To effectively implement Daily Direction Setting (DDS) in your manufacturing plant, you need a structured, repeatable process that aligns your teams, drives accountability, and enhances operational performance. Here’s a step-by-step approach to ensure success:

1. Define Clear Objectives

Start by establishing the purpose of DDS in your facility—whether it’s improving shift communication, driving continuous improvement, or increasing accountability. Set specific goals for what you want to achieve with each daily meeting.

2. Standardize the Meeting Format

Create a consistent agenda that covers:

- Review of previous day’s performance (safety, quality, production)

- Key metrics (KPIs, OEE, downtime, etc.)

- Today’s goals and priorities

- Staffing, equipment, or material updates

- Safety or compliance reminders

- Escalation of issues and action plans

Keep meetings short (10–15 minutes) and focused. According to Advisory, a recent poll of 2,000 workers showed that a third of respondents stopped paying attention in meetings after 15 minutes.

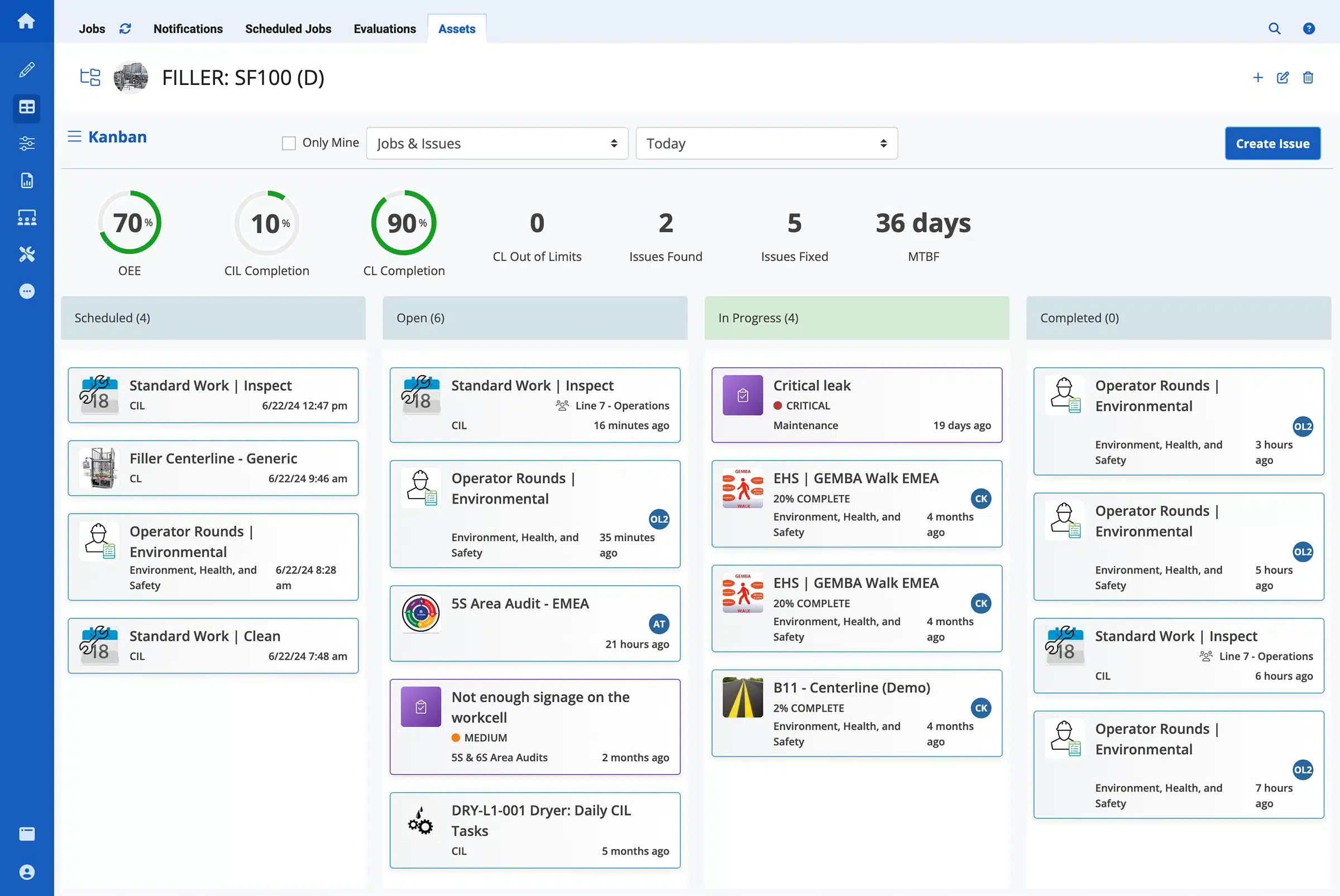

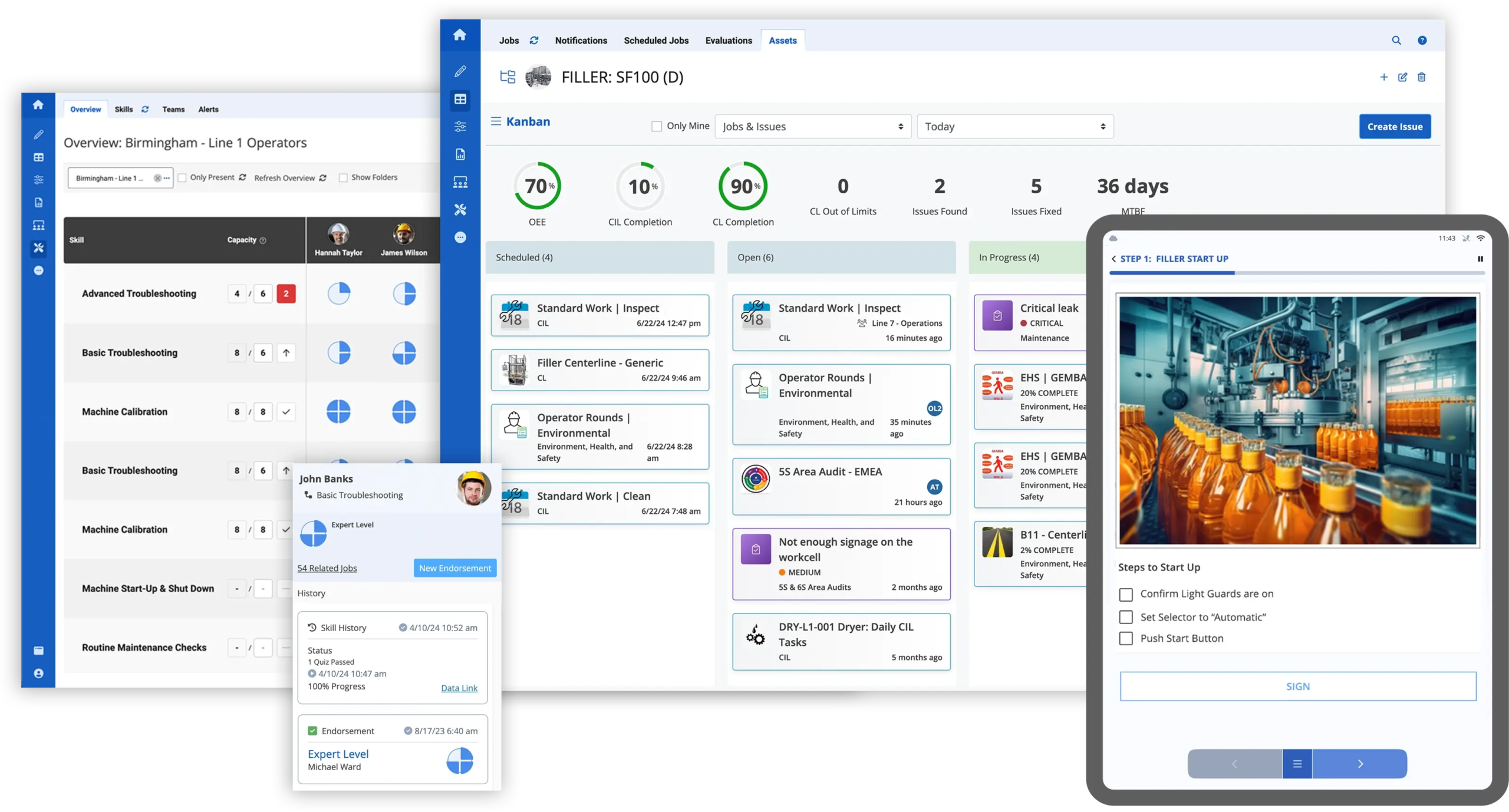

3. Use Visual Management Tools

Implement physical or digital dashboards to track and display key data. This can include performance boards, Gemba boards, or a connected worker platform, which offers digital DDS tools with real-time data and AI-driven insights.

4. Train Supervisors and Team Leads

Ensure your frontline leaders are trained on how to facilitate DDS meetings effectively. They should be comfortable communicating expectations, addressing issues, and encouraging team participation.

5. Involve the Right People

Include key team members such as line operators, maintenance, quality, and supervisors. Consistent participation across roles ensures alignment and helps catch issues early.

6. Document and Follow Up on Actions

Assign action items with owners and due dates. Use a tracking system to ensure accountability and follow-through. This reinforces a continuous improvement mindset.

7. Leverage Technology

Digital platforms like connected worker technology can automate data capture, integrate with your existing systems (MES, ERP), and streamline communication across shifts. This makes DDS more efficient and less reliant on manual inputs. According to LNS Research, the majority of industrial transformation leaders are digitizing the management of their operations with digital software systems.

8. Evaluate and Improve

Regularly review the effectiveness of your DDS process. Gather feedback from participants and look for ways to improve meeting quality, data accuracy, and follow-up discipline.