It’s vital that customers receive products that are free of defects. Learn 5 steps for improving production quality and how the right software can help.

Unexpected product quality issues can be a hassle to manage, especially when staff is stuck with processing time-consuming complaints, replacements, and refunds. Even worse, the impact on your bottom line can be substantial.

Manufacturers risk a significant cut to their profit margins when quality standards are not followed during the production process. To improve quality on the shop floor, plant managers need to pinpoint the root cause of quality issues.

Explore this article to learn how to start boosting your industrial processes today:

- What is Production Quality

- 5 steps to improve production quality

- FAQs about improving production quality

What is Production Quality

Production quality, or manufacturing quality, measures how well a manufacturing process develops products to fit design specifications. Manufacturers must devise a plan for how they want specific items to appear and function before creating them. This can include things like colors, durability, range of motion, measurements, and more. How well a product is made will depend on meeting these conditions.

After the design is planned, a number of factors can affect production quality, including:

- Equipment/machines

- Materials

- Batch size

- Human mistakes

- Environmental issues

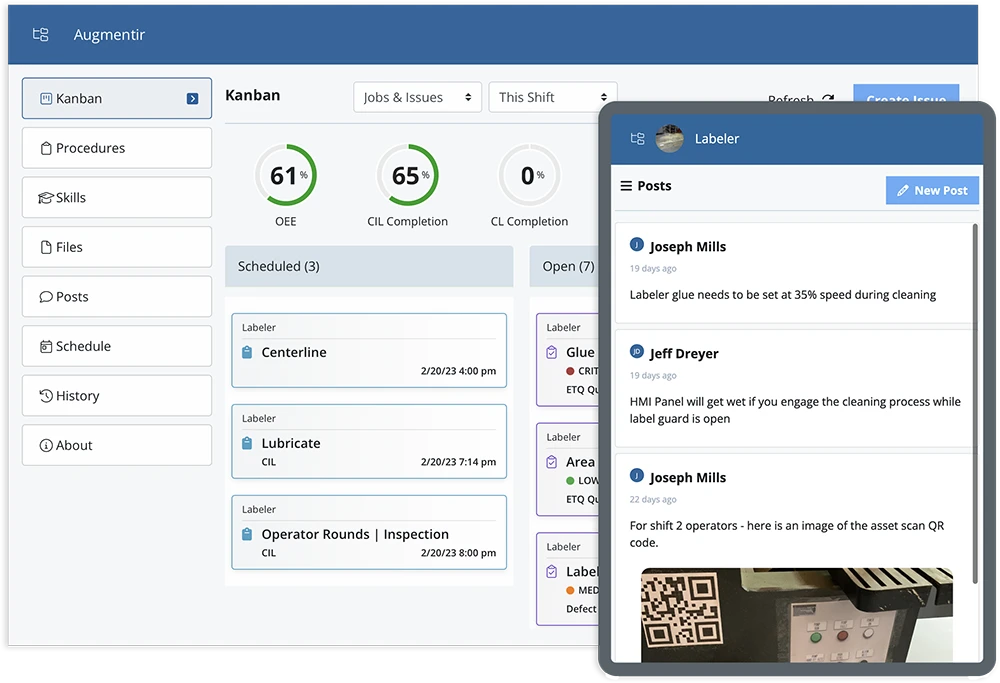

Frontline workers often witness quality issues on the factory floor. They are effectively a “human sensor” in the manufacturing process and can readily identify issues that need to be addressed. Today, recording data and resolving those quality issues is most often a manual and paper-based process. As such, there is minimal data collection, latency in resolving the issue, and little-to-no feedback to the frontline worker on resolution.

Equipping workers with mobile and digital tools can help optimize production quality.

5 steps to improve production quality

Although there may not be one single method for improving manufacturing quality, there are steps you can take to maximize success.

Here are five steps that should be part of your strategy.

Step 1: Assess your current workflow.

Start by reviewing your existing manufacturing processes. We encourage management to ask the following questions as part of their review:

- What quality benchmarks do you hope to achieve for each product?

