Boost your Clean Inspect Lubricate (CIL) processes with modern digital tools to enhance efficiency, ensure compliance, and reduce equipment downtime.

In manufacturing, it’s often the simplest routines that have the biggest impact. Take CIL—Clean, Inspect, Lubricate, a key part of Autonomous Maintenance. CIL is one of the first maintenance activities operators learn, and one of the most frequently performed. But here’s the thing: when done right, CIL can become a powerful driver of equipment reliability, lean efficiency, and frontline ownership.

Unfortunately, in too many factories, CIL is stuck in the past—paper checklists, inconsistent execution, and little visibility into whether it’s even being done. It becomes a checkbox exercise instead of a value-generating process.

At Augmentir, we’re changing that.

Taking CIL Beyond Machine Upkeep

CIL isn’t just about machine upkeep—it’s about unlocking the full potential of your frontline teams. While it’s often viewed as a basic task to keep machines running, we believe CIL plays a far more strategic role in manufacturing. It’s one of the few consistent, hands-on opportunities operators have to engage with their equipment and contribute to its health, performance, and longevity. When done right, CIL boosts equipment reliability, minimizes unplanned downtime, and forms the foundation for Total Productive Maintenance (TPM) and Lean Manufacturing—core principles of the Toyota Production System.

However, the traditional approach to CIL—paper checklists, manual logs, and inconsistent training—limits its potential. Without real-time visibility or standardization, it’s easy for these tasks to become rushed or overlooked, turning CIL into a reactive or even forgotten process. That’s why we approach CIL as a digitally connected, people-centric process. When CIL is embedded into daily workflows, supported with intuitive guidance, and tied into data-driven insights, it becomes far more than routine—it becomes a driver of reliability, workforce engagement, and continuous improvement. In short, we see CIL as a launchpad for smarter operations, and a powerful opportunity to elevate the role of the frontline worker.

It’s about building a smarter, more proactive, more connected manufacturing environment—one that prevents problems instead of reacting to them.

Modernizing CIL for Today’s Workforce with Augmentir

At Augmentir, we believe CIL isn’t just a task—it’s a pivotal moment. A moment when operators pause to care for the equipment that powers your operation. Though simple, this act has the potential to connect people, processes, and machines in a way that drives long-term reliability and performance.

Yet in many manufacturing environments, CIL remains an undervalued routine. But we know better. These everyday actions—cleaning a part, inspecting for wear, applying lubrication—are where operational excellence begins. They’re the frontline’s first defense against equipment failure, quality issues, and lost productivity. More importantly, they’re one of the few daily touchpoints where workers can directly influence performance.

Here’s how Augmentir is modernizing CIL to make every moment count:

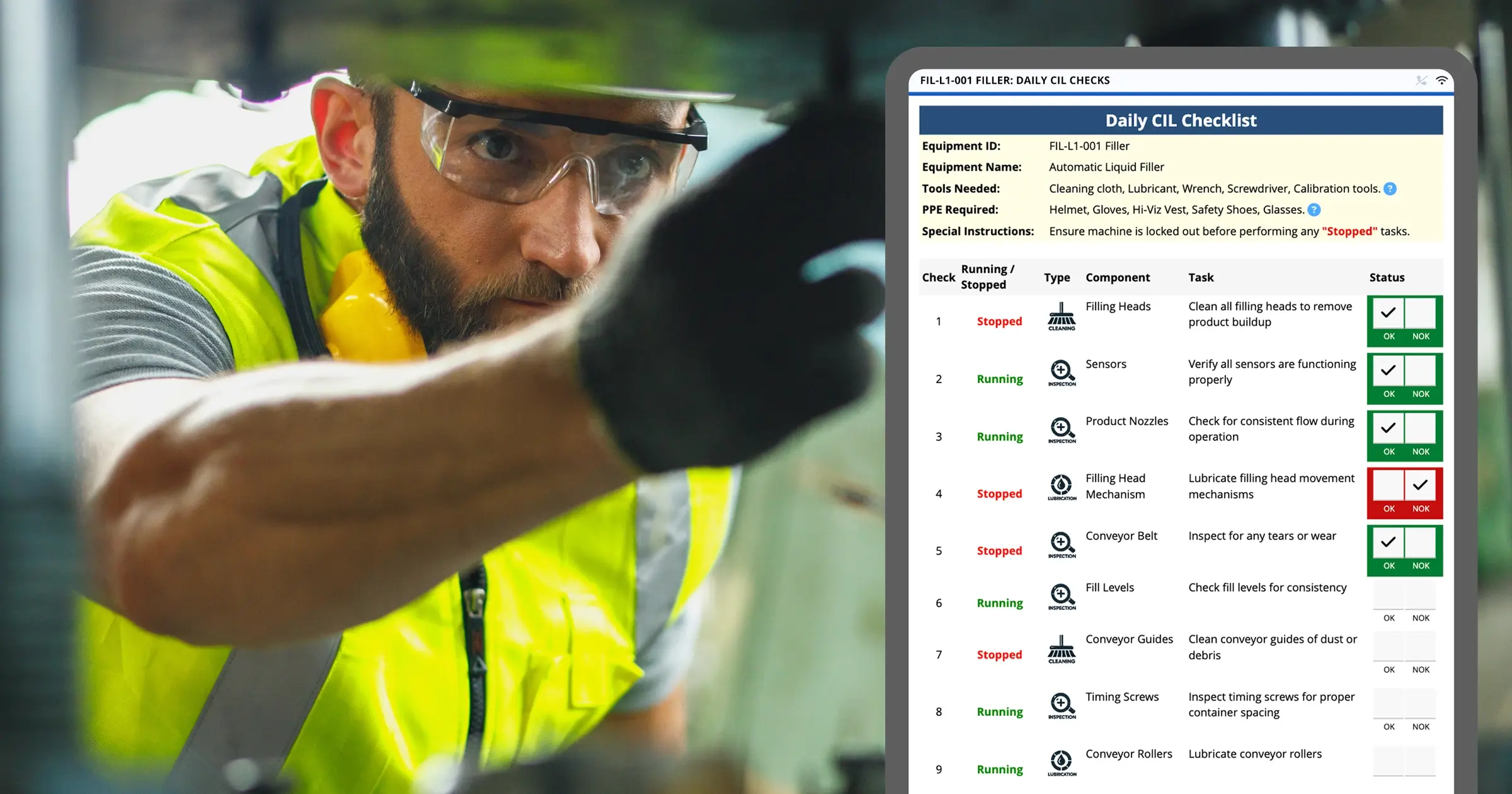

1. Digital CIL Workflows that Guide and Empower

Frontline workers can access step-by-step instructions on any mobile device or tablet. With clear visuals, safety prompts, and machine-specific guidance, every task is executed correctly—every time. No more guesswork. No more paper binders.

