Learn how to improve manufacturing shift handover with our downloadable template and AI-powered connected worker solution.

Improving shift handover in manufacturing involves implementing strategies to enhance communication, streamline processes, and ensure a smooth transition between shifts. These strategies can include creating a shift handover template (shift handoff template), implementing digital processes with a connected worker platform, and establishing standardized shift handover protocols.

Encouraging active participation and engagement from both incoming and outgoing personnel fosters a culture of accountability and collaboration. Regular training sessions and feedback mechanisms enable teams to continuously refine their handoff procedures and address any challenges. By prioritizing clear communication, standardized processes, and ongoing improvement efforts, manufacturing facilities can optimize shift handoff practices and maximize operational efficiency.

Read below to learn why shift handover is important, how to standardize shift handoffs for safer operations, examples of shift handover templates (shift handoff templates), and how to digitize shift handoffs with connected worker software tools.

- Why are shift handovers important?

- Standardizing Shift Handoff for Safer Operations

- Shift Handover Template Examples

- Digital Shift Handover with Connected Worker Software

You can now import existing PDF, Word, or Excel documents (just like the PDF above) directly into Augmentir create digital, interactive work procedures and checklists using Augie™, a Generative AI content creation tool from Augmentir. Learn more about Augie – your industrial Generative AI Assistant.

Why are shift handovers important?

Shift handoff in manufacturing is a critical process where incoming and outgoing personnel exchange information, ensuring continuity and efficiency in production operations. During this transition, which is often referred to as the golden hour in manufacturing, essential details such as production status, equipment condition, safety concerns, and any ongoing issues are communicated to ensure a seamless transfer of responsibility.

The consequences of improper shift handover communication and processes can be devastating. For example, a U.S. Chemical Safety and Hazard Identification Board investigation found that a series of shift communication mistakes beginning five days before an incident led to the release of nearly 24,000 pounds of methyl mercaptan, a toxic chemical. This caused not only OSHA fines over $270,000, but also the death of four employees who inhaled the toxic fumes.

Effective communication during shift handoff is paramount to effective daily management, enabling the incoming team to understand the current state of affairs, anticipate potential challenges, and maintain productivity levels. By prioritizing clear communication and thorough documentation, manufacturing facilities can enhance operational effectiveness and maintain high standards of safety and quality across shifts. Additionally, documenting key information facilitates future reference and aids in problem-solving.

Standardizing Shift Handovers for Safer Operations

Pen and paper shift handover reports and verbal handoffs are often ineffective due to a lack of structured communication between shifts, other departments/teams, and reports that lack crucial details. Data is often exchanged verbally, through emails, and physical notes that can be misinterpreted or misunderstood by the next person or by a later shift. This process can be streamlined through standardization, saving time and effort.

Standardized work is a core pillar of operational safety excellence, in essence, it is the process of completing repetitive activities in a consistent way to ensure optimal outcomes. Applying this concept to shift handoffs and shift handover reports creates efficient methods for communicating and collaborating across shifts ensuring smoother handovers, improved responses, and increased safety.

Shift Handover Template Examples

Regardless of industry, creating a shift handover template (shift handoff template) is a best practice that can have a big impact on productivity, satisfaction, and safety. The following is an example of a shift handover templates that can be modified to fit organizational needs:

Not all shift handover reports will look the same, they will vary from industry to industry, department to department, and company to company. However, the example above captures the essence and key elements needed in a shift handoff report.

Shift handover templates need to be comprehensive yet to the point. Keeping it simple, asking for the relevant information, and refraining from lengthy or tedious forms will help ensure completion and participation from frontline workers.