- How much money have you lost from material, energy waste, and wasted time due to quality problems?

- What is your margin for improvement?

- What quality standards are implemented in the creation of products?

- Is your equipment inter-connected with different databases, or just a single database?

We recommend connecting your factory devices to one central database with a cloud-based, connected worker solution that operations management can use to create, assign, manage, and monitor the work being done. This kind of software can help streamline operational processes and track results in real-time.

Step 2: Remove unneeded processes.

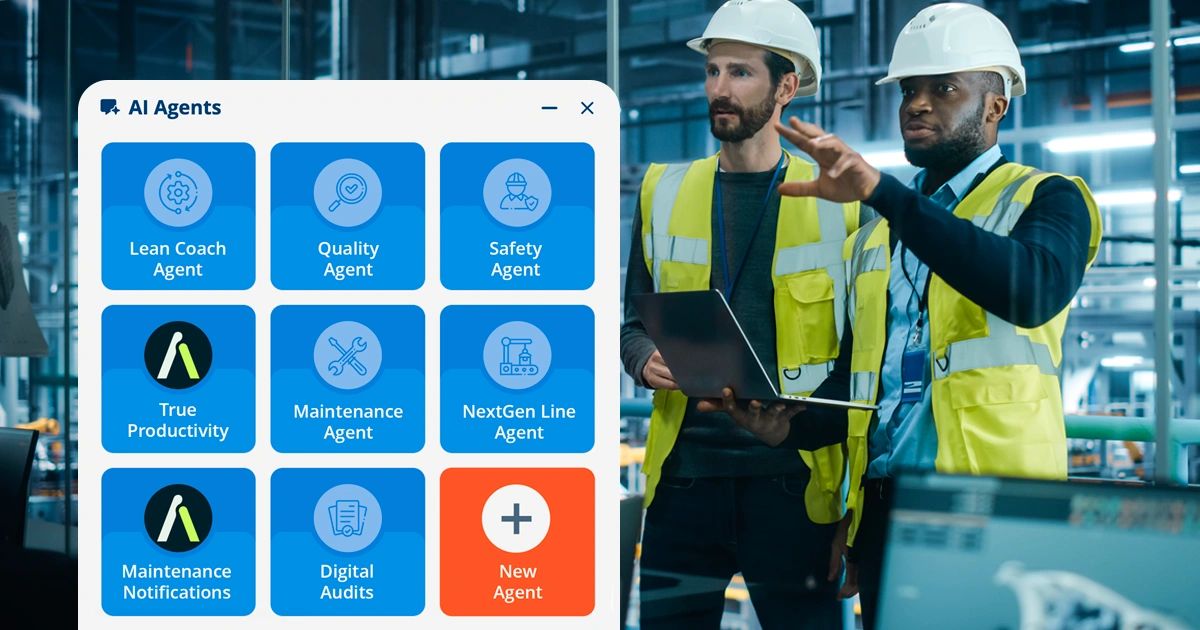

Once you’ve accessed your current workflow and set up a connected worker solution to collect frontline worker data, we recommend coupling it with AI-powered analytics that can derive actionable insights. Then you can use these actionable, data-led insights to see which processes are adding value and which ones are not.

Step 3: Boost worker training.

