After more than a year of virtual conferences, we were finally able to participate in person at the AI Manufacturing conference in Dallas early this November and discuss how AI is shaping the future of the manufacturing workforce.

After more than a year of virtual conferences, we were finally able to participate in person at the AI Manufacturing conference in Dallas early this November. This year’s event was hybrid, face-to-face on November 3 and 4th, and virtually on November 5th. While it was refreshing to be able to network face to face with leaders in the Manufacturing industry, it was great to have the opportunity to also network virtually on November 5th. If you aren’t familiar with the AI Manufacturing conference, this conference is the leading Artificial Intelligence event for Manufacturing Industries. This year’s event focused on:

- The use of AI to Improve Quality, Reduce Defects, and Increase Profits

- Developing a Digital Twin to Optimize Plant Operations

- Using Building Blocks to Modernize Manufacturing Activities and Facilitate Growth

- Designing Products Enabled by Additive and Hybrid Manufacturing Techniques

- Exploring the Use of AI in Industrial Attacks and Defense

Using AI to Unlock the True Potential of Today’s Modern, Connected Workforce

Dave Landreth, Augmentir’s Head of Customer Strategy had the opportunity to present on “Using AI to Unlock to the True Potential of Today’s Connected Workforce”. In this session, he discussed the variability of the workforce with generations, how they need to be trained differently, and how AI can assist in worker proficiency. Dave also discussed Bob Mosher’s 5 moments of need and how AI can be applied at the time of learning.

The Misunderstood Fear of AI

Our founders saw that the humanistic approach was missing with traditional connected worker platforms and realized that AI was the key to saving the manufacturing world and unlocking worker potential. However, companies are reluctant to adopt AI in fear that automation will take over and eventually replace human workers in manufacturing. Others fear that AI would be used negatively to track workers, in a “big brother” type of way.

As we’ve seen with our customers, this couldn’t be farther from the truth. When AI is leveraged ethically with the workforce in mind, it can be used to help improve and ultimately grow the talent of your workers. Assessing workers on their performance has been done for years through subjective performance reviews. Using AI allows the assessments to be based on data and can provide a path forward for worker improvement and continued growth.

