Learn about what an asset hierarchy is and how it can help with asset maintenance and equipment reliability.

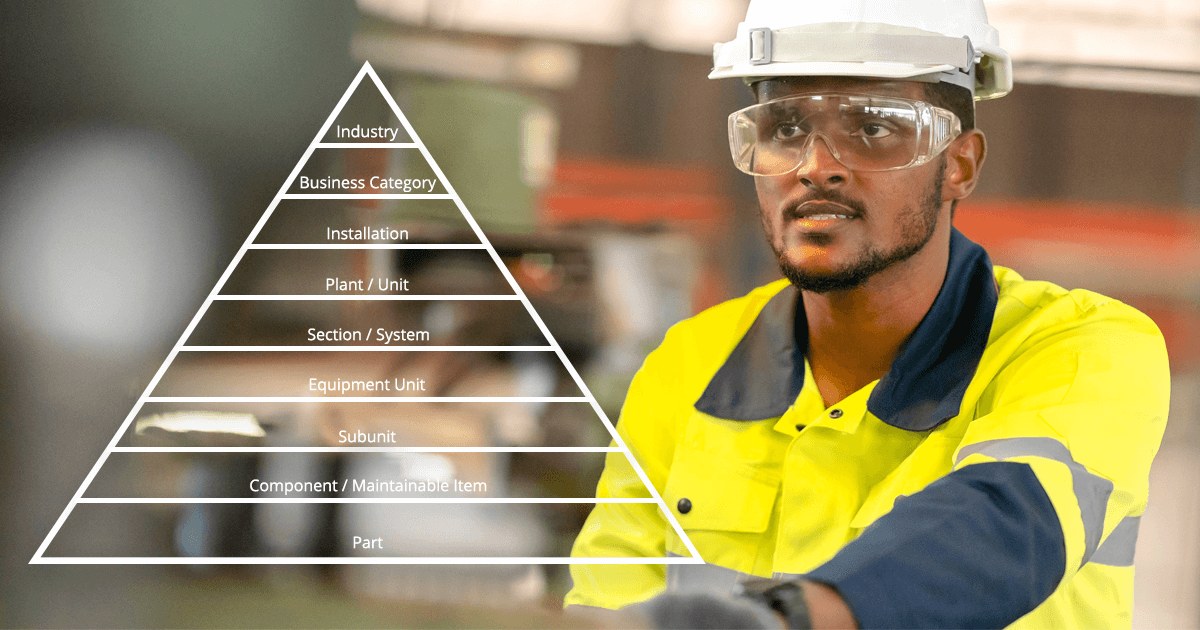

An asset hierarchy outlines all of a business’s top equipment, machines, and components visually to help the business plan, execute and track maintenance activities. Asset hierarchies are usually in the shape of a pyramid, similar to an organizational chart. And since every operation is different, it’s likely you won’t have the same hierarchy as your competitor.

The benefits of an asset hierarchy include accurate maintenance planning, faster failure root cause analysis, and improved cost tracking. By implementing an asset hierarchy in conjunction with a frontline operations system, such as a solución de trabajador conectado, manufacturers can benefit by dramatically improved maintenance planning and execution. This article answers the following questions to help you learn more:

- What is an asset hierarchy?

- What is asset maintenance?

- How does an asset hierarchy improve asset maintenance?

What is an asset hierarchy?

An asset hierarchy is an index of your most critical equipment, machines, and parts to better understand how these assets work together and monitor their maintenance needs. For example, building and maintaining your manufacturing business’s hierarchy can help you track and identify root causes of failure in your equipment.

