Discover how Hershey’s Digital Lean transformation combines lean principles and connected worker technology to empower frontline teams and drive operational excellence.

In an era where digital transformation is reshaping manufacturing, The Hershey Company offers a compelling roadmap for blending traditional lean principles with modern digital technologies. Through its Digital Lean initiative, Hershey is reimagining daily operations — putting frontline workers at the center of change, reinforcing standardized processes, and building a future-ready digital backbone that enables continuous improvement and operational visibility like never before.

Building the Foundation for Digital Lean

Hershey’s Digital Lean journey did not begin with new technology — it began with strengthening the basics of lean execution. Before digitizing operations, the company focused on standardizing lean processes across its manufacturing network to ensure consistency in how work was performed and improved.

According to Will Bonifant, VP of Manufacturing, Engineering, and Supply Chain Strategy, the groundwork focused on three key areas:

- Standardizing and refining core processes so they were truly lean and repeatable before being digitized.

- Preparing and engaging the workforce early, ensuring employees understood the purpose of Digital Lean and how new tools would support their daily work rather than disrupt it.

- Creating a connected digital infrastructure that links systems, data, and people across sites, enabling reliable, real-time visibility into operations.

With these elements in place, Hershey was able to move away from manual, disconnected workflows and toward digitally enabled daily management systems. This shift allowed teams at all levels to access consistent information, identify issues faster, and drive continuous improvement more effectively — defining characteristics of a mature Digital Lean approach.