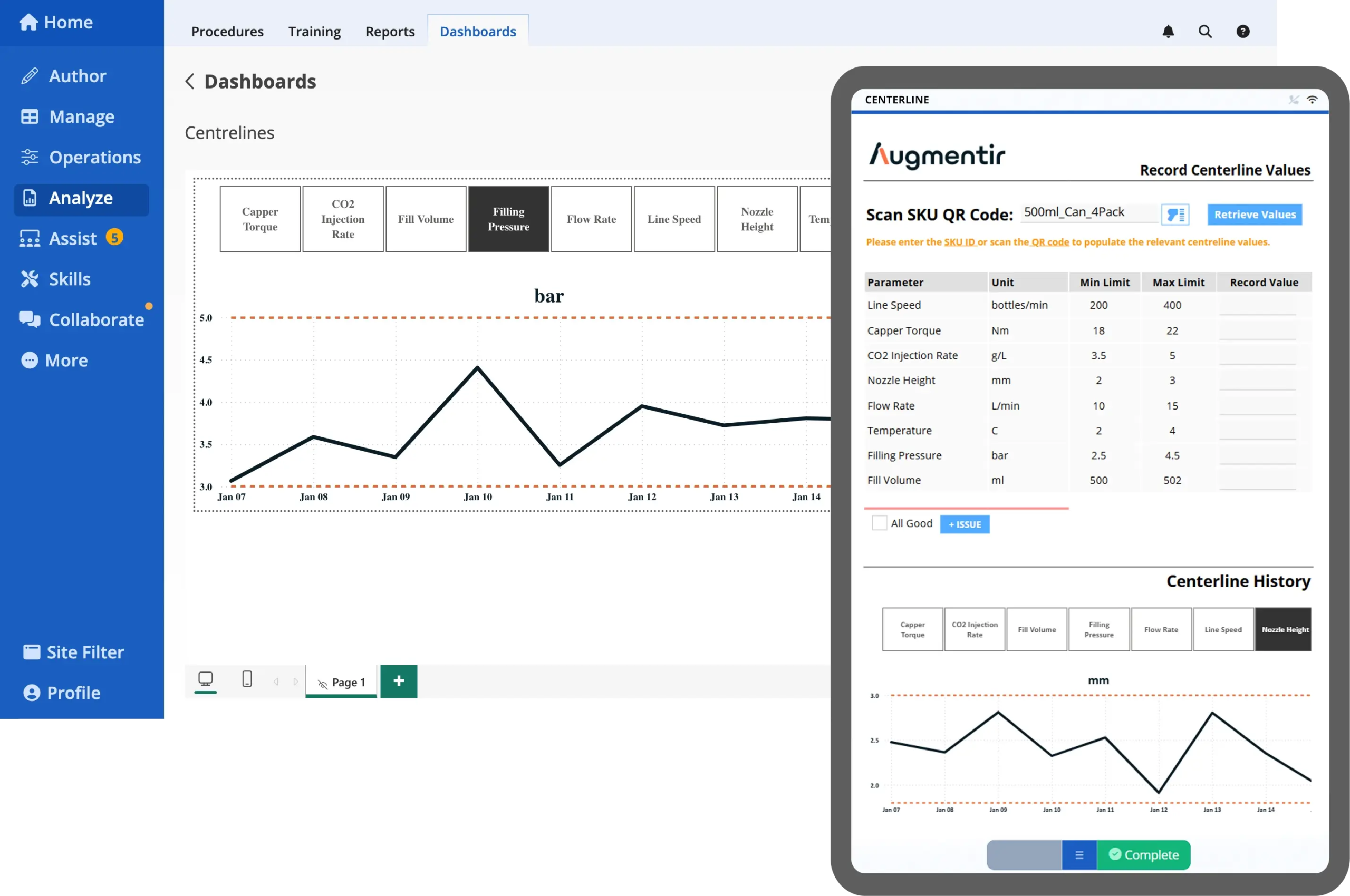

2. Smart Insights that Drive Action

Our AI-powered platform captures and analyzes every CIL activity, helping you spot inefficiencies, missed steps, and recurring issues. Routine maintenance becomes a powerful engine for continuous improvement.

