Connected frontline operations platforms are helping manufacturers reduce downtime and provide a foundation for a holistic preventive maintenance strategy.

Your supply chain turns raw materials into finished products that meet customer expectations. It takes a whole network of people, from suppliers and manufacturers to distributors and partners, working together to produce the best quality products on the market. But how is it possible to build a “world class” supply chain?

According to Harvard Business Review, recent events such as the Covid-19 pandemic have exposed supply chain vulnerabilities and prompted a reevaluation of global approaches to improve resilience. Fortunately, the idea of a supply chain being world-class goes hand in hand with world class manufacturing, and there is a set of guiding principles to follow. Following them will help you successfully operate and manage a manufacturing firm that can remain competitive in the global marketplace.

In this article, you’ll learn the five steps for building a world class supply chain and how Augmentir can help you transform the process:

- 5 steps for making your supply chain world class

- Step 1: Define clear objectives

- Step 2: Gather necessary data

- Step 3: Choose a supply chain management system

- Step 4: Conduct supply chain network analysis

- Step 5: Refine and improve

- Elements of world class supply chain management and how Augmentir can help

5 steps for making your supply chain world class

Making your supply chain world class is about meeting or even exceeding customer expectations and delivering top-notch performance every time.

Step 1: Define clear objectives

Start by identifying overarching goals that will create consumer satisfaction. To help define those goals, ask yourself the following questions:

- How much inventory needs to be stored, and where should it be?

- Which modes of transportation would best balance out cost versus customer service objectives?

- Which warehouses should administer which products to people?

- How many warehouses are needed and what is the role of each?

- What are the best routes to get products to customers the fastest?

Step 2: Gather necessary data

It’s important to gather the appropriate data to ensure that you’re meeting company-specific goals. For example, you may track data so you can keep an eye on product demand, transportation rates, lead times, and warehouse and inventory expenses.

Step 3: Embrace technology and digitalization

Leverage technology to automate manual tasks, improve visibility, and enhance decision-making. It’s crucial to pick software that addresses all of your production criteria and facilitates your unique business model. Adopt advanced supply chain management systems (SCM), enterprise resource planning (ERP) software, connected worker software, and warehouse management systems (WMS). Explore emerging technologies like blockchain, AI, and robotics to further optimize operations.

Step 4: Conduct supply chain network analysis

Once you’ve picked the perfect supply chain software, it’s time to analyze how well your production processes are faring. Consider evaluating if there are any gaps in product development and how long it takes for goods to be delivered.

Step 5: Refine and continually improve

Carefully examining your supply chain network and processes is a great starting point for becoming world class. But if you don’t make steady strides toward improvement, you’re left at a standstill. Things are constantly evolving in the manufacturing industry, so it’s helpful to check some of the following: production capacity, price fluctuations in raw materials, and any new large customer orders (especially if they were added in a different location).

Encourage a culture of learning, innovation, and continuous improvement within the organization. Promote employee engagement, provide training and development opportunities, and empower employees to contribute ideas for process optimization and supply chain innovation.

Continuous improvement is a must. So revisit your processes regularly, whether that’s monthly, quarterly, or annually.

Elements of world class supply chain management and how Augmentir can help

Implementing a world class supply chain management system can change the way manufacturers handle daily operations.

A world class supply chain usually is:

- Customer focused: Consumers should be at the forefront of all production activities to ensure that goods are being made and sold in a timely, cost-effective manner.

- Adaptable to changes: The manufacturing industry is changing fast, so manufacturers have to be responsive to changing customer demands, market factors, and more.

- Collaborative: An effective supply chain fosters strong relationships among manufacturers, suppliers, distributors, and customers.

- Highly efficient: Incorporating streamlined production processes, smart tech, and other resources is crucial to stand out among competitors.

- Innovative: Constantly improving procedures drives growth and innovation.

- Sustainable: Implementing sustainable techniques for cutting waste and maximizing productivity can lead to significant savings over time.

