Discover how Augmentir’s Connected Worker platform revolutionizes dairy manufacturing by improving quality, reducing downtime, and empowering frontline workers with AI-driven tools.

As the dairy industry struggles with increasing demand, shifting regulatory landscapes, and a widening skills gap, manufacturers are turning to digital tools to modernize their operations.

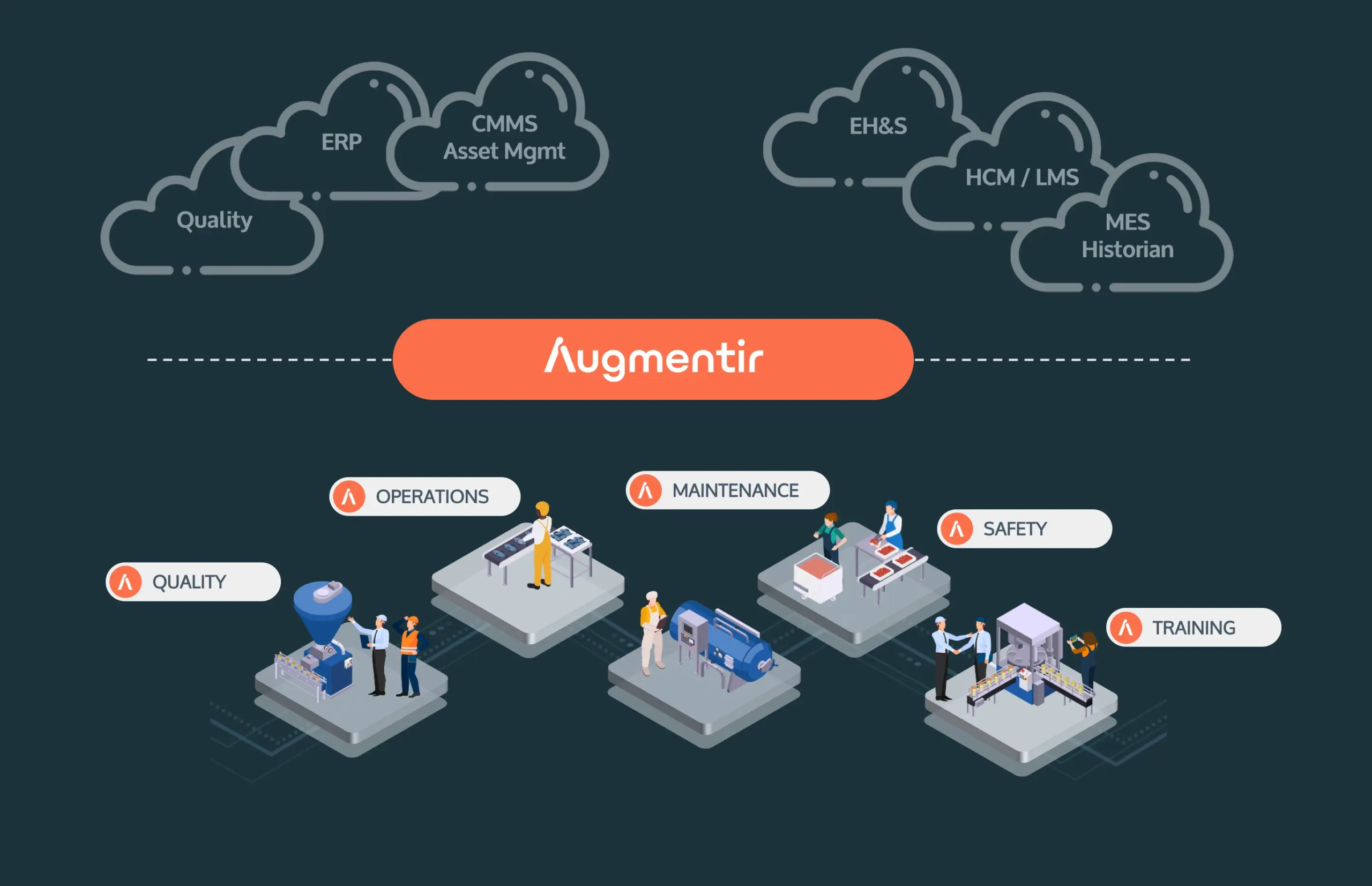

One solution that stands out in this transformation is Connected Worker software, a category that empowers frontline workers through real-time guidance, remote collaboration, and intelligent insights. And among the leaders in this space is Augmentir, a platform purpose-built to optimize frontline operations across food and beverage manufacturing — including dairy.