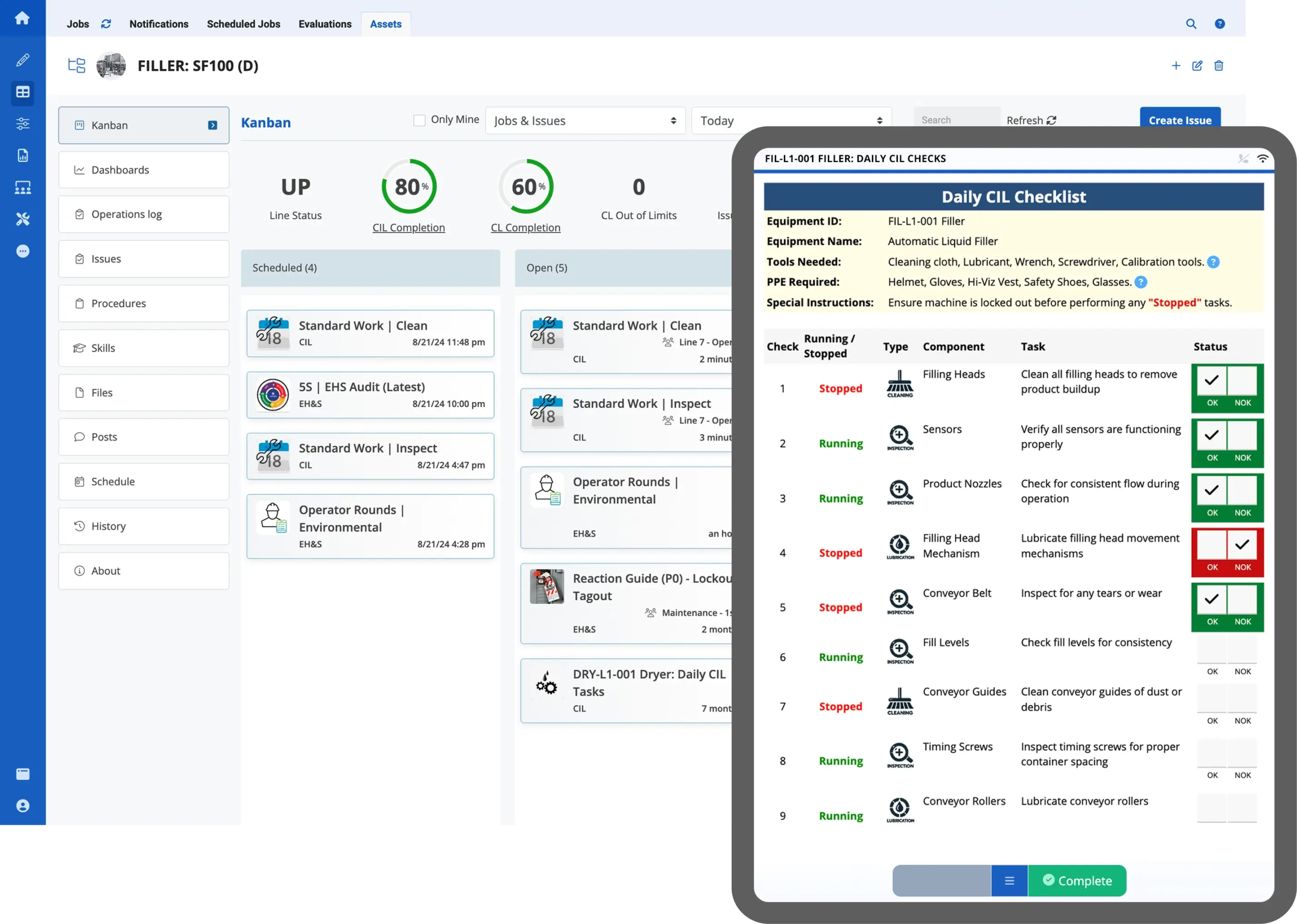

3. Real-Time Visibility and Accountability

Supervisors and maintenance teams gain instant visibility across all lines and shifts. See which equipment has been serviced, who completed the work, and what issues were flagged—without chasing checklists or relying on memory.

