Recently, Augmentir completed a rigorous qualification audit as part of a Tier 1 Pharmaceutical Manufacturing company’s Good Manufacturing Practice (GMP), and we are pleased to announce that our product successfully passed the audit.

A recent article published by The Washington Post shows some shocking numbers on the amount of Americans leaving their jobs over the past year. It’s no surprise that hotel and restaurant workers are resigning in high numbers due to the pandemic, but what is surprising is the fact that the manufacturing industry has been hit the hardest with “a nearly 60 percent jump” compared to pre-pandemic numbers. This “Great Resignation in Manufacturing” is the most of any industry, including hospitality, retail, and restaurants, which have seen about a 30% jump in resignations.

However, if you dig deeper, this trend isn’t new. This recent increase in job quitting in manufacturing has simply magnified a problem that had already been brewing for years, even prior to the start of the pandemic. In fact, in the four years prior to the pandemic (2015-2019), the average tenure rate in manufacture had decreased by 20% (US Bureau of Labor Statistics).

This accelerating workforce crisis is placing increased pressure on manufacturers and creating significant operational problems. The sector that was already stressed with a tight labor market, rapidly retiring baby-boomer generation, and the growing skills gap is now facing an increasingly unpredictable and diverse workforce. The variability in the workforce is making it difficult, if not impossible to meet safety and quality standards, or productivity goals.

Manufacturing leaders’ new normal consists of shorter tenures, an unpredictable workforce, and the struggle to fill an unprecedented number of jobs. These leaders in the manufacturing sector are facing this reality and looking for ways to adjust to their new normal of building a flexible, safe and appealing workforce. As a result, managers are being forced to rethink traditional onboarding and training processes. In fact, the entire “Hire to Retire” process needs to be re-imagined. It’s not the same workforce that our grandfather’s experienced, and it’s time for a change.

The Augmented, Flexible Workforce of the Future

The reality is that this problem is not going away. The Great Resignation in manufacturing has created a permanent shift, and manufacturers must begin to think about adapting their hiring, onboarding, and training processes to support the future workforce in manufacturing – an Augmented, Flexible Workforce.

What does this mean?

- It means adopting new software tools to support a more efficient “hire to retire” process to enable companies to operate in a more flexible and resilient manner.

