SPC in Manufacturing: Definition, Control Chart Types, and Modern Software Tools

Statistical Process Control (SPC) is a powerful methodology used in manufacturing to monitor, control, and improve processes through data-driven decision-making. By leveraging real-time insights and quality tools, SPC helps manufacturers reduce variability, improve product quality, and minimize waste.

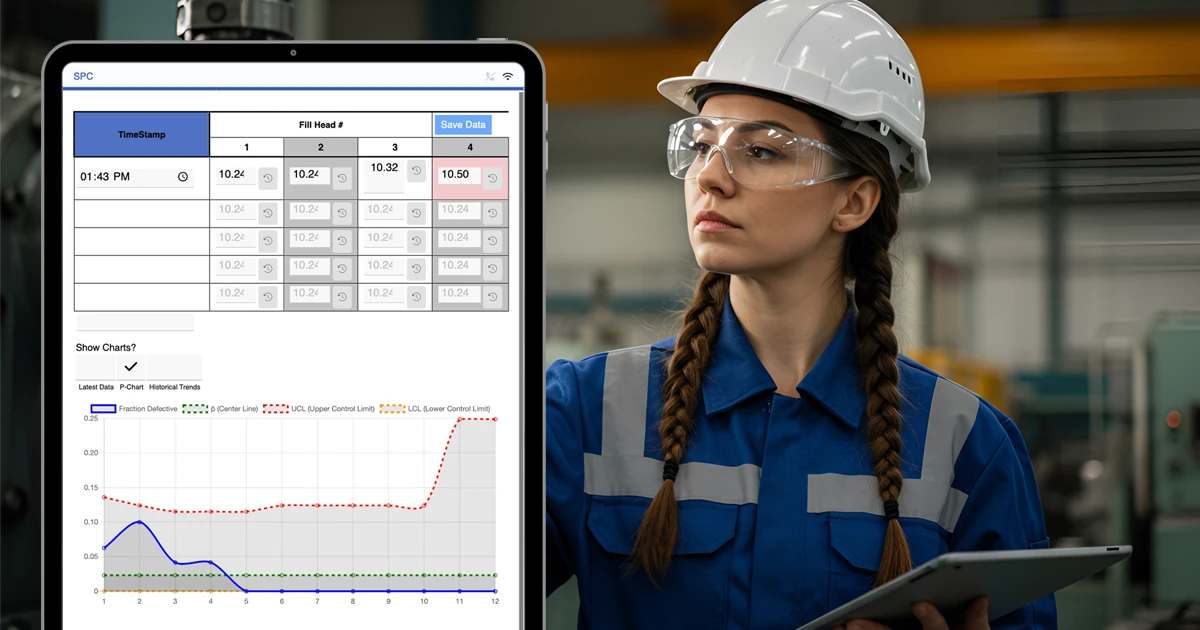

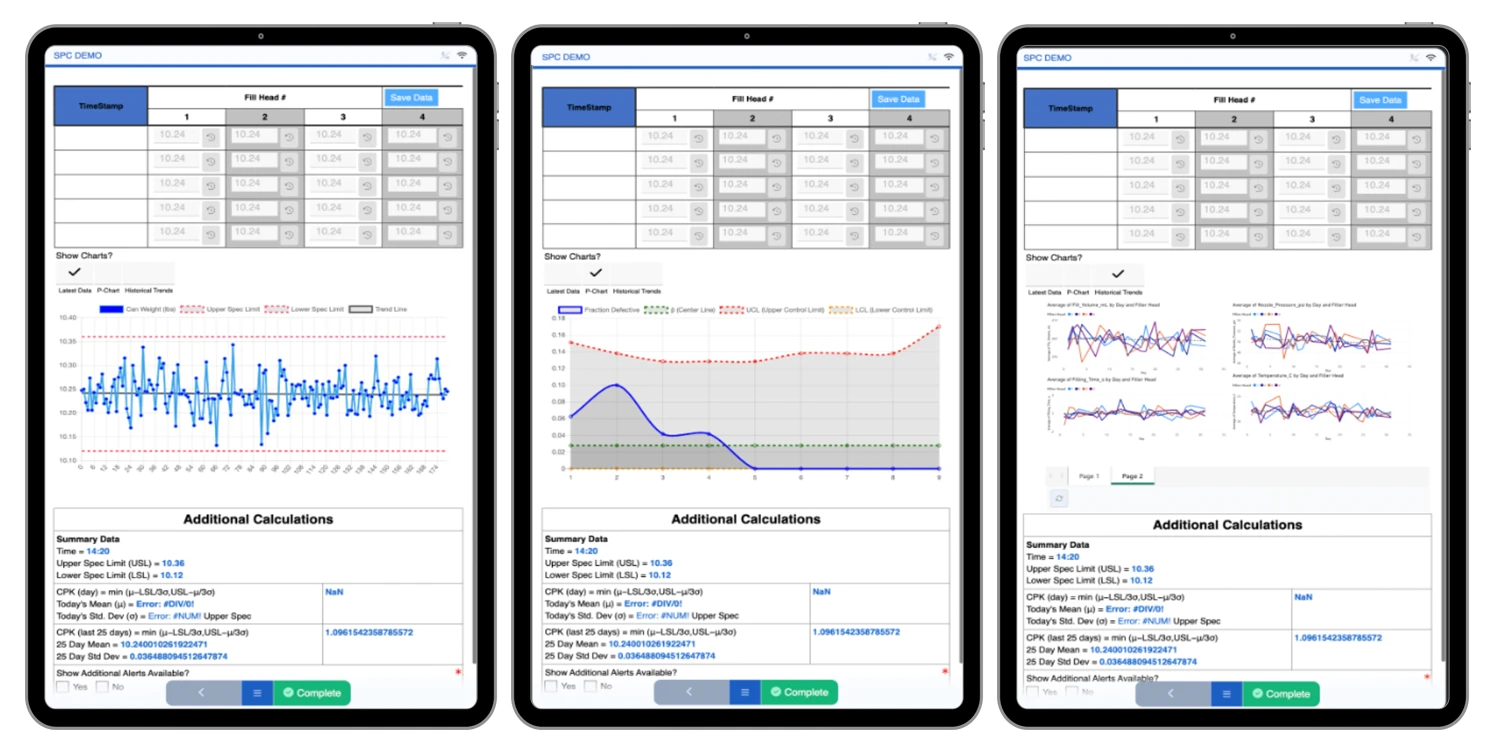

Modern software tools, such as Connected Worker Software, enhance SPC by bringing frontline workers directly into quality workflows through digital platforms. These tools incorporate mobile SPC data