The Unique Challenges of Dairy Manufacturing

Dairy processors operate in a high-pressure environment with narrow margins and tight compliance requirements, and uncompromising safety and quality standards. They face:

- Stringent sanitation and traceability regulations

- Perishable raw materials and products

- High variability in production lines and product SKUs

- An aging workforce and high turnover rates

- Lack of real-time visibility into frontline work

These factors place immense stress on both the workforce and the systems that support them. Maintaining consistent safety and quality while navigating these challenges is difficult—especially when legacy systems fall short in enabling knowledge transfer, standardizing procedures, and responding quickly to non-conformances or equipment issues.

Addressing Dairy Challenges with Technology

Technology plays a critical role in addressing workforce, compliance, safety, and quality challenges in dairy manufacturing. Connected worker platforms, in particular, enable real-time communication, guided digital workflows, and smart data capture that help ensure procedures are followed consistently and correctly.

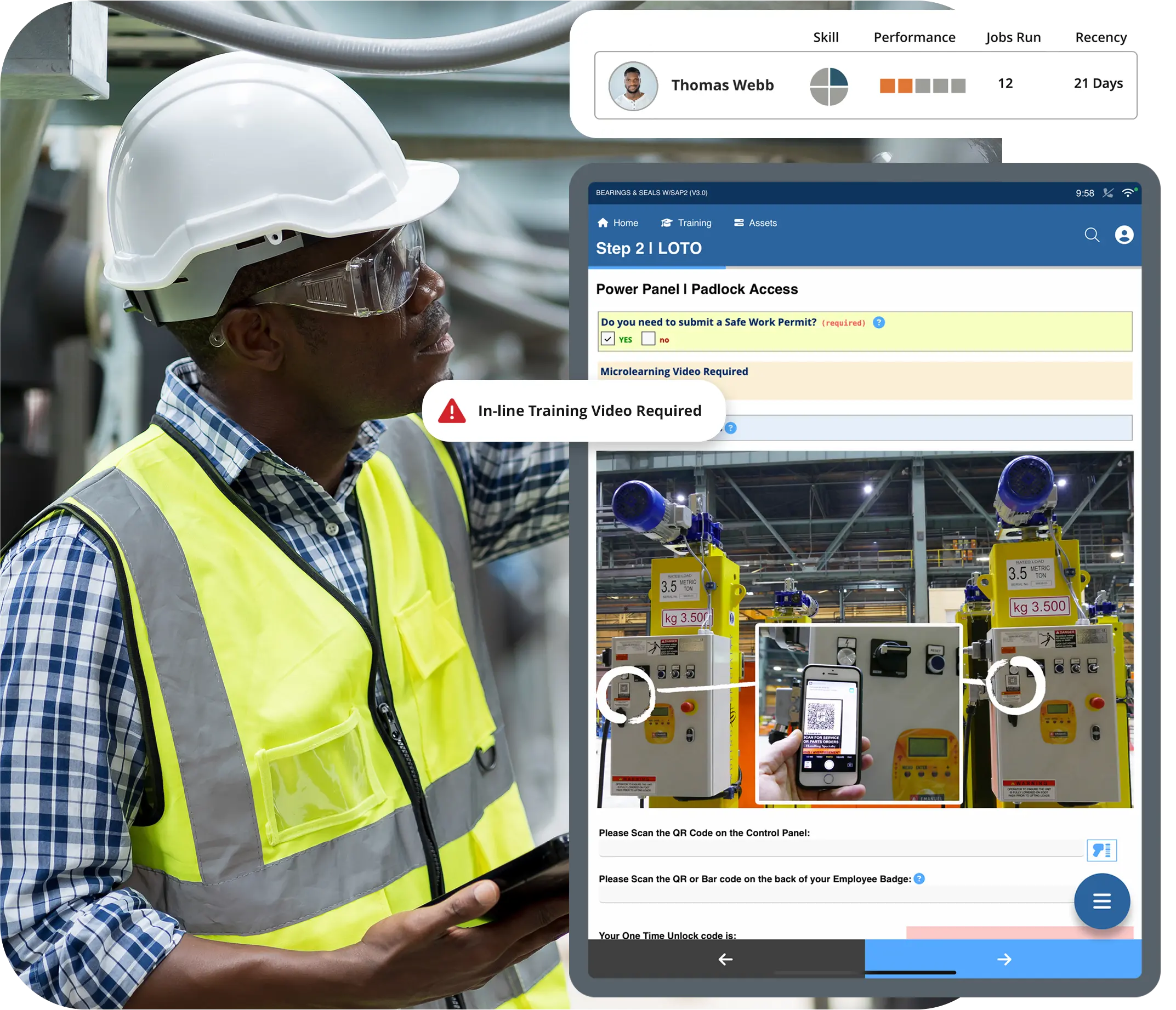

A Connected Worker platform is a digital layer that equips frontline workers with smart tools — often via mobile devices or wearables — to complete tasks more effectively. These platforms empower frontline workers with step-by-step instructions, instant access to support, and automated documentation—improving adherence to safety and quality standards while reducing training time and human error. By digitizing and connecting the workforce, dairy manufacturers can drive greater operational efficiency, accountability, and continuous improvement across their operations.

The result is a safer, more efficient, and more agile workforce — even amidst labor shortages or high variability in operations.

Why Augmentir for Dairy?

Augmentir goes beyond digitizing work — it optimizes it through AI. This means that the platform continuously learns from workforce behavior and system performance to identify where improvements can be made.

Key features that make Augmentir ideal for dairy manufacturers include:

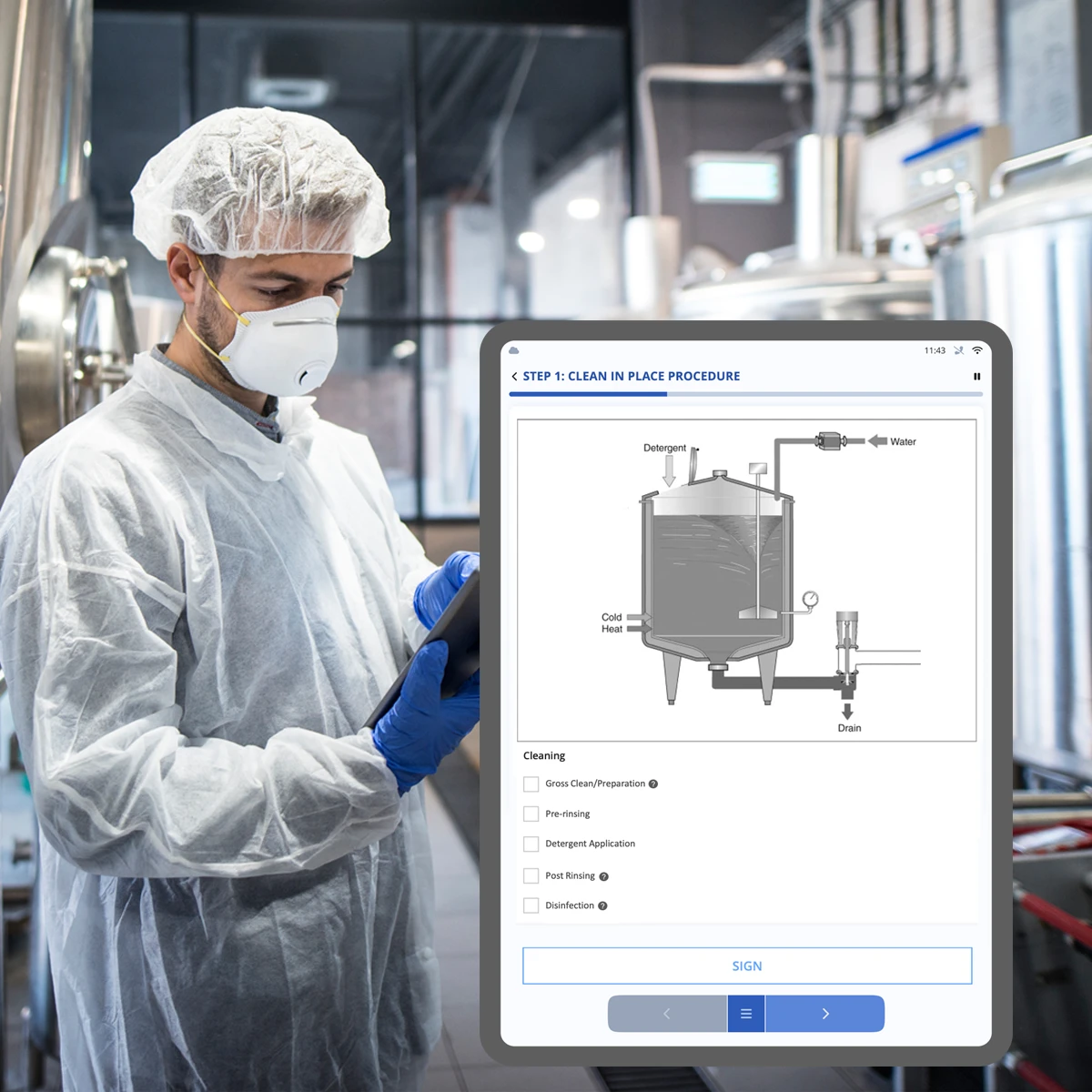

1. Smart Workflows for Sanitation and Quality Control

Augmentir helps ensure that Standard Operating Procedures (SOPs) for Clean-in-Place (CIP) systems and product changeovers are followed consistently and documented in real time. This reduces the risk of contamination and non-compliance.

