These virtual events were a great way to connect with manufacturing professionals and discuss some of the industry’s top challenges and topics – workforce transformation, learning and development, lean manufacturing, and autonomous maintenance.

Last week, Augmentir participated as a sponsor in the 2021 American Food Manufacturing Summit. This 3-day virtual event was designed to bring food and beverage manufacturers together to discuss current trends, strategic insights, and best practices in an ever-evolving environment. The event focused on addressing today’s top challenges and future of food processing and manufacturing, specifically around embracing digital transformation and technology for manufacturing excellence. Attendees were able to connect with top industry influencers and learn about different strategies to improve automation, operational excellence, quality, and safety in the food manufacturing industry through open roundtables and 1:1 meetings.

Augmentir’s Enablement Director, Shannon Bennett, hosted an open roundtable discussion on the role digital transformation plays in food and beverage manufacturing, and how technologies like artificial intelligence (AI) and connected worker platforms are helping companies kick-start their digital transformation efforts. During the discussion, Shannon opened the floor to the attendees to discuss the day-to-day challenges they face at their manufacturing organizations and the tools they’re looking into to solve those challenges.

Solving Manufacturing’s Biggest Challenges with AI and Connected Worker Technology

The roundtable consisted of executives and manufacturing leaders from some of the world’s largest food and beverage companies to smaller family-owned and operated specialty food and beverage manufacturers. Throughout the roundtable, we heard the same challenges and frustrations related to standardization, moving from paper to digital processes, data collection, lack of traceability, and an overall need for digital transformation.

The overarching roundtable discussion was around digital transformation. Food and beverage manufacturers are accelerating the pace of digitization to address their top challenges – the labor crisis, increasing skills gap, and increased pressure for improved production efficiency, changes in consumer demands, and increased regulatory compliance related to food safety.

Moving from Paper to Digital

During our roundtable discussion, most of the manufacturing leaders were in the discovery phase of their modernizing process, where they were beginning to look into digital solutions to solve their challenges around manual processes and efforts to reduce paper. Some of the discussion around paper included issues with quality on the shop floor and wanting to go paperless, easier access to training for employees, lack of traceability (for example, maintenance schedules need more visibility of completion, where issues arise, and more transparency all around), and digitizing information from a quality standpoint.

Digital work instructions reduce the need for paper and deliver information to frontline workers when and where they need it. This provides frontline workers with a standardized way of performing technical work.

Lack of Data-Driven Insights into the Work Being Done

Another key challenge was the lack of insight into how workers were performing their jobs – whether it be in quality, equipment operation, or maintenance. One participant discussed labor challenges in their organization and that when they collect data it often gets lost and when they come back to it, they don’t know or remember why they’ve collected it in the first place.

Connecting workers with digital tools is merely a first step in the process of truly understanding and getting clarity on the work being done. Connected Worker data is inherently noisy, generating misleading signals that traditional business intelligence (BI) tools aren’t designed to handle. This leads to murky or contradictory conclusions that prevent organizations from taking anything but a “one size fits all” approach to work process and workforce investments. Or, even worse, false conclusions are generated about the state of work process and workforce opportunities, leading to targeted investments into the wrong areas.

The discussion shifted to AI as a solution not only bringing clarity to the work being done, but also more generally democratization of the workplace, and giving employees the tools to use data effectively to improve manufacturing operations. AI is designed for purpose to recognize patterns in the noisy data sets generated by a factory workforce, letting your continuous improvement and operations teams focus on what’s really going on.

Training

Employee onboarding and training was also a hot topic of discussion. Many participants spoke about manual processes and how traditional training methods are proving to be ineffective. Traditionally, there was a clear separation between training and work execution. However, many participants shared that they are starting to re-think how they are training and onboarding their workers, and shifting more towards delivering training at the moment of need. The roundtable participants discussed at length approaches and strategies for re-thinking how training is delivered for today’s workforce.

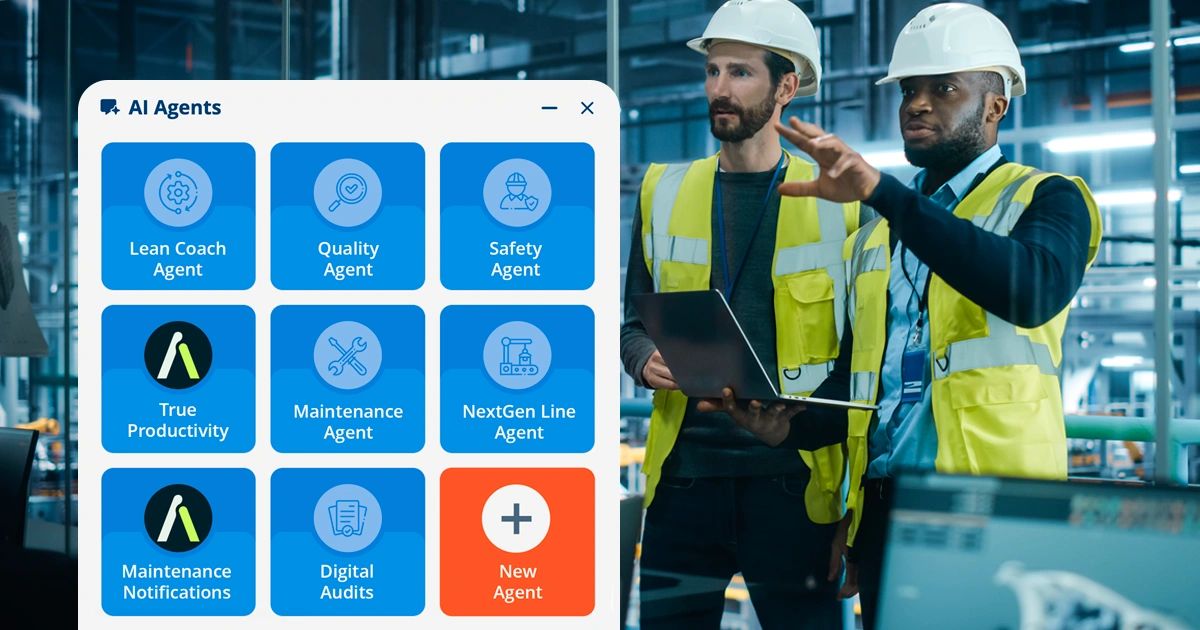

Build a Modern, Connected Workforce with AI

To address these challenges, the roundtable participants overwhelmingly agreed that digital transformation initiatives for food manufacturing should start by focusing on streamlining data collection and digitizing valuable data. Using an AI-powered connected worker platform to accelerate this effort not only furthers a company’s digital transformation efforts, but also provides a whole new set of data that can provide really interesting insights and optimization opportunities. AI doesn’t remove the human worker from the equation, but rather, takes the human worker and embeds them into the digital operation.

To learn more about how AI is being used to digitize and modernize manufacturing operations, check out our latest eBook – Build a Modern, Connected Workforce with AI.