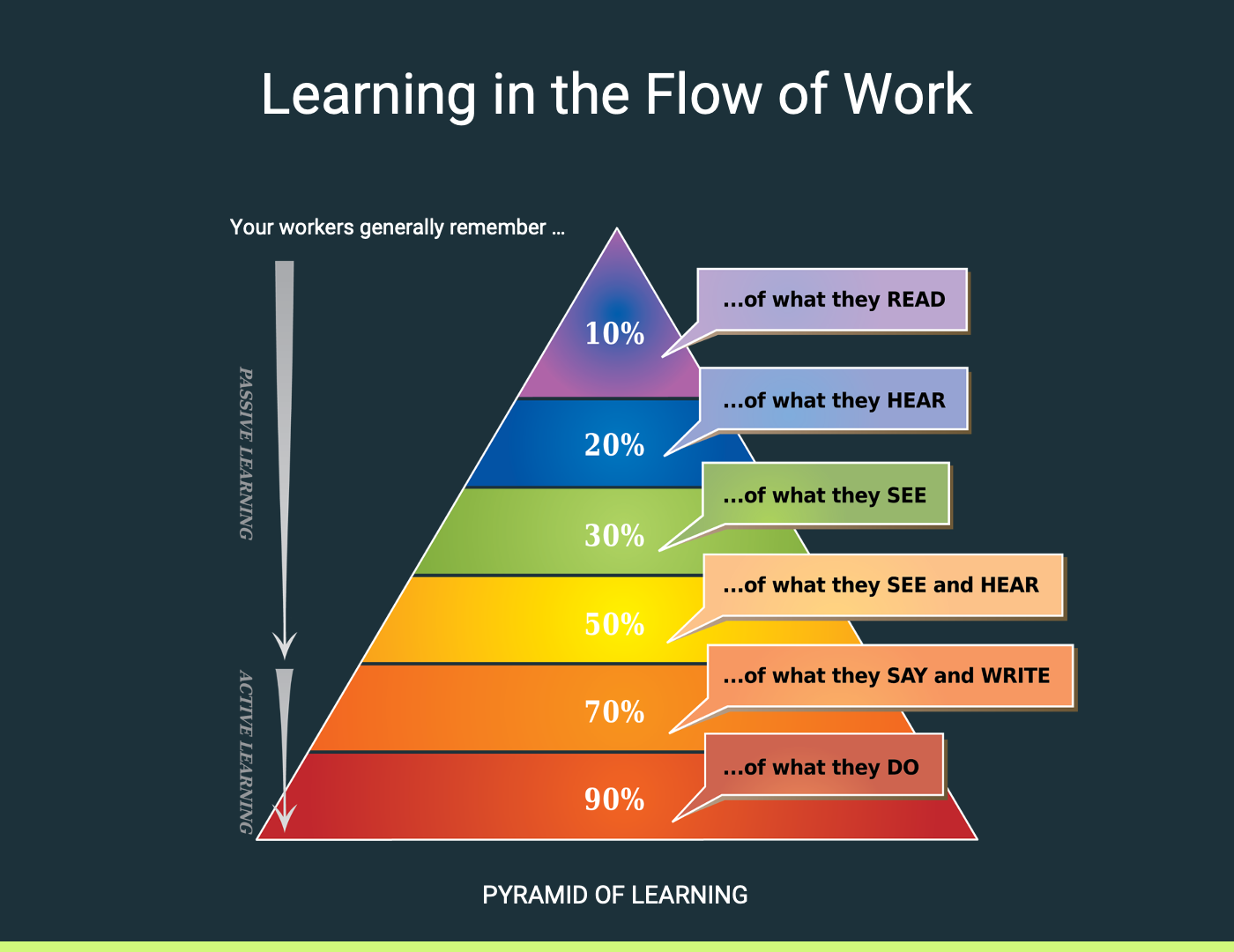

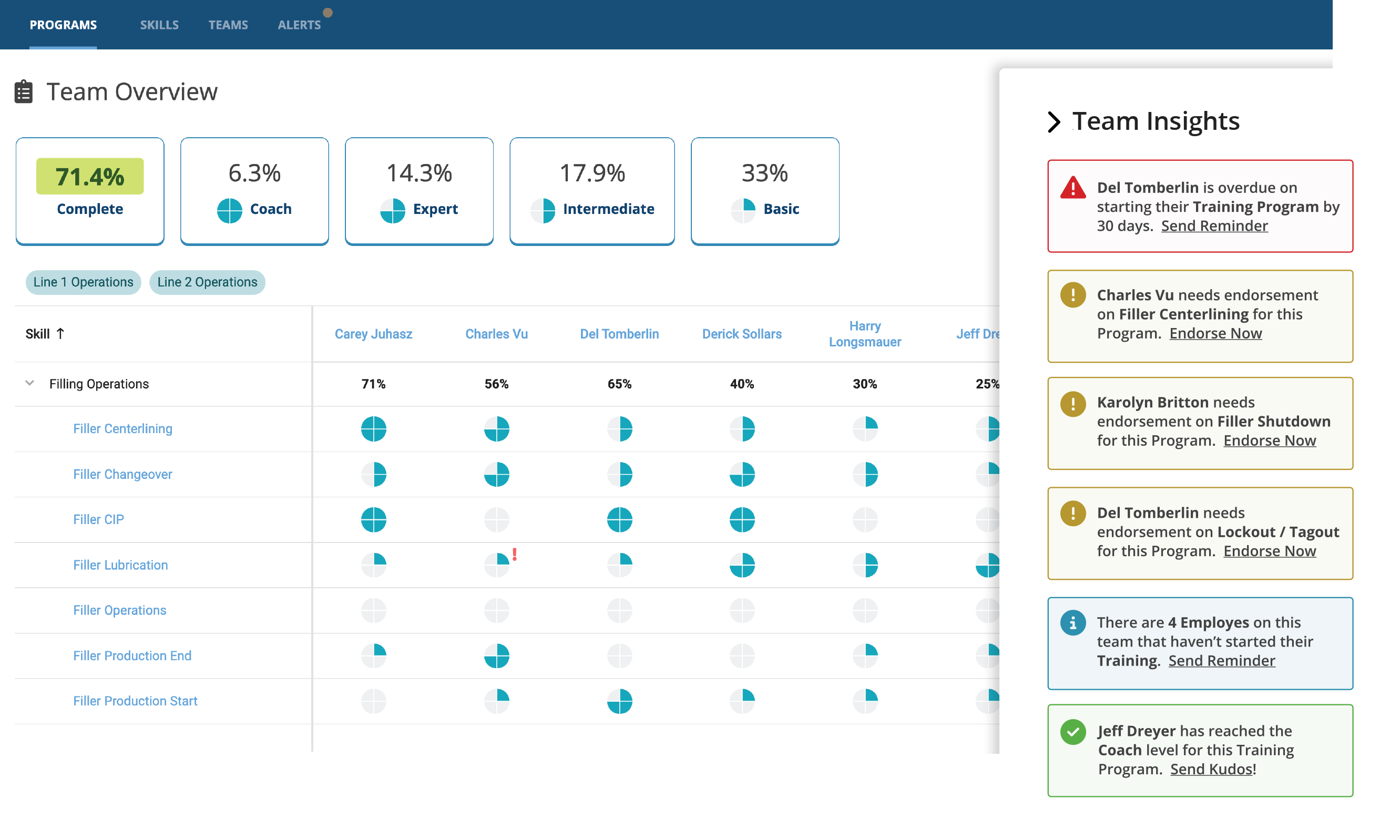

- It means starting to understand your workforce at an individual level and using data to intelligently closes skills gaps at the moment of need and enables autonomous work.