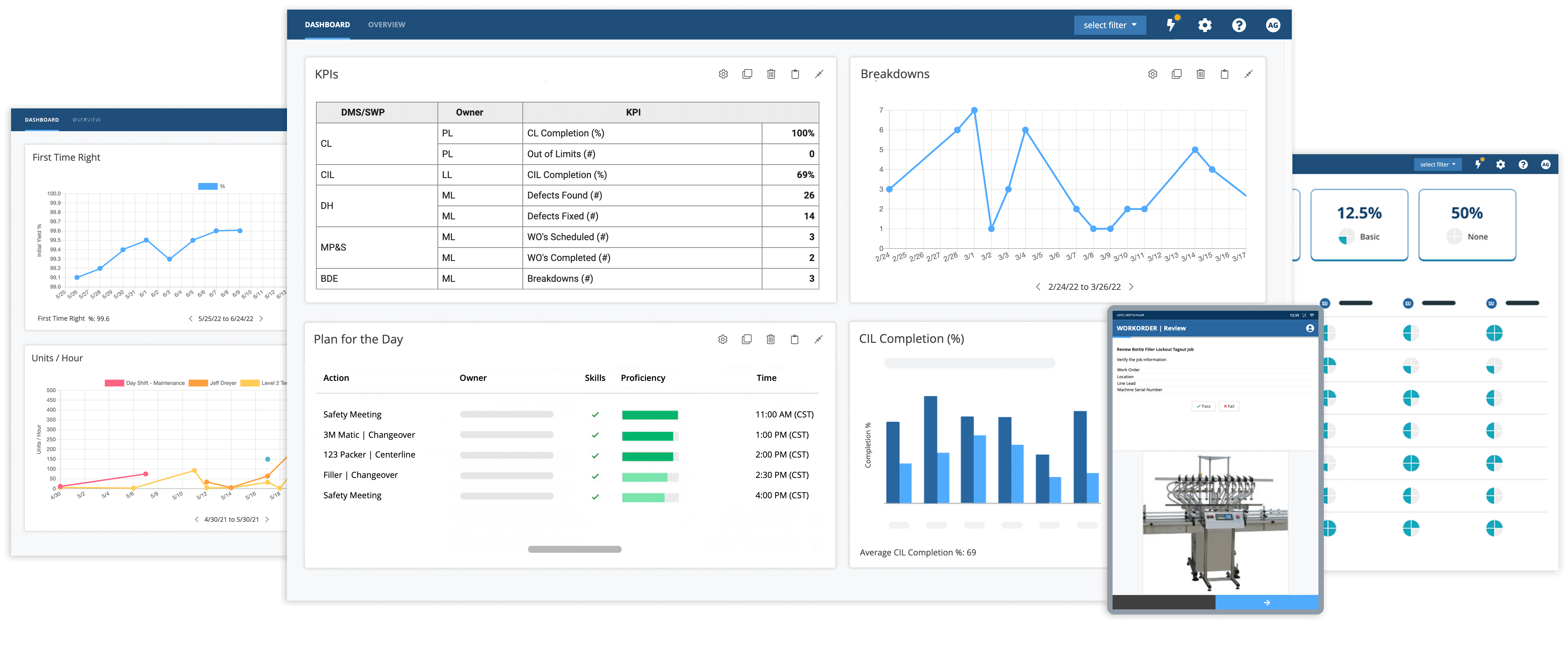

This is where Augmentir can help. We offer the world’s first AI-powered connected worker solution that advances how manufacturing firms handle day-to-day supply chain and other operations.

Our software lets you provide digital standard operating procedures for how to complete routine tasks and get the most out of worker output and productivity. We’ve helped frontline workers reduce training and rework time by 76%, and increase productivity levels by 36%.

With our software, you can build a world class supply chain that empowers workers across departments to make and deliver products of the highest quality. Request a live demo to learn more on how we’re the right fit for you!