Connected Workers as a Core Enabler of Digital Lean

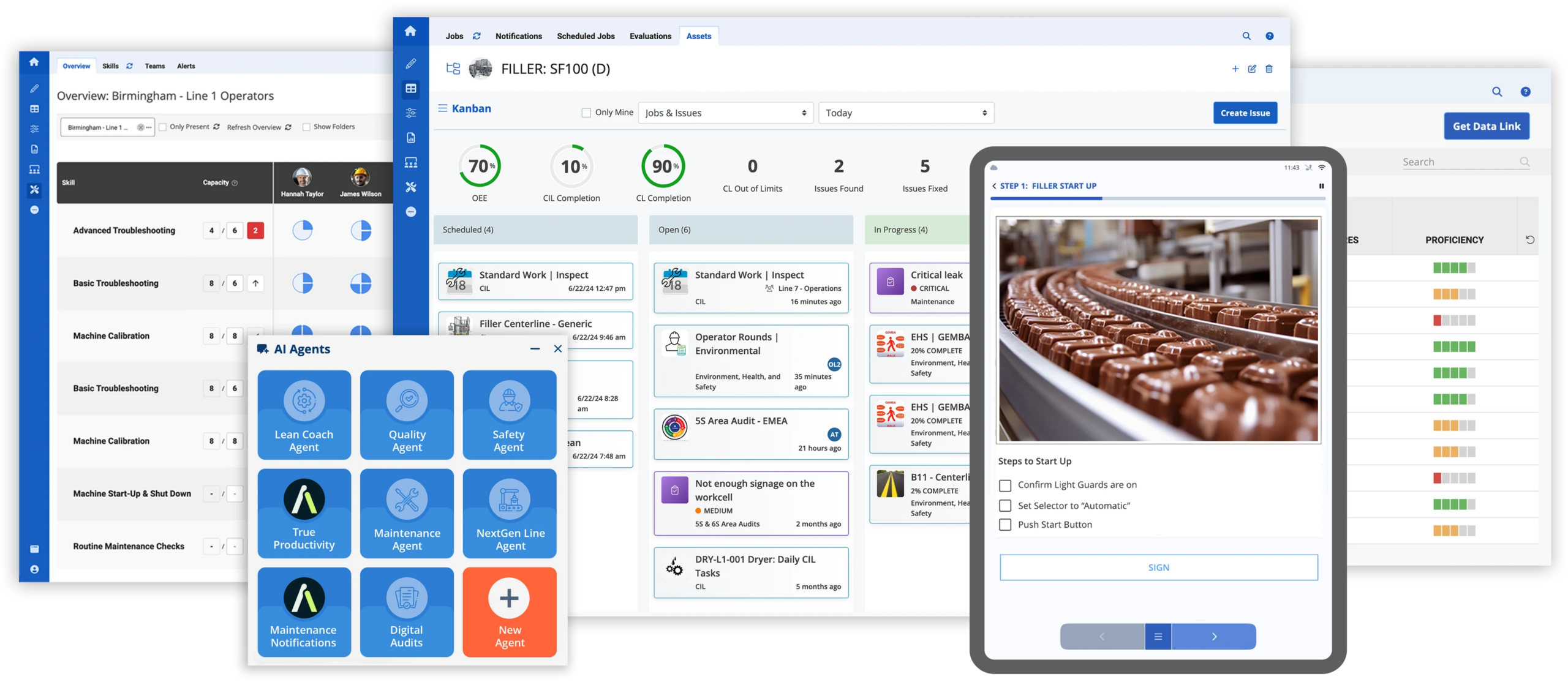

Digital Lean at Hershey is already delivering value because it is tightly integrated with connected worker capabilities. As part of this approach, front-line teams are equipped to access information seamlessly, collaborate in real time, and execute work through guided, digital workflows that support lean execution at the point of work.

By embedding connected worker technology directly into its Digital Lean program, Hershey ensures that lean insights don’t stay locked in dashboards or reports — they translate into consistent, actionable behaviors on the plant floor. This alignment reinforces accountability, accelerates problem resolution, and supports continuous improvement across operations.

This approach closely aligns with Augmentir’s philosophy: the future of manufacturing is a human + digital synergy, where technology amplifies worker capability, strengthens lean behaviors, and enables people to perform at their best — every day.

What Digital Lean Looks Like on the Floor

Digital Lean at Hershey isn’t just a tech upgrade — it’s a shift in how work gets executed and improved every day:

Empowered Operators

In the past, operators faced slow, fragmented workflows when problems arose. Today, operators can:

- Log issues directly via mobile devices,

- See real-time updates as those issues are resolved,

- Access performance data that helps them own outcomes on the line.

This enhanced visibility not only speeds problem resolution, but also boosts worker autonomy — a core principle of lean maturity.

Leadership Visibility, Real-Time Actions

Supervisors and plant managers gain a unified view of performance and losses from a single dashboard. This transparency allows them to:

- Identify bottlenecks and losses quickly,

- Prioritize corrective actions based on real data,

- Drive continuous improvement across shifts and sites.

The shift toward digital workflows also means that information no longer lives in silos. Everyone — from operators to executives — benefits from the same accurate, timely insights.

Why Digital Lean Matters for Manufacturers

Hershey’s journey highlights several lessons for operations leaders:

- Value starts with people first. Digital tools deliver impact only when they support equipped, engaged workers.

- Standardization enables scale. Ensuring processes are lean before digitizing them reduces frustration and drives sustainable improvements.

- Data unlocks action. Once lean processes are digitized, real-time insights accelerate problem solving and continuous improvement.

By anchoring digital transformation in lean principles, Hershey is proving that operational excellence and digital innovation are not separate pursuits — they’re mutually reinforcing.

Augmentir: Powering Hershey’s Connected Worker Strategy

As Hershey continues to mature its Digital Lean transformation, sustaining continuous improvement at scale requires more than visibility into performance — it requires connecting digital insights directly to frontline execution. To do this, Hershey leverages Augmentir as its connected worker technology, extending Digital Lean from dashboards into daily work on the factory floor.

Digital Lean provides the foundation by standardizing processes, digitizing daily management, and enabling real-time performance tracking. Augmentir operationalizes that foundation by connecting people, processes, and data at the point of work. Through AI-driven insights, Augmentir delivers personalized guidance, digital work instructions, and contextual support to operators — ensuring the right information reaches the right worker at the right time.

By using Augmentir as part of its Digital Lean ecosystem, Hershey is able to:

- Translate insights into action by embedding continuous improvement directly into daily workflows.

- Empower frontline workers with adaptive, skills-based guidance that evolves as experience and conditions change.

- Reduce variability and reinforce standard work consistently across lines, shifts, and sites.

- Capture and scale institutional knowledge to support onboarding, upskilling, and long-term operational resilience.

Within Hershey’s Digital Lean journey, Augmentir represents the critical bridge from visibility to execution — ensuring that digital insights don’t remain isolated in systems, but actively guide how work is performed every day.

As manufacturers move beyond digitizing processes toward truly augmenting human performance, Hershey’s use of Augmentir demonstrates how connected worker technology makes Digital Lean sustainable, scalable, and people-centric — turning continuous improvement into a daily habit rather than a periodic initiative.

Hershey’s Digital Lean transformation is a powerful example of how digital technologies — built on a solid lean foundation — can enhance operational agility, empower frontline workers, and drive measurable business value. As manufacturers navigate the next wave of digital disruption, the key takeaway is clear: start with people and processes, then scale with technology.