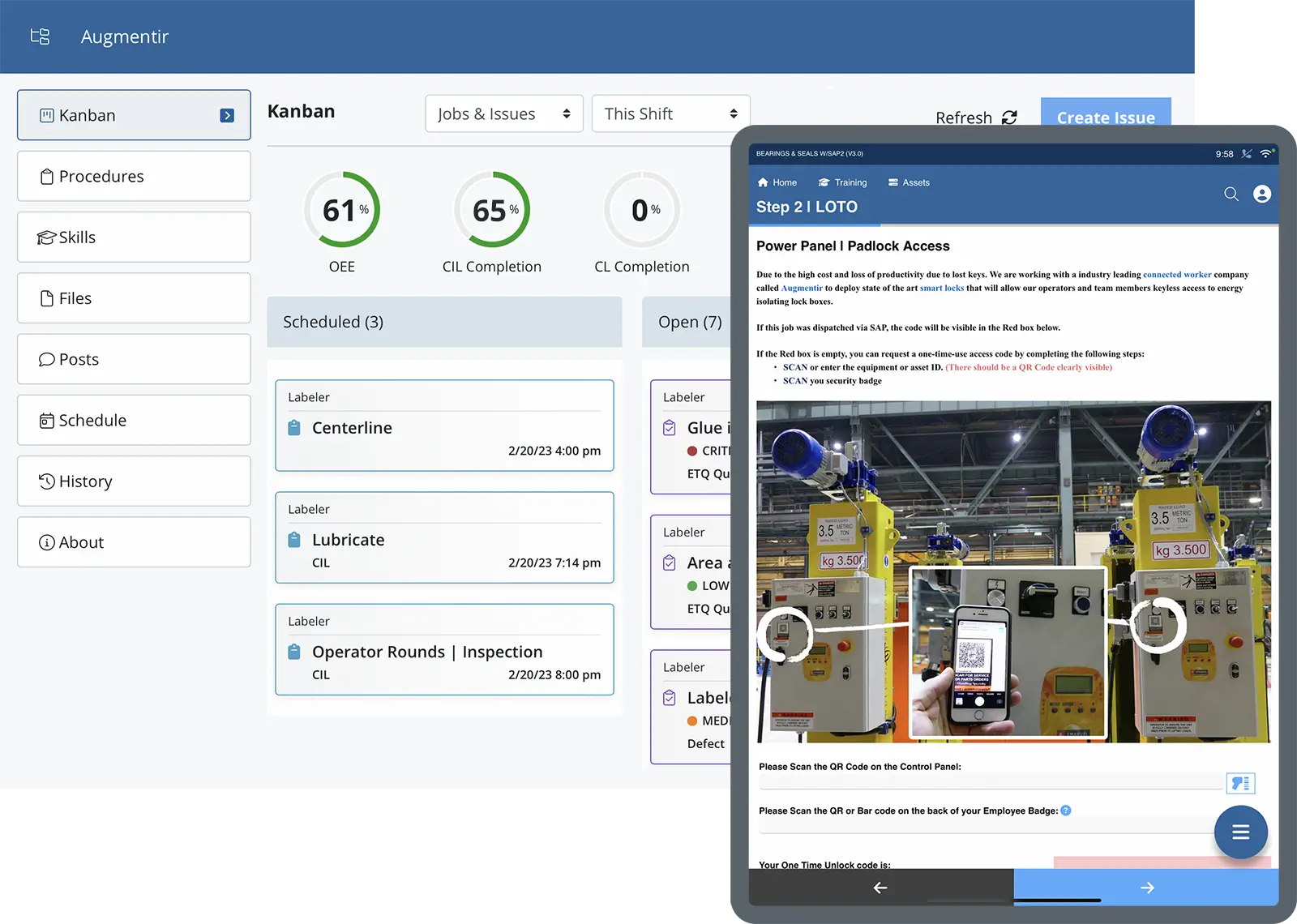

2. Context-Aware Work Instructions

Workers receive personalized, on-demand instructions that adapt to:

- Role

- Skill level

- Machine status

- Environmental factors

This eliminates confusion and empowers workers from minute one.

3. Data-Driven Shift Reports

Supervisors gain visibility into:

- Performance trends

- Downtime root causes

- Operator feedback

- Real-time metrics

This helps prioritize resources and make smarter decisions during the first critical hour.

4. Enhanced Collaboration & Communication

Connected platforms integrate chat, alerts, and escalation paths so teams across departments (maintenance, quality, operations) can collaborate instantly.

Optimizing the Golden Hour with Augmentir

In the fast-paced world of manufacturing, the first hour of every shift—the Golden Hour—can determine the trajectory of the entire day. It’s a window where clear communication, confident execution, and fast decision-making matter most. Augmentir, the world’s only AI-powered connected worker platform, is purpose-built to optimize this critical time by digitizing processes, guiding workers, and providing real-time operational intelligence.

Instead of relying on manual notes, whiteboards, or verbal updates, Augmentir transforms shift handovers into streamlined, digital experiences. Interactive, time-stamped logs capture production status, unresolved issues, and visual task assignments, ensuring incoming teams are aligned from the moment they clock in.

Workers no longer waste time figuring out what needs to be done. Augmentir’s intelligent platform delivers personalized work instructions, targeted task recommendations, and live feedback, helping every worker start their shift with confidence and clarity—whether they’re seasoned or new to the role.

For supervisors and plant leaders, Augmentir unlocks a deeper level of visibility into early shift performance.The analytics dashboard highlights inefficiencies, recurring downtime, and skill gaps that impact productivity—providing actionable insights right at the point of need.

Augmentir helps close the skills gap during this high-stakes hour. Integrated microlearning delivers training directly within the workflow, reducing ramp-up time and minimizing mistakes during the most impactful part of the day.

By turning the Golden Hour into a moment of alignment and acceleration, Augmentir helps manufacturers unlock new levels of efficiency, agility, and workforce performance—right from the very first minute of the shift.

Contact us today for a live demo.