collection and visualize SPC charts and dashboards, instantly displaying trends, limits, and deviations.

Read this article to learn more about Statistical Process Control in Manufacturing:

- What is Statistical Process Control (SPC)

- Why SPC is Important

- How SPC Works

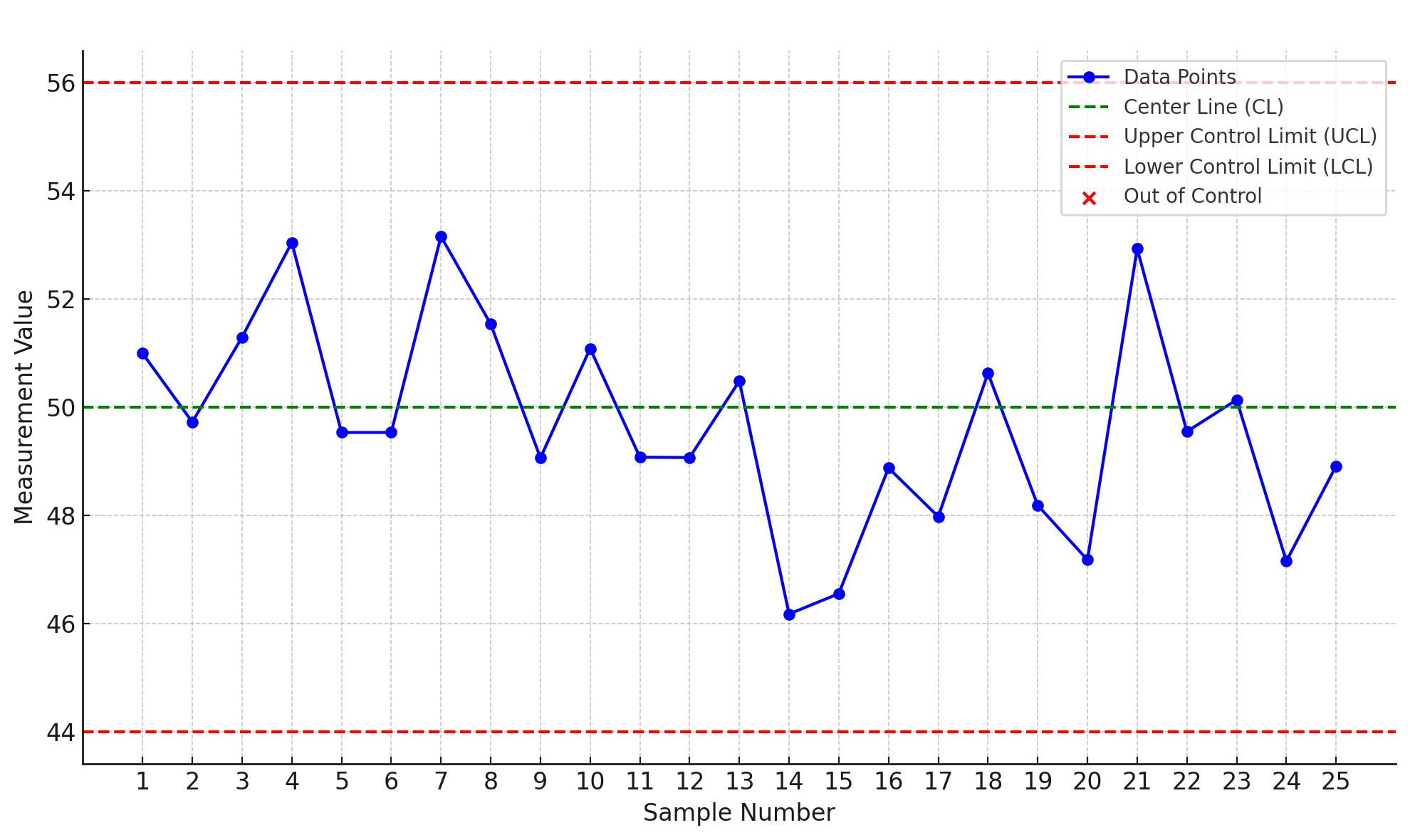

- What are SPC Charts

- Types of Control Charts Used in SPC

- SPC Tools and Software

- SPC Implementation in Manufacturing

- Example SPC Use Cases in Manufacturing

- Benefits of Real-Time SPC in Manufacturing

- Common Challenges and Best Practices

- Connected Worker Tools and SPC

- Augmentir: Connected Worker SPC Software for Manufacturing