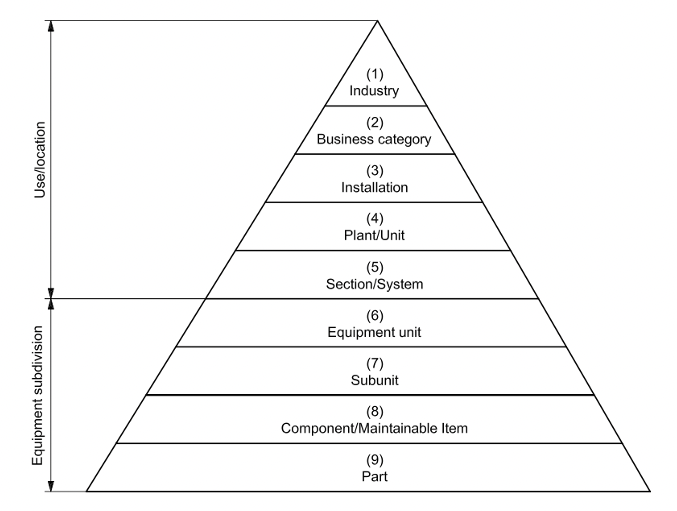

This taxonomy is often represented as a pyramid, based on the ISO 14224 standard, which was developed for the collection and exchange of

reliability and maintenance data for equipment. Initially developed for the Petroleum, Petrochemical, and Natural Gas industry, this taxonomy for equipment and failure data can apply to any manufacturing environment, and has become the de-facto standard for every other industry.

Asset hierarchies are typically built and maintained within an organization’s EAM (Enterprise Asset Management) or CMMS (Computerized Maintenance Management System), which tracks asset maintenance and condition data, as well as maintenance schedules. Increasingly, EAMs, CMMS, and asset hierarchy information are being integrated with digitized frontline operations systems to improve maintenance planning and execution.

It’s not enough to simply define your asset hierarchy with your EAM or CMMS. Innovative manufacturing companies are now extending this by integrating their asset hierarchies with soluciones para trabajadores conectados, which help digitize and optimize the actual work being done by frontline maintenance teams, improving maintenance execution.

Una mejor organización de los equipos también puede ayudar a los trabajadores a comprender cómo la acción de uno afecta al otro para resolver posibles problemas. Esta es otra ventaja de integrar la jerarquía de activos con una solución para trabajadores conectados. En resumen, unas jerarquías sólidas son una base sólida para una gestión adecuada del mantenimiento y la fiabilidad.

What is asset maintenance?

While maintenance is generally synonymous with repair, in effective manufacturing facilities, maintaining equipment can prevent the need for repairs. Asset maintenance is an umbrella term for everything that goes into keeping your assets in tip-top shape.

For example, asset maintenance in manufacturing machinery may mean frequent inspections to prevent breakdowns and repairs. Your space as a whole relies on this type of maintenance to ensure everything is running smoothly, from equipment to everyday production processes.

Lastly, this term makes daily manufacturing processes more productive to manage. That’s because effective asset management tells you where assets are located, how they are used, and when changes were made to them.

How does an asset hierarchy improve asset maintenance?

An asset hierarchy and asset maintenance work in conjunction with one another. This visual tool gives workers a better idea of what each asset is and the dependencies between them.

Knowing what each asset is can help you schedule preventative inspections and tasks. If any problems arise, you can more easily identify all the working parts, find the root cause and fix it.