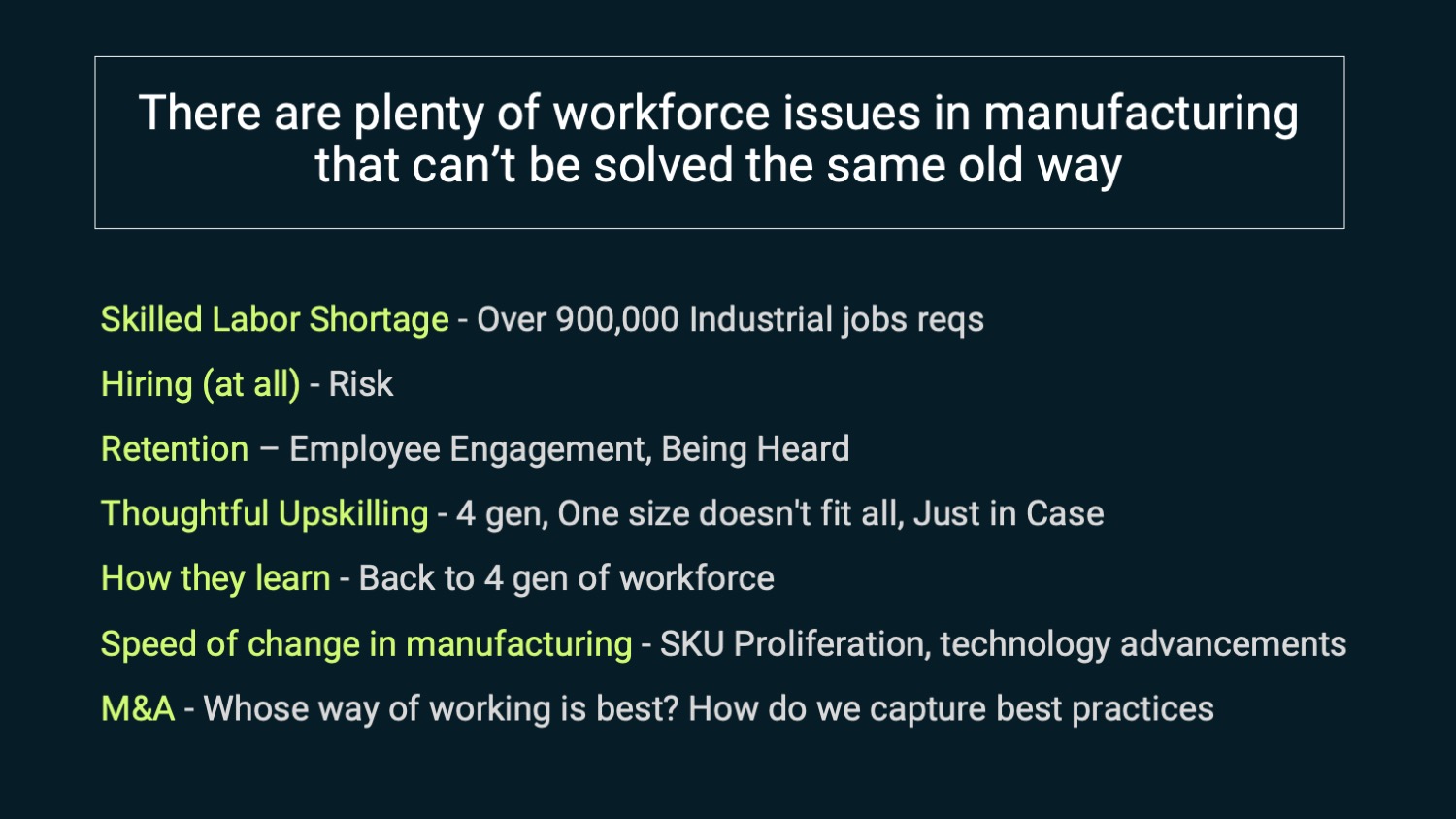

Understanding Today’s Struggles Within Manufacturing

The struggles that manufacturers face today aren’t the same struggles that were present 40 years ago. One of the number one issues in manufacturing is hiring. Today, most manufacturers believe that hiring is a risk, with a limited pool of candidates. They are struggling with employees who don’t have the needed skill set and are questioning how they can train them and evaluate their performance.

Manufacturing companies also struggle with retaining employees. We are all aware of the workforce retention issues right now. Employees are feeling like they aren’t heard and that they can’t contribute to the company, which causes them to look for a new career. There is also the struggle of thoughtful upskilling, meaning that formal training programs only recognize one type of worker. The average manufacturing plant sees 4 generations of workers, ranging from those fresh out of high school to the ones that have worked on a plant floor for 40+ years. Different generations learn differently and require different levels of support. There isn’t a one size fits all approach for teaching different generations.

Another challenge with the workforce that isn’t as obvious, is with mergers and acquisitions. An acquisition means that companies now consist of two workforces doing things differently and needing to understand what part of procedures from the newly acquired company is worth incorporating into the existing procedures.