- And it means taking advantage of data. More specifically, real-time workforce intelligence that can provide insights into training, guidance, and support needs.

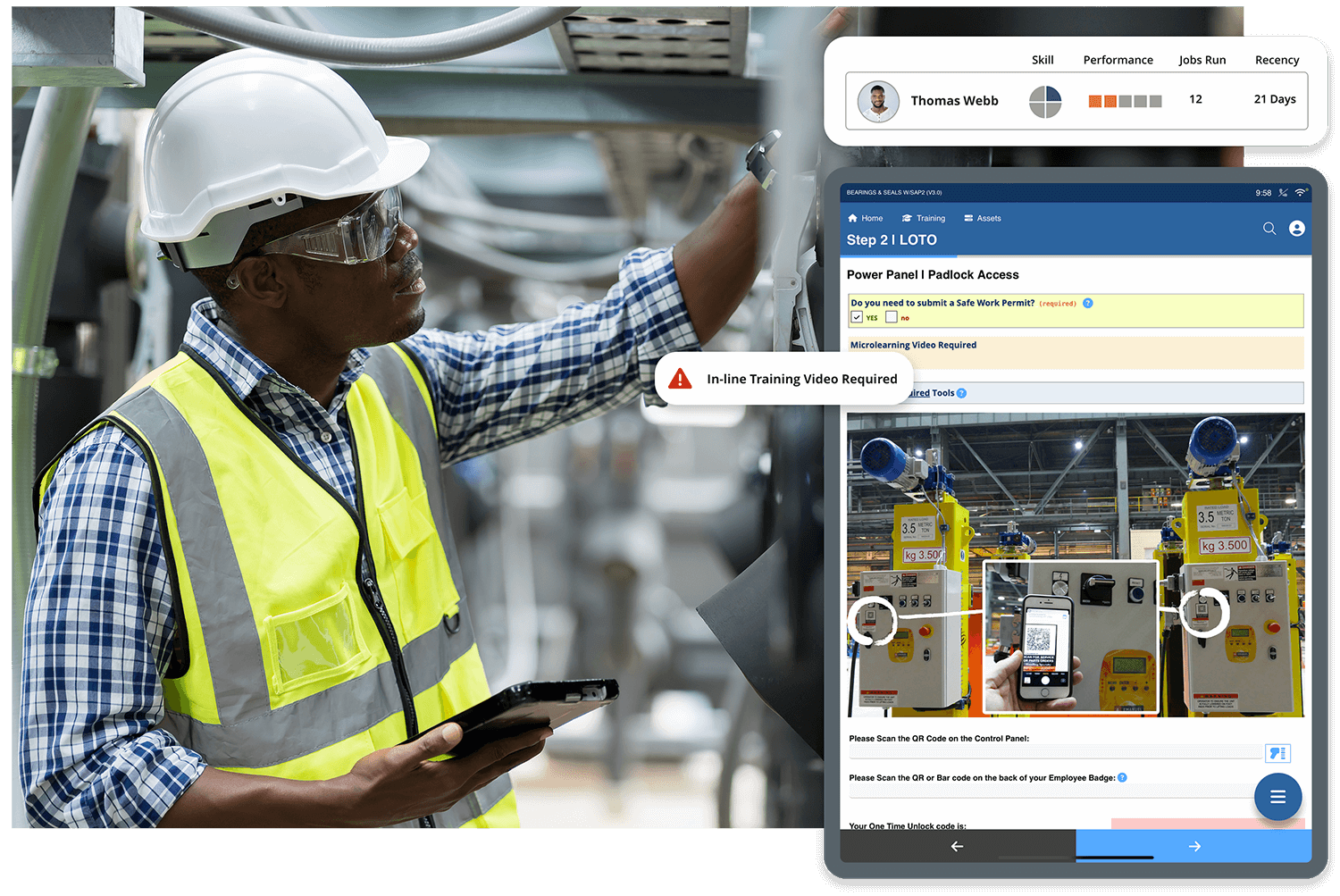

Investing in AI-powered connected worker technology is one way to boost this operational resiliency. Many manufacturing companies are using digital Connected Worker technology and AI to transform how they hire, onboard, train, and deliver on-the-job guidance and support. AI-based connected worker software provides a data-driven approach that helps train, guide, and support today’s dynamic workforces by combining digital work instructions, remote collaboration, and advanced on-the-job training capabilities.

As workers become more connected, manufacturers have access to a new rich source of activity, execution, and tribal data, and with proper AI tools can gain insights into areas where the largest improvement opportunities exist. Artificial Intelligence lays a data-driven foundation for continuous improvement in the areas of performance support, training, and workforce development, setting the stage to address the needs of today’s constantly changing workforce. Today’s workers embrace change and expect technology, support and modern tools to help them do their jobs.

To learn more about how AI is being used to digitize and modernize manufacturing operations, contact us for a personalized demo.