2. Workforce Development and Knowledge Retention

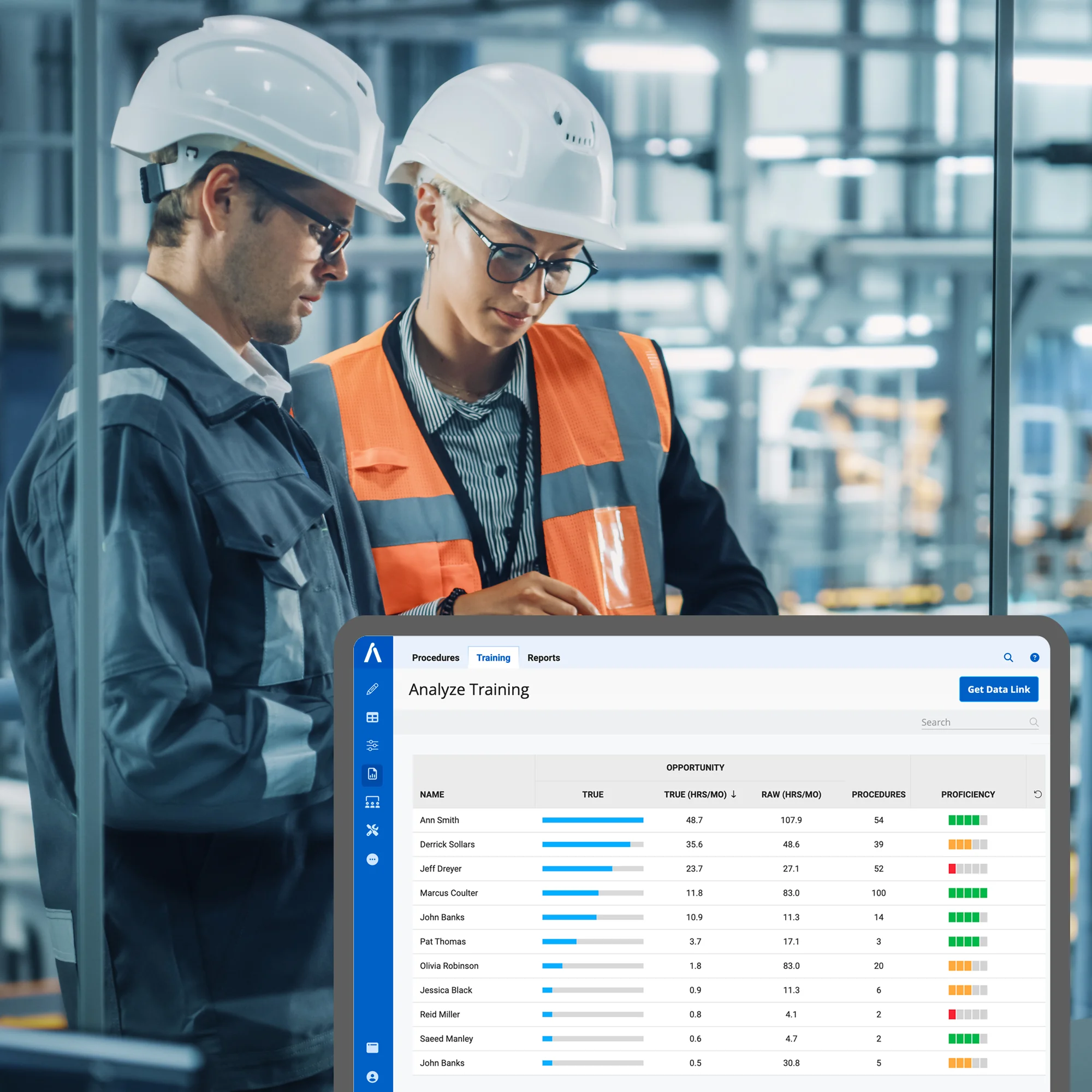

With an aging workforce and growing training demands, Augmentir’s embedded skills tracking and adaptive learning tools ensure that employees are properly trained and matched to the right jobs based on their evolving capabilities.

3. Real-Time Issue Resolution

Whether it’s a malfunctioning separator or an alert from a pasteurizer, frontline workers can instantly connect and collaborate using Augmentir’s connected worker technology. This reduces downtime and accelerates resolution—without waiting for external support.

Augmentir enables effective, context-based collaboration across shifts, sites, and languages. Teams can share information in real time, and directly update work procedures to reflect tribal knowledge exchanged during collaboration sessions. Augmentir’s AI captures and transforms this expertise into sharable corporate knowledge, improving visibility and communication.