Leveraging AI to Help Build and Grow a Top Performing Workforce

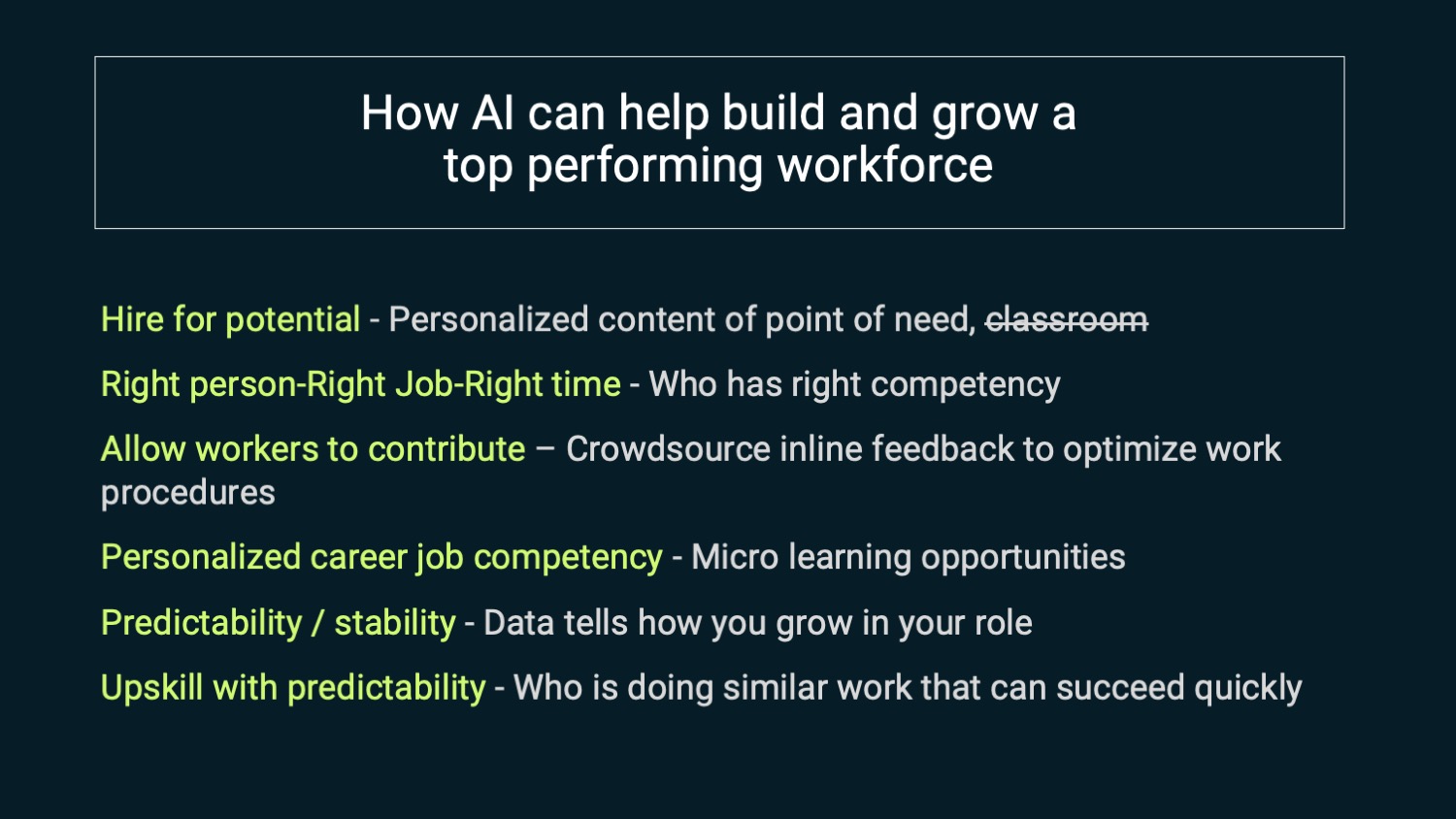

AI is uniquely suited to solve these challenges, and we recognized that early on at Augmentir. We started looking at how AI could help build and grow a top performing workforce. One way AI can help is the ability to hire for potential by increasing the hiring of candidates to those not as skilled. AI allows companies to understand a worker’s skillset and provides the ability for personalized workflows to guide them in the context of work while they are doing their job, whether it’s a new worker or one with dozens of years of experience. AI can also help with the “Right person – Right Job – Right Time” approach – always ensuring that the correct person is performing the task at the most efficient time.

The use of AI allows all workers to contribute by allowing inline feedback to optimize work procedures. In addition, AI can be used to ensure personalized career job competency allows workers to be hired even if they do not have the optimal set of skills and experience. Measuring a worker’s proficiency when they are completing the work allows the worker to focus on each specific step and guides them at the time of need, instead of during classroom training. AI provides workers with predictive and stable data to help them grow in their roles. Having a data-driven way to measure success and provide advancement opportunities helps establish career paths as well as opportunities to grow.

With an AI-based onboarding approach, organizations are able to hire a wider range of individuals with varying skill sets. If we can teach someone in the context of doing their work, onboarding time is reduced due to being able to train them in the field. We also see an increase in productivity and are constantly evolving their learnings. When workers feel included and confident about their careers, they are also more likely to want to stay and grow with the company. The ability to train workers in the field while doing their jobs with AI personalization allows you to clearly and quickly assess how a worker is doing, where you focus the help to them, and driving those 1:1 work procedures is a game-changer.

AI in Manufacturing will solve many of the challenges that we are seeing.

Learning & Development and the 5 Moments of Need

The Five Moments of Need methodology was created by Bob Mosher, a thought leader in learning and development with over 30 years of experience. He realized that after 20 years, classroom teaching was the wrong approach since it rarely teaches you things that you do in your job on the shop floor. Classroom learning allows an individual to gain a certain level of confidence, but quickly falls off when it’s time to apply it within context to a given workflow.

According to Bob’s methodology, the 5 moments when our workforce needs knowledge and information consists of:

- When people are learning how to do something for the first time (New).

- When people are expanding the breadth and depth of what they have learned (More).

- When they need to act upon what they have learned, which includes planning what they will do, remembering what they may have forgotten, or adapting their performance to a unique situation (Apply).

- When problems arise, or things break or don’t work the way they were intended (Solve).

- When people need to learn a new way of doing something, which requires them to change skills that are deeply ingrained in their performance practices (Change).

The approach that Bob and his team adopted in the last 10 years is to think more about performance support. The variability of the workforce, both skilled and young, proves that there’s not a one size fits all approach. This is where AI comes in: being able to deliver personalized work procedures for every worker, allowing for continuous learning and growth. Based on proficiency, there may be a more guided set of work instructions, a session with a remote expert, or a supervisor sign-off required in order to complete the job on quality and on schedule. AI can also be used to continuously measure and assess how the workers are doing. This is where organizations can start seeing growth within their workforce.

Looking Ahead

We had a blast at this year’s AI Manufacturing conference and are already looking forward to another successful event next year! If you’re interested in learning more about why AI is an essential tool in digital transformation, from reducing costs and downtime to improving over quality and productivity, we’d highly suggest considering attending next year. In the meantime, if you’re looking for information surrounding AI, digital transformation, and building a connected workforce, check out our eBook: “Building a Modern, Connected Workforce with AI”.