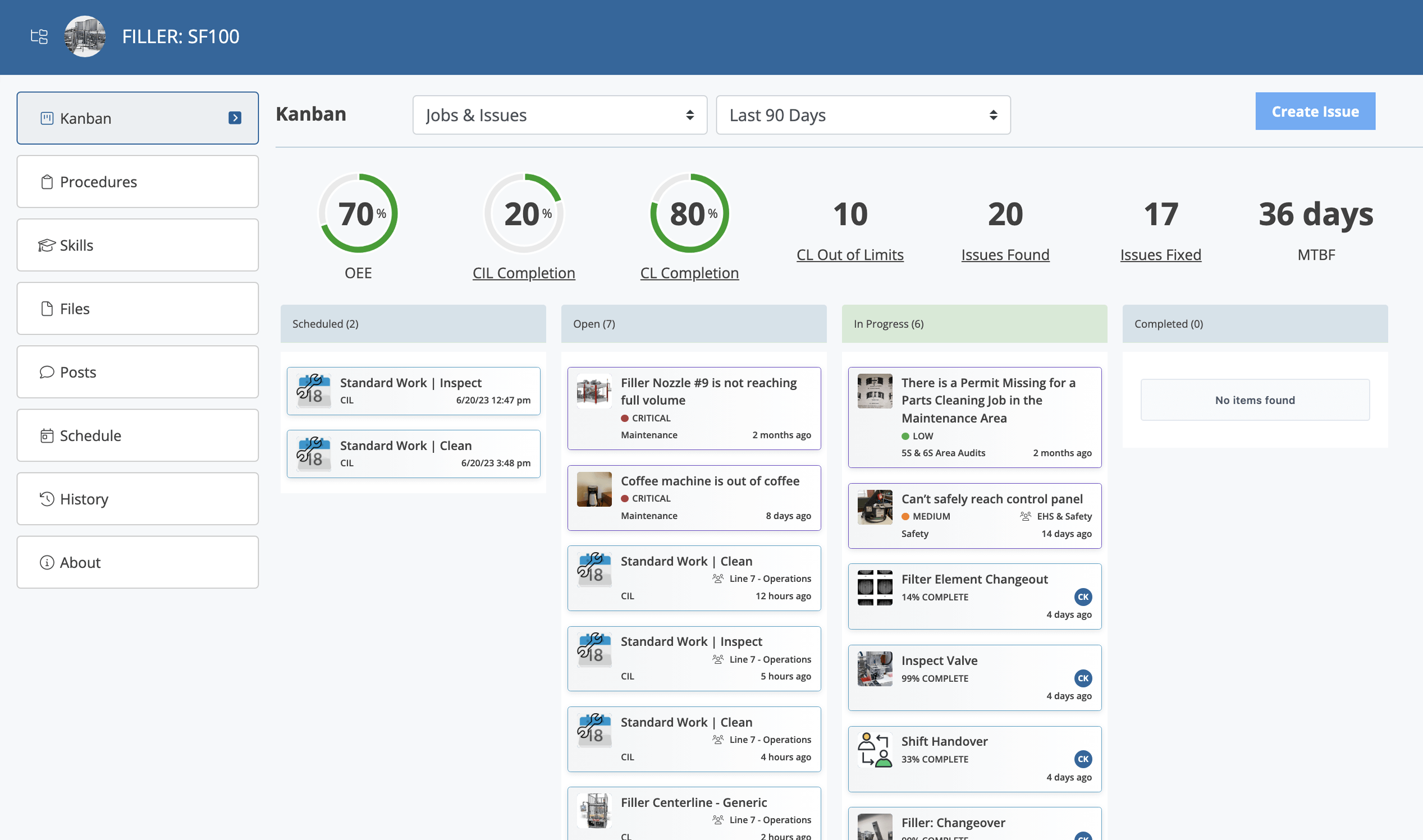

Augmentir’s AI-powered asset management software helps you simplify the operations and maintenance of your facility by integrating your asset hierarchy and maintenance data within a frontline operations system. Through Augmentir, organizations can benefit from a complete view of asset management, all through a visual mobile interface. Each asset contains a complete view of:

- Tablero Kanban para todas las actividades de activos

- Procedimientos de trabajo y mantenimiento

- Habilidades requeridas para operación y mantenimiento

- Colaboración relacionada con el activo

- Documentación asociada

- CIL/Horario de trabajo estándar

- Historial de todas las actividades en el activo

Augmentir’s asset management capabilities include an out-of-the-box autonomous maintenance solution, which gives equipment operators more control over equipment cleaning, inspections, and lubrications (CIL) to improve CIL completion rate, resulting in minimized machine downtime.

Request a demostración en vivo today to learn why companies are choosing Augmentir to help standardize and digitize their maintenance activities.