Digital Shift Handover with Connected Worker Software

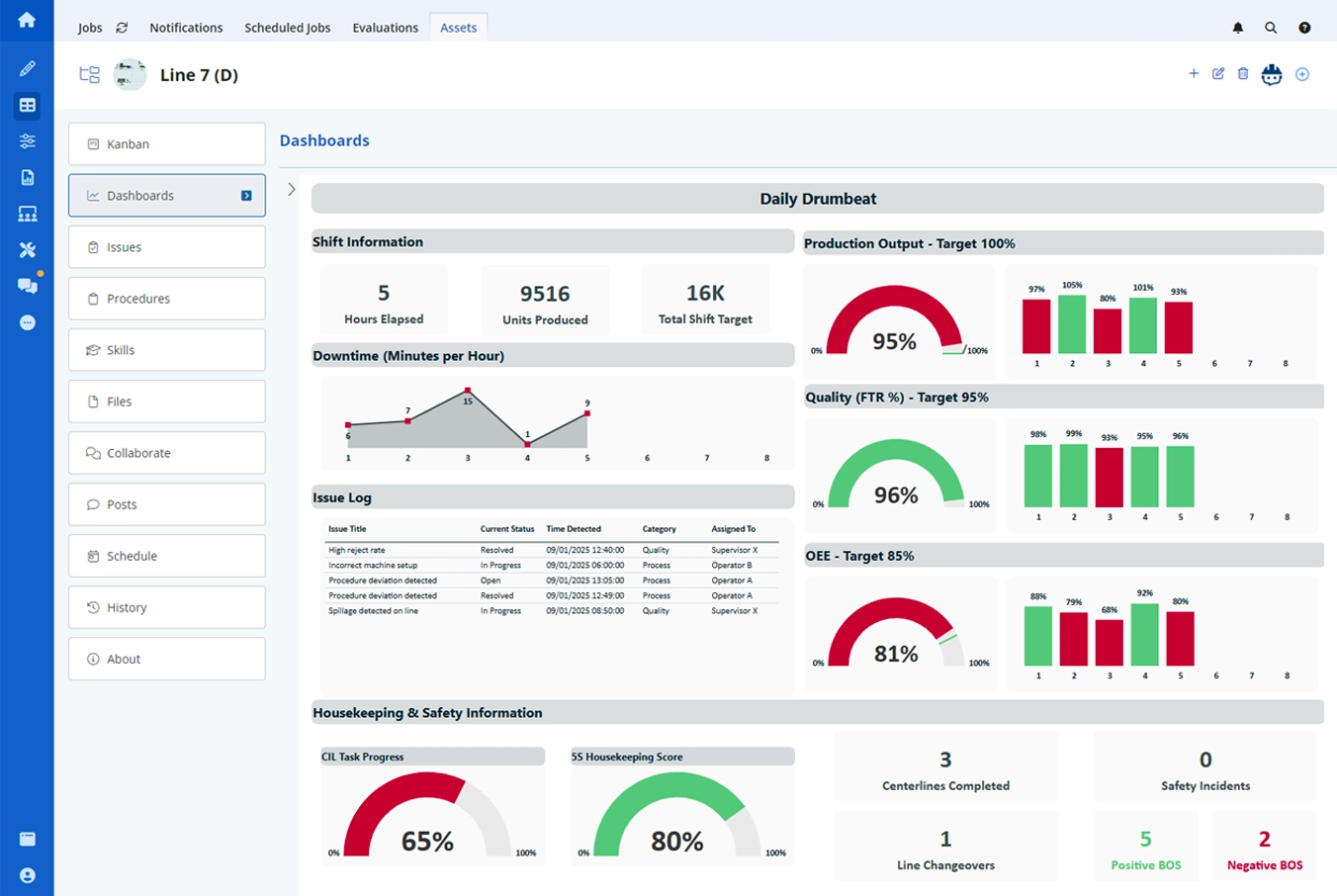

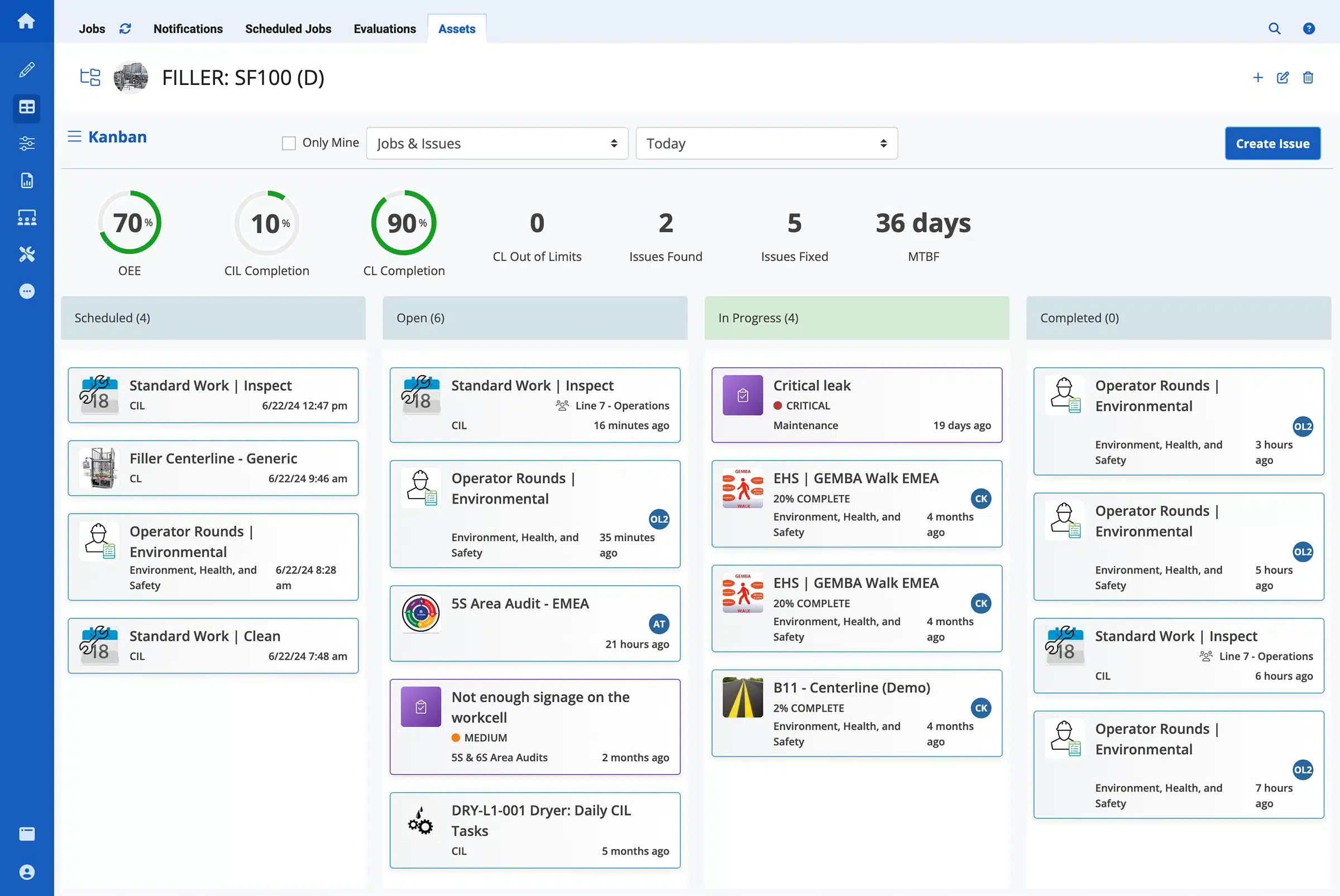

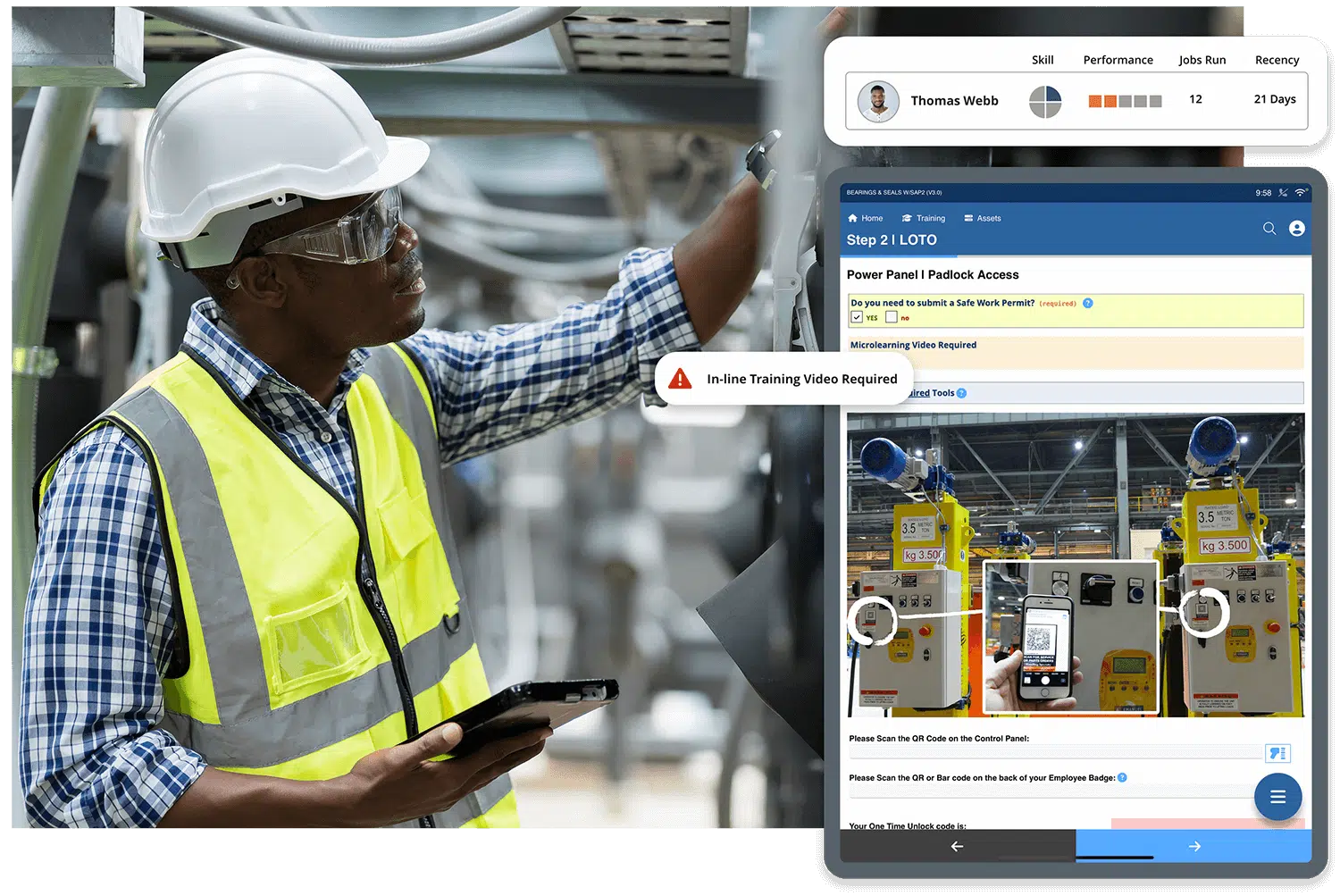

Leveraging smart connected worker tools to create digital shift handovers is revolutionizing the traditional manufacturing shift handoff process. Using connected worker solutions manufacturers facilitate real-time communication, improved data sharing, and enhanced task management between shifts. By incorporating features such as mobile and wearable devices, cloud-based platforms, and GenAI assistants, digital shift handovers enable seamless information exchange regardless of location, improving accessibility and efficiency.

Augmentir’s connected worker platform and suite of connected worker tools help manufacturers standardize work and continually improve operations. Import existing PDF, Word, or Excel documents directly into Augmentir and create digital, interactive work procedures and checklists using Augie™, a Generative AI content creation tool from Augmentir. Once digitized, workers can easily access shift reports, production metrics, equipment status updates, and safety protocols from mobile or wearable devices – ensuring continuity and transparency across shifts.

Moreover, smart connected worker tools facilitate proactive problem-solving and provide instant notifications for abnormalities or maintenance requirements, empowering teams to address issues promptly and prevent downtime.

Contact us to learn more about why Augmentir is trusted by leading manufacturers to transform their daily management and improve:

- Issue and Activity Management and Tracking

- Standard Work Audits and Scheduling

- Smart Forms and Checklists

- Smart Collaboration and Communication

- Closed-loop Worker Performance Support

- and more…