The Hershey Company is redefining the role of the frontline worker through digital transformation — not by replacing people with technology, but by empowering people through technology.

At the recent Connected Worker Summit in Chicago, The Hershey Company shared how it’s redefining the role of the frontline worker through digital transformation — not by replacing people with technology, but by empowering people through technology.

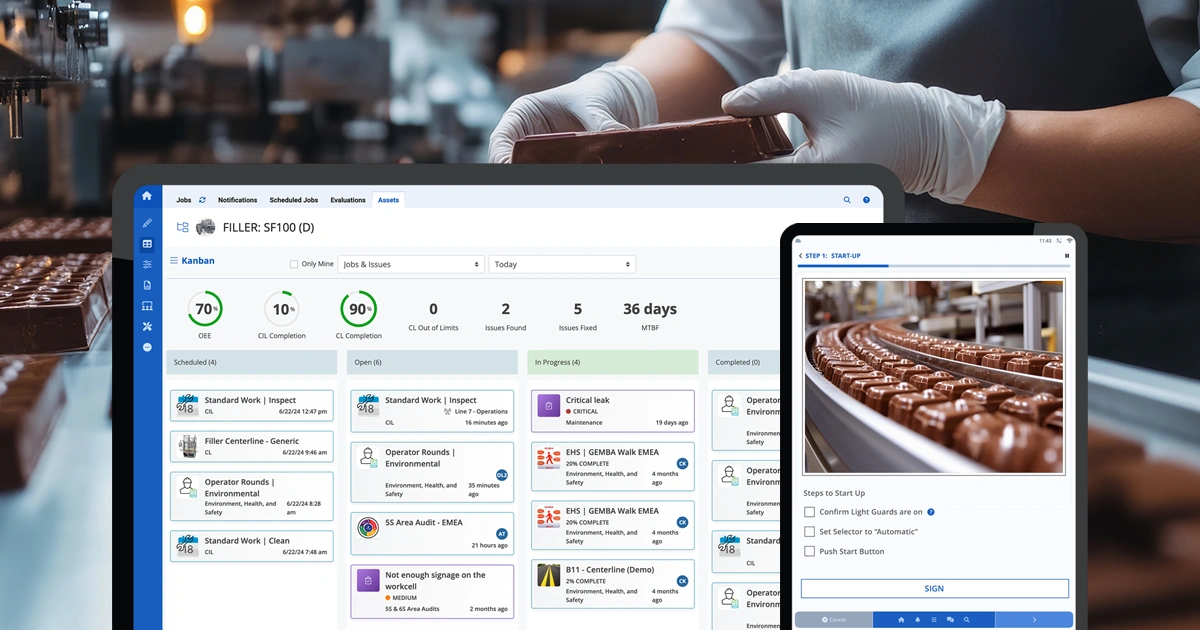

An article in FoodProcessing.com spotlights Hershey’s digital transformation — and we’re honored to be their partner on this connected worker journey. Powered by our Connected Worker Platform, this transformation is helping Hershey connect, support, and engage its workforce like never before.

Hershey’s Approach: People First, Technology Second

Logan McNear, Digital Manufacturing Program Lead at Hershey, emphasized a fundamental truth: digital transformation only succeeds when it starts with the people doing the work.

That philosophy guided Hershey’s decade-long lean transformation and its shift toward a more digital factory environment. Rather than imposing new tools from the top down, Hershey involves operators directly in the design and implementation of digital solutions — giving them ownership of both the process and the outcome.

This human-centered approach ensures that technology doesn’t just automate or monitor — it enhances capability, engagement, and pride.

Data That Empowers, Not Overwhelms

One of the most compelling stories McNear shared was about a packaging-line operator who wasn’t especially technical. With new connected worker tools, she gained easy access to:

- Shift performance data

- Previous shift hand-off information

- Simple maintenance request tools

Armed with this data, she could proactively manage performance and coordinate with other teams. Within weeks, she took pride in leading the best-performing shift on her line.

This example captures what the connected worker is all about — giving every operator real-time insights that drive ownership, performance, and engagement.

McNear summed it up perfectly:

“If we could just get a piece of that from every operator — that they’re looking at data, they’re connecting it to the problems on the floor and connecting it to the right people to solve those problems — we’d be in a whole different era of production and a different level of digital engagement.”

The Role of Augmentir in Hershey’s Transformation

Behind the scenes, Augmentir’s AI-powered Connected Worker Platform — including intelligent AI Agents — is enabling these very outcomes.

Our technology helps companies like Hershey deliver:

- Personalized, digital workflows that guide workers through tasks with step-by-step instructions and embedded insights, adapting dynamically based on worker skill level, context, and performance.

- Real-time data capture from the point of work, ensuring frontline actions feed directly into continuous improvement initiatives and organizational learning.

- Connected insights across shifts, lines, and sites, enabling teams to identify trends, uncover root causes, and pinpoint where coaching or process improvements will have the greatest impact.

- AI Agents that act on operational data and insights, proactively surfacing issues, recommending interventions, and automating follow-up actions to streamline operations and accelerate continuous improvement.

- Worker-centric analytics powered by Augmentir’s AI, helping manufacturers understand how work actually gets done and where targeted support, training, or process changes are needed most.

By focusing on people enablement rather than process enforcement, Augmentir transforms digital tools into intelligent, action-oriented systems — turning insight into impact and driving sustained engagement and operational excellence, as Hershey’s story demonstrates.

Lessons from Hershey’s Connected Worker Journey

Hershey’s experience offers a roadmap for manufacturers looking to empower their own frontline teams:

- Start with your people. Engage operators early and give them a voice in designing digital tools.

- Deliver data with purpose. Ensure information helps workers make decisions, not just report them.

- Combine lean thinking with digital agility. Use connected worker insights to accelerate continuous improvement.

- Celebrate empowerment as success. True transformation happens when operators feel ownership — not oversight.

Closing Thoughts

The Hershey story is proof that the future of manufacturing is human + digital — not one or the other.

By combining lean principles with Augmentir’s connected worker technology, Hershey is unlocking new levels of engagement, performance, and pride across its operations.

At Augmentir, we’re proud to help leading manufacturers like Hershey turn the “connected worker” vision into a daily reality — where every worker is informed, supported, and connected.