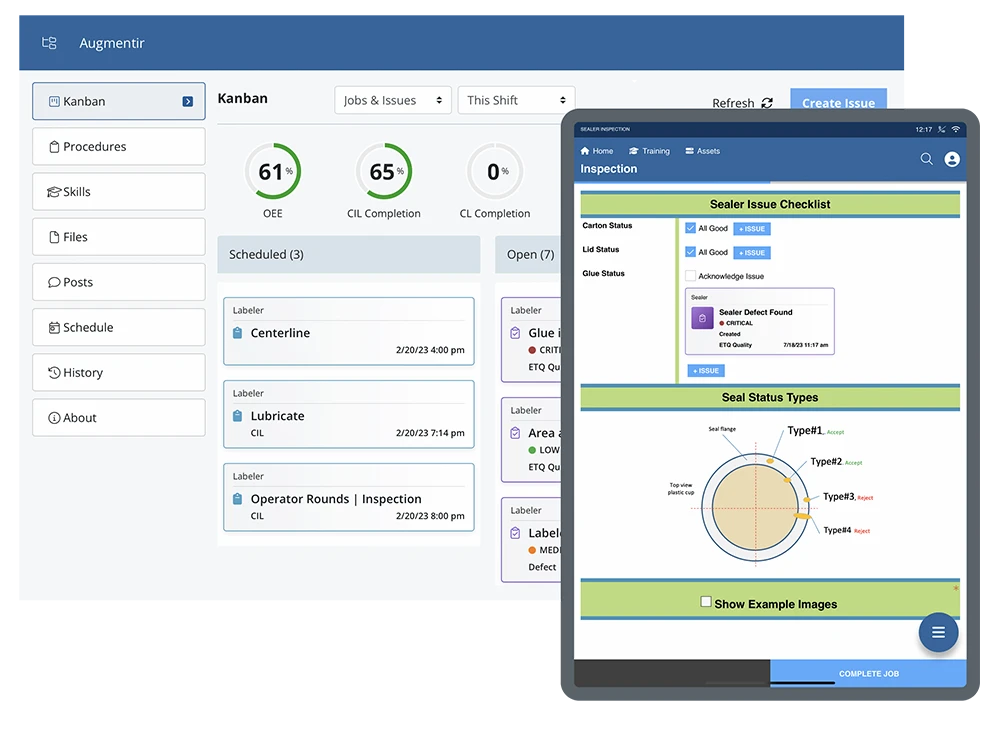

It’s important to maintain regular employee training and skills development programs to ensure workers are staying on top of industry best practices, equipment upkeep, and product knowledge. AI-powered connected worker solutions make learning more accessible, engaging, and effective.

Step 4: Create quality goals.

Developing quality goals is a great way to measure product benchmarks, production time, material usage, labor cost, working hours, and more. By digitizing and standardizing quality processes, you’ll be able to see which manufacturing processes are adding to your bottom line and which can be eliminated to bring value to the customer.

Step 5: Cut production waste.

Cutting waste from your production run can improve your business’s supply chain management. Connected worker solutions can identify which processes aren’t needed to reduce waste. It also gives real-time visibility into your supply chain to help you manage supply problems, optimize manufacturing processes, and adjust production schedules.

FAQs about improving production quality

How can the quality of the manufacturing industry be improved?

Measuring your current production processes to see which methods work can help improve product quality and increase the value of goods manufacturers make. You can strengthen the processes related to production by digitizing and automating them. Implementing a connected worker solution that offers real-time insights helps ensure that all goods meet quality standards and compliance criteria.

How do you ensure product quality in manufacturing?

There are a number of factors that can ensure product quality in manufacturing. We recommend following the five steps listed above to minimize defects as well as improve workflow and output.

What are 5 ways to improve production quality?

Assessing your current workflow, eliminating needless production processes, boosting work training, creating quality goals, and cutting production waste can all help improve production quality (see list above for a full description of each, as well as how implementing a connected worker solution can boost their overall impact).

Why is quality improvement important in manufacturing?

Enhancing production quality in manufacturing is a must as the industry moves towards fully connected enterprises, digital transformation, and automation. Businesses risk huge profit losses when quality standards are neglected in the creation of each product.

Digitize and Improve Production Quality with Augmentir

By digitizing and standardizing quality protocols, organizations can maintain compliance through an auditable and verifiable quality management system that gives workers access to the correct procedures as they need them with expert guidance. This ensures that tasks are performed in a standard manner to avoid errors on the production floor, reduce defects, and decrease resources lost to rework.

Refining your manufacturing methods can be difficult without the right technology. Augmentir’s AI-based connected worker solution makes streamlining and optimizing your production and quality procedures easier than ever before. Get in touch for a live demo today and learn why manufacturers are choosing Augmentir to help standardize and digitize quality processes!