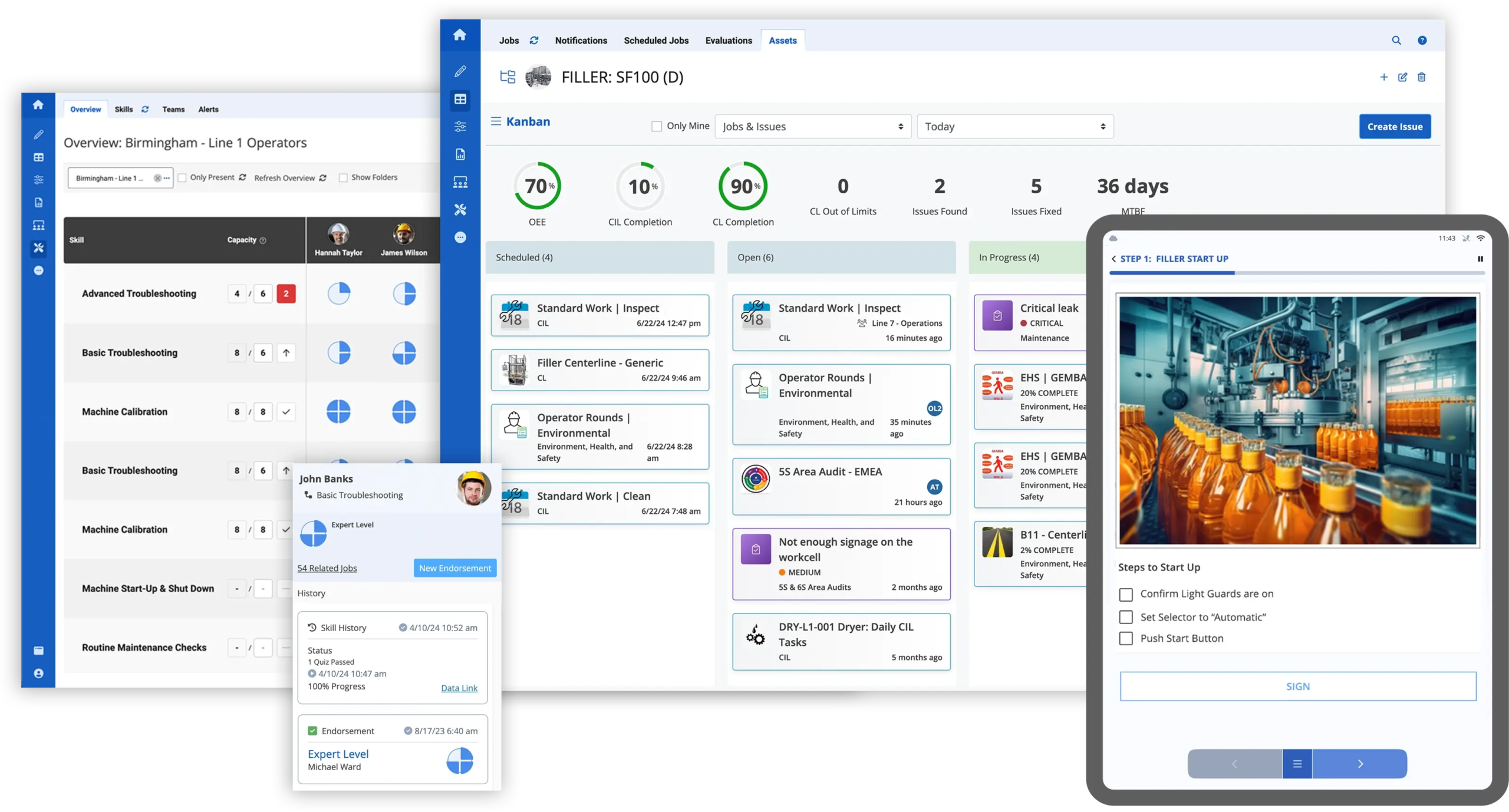

4. Embedded Knowledge and Skill Development

CIL is also an opportunity to upskill. Augmentir embeds tribal knowledge into workflows, enabling operators to learn on the job and contribute valuable feedback that strengthens the entire system.

When powered by real-time data and AI, CIL transforms from a basic task into a strategic asset. It boosts decision-making, reveals hidden issues, supports autonomous maintenance, and empowers your workforce. The result? More uptime. More consistency. More engaged frontline teams—and less waste.

At Augmentir, we’re committed to turning these everyday moments into measurable impact. With the right tools, even routine tasks can fuel innovation and resilience.

Ready to turn your CIL program into a competitive advantage?