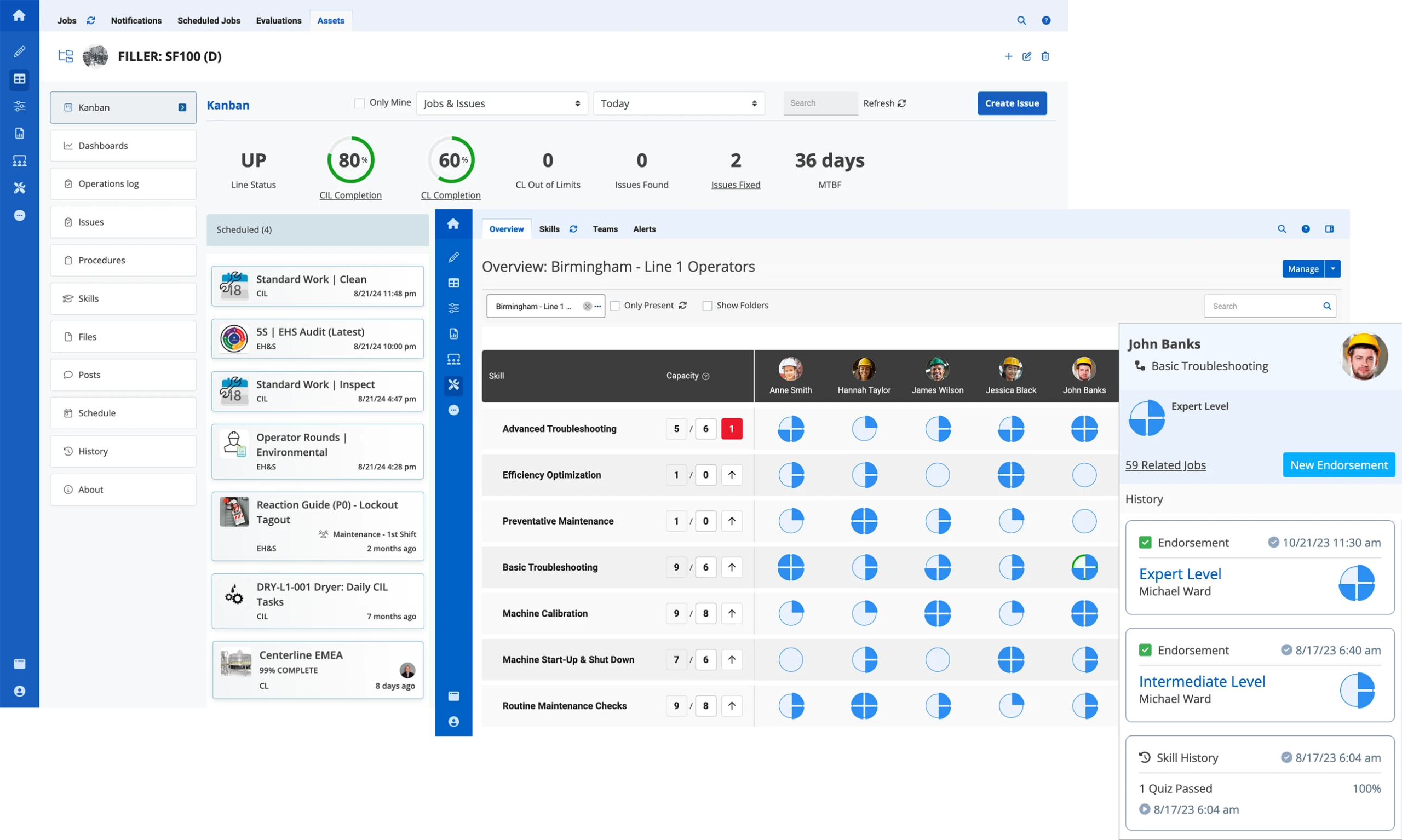

Workers can also raise, track, and manage maintenance notifications digitally using a visual Kanban board. Monitor operational KPIs, and seamlessly escalate issues to enterprise Plant Maintenance systems or CMMS platforms.

4. AI-Powered Insights

Augmentir’s AI continuously analyzes data from work execution to uncover patterns and opportunities for optimization — such as which procedures cause delays, or where additional training is needed.

5. Integration-Friendly

Augmentir can seamlessly integrate with existing ERP, MES, CMMS, and QMS systems, providing a flexible way to modernize without ripping and replacing core infrastructure. This integration infrastructure allows Augmentir to act as a “Single Pane of Glass” for a manufacturer’s frontline operations.

Real-World Impact

Dairy companies adopting Augmentir’s Connected Worker platform reports:

- Up to 72% reduction in onboarding and training time

- 27% reduction in quality issues and improved first-time quality and compliance adherence

- 21% decrease in unplanned downtime

- Higher worker engagement and retention

A New Standard for Frontline Excellence

In an era where labor shortages, quality demands, and operational agility define success, the world’s leading dairy manufacturers, such as Müller Milk, are turning to Augmentir to modernize their frontline operations. By replacing manual, paper-based processes with AI-powered digital tools, these industry leaders are empowering their workforce, optimizing every task, and transforming their plants into smart, data-driven operations. Augmentir is not just a tool — it’s becoming the new standard for operational excellence in the dairy industry.

Request a demo to learn how Augmentir can modernize your dairy operations.