Gartner recently published their annual Hype Cycle for Manufacturing Operations Strategy and Innovation in Manufacturing Industries. These two Hype Cycles focus on the leading-edge technologies and methodologies that will significantly change how manufacturers innovate, deliver and support products and services. Augmentir was recognized as an important player in both Hype Cycle reports. Emerging Technologies in […]

Gartner recently published their annual Hype Cycle for Manufacturing Operations Strategy and Innovation in Manufacturing Industries. These two Hype Cycles focus on the leading-edge technologies and methodologies that will significantly change how manufacturers innovate, deliver and support products and services.

Augmentir was recognized as an important player in both Hype Cycle reports.

Emerging Technologies in Manufacturing

According to the report, “manufacturers that adopt the breakthrough opportunities presented as innovation profiles on this Hype Cycle will accelerate digitalization that increases the agility and ability to innovate products and business operations”.

This Gartner Hype Cycle, reflects the convergence of the physical and virtual worlds, innovation in manufacturing, as well as presents several key mature and emerging technologies, including the following:

- Connected Worker: Connected workers use digital technologies to improve and integrate their interactions with both physical and virtual surroundings. Through the use of digital work instructions, as well as augmented/mixed reality delivered through mobile/wearable devices, they are able to make faster and better decisions that optimize and improve a process or workflow that they participate in.

- Immersive Experiences – Manufacturing Operations: According to Gartner, immersive experiences refer to enabling the perception of being physically present in a nonphysical world or enriching people’s presence in the physical world with content from the virtual world. The report covers three kinds of immersive experiences: Augmented Reality (AR), Mixed Reality (MR), and Virtual Reality (VR).

- Machine Learning: Machine learning is a technical discipline that identifies patterns and generates predictions based on analyzing large sets of data. According to Gartner’s research: “In manufacturing operations, machine learning (ML) can take advantage of available data and rely on the algorithms to identify patterns and correlations. It can also use them to predict outcomes, to find the best course(s) of action and to control processes. Typical use cases include eliminating unplanned downtime and stoppages, increasing yield optimization, reducing energy usage, improving product quality or stabilizing production processes.”

Augmentir is mentioned in the context of Connected Workers and Immersive Experiences in Manufacturing Operations as software and solution provider.

Augmentir’s Approach to Connected Workers and Immersive Experiences in Manufacturing

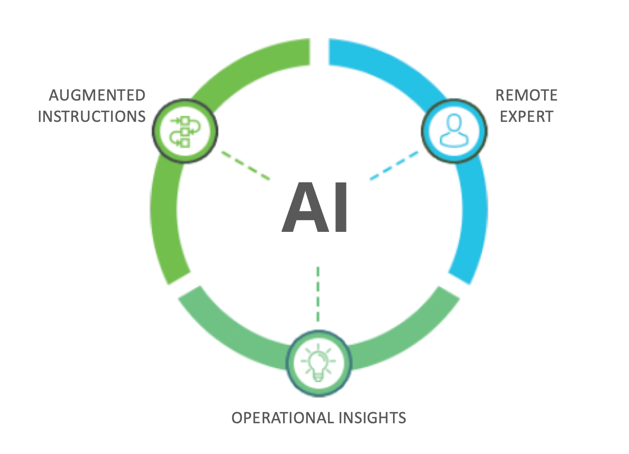

Augmentir sits and the intersection of these innovation profiles, using artificial intelligence and machine learning (AI/ML) to amplify the value that digital technologies bring to the connected worker.

Digital Work Instructions help guide connected workers with visual aids and augmented with AI-driven insights and contextual information enable workers to perform at their best.

Integrated Remote Expert assistance helps workers resolve issues faster using insights from Augmentir’s AI and information from the guided procedure.

Augmentir’s AI uses granular data to identify the largest opportunities in improving the skills of the frontline workforce, and helps to drive continuous improvement throughout the organization.

At Augmentir, our AI identifies patterns and generates insights based on analyzing data from connected workers. These insights improve worker performance as well as provide positive impact on training, operational workflows, and quality. According to Gartner, “The possibility of predicting performance is extremely attractive for manufacturers. This is driving the strong interest in ML. ML is an essential enabler of artificial intelligence (AI), smart factories and intelligent automation”.

Our view at Augmentir is that the purpose of a connected worker platform isn’t simply to deliver instructions and remote support to a frontline worker, but rather to optimize the performance of the connected worker ecosystem. Artificial intelligence is uniquely able to address the fundamental macrotrends of growing skills gaps and the loss of tribal knowledge. With an ecosystem of content authors, frontline workers, subject matter experts, operations managers, continuous improvement engineers, and quality specialists, there are were dozens of opportunities to improve performance.